In the realm of construction and excavation, comprehending the intricate network of machinery is vital for optimal performance and maintenance. The effective functioning of these robust machines relies heavily on their various elements, which work in harmony to achieve the ultimate efficiency.

By exploring the interconnections between individual parts, operators and technicians can gain valuable insights into the mechanics of their equipment. This knowledge not only aids in troubleshooting but also enhances overall operational longevity.

To delve deeper into this subject, we will examine a specific model, providing a detailed overview of its components. This exploration will serve as a reference point for anyone seeking to understand the assembly and functionality of such machinery.

Kubota KX080-3 Overview

This section provides a comprehensive look at a robust machine known for its efficiency and versatility in various applications. It stands out due to its powerful engine, advanced features, and user-friendly design, making it an ideal choice for both professionals and enthusiasts in the construction and landscaping industries.

Key characteristics of this equipment include:

- Exceptional digging performance and reach

- Compact size that allows for easy maneuverability

- Durable construction to withstand rigorous tasks

- Advanced hydraulic systems for improved operation

In terms of functionality, this machinery excels in:

- Excavation tasks

- Site preparation and grading

- Trenching and landscaping

- Utility installation and maintenance

The blend of reliability and innovative technology ensures that this machine meets the diverse needs of its users while providing optimal performance in every job. With a focus on comfort and efficiency, it is designed to enhance productivity and reduce operational fatigue.

Key Features of the KX080-3

This powerful machine offers a blend of advanced engineering and efficiency, making it a top choice for various construction and excavation tasks. Its robust design ensures durability while maximizing performance in challenging environments.

Exceptional Maneuverability

The compact dimensions of this equipment facilitate easy navigation in tight spaces. Operators can effortlessly move around job sites without sacrificing stability or control.

Advanced Hydraulic System

Equipped with a sophisticated hydraulic system, this model delivers impressive lifting and digging capabilities. The enhanced power allows for rapid cycle times, improving overall productivity and effectiveness on the job.

Importance of Parts Diagrams

Understanding the components of any machinery is crucial for effective maintenance and repair. Visual representations of these elements not only simplify identification but also enhance communication among technicians and operators. This clarity can significantly reduce downtime and improve efficiency.

Having a clear reference allows users to quickly locate specific elements, streamlining the process of repairs. This can prevent costly mistakes and ensure that the right tools and replacement items are utilized. Furthermore, these illustrations foster a deeper comprehension of how each part interacts within the whole, empowering users to troubleshoot issues more effectively.

In summary, comprehensive visual guides are an ultimate resource for anyone involved in the upkeep of machinery, offering both practical benefits and educational insights.

How to Read a Parts Diagram

Understanding an illustration that details components and their relationships is essential for effective maintenance and repair. These visuals serve as a roadmap, guiding users through the various elements and their respective functions within a machine. By familiarizing oneself with these representations, one can streamline the identification and acquisition of necessary components.

Here are key steps to effectively interpret such illustrations:

- Familiarize with Symbols:

- Identify common icons used to represent different components.

- Learn the meanings behind various lines and arrows indicating movement or connections.

- Understand the Layout:

- Note the organization of the illustration, which typically groups related components together.

- Look for sections that may indicate the assembly order or hierarchy of parts.

- Refer to the Legend:

- Utilize the key provided, which explains symbols and codes used throughout the visual.

- Cross-reference numbers or letters in the illustration with the legend for detailed descriptions.

- Identify Components:

- Locate specific parts needed for maintenance or repair tasks.

- Verify any required specifications or compatibility information associated with each item.

- Consult Additional Resources:

- Seek manuals or guides that provide further clarification on complex components.

- Engage with online forums or communities for tips and shared experiences.

By following these steps, one can efficiently navigate through complex visuals and ensure a thorough understanding of machine components, leading to successful repairs and maintenance.

Commonly Replaced Components

In the world of heavy machinery, certain elements tend to wear out or fail more frequently than others. Understanding which components are typically replaced can help in maintaining efficiency and minimizing downtime. Below are some of the most commonly serviced parts in construction equipment.

- Hydraulic Filters

- Seals and Gaskets

- Oil Filters

- Batteries

- Track Shoes

Regular inspection of these items can prevent unexpected breakdowns and ensure smooth operation. Below are more details on specific components.

- Hydraulic Filters: Essential for keeping the hydraulic system clean and functioning properly.

- Seals and Gaskets: Vital for preventing leaks and maintaining pressure in various systems.

- Oil Filters: Critical for maintaining engine health by filtering contaminants from the oil.

- Batteries: Often require replacement due to the harsh working conditions that can affect performance.

- Track Shoes: Subject to wear and tear, impacting mobility and stability on various terrains.

Awareness of these frequently replaced components can lead to better maintenance practices and improved longevity of the equipment.

Finding Genuine Kubota Parts

When seeking authentic components for machinery, it’s essential to ensure quality and compatibility. Genuine items not only enhance performance but also extend the lifespan of your equipment. Identifying the right source for these essential elements can significantly impact efficiency and reliability.

Benefits of Authentic Components

Utilizing original items provides numerous advantages. They are designed to fit perfectly, reducing wear and tear, and often come with warranties that cover defects. Additionally, genuine parts can enhance resale value, making them a wise investment for any owner.

How to Locate Trusted Sources

Finding reliable vendors is crucial. Check authorized dealers or certified online platforms. Always verify the legitimacy of the seller to avoid counterfeit goods. Read customer reviews and confirm that they offer the specific items you need.

| Source Type | Pros | Cons |

|---|---|---|

| Authorized Dealers | Guaranteed authenticity, expert advice | Higher prices |

| Online Retailers | Convenience, often competitive pricing | Risk of counterfeits |

| Local Mechanics | Hands-on help, local support | Limited stock |

Maintenance Tips for Longevity

Ensuring the durability of your machinery requires consistent upkeep and attention to detail. Implementing effective maintenance practices not only enhances performance but also extends the lifespan of your equipment. Below are some essential tips to keep in mind.

Regular Inspections

- Check fluid levels frequently, including oil, coolant, and hydraulic fluids.

- Inspect belts and hoses for signs of wear or damage.

- Examine filters and replace them as needed to maintain optimal function.

Cleaning and Lubrication

- Keep surfaces clean from debris and dirt to prevent corrosion.

- Lubricate moving parts regularly to reduce friction and wear.

- Ensure that all joints and bearings are well-greased for smooth operation.

By following these guidelines, you can significantly enhance the performance and reliability of your machinery over time.

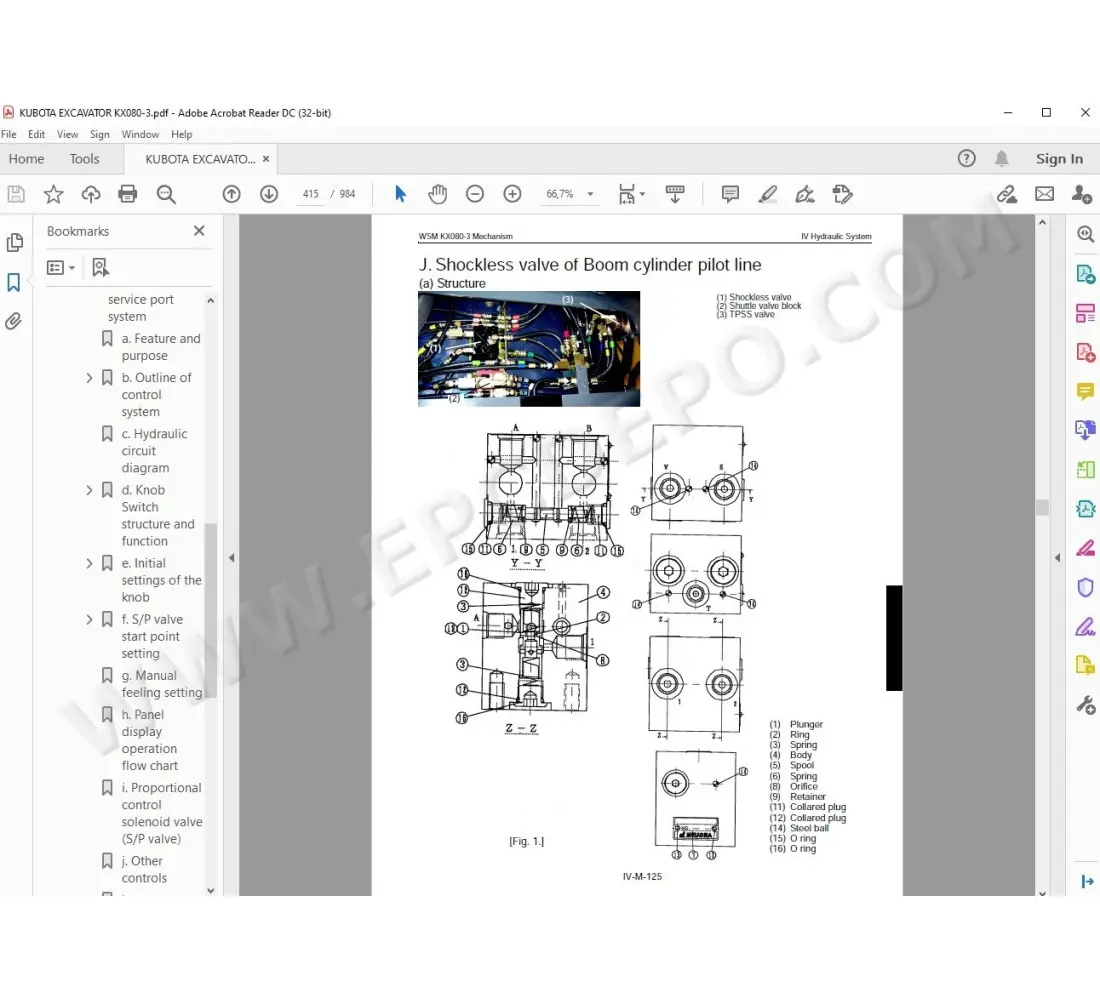

Understanding Hydraulic Systems

Hydraulic systems play a crucial role in modern machinery, harnessing fluid power to perform various tasks efficiently. These systems utilize pressurized liquid to transmit energy, enabling movements and operations that are essential in construction, agriculture, and manufacturing. Grasping the fundamentals of these systems can enhance both performance and maintenance practices.

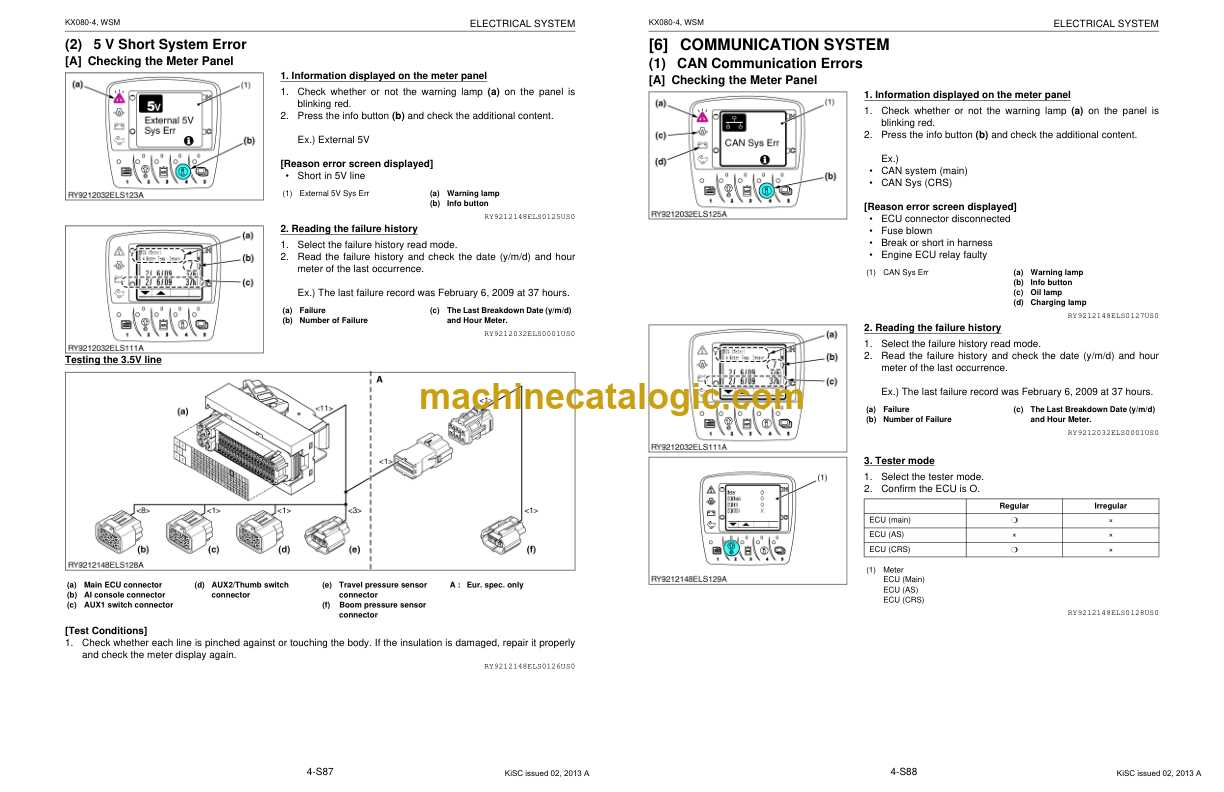

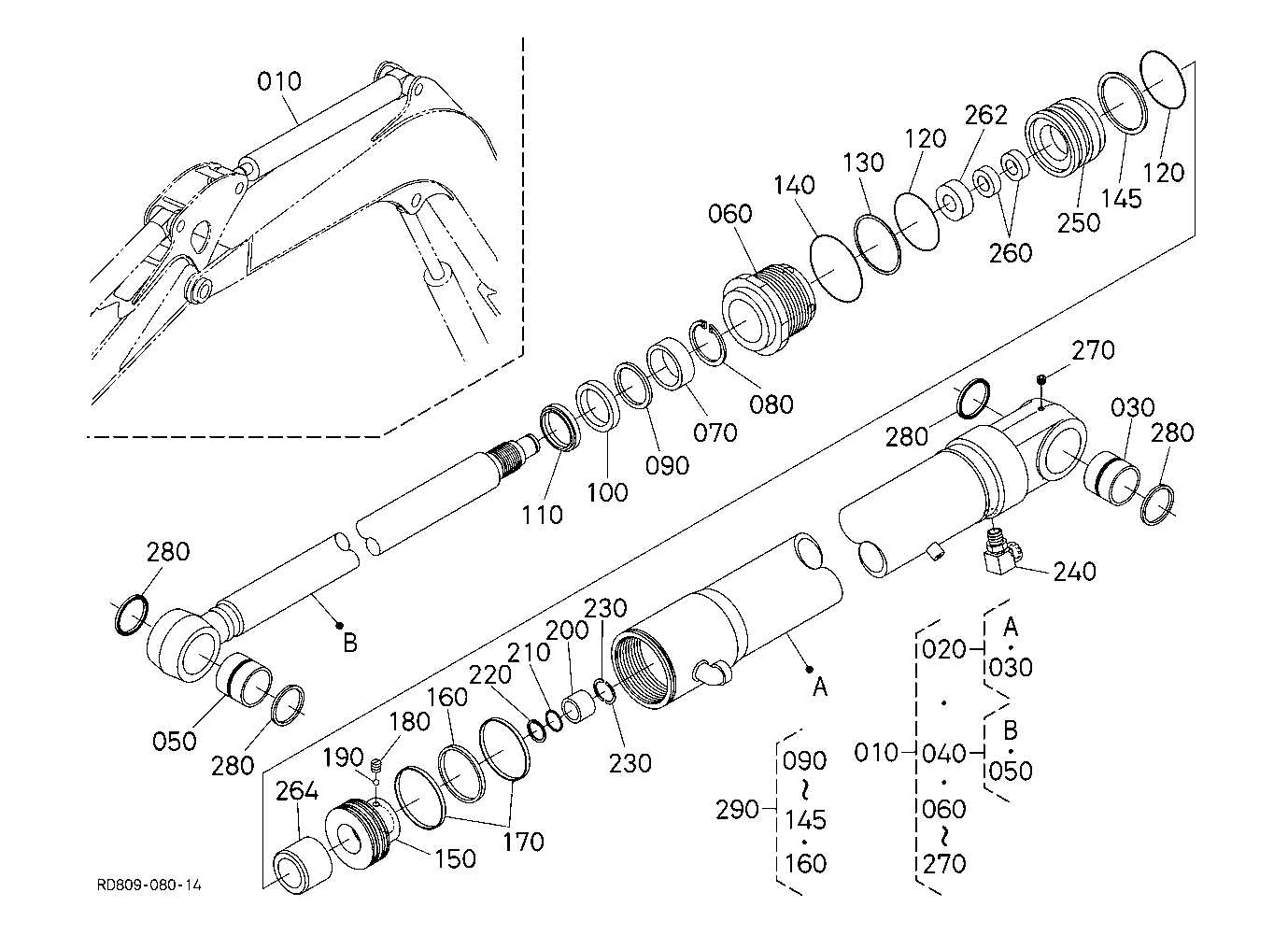

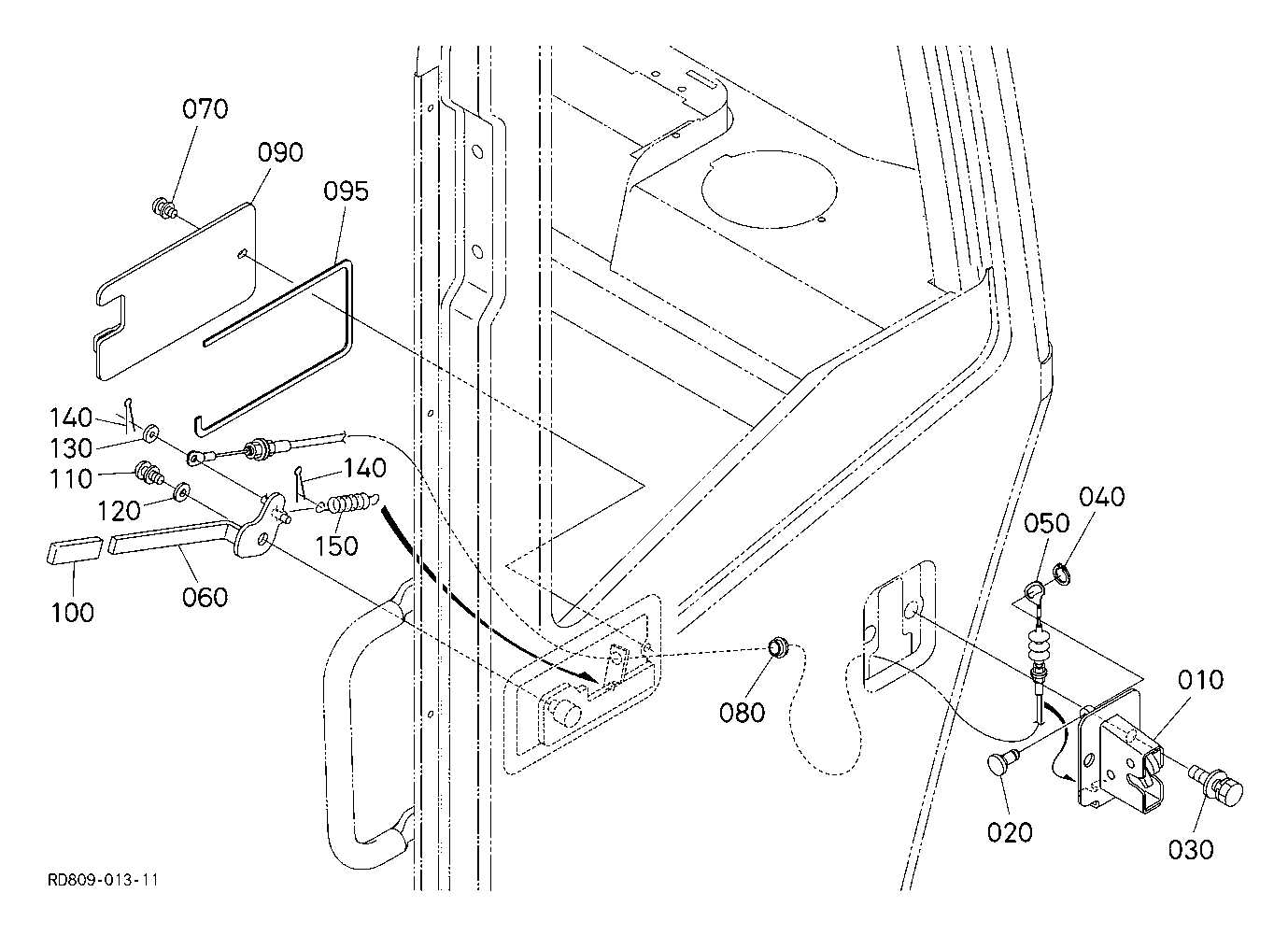

Components of Hydraulic Systems

The primary components include pumps, cylinders, valves, and reservoirs. Each element serves a specific purpose, with pumps generating flow, cylinders converting hydraulic energy into mechanical force, and valves controlling the direction and pressure of the fluid. Understanding the interconnectivity of these parts is vital for troubleshooting and optimizing functionality.

Principles of Operation

At the heart of hydraulic systems lies Pascal’s principle, which states that pressure applied to a confined fluid is transmitted equally in all directions. This fundamental concept allows for the efficient transfer of force, making it possible to lift heavy loads with minimal effort. By delving into these principles, operators can appreciate the ultimate efficiency and power that hydraulic systems provide.

Impact of Quality on Performance

In any machinery, the integrity and precision of components significantly influence overall functionality. High-quality materials and manufacturing processes ensure reliability, enhancing operational efficiency and longevity. When each element is crafted with care, the machine operates seamlessly, ultimately maximizing productivity.

Durability is a crucial factor; well-made parts withstand wear and tear, reducing the need for frequent replacements. This not only saves time but also minimizes operational costs. Conversely, inferior components can lead to breakdowns, resulting in unexpected downtime and increased expenses.

Moreover, performance consistency is linked to the quality of the parts. Machines built with superior materials maintain optimal performance levels over time, fostering trust among users. Investing in high-caliber components is, therefore, a vital strategy for ensuring long-term success in any operational setting.

Resources for Parts Lookup

Finding the right components for your machinery can be a daunting task, but with the right resources, it becomes much easier. Numerous platforms and tools are available to assist in identifying and acquiring the necessary elements for effective repairs and maintenance. Here are some valuable resources to consider:

- Official Manufacturer Websites: Many manufacturers offer comprehensive online catalogs that allow users to search for specific items based on model numbers or specifications.

- Online Retailers: Websites specializing in machinery supplies often provide detailed listings and schematics, making it easier to locate what you need.

- Local Dealerships: Engaging with nearby dealerships can yield insights and direct access to components, as well as expert advice.

- Forums and Online Communities: Participating in discussions with other machinery enthusiasts can provide recommendations and tips for sourcing parts.

Utilizing these resources can greatly enhance your ability to locate and acquire the correct components, ensuring that your equipment remains in optimal working condition.

Repair vs. Replacement Decisions

Making choices between fixing and substituting machinery components is a critical aspect of equipment maintenance. It involves evaluating the condition, performance, and overall costs associated with each option. Proper analysis can lead to enhanced efficiency and longevity of the equipment.

Factors to Consider

Key considerations include the age of the equipment, frequency of repairs, and the availability of parts. If the machine is relatively new and has had minimal issues, repair might be the more economical choice. Conversely, if breakdowns are frequent and costly, investing in new components could ultimately provide better value.

Cost-Benefit Analysis

A thorough cost-benefit analysis is essential. This involves not only the immediate financial impact but also the potential downtime and productivity loss associated with repairs. Assessing long-term implications helps in making an informed decision that aligns with operational goals.