In the realm of compact construction machinery, a comprehensive grasp of the intricate components is essential for efficient operation and maintenance. Whether you are a seasoned operator or a new enthusiast, familiarizing yourself with the layout of these crucial elements can greatly enhance your understanding and ability to troubleshoot potential issues.

Delving into the intricate arrangement of machinery parts not only aids in effective repairs but also empowers users to optimize performance. Each segment of the equipment plays a vital role, and knowing how they interconnect can lead to more informed decisions when it comes to servicing and upgrades.

Moreover, visual representations of these assemblies serve as valuable tools for both education and practical application. By studying the specific configurations, one can gain insights into the functionality and potential areas of wear, thus ensuring that the machinery remains in peak condition for years to come.

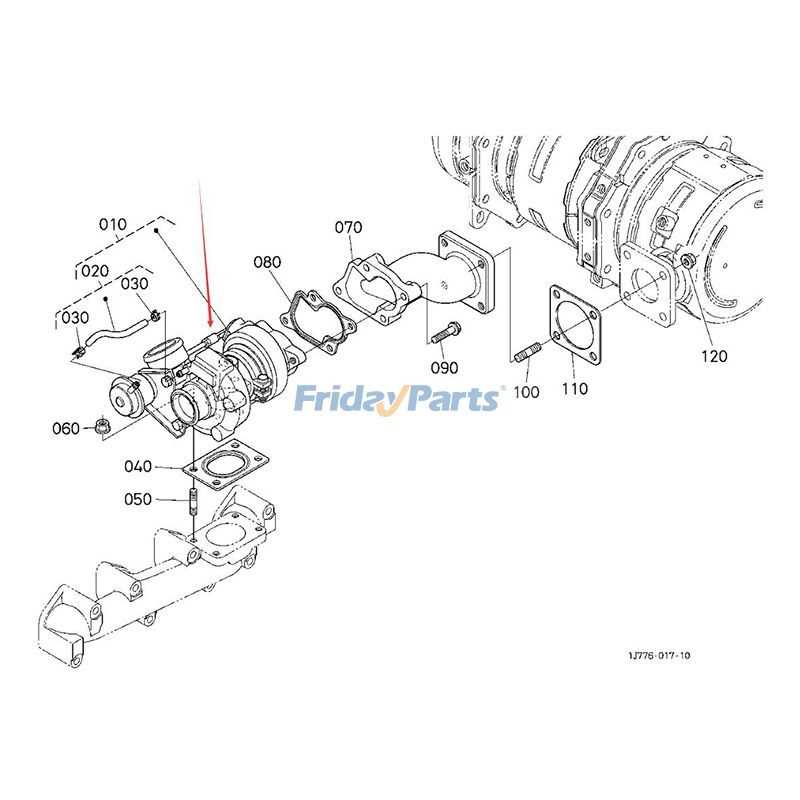

Understanding the visual representation of components is essential for effective maintenance and repair. This guide will help you navigate through the illustration, enabling you to identify and locate individual elements efficiently.

Begin by familiarizing yourself with the overall layout:

- Examine the key or legend, which explains the symbols used.

- Identify the main sections or groups of components, often organized by function.

Next, focus on specific items:

- Locate the item number next to each component for easy reference.

- Check for any additional notes that may provide context or specifications.

Finally, always cross-reference with the manual for further details on each component, ensuring accurate identification and procurement.

Common Issues and Solutions

When working with compact machinery, operators often encounter various challenges that can hinder performance and efficiency. Understanding these common problems and their respective solutions is crucial for maintaining optimal functionality and prolonging the lifespan of the equipment.

1. Engine Starting Difficulties

One frequent issue is trouble starting the engine. This can result from a weak battery or fuel system problems. Solution: Ensure the battery is charged and connections are clean. Check the fuel lines for blockages and replace the fuel filter if necessary.

2. Hydraulic System Leaks

Leaks in the hydraulic system can significantly affect lifting capabilities. These leaks may occur due to worn seals or damaged hoses. Solution: Inspect all hydraulic connections and replace any damaged components promptly to prevent further fluid loss.

3. Overheating

Overheating is another common concern that can lead to serious damage if not addressed. This issue may arise from low coolant levels or a malfunctioning thermostat. Solution: Regularly check coolant levels and ensure the radiator is clean. Replace the thermostat if it is found to be defective.

4. Uneven Tire Wear

Operators may notice uneven wear on tires, which can affect handling and traction. This often stems from improper inflation or alignment issues. Solution: Regularly inspect tire pressure and adjust as needed. Ensure that the wheels are aligned correctly to promote even wear.

5. Electrical Failures

Electrical issues can manifest as malfunctioning lights or non-responsive controls. These problems may be due to faulty wiring or blown fuses. Solution: Conduct a thorough inspection of the electrical system, replacing any damaged wires and fuses to restore functionality.

Maintenance Tips for K008 Parts

Regular upkeep is essential for ensuring the longevity and optimal performance of machinery components. By adhering to a few straightforward guidelines, you can prevent unexpected breakdowns and enhance the efficiency of your equipment. Proper care not only extends the lifespan of each element but also contributes to overall operational reliability.

First, always consult the manufacturer’s recommendations regarding service intervals and specific maintenance procedures. This information provides valuable insights into how often certain components should be inspected or replaced. Keeping a maintenance log can also help track the condition of various elements over time.

Next, ensure that all moving parts are adequately lubricated to minimize friction and wear. Using the correct type of lubricant is crucial, as it can significantly impact performance. Regularly checking fluid levels and topping them up as necessary is another vital practice that should not be overlooked.

Additionally, routinely examine all connections and fasteners for signs of looseness or wear. Tightening or replacing any compromised components promptly can prevent further damage. It’s also important to keep the equipment clean, as debris accumulation can lead to overheating or mechanical failure.

Lastly, consider scheduling periodic professional inspections. Experienced technicians can identify potential issues that may not be apparent during routine checks. This proactive approach can save both time and money by addressing problems before they escalate.

Replacement Parts Availability

Access to quality components is crucial for maintaining the efficiency and longevity of machinery. Ensuring that these items are readily obtainable can significantly impact operational performance and minimize downtime.

Sources for Components

- Authorized dealers

- Aftermarket suppliers

- Online marketplaces

Considerations for Purchasing

- Quality assurance and warranty

- Compatibility with existing equipment

- Cost-effectiveness

Compatibility with Other Models

Understanding the interchangeability of components across various machinery can enhance efficiency and reduce downtime. Many operators find value in identifying which models share similarities in design and functionality.

Several machines within the same category often utilize compatible elements, making maintenance simpler and more cost-effective. This can be especially beneficial for those managing fleets of equipment.

- Similar specifications can lead to component interchangeability.

- Shared engineering practices among models can facilitate easy replacements.

- Common issues may arise across different models, allowing for standardized solutions.

Operators should consult technical resources to verify compatibility, ensuring optimal performance and longevity of their equipment.

Assembly Instructions for Components

This section provides a detailed overview of the process for assembling various elements of a compact machinery unit. Proper assembly is crucial to ensure optimal performance and longevity, and following these instructions will guide you through each step methodically.

Step-by-Step Assembly

Begin by gathering all necessary components and tools. Refer to the user manual for a comprehensive list of required items. Start with the foundation piece, ensuring it is level and securely positioned. Gradually add additional elements, verifying that each part fits snugly and aligns with the designated connectors.

Final Checks and Adjustments

Once all components are assembled, conduct a thorough inspection. Ensure that all fasteners are tightened to the specified torque settings. It’s also advisable to check for any potential misalignments and make adjustments as necessary. Proper setup will enhance the overall functionality and efficiency of the machinery.

Identifying Genuine Parts

Ensuring the quality and reliability of machinery components is crucial for optimal performance and longevity. Recognizing authentic components can prevent issues associated with substandard alternatives, ultimately saving time and resources. This section will guide you through the key indicators that help distinguish original items from counterfeit ones.

Key Features of Authentic Components

- Manufacturer Branding: Genuine items often display distinct logos or markings. Look for clear and well-defined symbols that reflect the manufacturer’s identity.

- Packaging Quality: Original components typically come in high-quality packaging, featuring proper seals and labels that denote authenticity.

- Part Numbers: Verify that the part number matches the specifications provided by the manufacturer. Counterfeit items often have inconsistent or missing numbers.

- Material and Finish: Authentic products are made from high-grade materials with precise finishes, ensuring durability and performance.

Where to Purchase Authentic Components

- Authorized Dealers: Always purchase from certified distributors who are recognized by the manufacturer.

- Reputable Online Retailers: Look for online platforms with positive reviews and a solid return policy to ensure your purchase is legitimate.

- Direct Manufacturer Purchase: Buying directly from the manufacturer is the safest way to ensure you receive genuine items.

By being vigilant and informed, you can effectively identify authentic components and maintain the integrity of your machinery.

Resources for Parts Diagrams

When it comes to maintaining machinery, having access to detailed visual references is essential for effective repair and replacement tasks. Such resources enable users to identify components accurately and understand how they fit together, enhancing overall efficiency and precision during maintenance. This section highlights various platforms and tools that provide essential visual aids for equipment servicing.

Online Manuals: Many manufacturers offer downloadable manuals that include comprehensive illustrations of equipment assemblies. These documents typically contain exploded views, making it easier to pinpoint specific parts and their placements.

Community Forums: Engaging with online communities can be invaluable. Members often share their own diagrams and experiences, providing insights that may not be readily available in official publications. These platforms foster collaboration and knowledge sharing among users.

Parts Retailers: Numerous retailers specialize in machinery components and often provide visual references on their websites. These can be extremely helpful for identifying parts needed for repairs, along with descriptions and compatibility information.

Video Tutorials: Many mechanics and enthusiasts share their repair experiences through video content. These visual demonstrations can clarify assembly and disassembly processes, offering a step-by-step approach to handling various tasks.

Manufacturer Support: Direct support from manufacturers can be a reliable resource. Contacting customer service or technical support often yields access to specialized resources, including tailored diagrams and troubleshooting guides.

Utilizing these various resources can significantly improve the maintenance process, ensuring that equipment remains in optimal working condition for years to come.

Frequently Asked Questions

This section aims to address common inquiries related to maintenance and component identification for compact machinery. Whether you’re a seasoned operator or a newcomer, understanding the essential elements can greatly enhance your efficiency and equipment longevity.

1. What resources are available for identifying specific components?

Various manuals and online resources provide detailed visual aids to help you locate and recognize the necessary elements for your machinery.

2. How can I find replacement components for my equipment?

You can source replacements through authorized dealers, online marketplaces, or specialized retailers that cater to construction and agricultural machinery.

3. What should I do if I can’t locate a particular part?

If a specific item is hard to find, consider reaching out to local service centers or forums where experienced operators share insights and recommendations.

4. Are there any tips for proper maintenance of these machines?

Regular inspections, timely oil changes, and proper cleaning can significantly extend the lifespan of your equipment and ensure optimal performance.

5. How often should I consult manuals or guides?

It’s advisable to refer to these documents periodically, especially before undertaking maintenance or repairs, to ensure you’re following the recommended procedures.

Customer Support and Assistance

In any industry, effective customer support is essential for maintaining strong relationships and ensuring user satisfaction. It serves as a vital resource for individuals seeking guidance, troubleshooting help, or product information. A dedicated support team can greatly enhance the experience, offering timely solutions and fostering trust between the provider and the consumer.

Available Resources

Customers have access to a variety of resources designed to assist them with inquiries and challenges. Comprehensive manuals and online platforms provide detailed information, enabling users to find answers at their convenience. Additionally, a responsive customer service team is available through multiple channels, including phone, email, and live chat, ensuring that assistance is just a message away.

Expert Guidance

For those needing personalized help, expert consultants are on hand to offer tailored advice and support. Whether it’s technical issues or general questions, these specialists leverage their knowledge to address concerns efficiently. By prioritizing customer needs and understanding the intricacies of the products, they contribute to a seamless user experience.

Ultimately, a robust support system not only resolves immediate issues but also enhances overall satisfaction and loyalty among users. Engaging with customers and providing them with the necessary tools fosters a positive relationship that benefits everyone involved.