When it comes to machinery that requires reliable maintenance and smooth operation, knowing the arrangement of various elements is crucial. By familiarizing oneself with the layout, you can ensure that every component is in its proper place, helping to maintain performance and prevent unexpected breakdowns.

Identifying essential components within a complex system allows users to address any challenges efficiently. Recognizing the location and function of each element can simplify routine care and enhance the overall lifespan of the equipment. This knowledge is particularly valuable for those who prioritize both functionality and long-term durability.

Visualizing the structure of interconnected parts can offer a deeper understanding of how different mechanisms work together. This insight is fundamental for anyone aiming to maintain optimal performance. With a comprehensive overview, managing each element becomes much simpler, ensuring that repairs or replacements are carried out smoothly.

Kubota LA524 Parts Overview

This section provides a comprehensive look at the essential elements that ensure optimal functioning of the equipment. Each component plays a crucial role in maintaining efficiency, offering durability and reliability over time. Understanding the details of these elements allows for better care and maintenance, ensuring the machinery continues to perform at its best.

- Hydraulic System: This system powers lifting and tilting, allowing smooth operation. It helps to manage weight effectively, providing seamless adjustments and ease of use.

- Structural Framework: The core structure supports the entire setup, offering strength and stability. Built to withstand rigorous use, it ensures that the machine remains steady during operations.

- Attachment Mechanisms: These connectors enable the use of various tools and accessories. Designed for versatility, they make the equipment adaptable to different tasks.

- Control Levers: The levers offer precise handling, giving the user full command over the machinery’s movements. They contribute to the accuracy and efficiency of every task performed.

- Safety Components: These include protective features that safeguard both the operator and the machine. They are crucial for preventing accidents and ensuring long-term functionality.

By recognizing the role of each component, users can ensure smoother operation and a longer lifespan for their equipment, adapting it to a variety of needs and working conditions.

Understanding Key Components

Exploring the essential elements of this equipment involves examining various mechanical and structural parts that ensure its smooth operation. Each component plays a crucial role in maintaining balance and efficiency, contributing to the overall functionality. Understanding how these pieces interact helps in recognizing the importance of each element.

Power Transmission is one of the fundamental systems, ensuring that energy is effectively transferred to different sections. This mechanism supports the movement and functioning of the entire machinery, ensuring smooth transitions and efficient performance.

The lifting mechanism is another vital aspect, designed to provide support and adjustability. This system allows for flexibility in handling diverse tasks, making it a key element for adaptability and precision during operation.

Additionally, the hydraulic system serves as a backbone for controlling various functions. It enables precise control and power management, ensuring that each motion is smooth and responsive. This system enhances the overall reliability of the machinery.

Finally, the structure’s stability components are critical for safe usage. These parts ensure that the equipment remains balanced during different tasks, providing safety and consistency in diverse working conditions.

Maintenance Tips for Kubota Attachments

Regular upkeep of equipment add-ons ensures their longevity and efficient performance. A proactive approach to care can prevent unexpected issues and enhance the reliability of various tools used with machinery.

Cleaning and Lubrication

Maintaining the cleanliness of all components is crucial. Dirt and debris accumulation can affect the smooth operation of moving parts. Use a soft brush to remove loose particles and follow up with a suitable cleaning agent. After cleaning, apply the appropriate lubricant to reduce friction and wear.

- Inspect joints and connections for signs of wear before applying lubricant.

- Avoid over-lubricating, as this may attract dust and debris.

- Focus on areas prone to rust to ensure smooth movement.

Inspection and Tightening

Frequent inspection helps identify potential issues before they become significant problems. Check for any loose fasteners and ensure that all fittings are securely tightened. This can prevent unnecessary vibrations and component damage during use.

- Inspect fasteners like bolts and screws weekly.

- Replace worn-out parts immediately to avoid further damage.

- Make adjustments to alignment if needed for optimal function.

With consistent care and attention, attachments can remain in peak condition, providing reliable assistance across various tasks. Regular maintenance not only extends their lifespan but also contributes to safe and effective operation.

Diagram for Hydraulic System

Understanding the layout of a hydraulic system is essential for efficient maintenance and troubleshooting. This system uses fluid pressure to transfer energy, allowing various components to work seamlessly together. A clear view of the fluid pathways and connections aids in identifying key areas for inspection or adjustment.

Flow Paths and Connections

The system includes multiple pathways where the fluid moves through pipes and valves, ensuring smooth power delivery. These channels connect pumps, cylinders, and control valves, allowing precise control of pressure and flow. Recognizing these connections helps in adjusting performance or diagnosing issues.

Key Components and Their Role

The main elements include the pump, control valves, cylinders, and various hoses. Each part plays a vital role in controlling the movement and force within the system. Identifying their placement helps in targeting specific areas for maintenance, ensuring longevity and optimal performance.

Front Loader Mechanism Breakdown

The front loader is a versatile tool designed for various lifting and moving tasks. Its structure consists of several interconnected components that work together, allowing smooth operation and efficient handling of different materials. Understanding these elements and their functions ensures proper maintenance and extends the operational lifespan.

| Component | Function |

|---|---|

| Hydraulic Cylinders | Responsible for lifting and tilting actions, providing the necessary force for movement. |

| Lift Arms | Connects the attachment to the frame, offering stability during lifting and lowering. |

| Control Valves | Manage the flow of hydraulic fluid, controlling the speed and direction of the loader’s actions. |

| Attachment Mount | Secures different tools like buckets or forks, enabling adaptability for various tasks. |

| Support Frame | Provides structural integrity, ensuring the loader remains balanced during operation. |

Parts Replacement Guide

This section provides essential information for the effective substitution of components within your machinery. Understanding the process of replacing various elements can significantly enhance performance and prolong the lifespan of your equipment.

When considering component replacement, it is crucial to follow a systematic approach:

- Identify the component that requires substitution.

- Gather the necessary tools for removal and installation.

- Ensure that you have the correct replacement component ready.

- Refer to the maintenance manual for specific instructions.

Below are some tips to keep in mind during the replacement process:

- Always prioritize safety by wearing appropriate protective gear.

- Disconnect the power source before starting any work.

- Keep a clean workspace to prevent contamination.

- Document the process to aid future replacements.

By adhering to these guidelines, you can ensure that the replacement of components is carried out smoothly, contributing to the overall efficiency and reliability of your machinery.

Compatible Accessories for Kubota LA524

When enhancing the functionality of your equipment, selecting suitable accessories is crucial. These additional components can significantly improve performance, versatility, and overall user experience, making tasks more efficient and enjoyable.

Types of Accessories

- Loader Attachments: Various implements designed for lifting and moving materials, such as forks and buckets.

- Tires: Options that provide better traction and stability for different terrains.

- Lighting Kits: Enhancements that improve visibility during low-light conditions.

- Safety Features: Devices like roll bars and protective shields to ensure operator safety.

Benefits of Upgrading Accessories

- Increased productivity through tailored tools for specific tasks.

- Enhanced durability with robust attachments designed to withstand heavy use.

- Improved versatility, allowing for a wider range of applications and environments.

Improving Efficiency with Correct Parts

Utilizing the right components is crucial for enhancing operational effectiveness in any machinery. When the elements are well-suited to each other, they work harmoniously, leading to optimal performance and reduced downtime. This section discusses how selecting appropriate components can significantly impact productivity and longevity.

To ensure that machinery functions at its best, consider the following strategies:

- Compatibility: Always verify that each component is compatible with the machine. Mismatched parts can lead to inefficiencies and potential damage.

- Quality: Invest in high-quality components that meet industry standards. Quality materials often last longer and perform better, resulting in fewer replacements.

- Regular Maintenance: Conduct routine inspections and maintenance to identify worn or damaged components early. Prompt replacements can prevent larger issues down the line.

- Manufacturer Guidance: Follow the recommendations provided by the manufacturer for selecting and replacing components. This guidance is based on extensive testing and expertise.

Implementing these strategies will help in maximizing the performance of your machinery, ultimately leading to improved efficiency and reduced operational costs.

Troubleshooting Loader Issues

Identifying and resolving challenges with a lifting mechanism is crucial for maintaining optimal performance. Common problems can arise due to various factors, including mechanical wear, hydraulic system failures, or operator error. A systematic approach to diagnosing these issues ensures efficient operation and minimizes downtime.

Common Symptoms and Their Causes

Recognizing the signs of malfunction is the first step in troubleshooting. Typical indicators include:

- Inadequate lifting capacity: This may result from fluid leaks or worn hydraulic seals.

- Unresponsive controls: Check for issues with electrical connections or faulty actuators.

- Strange noises: Unusual sounds can indicate internal damage or insufficient lubrication.

Steps for Effective Diagnosis

To efficiently address the issues:

- Perform a visual inspection of all components for signs of damage or wear.

- Check fluid levels and condition, ensuring that hydraulic fluid is clean and at the correct level.

- Test the control system to ensure all electrical connections are secure and functioning.

- Refer to the maintenance manual for specific troubleshooting guidelines related to your model.

By following these steps, operators can effectively identify and rectify issues, ensuring the loader operates at peak performance.

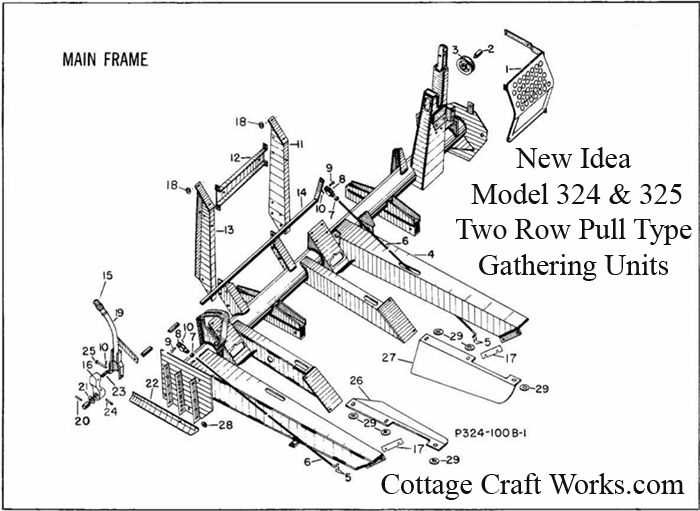

How to Read the Parts Diagram

Understanding an assembly illustration is essential for effective maintenance and repairs of machinery. These visual aids provide a detailed overview of components, their locations, and connections, enabling users to navigate complex systems with ease.

When examining the illustration, focus on the accompanying labels and numbers that correspond to each component. These references typically relate to a list of items, simplifying the identification of parts necessary for repairs or replacements. Carefully studying the layout will enhance your ability to pinpoint specific elements and their functions within the overall system.

Additionally, it is beneficial to familiarize yourself with any color codes or symbols used in the illustration, as they often indicate different categories or conditions of the components. By mastering this skill, you will improve your efficiency when sourcing and managing the necessary components for your machinery.

Assembly Tips for New Parts

When integrating fresh components into machinery, attention to detail is essential for ensuring optimal functionality. Proper assembly techniques can significantly enhance the performance and longevity of new elements. This section will provide valuable insights into effective practices that facilitate a smooth integration process.

1. Review Instructions Carefully: Prior to beginning the assembly, thoroughly examine the provided guidelines. Understanding each step and component’s role will help prevent errors during installation.

2. Organize Components: Lay out all new elements in a logical order. Grouping similar items together can streamline the assembly process and reduce the likelihood of misplacing or overlooking any part.

3. Use the Right Tools: Ensure you have the appropriate tools readily available. Utilizing the correct instruments not only simplifies assembly but also minimizes the risk of damaging new components.

4. Double-Check Alignments: As you begin to assemble, consistently check the alignment of each part. Proper positioning is crucial for achieving optimal functionality and preventing future complications.

5. Tighten Fasteners Securely: Once components are in place, securely fasten them according to specifications. Avoid overtightening, as this can lead to damage, but ensure they are sufficiently snug to maintain stability.

6. Test Functionality: After assembly is complete, perform thorough tests to verify that everything operates as intended. Monitoring performance early on can help identify any issues that need addressing.

By adhering to these guidelines, the integration of new components can be accomplished with greater ease and success, ultimately contributing to the efficient operation of your equipment.

Optimizing Performance with Regular Checks

Maintaining optimal functionality of machinery involves systematic inspections and timely maintenance activities. Regular assessments ensure that all components are operating efficiently, reducing the risk of unexpected failures and prolonging the equipment’s lifespan. By integrating routine evaluations into operational practices, users can identify potential issues early and take corrective actions, enhancing overall performance.

Benefits of Routine Maintenance

Consistent upkeep not only enhances efficiency but also fosters safety in operation. Regular checks allow operators to monitor wear and tear, ensuring that any irregularities are addressed promptly. This proactive approach minimizes downtime and maximizes productivity, ultimately leading to cost savings.

Key Areas to Monitor

Focus on critical aspects such as fluid levels, filter conditions, and the integrity of mechanical connections. Additionally, keeping an eye on electrical systems and safety features can prevent more significant problems down the line. Establishing a comprehensive maintenance schedule tailored to specific operational needs can significantly boost the reliability of equipment.