Understanding the intricate structure of machinery is essential for effective maintenance and operation. A clear representation of various elements within a system can enhance the efficiency of repairs and upgrades. By examining these visual guides, users can gain insights into the functionality and interconnections of different components.

Each machine has a unique assembly of parts that work harmoniously to achieve optimal performance. Recognizing how these elements fit together allows operators to troubleshoot issues more efficiently and make informed decisions regarding replacements or enhancements. Moreover, familiarizing oneself with the configuration can lead to improved operational practices and extended lifespan of the equipment.

Utilizing detailed illustrations of components serves as a valuable resource for both experienced professionals and newcomers. These visual aids can simplify the understanding of complex machinery, making it easier to identify specific elements and comprehend their roles. With this knowledge, users can approach maintenance tasks with confidence and precision.

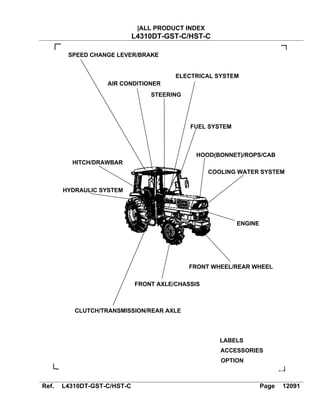

This section explores the essential attributes of a versatile agricultural machine designed for various tasks. Its robust construction and innovative design elements contribute to efficiency and ease of use, making it a valuable asset in both commercial and personal applications.

| Feature | Description |

|---|---|

| Engine Performance | Equipped with a powerful engine that ensures optimal output for heavy-duty operations. |

| Hydraulic System | A highly efficient hydraulic system enhances lifting capacity and maneuverability, facilitating a range of attachments. |

| Transmission | Offers a smooth-shifting transmission that allows for seamless transitions between different speeds and terrains. |

| Operator Comfort | Designed with an ergonomic operator station, providing comfort and reducing fatigue during long hours of work. |

| Versatility | Compatible with a wide range of implements, making it adaptable for various agricultural and landscaping tasks. |

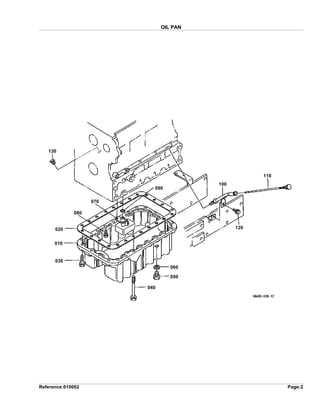

Importance of Parts Diagrams

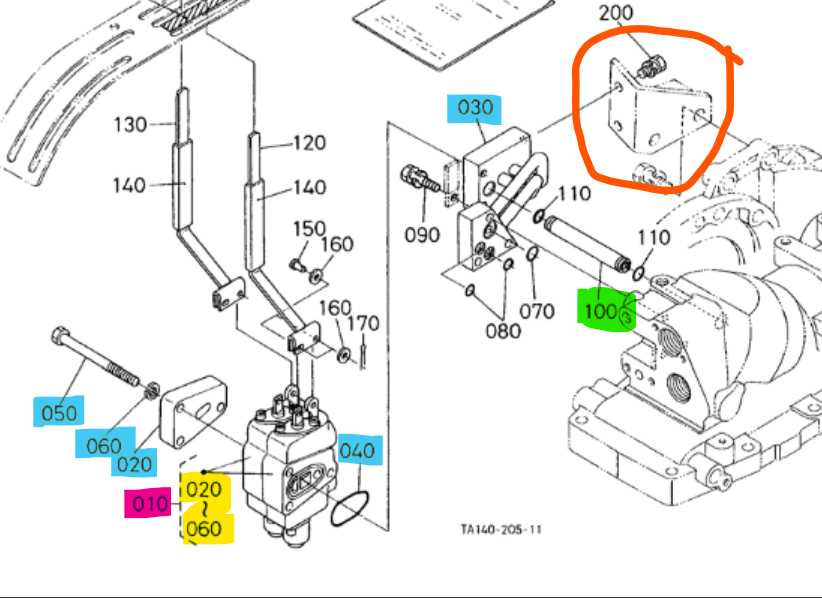

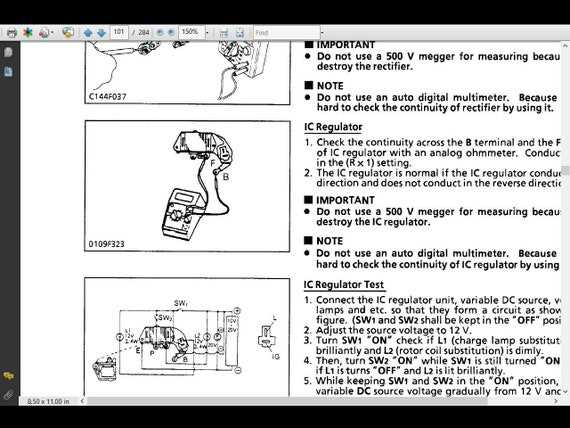

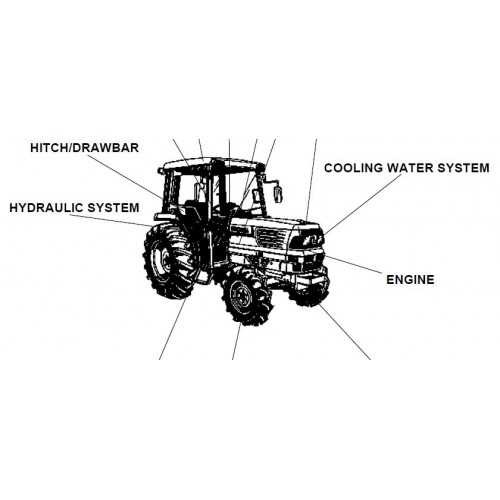

The representation of components and their relationships is crucial in understanding complex machinery. Such illustrations serve as valuable tools for technicians and users, enabling them to identify individual elements within a system effectively. This clarity aids in troubleshooting, maintenance, and repair tasks.

Moreover, these visual guides enhance communication among team members by providing a common reference point. When everyone can visualize how components fit together, it reduces misunderstandings and errors during assembly or disassembly. In addition, having access to these resources can significantly decrease downtime, as users can quickly locate and address issues.

In the long run, comprehending these illustrations contributes to the longevity and efficiency of machinery. Regular maintenance becomes more manageable when users can pinpoint specific components needing attention. Therefore, incorporating such visual aids into the maintenance process is not just beneficial but essential for optimal performance.

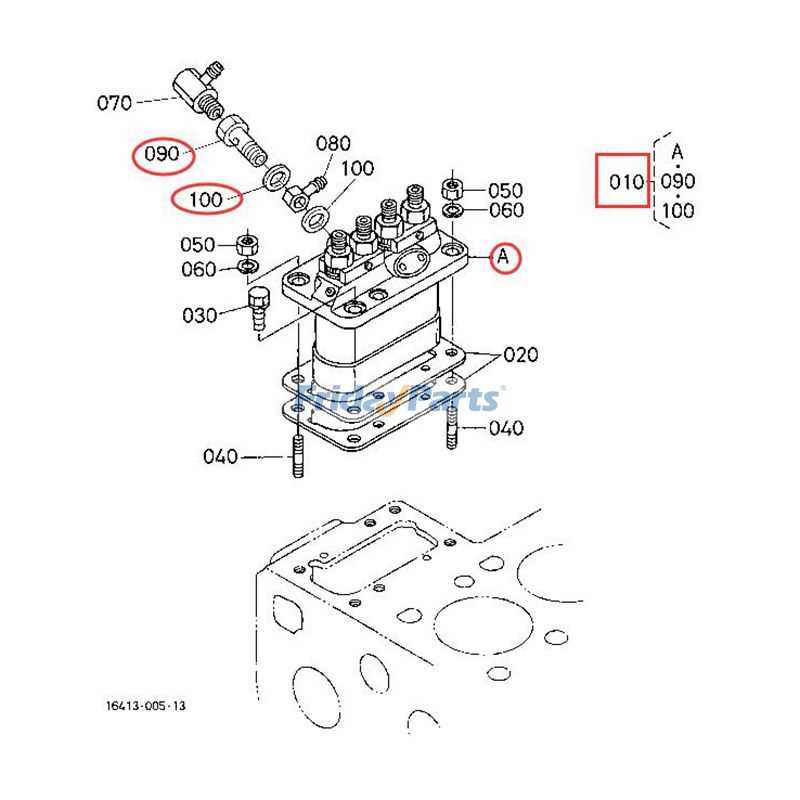

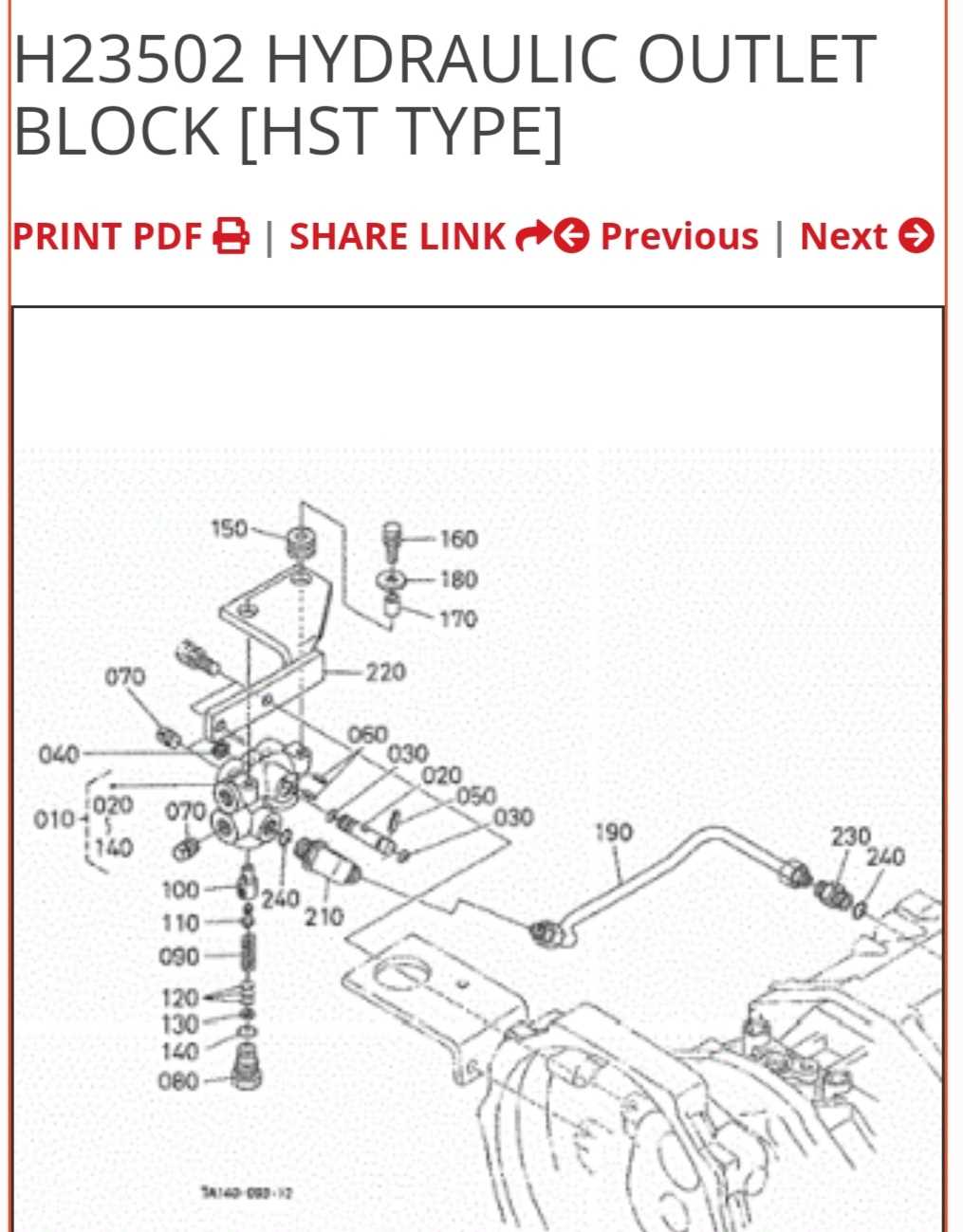

Understanding the Parts Breakdown

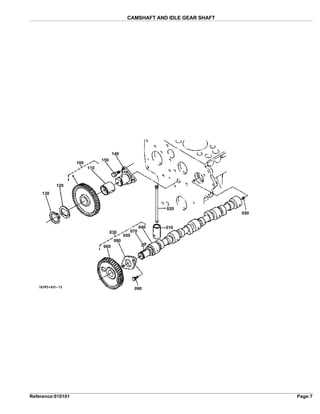

The analysis of component structures is crucial for effective maintenance and repair of machinery. This section delves into the intricacies of how various elements are organized, facilitating a clearer understanding of their functionality and interrelations. By breaking down these assemblies, users can better comprehend the overall operation of the equipment.

Importance of Component Analysis

Grasping the composition of machine elements enables operators to:

- Identify individual components easily.

- Diagnose issues more efficiently.

- Plan maintenance tasks effectively.

Key Elements of Breakdown Structure

When exploring the composition of machinery, consider the following key elements:

- Groupings: Components are often categorized based on their functions.

- Connections: Understanding how parts interact is essential for troubleshooting.

- Specifications: Familiarity with size, shape, and material enhances repair effectiveness.

Commonly Replaced Components

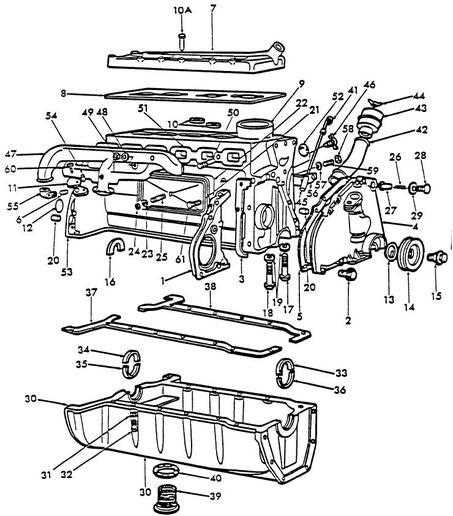

When maintaining machinery, certain elements often require attention due to wear and tear. Understanding these frequently replaced parts can help in planning repairs and ensuring optimal performance. Regularly addressing these components can prevent more significant issues and extend the lifespan of the equipment.

Engine Components

One of the most critical areas to monitor is the engine, where several components are prone to deterioration. Filters play a vital role in keeping the engine running smoothly, and replacing them regularly is essential. Additionally, gaskets and seals can wear out, leading to leaks that may affect performance.

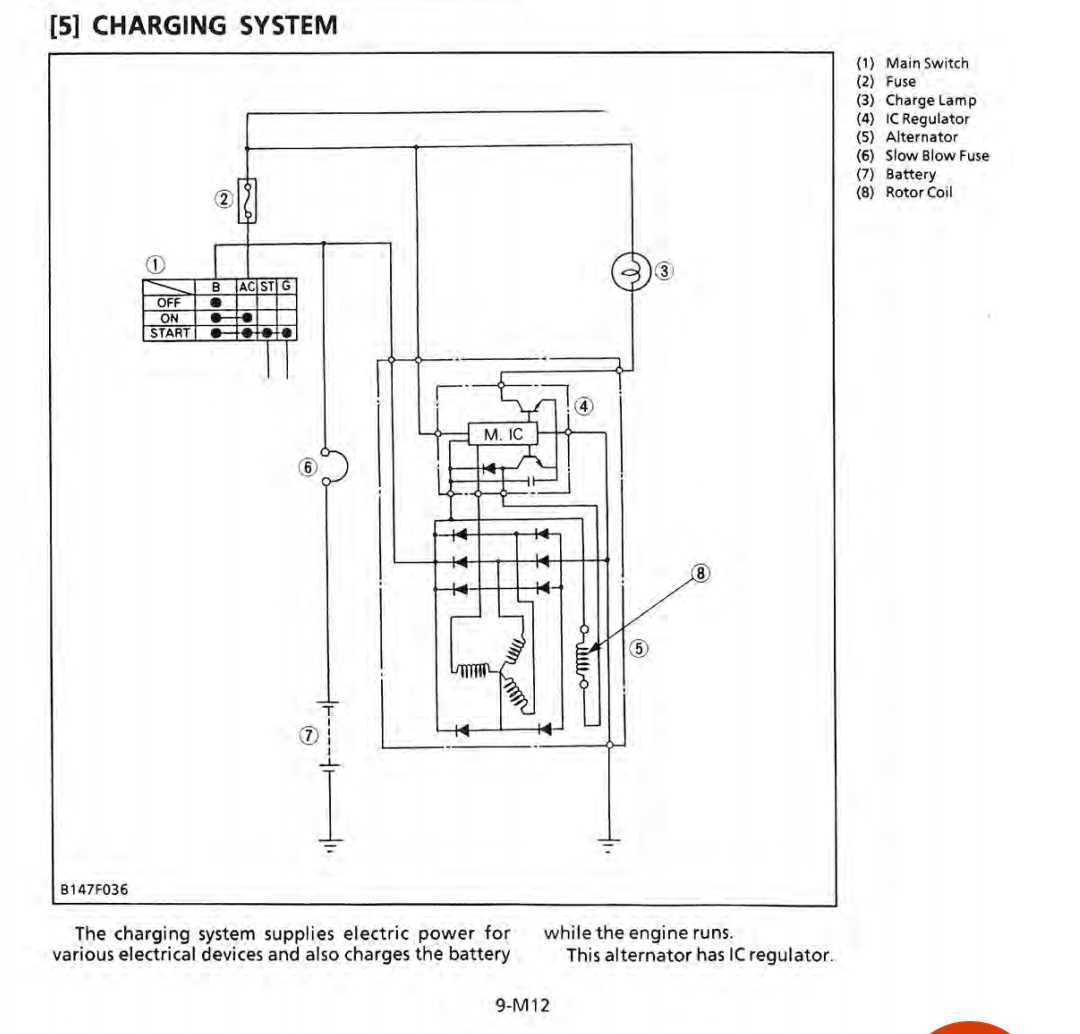

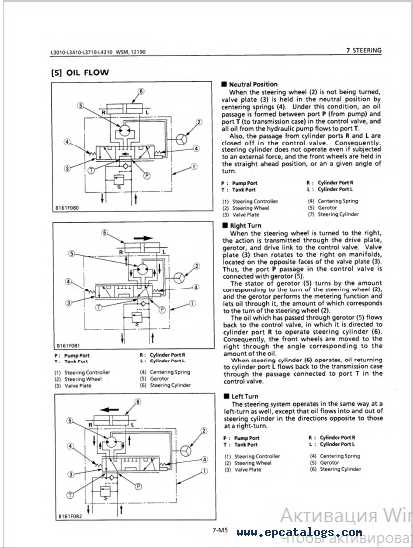

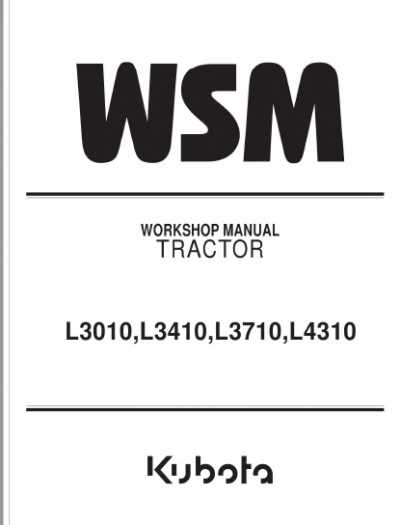

Hydraulic System Parts

The hydraulic system is another area where replacements are common. Hoses and fittings can experience damage from pressure and environmental factors. Keeping a close eye on these parts ensures that the system operates efficiently and reduces the risk of hydraulic failures.

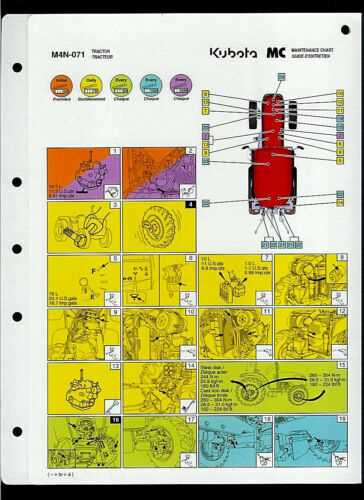

Maintenance Tips for L4310

Proper upkeep of agricultural machinery is essential for ensuring optimal performance and longevity. Regular maintenance not only prevents unexpected breakdowns but also enhances efficiency, saving both time and resources. This section offers practical advice to keep your equipment running smoothly.

Regular Inspections

Conducting routine inspections is crucial. Check for any signs of wear or damage in various components, such as the engine, hydraulic system, and tires. Early detection of issues can prevent costly repairs in the future.

Fluid Checks and Changes

Maintaining proper fluid levels is vital for the machinery’s operation. Regularly inspect and replace engine oil, hydraulic fluid, and coolant as necessary. Using high-quality fluids tailored to your equipment’s specifications can significantly improve performance.

Where to Find OEM Parts

Locating genuine components for your machinery is essential for ensuring optimal performance and longevity. These authentic parts are designed specifically for your equipment, guaranteeing compatibility and reliability. To acquire these essential items, various avenues can be explored.

Authorized dealerships are often the best starting point. They typically stock a comprehensive selection of genuine components and can provide expert advice tailored to your specific requirements. Additionally, many manufacturers offer online platforms where you can browse and order parts directly, making the process more convenient.

Another option is to seek out specialized retailers that focus on original equipment. These stores often carry a wide array of components and can assist in identifying the right items for your machinery. Furthermore, joining online forums or communities dedicated to machinery enthusiasts can provide valuable insights and recommendations on where to source genuine parts.

Lastly, consider checking local classified ads or auction sites, where authentic components are sometimes available at competitive prices. Ensuring that you obtain genuine items is crucial for maintaining the integrity and efficiency of your equipment.

Identifying Aftermarket Options

When it comes to enhancing the performance of your machinery, exploring alternative components can be a practical approach. Aftermarket alternatives often provide cost-effective solutions while maintaining quality standards. Understanding the benefits and features of these options is essential for making informed decisions.

One of the main advantages of aftermarket components is the variety they offer. Many manufacturers specialize in creating compatible parts that can often outperform the original equipment. This diversity allows operators to tailor their machinery to better suit specific needs or preferences.

Before purchasing, it’s crucial to assess the quality and compatibility of the components. Researching reputable suppliers and reading customer reviews can provide insights into the reliability of different options available in the market. Below is a comparison table highlighting key aspects to consider when evaluating aftermarket choices.

| Feature | OEM Parts | Aftermarket Options |

|---|---|---|

| Cost | Higher | Lower |

| Quality Assurance | Guaranteed | Varies |

| Availability | Limited | Widely Available |

| Performance | Standard | Potentially Enhanced |

Assembly and Disassembly Instructions

Properly managing the assembly and disassembly of machinery components is crucial for ensuring optimal performance and longevity. This section provides essential guidelines for effectively handling the various elements involved in the process, promoting safety and efficiency throughout.

Preparation is Key: Before beginning, gather all necessary tools and components. Ensure that the work area is clean and organized to facilitate smooth operations. It is also advisable to wear appropriate safety gear to protect against potential hazards.

Disassembly Steps: Start by carefully removing any external covers or guards that may obstruct access. Use the appropriate tools to unscrew or detach each component systematically. Keep track of all fasteners and small parts to avoid misplacement. If necessary, refer to a reference guide to ensure correct procedures are followed.

Assembly Steps: Begin by cleaning all components to remove any debris or residue. Follow the reverse order of disassembly, ensuring each part is aligned correctly. Tighten all fasteners securely, but be cautious not to overtighten, as this may cause damage. Once fully assembled, double-check the work to confirm that everything is in place.

Final Inspection: After assembly, conduct a thorough inspection of the machine to ensure all components are properly installed. Testing the machinery before putting it into operation can prevent potential issues and enhance overall performance.

Utilizing the Diagram Effectively

Understanding the layout of components in a machine is crucial for efficient maintenance and repairs. By effectively interpreting the visual representation of parts, users can streamline their troubleshooting processes and enhance the longevity of their equipment. This section explores strategies for maximizing the usefulness of such illustrations in practical applications.

Identifying Components

Begin by familiarizing yourself with each section of the illustration. Recognizing various elements will facilitate a quicker assessment of the machine’s condition. Focus on common areas such as the engine, transmission, and hydraulic systems to understand their respective functions.

Referencing During Repairs

When undertaking repairs or replacements, consistently reference the visual representation. This practice will ensure you are aware of the correct installation procedures and help prevent errors that may arise from misinterpretation of component placements.

| Component | Description |

|---|---|

| Engine | The primary source of power, responsible for converting fuel into mechanical energy. |

| Transmission | Responsible for transferring power from the engine to the wheels, allowing for movement. |

| Hydraulic System | Facilitates the operation of various implements and attachments through fluid pressure. |

Frequently Asked Questions

This section aims to address common inquiries regarding the components and maintenance of specific machinery models. Understanding the intricacies of these machines can help users optimize their performance and extend their lifespan.

- What are the key components to check regularly?

Regular checks should include:

- Fluid levels

- Filters

- Belt tension

- Battery condition

- How can I find replacement components?

Replacement components can be sourced through:

- Authorized dealers

- Online marketplaces

- Local repair shops

- What are common signs of wear and tear?

Common indicators include:

- Unusual noises during operation

- Decreased efficiency

- Visible damage on parts

- Is there a maintenance schedule I should follow?

A typical maintenance schedule involves:

- Daily checks before use

- Weekly inspections of critical systems

- Monthly servicing for deep cleaning and part replacement

lessCopy code

Resources for Further Learning

This section aims to provide valuable materials and platforms for individuals seeking to deepen their understanding of machinery components and their functionalities. Engaging with a variety of resources can enhance both theoretical knowledge and practical skills.

Numerous online forums and communities offer insights from experienced users, making them excellent places for knowledge exchange. Websites dedicated to technical manuals and repair guides serve as essential references for those interested in hands-on work.

Additionally, video tutorials available on popular platforms can visually demonstrate complex procedures, making it easier for learners to grasp intricate concepts. Workshops and local classes also provide opportunities for direct interaction with experts and fellow enthusiasts.