Exploring the intricate systems of compact machinery reveals a wealth of knowledge essential for maintenance and repair. Each segment plays a pivotal role, ensuring optimal performance and longevity. Gaining insights into these elements can significantly enhance operational efficiency.

Visual aids provide invaluable support in identifying various sections and their interconnections. These illustrations not only simplify the comprehension of complex structures but also aid in the troubleshooting process. By grasping the layout, operators can make informed decisions when addressing mechanical issues.

Furthermore, having access to comprehensive resources allows enthusiasts and professionals alike to delve deeper into the mechanics of their equipment. Understanding how each component contributes to the ultimate functionality empowers users to undertake repairs with confidence and precision.

Kubota KX41-3V Overview

This section provides a comprehensive insight into a compact excavator renowned for its versatility and performance in various applications. Designed for efficiency, it stands out in the construction and landscaping sectors.

- Compact Size: Ideal for tight spaces, making it suitable for urban projects.

- Powerful Engine: Equipped with a robust powertrain that ensures optimal performance.

- Hydraulic System: Advanced hydraulics for improved lifting and digging capabilities.

- User-Friendly Controls: Intuitive operation, making it accessible for operators of all skill levels.

- Durability: Built with high-quality materials to withstand rigorous working conditions.

With its combination of strength and agility, this excavator is the ultimate choice for professionals seeking reliability in their machinery.

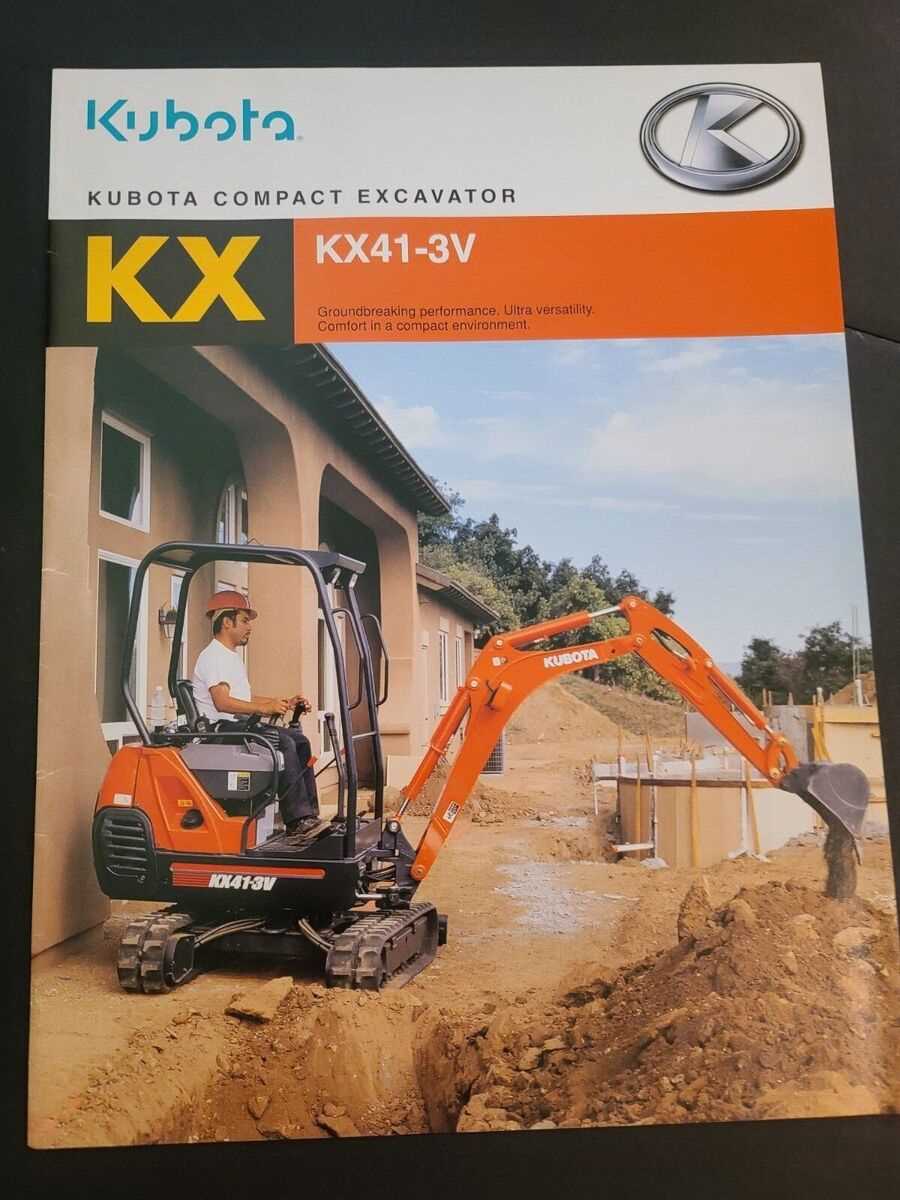

Key Features of KX41-3V Model

This model stands out due to its compact design and powerful capabilities, making it ideal for various tasks in tight spaces. With a focus on efficiency and ease of use, it caters to both professional contractors and DIY enthusiasts alike.

Compact Size

The small footprint allows for maneuverability in confined areas, ensuring that users can tackle projects without restrictions. This feature is particularly beneficial in urban settings or landscaping work.

Enhanced Performance

Equipped with a robust engine, the machine delivers impressive power while maintaining fuel efficiency. This balance of strength and sustainability makes it an ultimate choice for demanding jobs. Additionally, the hydraulic system provides smooth operation and precision control.

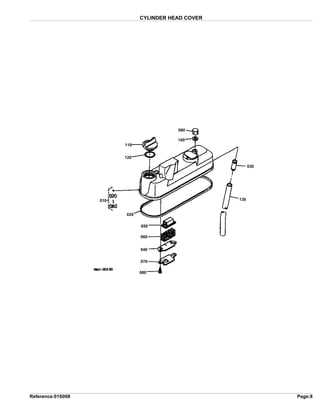

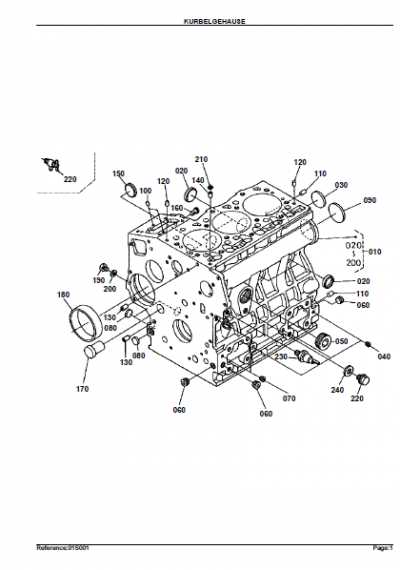

Importance of Parts Diagrams

Understanding the components of machinery is essential for effective maintenance and repair. Visual representations play a crucial role in illustrating the relationships and functions of each element, enabling users to identify issues swiftly and accurately.

Benefits of Visual Guides

- Facilitates quick identification of components.

- Aids in understanding assembly and disassembly processes.

- Enhances communication among technicians and engineers.

Improving Efficiency

- Reduces downtime during repairs.

- Minimizes the risk of errors in maintenance tasks.

- Streamlines ordering of necessary components.

Common Components of KX41-3V

Understanding the fundamental elements of this compact excavator is crucial for effective maintenance and operation. Each part plays a vital role in ensuring optimal performance and reliability.

- Engine: The heart of the machine, providing necessary power.

- Hydraulic System: Essential for movement and control of attachments.

- Tracks: Provide stability and traction on various terrains.

- Cab: Protects the operator and houses controls for operation.

- Boom: Facilitates digging and lifting functions.

By familiarizing yourself with these components, you can ensure the longevity and efficiency of your equipment.

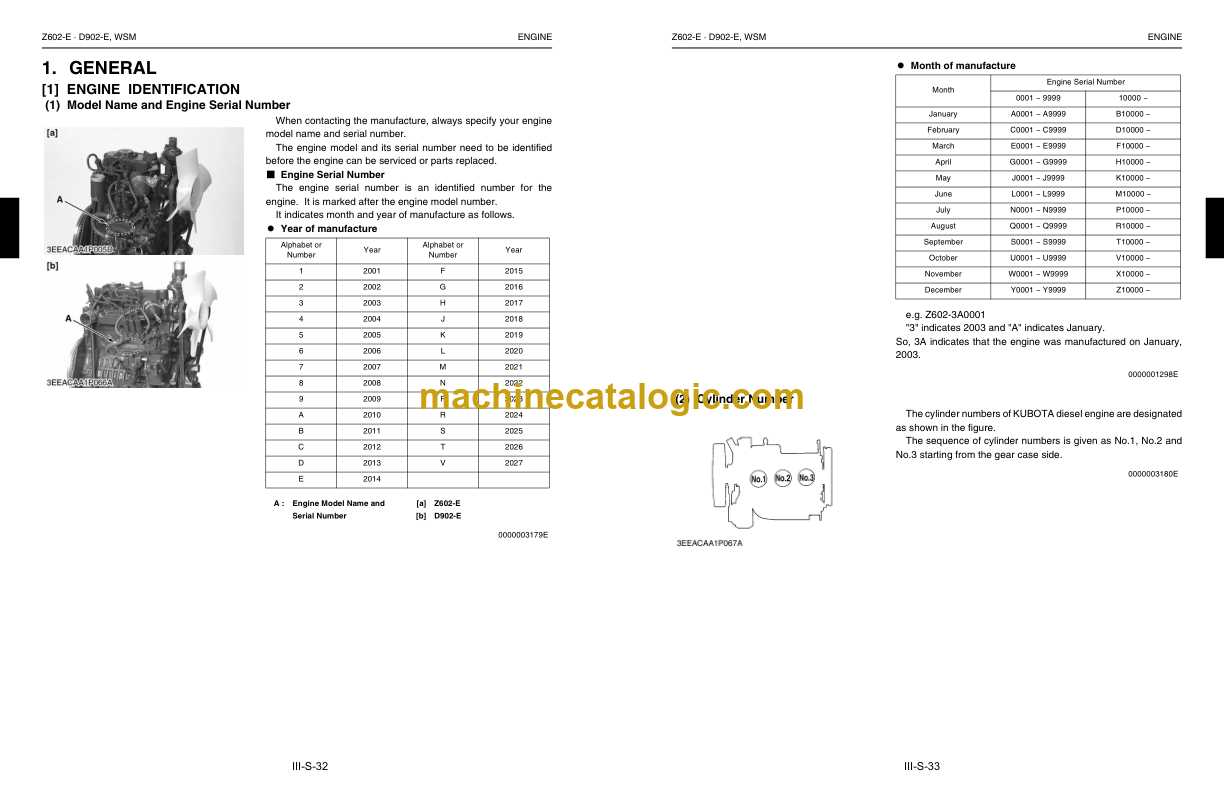

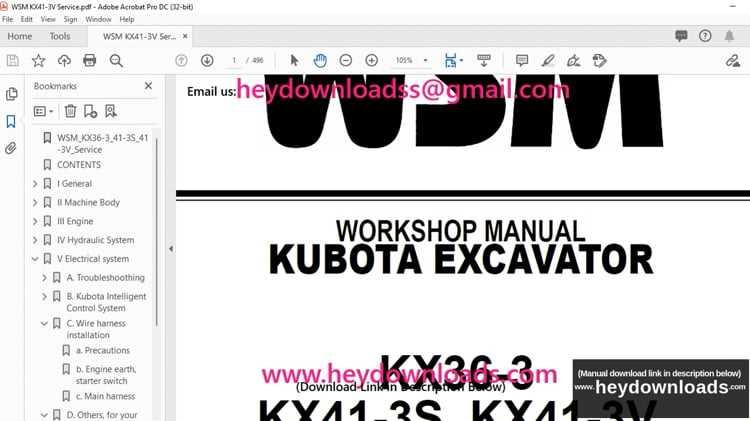

How to Read the Parts Diagram

Understanding a technical illustration is crucial for anyone involved in maintenance or repair tasks. These visuals serve as a guide to identifying individual components and their relationships within a complex machine. Mastering the art of reading these schematics can significantly enhance your ability to troubleshoot and perform effective repairs.

First and foremost, familiarize yourself with the layout. Typically, these illustrations are organized systematically, allowing you to follow the flow from one section to another. Look for a legend or key that explains the symbols used; this will help you decode the various parts represented in the image.

Next, pay attention to the numbering system. Each component is usually labeled with a specific number or code that corresponds to a list of items. This list often provides detailed information, such as the part’s name, specifications, and sometimes even the part’s location within the larger assembly. Cross-referencing these numbers will aid in understanding how each piece fits together.

Lastly, practice is essential. The more you engage with these illustrations, the easier it will become to quickly identify components and their functions. Over time, you’ll develop a keen eye for recognizing common patterns and structures, allowing you to navigate the complexities of the visual representations with confidence.

Replacement Parts for KX41-3V

Maintaining machinery requires access to quality components to ensure optimal performance and longevity. This section focuses on essential replacements that can enhance the functionality of your equipment. Understanding the available options can help you make informed decisions for repairs and upkeep.

| Component | Description | Part Number |

|---|---|---|

| Engine Oil Filter | Filters contaminants from engine oil, ensuring smooth operation. | 12345-67890 |

| Hydraulic Filter | Removes particles from hydraulic fluid to protect the system. | 09876-54321 |

| Fuel Filter | Prevents dirt and debris from entering the fuel system. | 11223-44556 |

| Air Filter | Ensures clean air intake for the engine, enhancing efficiency. | 33445-66778 |

| Track Roller | Supports the weight of the machine while providing stability. | 55667-88990 |

Choosing the right components can significantly impact the performance and reliability of your machinery. Ensure you source high-quality replacements to keep your equipment in prime condition.

Maintenance Tips for Optimal Performance

Ensuring peak efficiency and longevity of your machinery requires a proactive approach to upkeep. Regular checks and thoughtful interventions can significantly enhance performance and reduce the likelihood of unexpected breakdowns.

Regular Inspections

Conduct frequent evaluations of all vital components. Look for signs of wear, leaks, or damage, as early detection can prevent more extensive issues later. Establish a routine that includes checking fluid levels, filters, and belts.

Proper Cleaning

Maintaining cleanliness is crucial for optimal functioning. Remove dirt and debris from critical areas to promote airflow and prevent overheating. A clean machine is not only more efficient but also easier to inspect for potential problems.

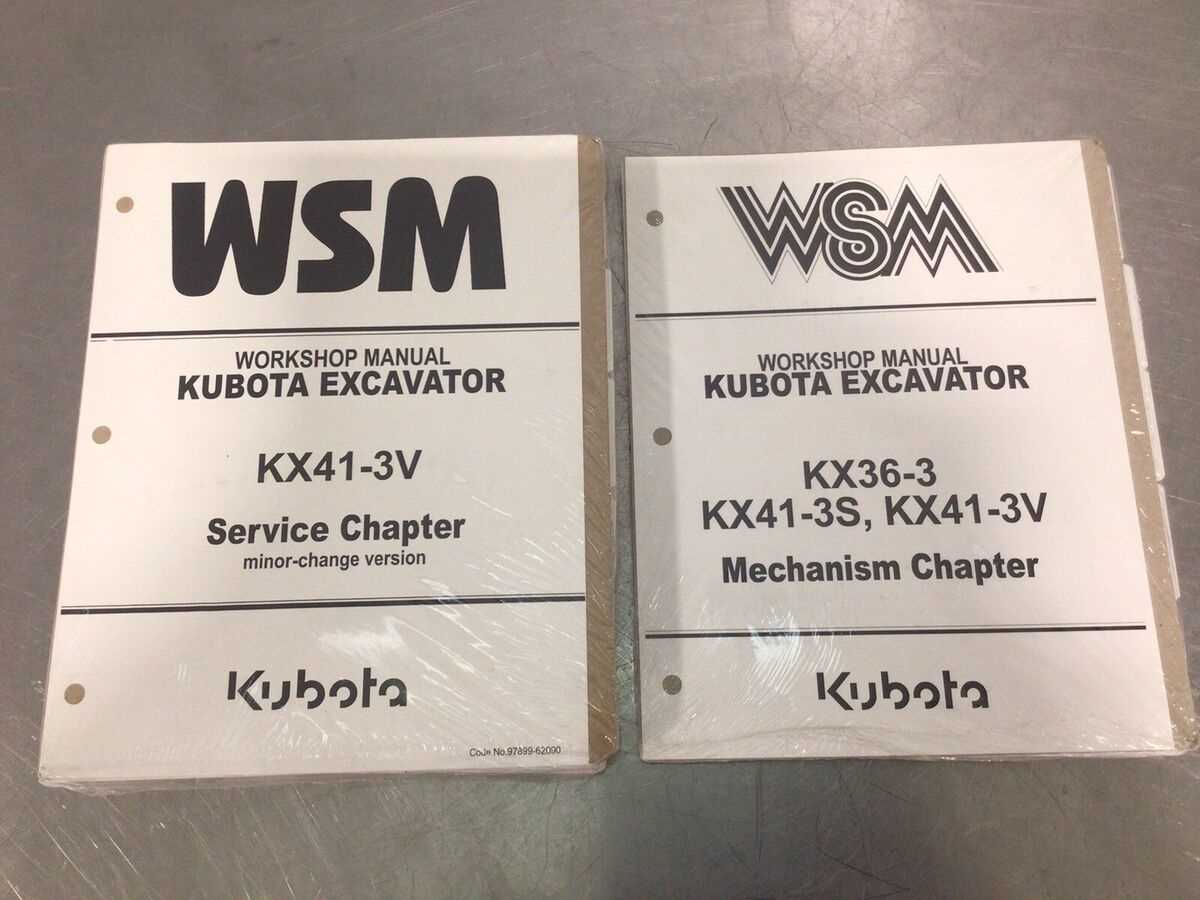

Where to Find Parts Diagrams

Finding detailed illustrations for machinery components can greatly enhance maintenance and repair efforts. These resources provide valuable insights into the assembly and functionality of various elements, helping users identify and procure necessary items effectively.

Online Resources

Numerous websites specialize in offering visual aids and manuals for equipment. These platforms often feature searchable databases, enabling users to quickly locate the information they need.

Local Dealers

Authorized retailers typically possess comprehensive resources, including reference materials. Engaging with them can yield both guidance and access to essential documentation that may not be readily available online.

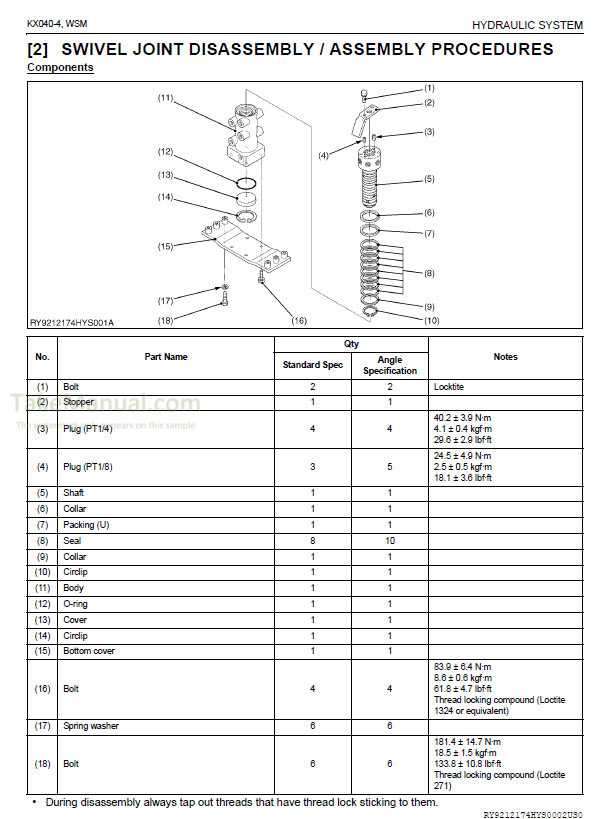

Understanding Hydraulic System Components

Hydraulic systems are integral to various machinery, enabling efficient power transfer through fluid movement. Grasping the elements that constitute these systems is essential for optimal performance and maintenance.

Main Elements of Hydraulic Systems

- Fluid Reservoir: Stores hydraulic fluid, ensuring an adequate supply for operation.

- Pump: Converts mechanical energy into hydraulic energy, creating fluid flow.

- Actuators: Devices like cylinders and motors that convert hydraulic energy back into mechanical motion.

- Valves: Control the direction and flow of fluid within the system.

- Filters: Remove contaminants from the hydraulic fluid to protect components.

Functions and Importance

Each component plays a vital role in the system’s efficiency:

- Fluid reservoirs maintain a steady supply of hydraulic fluid.

- Pumps ensure the fluid reaches necessary components under pressure.

- Actuators provide the force needed for tasks, enhancing productivity.

- Valves regulate flow, ensuring precise control of movement.

- Filters keep the system clean, prolonging the life of the components.

Electrical System Breakdown

The electrical framework of heavy machinery is crucial for its functionality and performance. Understanding its components and their interactions can enhance maintenance and troubleshooting efforts, ensuring optimal operation.

Key Components

This section outlines the primary elements that make up the electrical system, each playing a significant role in the machinery’s overall operation.

| Component | Function |

|---|---|

| Battery | Stores electrical energy for starting and powering electrical systems. |

| Alternator | Generates electrical power while the engine is running. |

| Wiring Harness | Facilitates electrical connections between various components. |

| Fuses | Protects the system from overload by breaking the circuit if necessary. |

| Control Module | Manages various electrical functions and diagnostics. |

Troubleshooting Tips

To effectively address issues within the electrical system, it is important to conduct systematic checks and use diagnostic tools. Common problems include poor connections, blown fuses, and component failures. Regular inspections can prevent major breakdowns and enhance reliability.

Tracks and Undercarriage Details

The undercarriage of compact machinery plays a crucial role in ensuring stability and mobility. Understanding its components can greatly enhance maintenance and operational efficiency.

Key Components

- Tracks

- Sprockets

- Idlers

- Rollers

- Frames

Maintenance Tips

- Regularly inspect tracks for wear and tear.

- Ensure proper tension to prevent slippage.

- Clean debris from rollers and sprockets.

- Lubricate moving parts as needed.

Attachments Compatible with KX41-3V

When it comes to enhancing the versatility of compact excavators, a range of attachments can significantly expand their functionality. These implements are designed to seamlessly integrate with the machine, enabling operators to tackle a variety of tasks with ease. From digging to lifting, the right tools can make a substantial difference in productivity and efficiency.

Common Attachment Types

Several common implements are often used with these compact machines. Among the most popular are buckets, which come in various sizes and shapes to accommodate different digging needs. Additionally, thumbs can be attached to improve material handling capabilities, allowing for better grip on irregularly shaped objects.

Specialized Tools

For more specialized tasks, operators may consider options like augers for drilling into the ground or breakers for demolition work. Each attachment is engineered to enhance the base machine’s capabilities, providing users with the flexibility needed for diverse projects.

Troubleshooting Common Issues

Identifying and resolving frequent problems can enhance the efficiency of your machinery and prolong its lifespan. By understanding typical challenges, operators can take proactive steps to mitigate disruptions and ensure optimal performance.

Starting Difficulties: If the engine struggles to start, check the battery charge and connections. Inspect the fuel system for clogs or leaks, and ensure that the ignition components are functioning properly.

Hydraulic Performance Issues: If you notice sluggish movement, examine the hydraulic fluid levels and the condition of the filters. Contaminated fluid or blocked lines can significantly impair operation.

Unusual Noises: Strange sounds during operation may indicate wear or damage. Investigate the source, whether it’s bearings, belts, or other components, to prevent further issues.

Overheating: If the unit becomes excessively hot, check the cooling system. Ensure that the radiator is clean and that coolant levels are adequate. A malfunctioning thermostat can also lead to overheating.

By addressing these common concerns promptly, operators can maintain performance and avoid costly repairs.