Understanding how various elements come together in a machine is essential for ensuring smooth operation and maintenance. Every mechanism is designed with precision, and knowing the structure of its elements can significantly assist in both identifying issues and performing repairs. This article delves into the detailed structure of one such machine, highlighting the various components and their interconnections.

Efficiency and performance rely heavily on understanding the physical layout of individual elements. Whether you’re performing routine maintenance or troubleshooting, having a clear view of the internal structure provides valuable insight. This section will walk through each segment, giving you a clear picture of how everything is organized.

Additionally, we will discuss the most critical components that ensure the machine’s overall functionality. Recognizing these will help you stay ahead of any potential issues and keep your equipment running smoothly.

Understanding the Kubota L3830 Parts System

The structure of mechanical components in agricultural equipment can often seem complex, but with the right understanding, maintaining and servicing these machines becomes much easier. It’s important to have a clear picture of how each element works together to ensure smooth operation.

Key assemblies include critical sections like the engine, transmission, and hydraulics, all designed to function in harmony. By recognizing how these systems connect and interact, operators can efficiently troubleshoot issues and keep everything in optimal condition.

Additionally, having a visual representation of the various elements and how they integrate into the machinery can aid in identifying potential problem areas early on.

Key Components of Kubota L3830 Tractor

The machine consists of several essential elements, each contributing to its overall efficiency and performance. Understanding the key parts that make up this tractor is crucial for both its maintenance and operation. Below is an overview of the core components that ensure smooth functioning in various agricultural tasks.

- Engine System: The powerhouse that drives the machine, offering reliable performance and fuel efficiency.

- Transmission: A robust system that allows smooth shifting between gears, ensuring optimal control during fieldwork.

- Hydraulic System: Essential for powering attachments and ensuring precise control of various implements.

- Steering Mechanism: This system provides accurate maneuverability, allowing the operator to handle tight spaces and challenging terrain with ease.

- Braking System: Ensures safety by offering responsive braking in different conditions.

- Cooling System: Keeps the engine at a stab

How to Read a Kubota Parts Diagram

Understanding how to navigate technical illustrations can make the process of identifying components much easier. These diagrams serve as a visual map, helping users find individual items and their placement within larger systems.

- Component Labels: Most diagrams use labels to indicate specific items, often in combination with a corresponding list. Look for numbers or symbols that match the index provided.

- Assembly Breakdown: Diagrams are typically broken into sections, showing how various pieces fit together. Follow the flow of connections from one part to another to understand the complete structure.

- Orientation: Ensure you’re viewing the illustration from the correct perspective. Pay attention to directional arrows or positioning cues that indicate how parts should align.

By carefully analyzing these visual guides, you can more efficiently locate components and understand their functions within the system.

Maintenance Tips for Essential Machine Components

Regular upkeep of your equipment ensures it runs smoothly and extends its lifespan. Adopting proper care routines can prevent issues before they occur, saving time and costly repairs. Below are key practices for maintaining vital components in any heavy-duty machinery.

Component Maintenance Action Engine Check oil levels regularly and change oil according to the manufacturer’s schedule to keep the engine running efficiently. Hydraulics Inspect hydraulic fluid levels and hoses for leaks or damage, ensuring smooth operation of all moving parts. Transmission Regularly monitor transmission fluid and replace it when necessary to maintain gear performance. Common Replacement Parts for Kubota L3830

Maintaining the longevity of your machine often requires replacing certain components over time. Regular wear and tear affect various elements, which need to be refreshed to ensure efficient operation. Below is a list of frequently swapped parts that keep the equipment functioning smoothly.

Engine Components

- Air filters

- Fuel filters

- Oil filters

- Belts and hoses

Hydraulic and Electrical Elements

- Hydraulic pumps

- Seals and gaskets

- Fuses and relays

- Switches and wiring

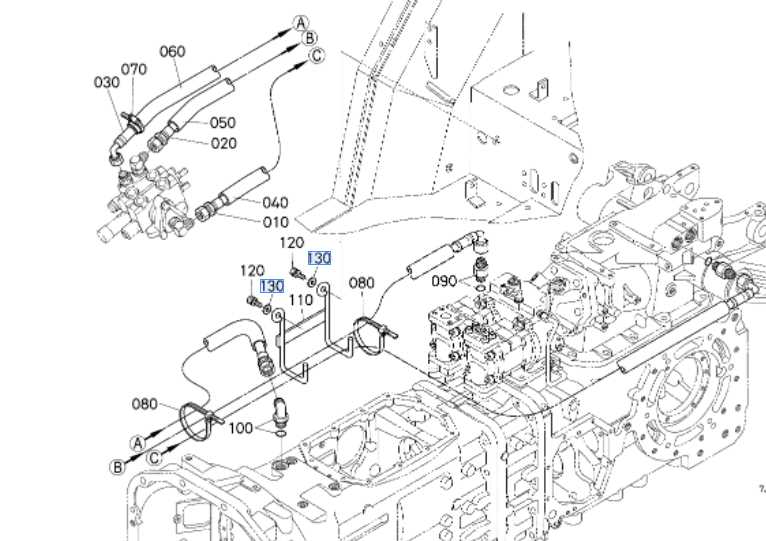

Hydraulic System Overview in Kubota L3830

The hydraulic system is a crucial component in the operation of various machinery, enabling efficient power transmission and control. This overview focuses on the essential aspects of the hydraulic system, highlighting its functionality, components, and significance in ensuring optimal performance.

At its core, the hydraulic system utilizes fluid to transfer force and motion, allowing for precise control of different functions within the equipment. Understanding the key elements involved can enhance maintenance practices and improve overall efficiency.

Component Description Hydraulic Pump Generates flow and pressure, supplying fluid to the system. Hydraulic Fluid The medium through which power is transmitted; vital for lubrication and cooling. Control Valves Regulate the direction and flow of hydraulic fluid, allowing for movement and operation of various parts. Cylinders Convert hydraulic energy into mechanical movement, powering different functions such as lifting and steering. Filters Remove contaminants from the hydraulic fluid, ensuring the system operates smoothly and preventing damage. Engine Parts Breakdown for Kubota L3830

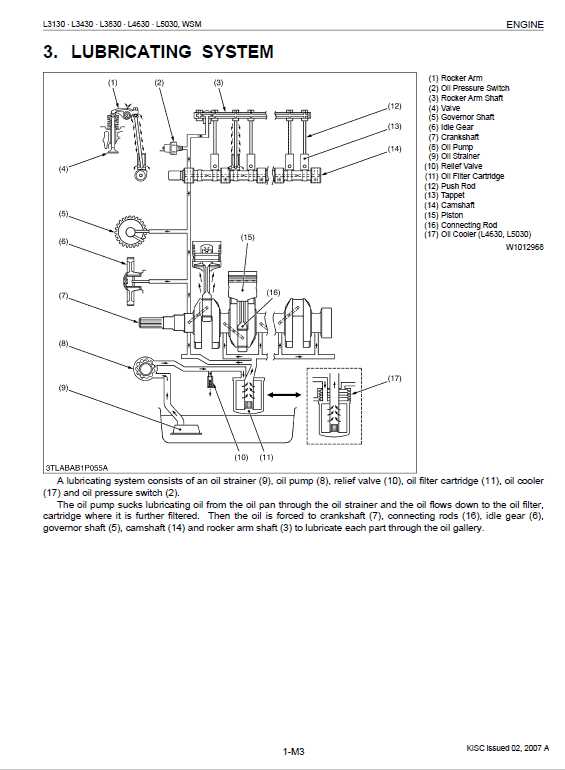

This section provides a comprehensive overview of the key components that make up the engine system of the specified model. Understanding these elements is essential for effective maintenance and repair.

- Cylinder Block: The core structure housing the cylinders, providing strength and stability.

- Pistons: Moving parts within the cylinders that facilitate the combustion process.

- Cylinder Head: Covers the top of the cylinders, containing essential parts like valves and spark plugs.

- Crankshaft: Converts linear motion from the pistons into rotational motion, driving the vehicle’s powertrain.

- Camshaft: Controls the timing of valve openings and closings, essential for efficient engine operation.

- Oil Pan: Reservoir for engine oil, crucial for lubrication and cooling of moving parts.

Each component plays a vital role in ensuring the engine runs smoothly and efficiently. Regular inspections and maintenance of these elements can prevent breakdowns and extend the lifespan of the machinery.

- Regularly check the oil level and quality.

- Inspect the cylinder head for any signs of wear or damage.

- Ensure the crankshaft is properly lubricated to prevent overheating.

Understanding the function and maintenance needs of these components can greatly enhance the reliability and performance of the engine system.

Electrical Components in Kubota L3830

The electrical system of this machinery plays a crucial role in its overall performance, ensuring efficient operation and reliable functionality. Understanding the various elements involved is essential for effective maintenance and troubleshooting.

Key Elements of the Electrical System

The system consists of several critical components, including batteries, alternators, and wiring harnesses. Each part serves a specific purpose, contributing to the machine’s ability to start, operate, and power various attachments.

Importance of Regular Maintenance

Regular inspections and maintenance of electrical components are vital to prevent potential failures. Keeping connections clean and ensuring that all elements are functioning correctly can enhance the durability and efficiency of the equipment.

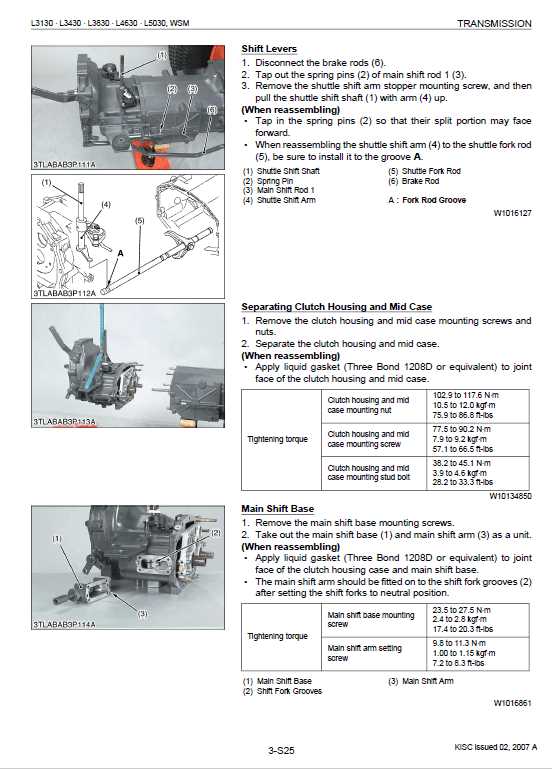

Transmission System in Kubota L3830

The transmission system plays a crucial role in the overall functionality of agricultural machinery, ensuring the effective transfer of power from the engine to the wheels. This section delves into the essential components and mechanisms that facilitate smooth operation and optimal performance.

Key Components of the Transmission

Understanding the main elements involved in the transmission system helps in appreciating its significance. The following table summarizes the primary components:

Component Function Gearbox Regulates the power transfer and speed adjustment. Clutch Engages and disengages the transmission system for smooth shifting. Transmission Fluid Lubricates and cools the internal components, preventing wear. Drive Shafts Transfers torque from the gearbox to the wheels. Operational Mechanism

This system operates by converting engine output into mechanical power, allowing the vehicle to move effectively across various terrains. The interaction between components ensures that the machinery can adapt to changing load conditions, enhancing its efficiency and reliability during operation.

Finding Genuine Parts for Kubota L3830

When maintaining machinery, securing authentic components is crucial for ensuring optimal performance and longevity. Using quality replacements not only enhances functionality but also minimizes the risk of malfunction. It’s essential to explore various avenues to locate reliable sources for these vital elements.

Importance of Authenticity

Authentic components are engineered specifically for your equipment, guaranteeing compatibility and superior performance. Utilizing imitation items may lead to premature wear or unexpected failures, ultimately resulting in higher costs for repairs. Therefore, prioritizing genuine replacements is a smart choice for any owner.

Where to Source Quality Components

Several avenues exist for obtaining these essential items. Authorized dealers often provide a range of genuine options, complete with warranties and expert guidance. Additionally, online marketplaces dedicated to machinery can be valuable resources, offering both new and refurbished selections. Engaging with community forums can also yield recommendations and insights from other users who have successfully sourced high-quality replacements.

Upgrading Your Kubota L3830 Parts

Enhancing the functionality of your agricultural machinery is essential for optimal performance. Whether you are looking to improve efficiency or prolong the lifespan of your equipment, upgrading components can make a significant difference. This section will explore various enhancements that can be made to boost your machine’s capabilities.

Key Components for Enhancement

When considering upgrades, it is crucial to identify which parts will yield the most benefit. Below are some vital elements that are often targeted for improvement:

Component Benefits of Upgrading Engine Filters Improved airflow and better fuel efficiency Hydraulic System Enhanced lifting capacity and quicker response times Transmission Fluid Smoother operation and reduced wear Tires Increased traction and improved stability Choosing the Right Upgrades

Selecting the appropriate enhancements involves evaluating your specific needs and the tasks your machinery will perform. Consult with experts or refer to reputable sources to ensure that the components you choose will fit correctly and function effectively. Upgrading can lead to substantial improvements in productivity and overall satisfaction.