Understanding the layout and connections of critical equipment is essential for maintaining the performance of any machine. Whether it’s routine upkeep or troubleshooting, having a clear view of how elements are structured can simplify many tasks. Knowing the proper arrangement helps ensure each element functions as intended, contributing to the overall efficiency and longevity.

Each mechanical system is made up of interconnected elements that work in harmony. When one of these elements needs attention, it’s important to have a reference that provides a clear outline. With a detailed overview of the various pieces, you can more easily locate and identify what may need repair or replacement, ensuring smoother operation and less downtime.

In this guide, we’ll take a closer look at how key mechanical and functional aspects come together. The goal is to provide a resource that makes it easier to manage and maintain your equipment, whether for routine checkups or when issues arise. Having a solid understanding of how these components fit together will empower you to keep everything running smoothly.

Understanding the Kubota M9000 Parts Structure

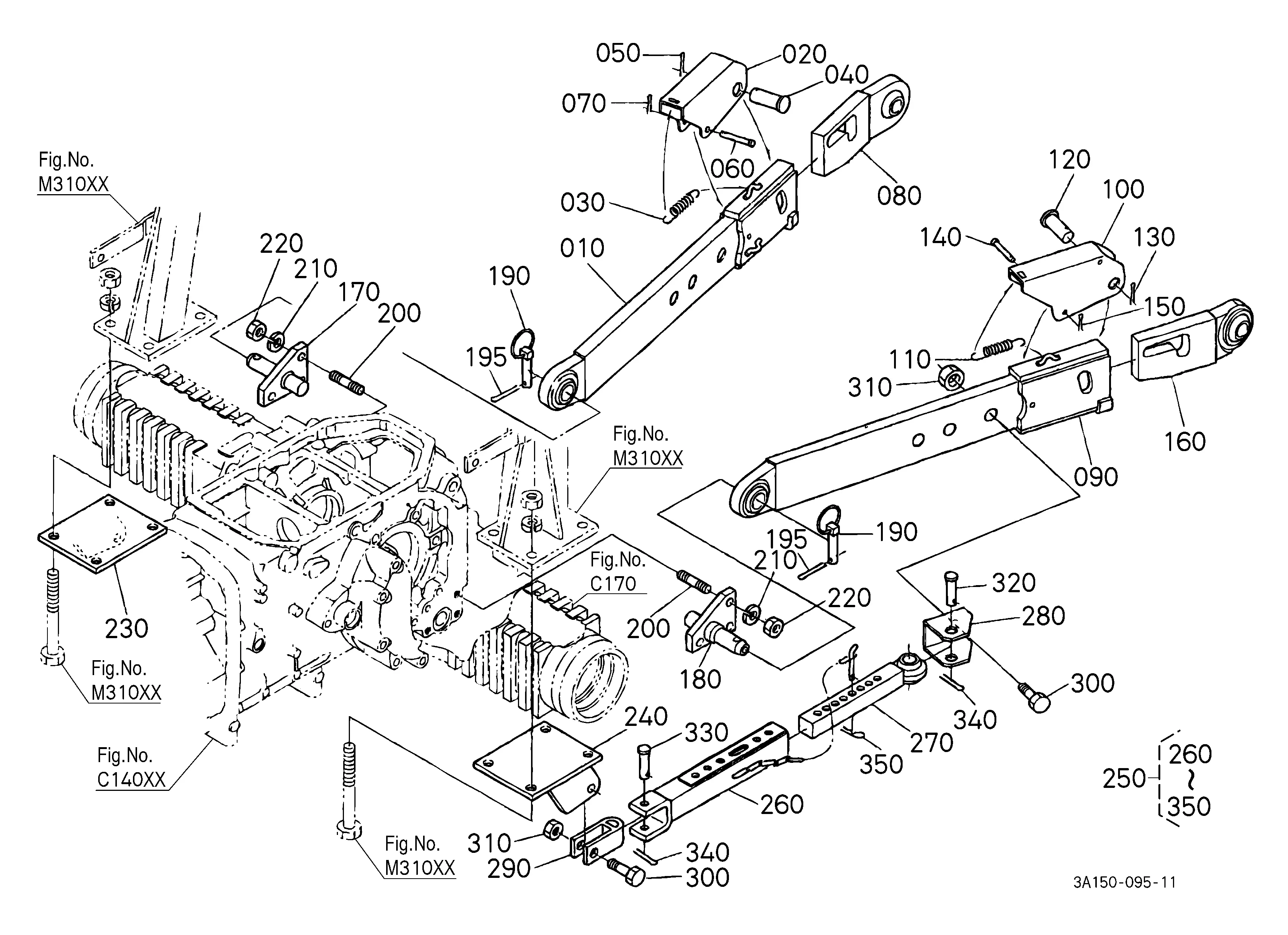

Exploring the mechanical composition of this agricultural machine involves recognizing the key elements that ensure its efficient performance. Each section of the equipment is designed to work in harmony, contributing to the overall durability and functionality of the vehicle. Knowing the layout of its components helps in maintaining, repairing, and enhancing its operation.

Core Mechanical Components

The machinery’s structure consists of essential sections that manage power, control, and movement. These include elements that regulate the engine, transmission, and hydraulic systems. Understanding how these elements interact is crucial for smooth operation.

- Engine block and attachments

- Transmission gears and drives

- Hydraulic connections

Frame and Control Systems

The framework supports both the physical structure and control elements. It includes a sturdy chassis, steering mechanisms, and advanced safety features. Together, they ensure

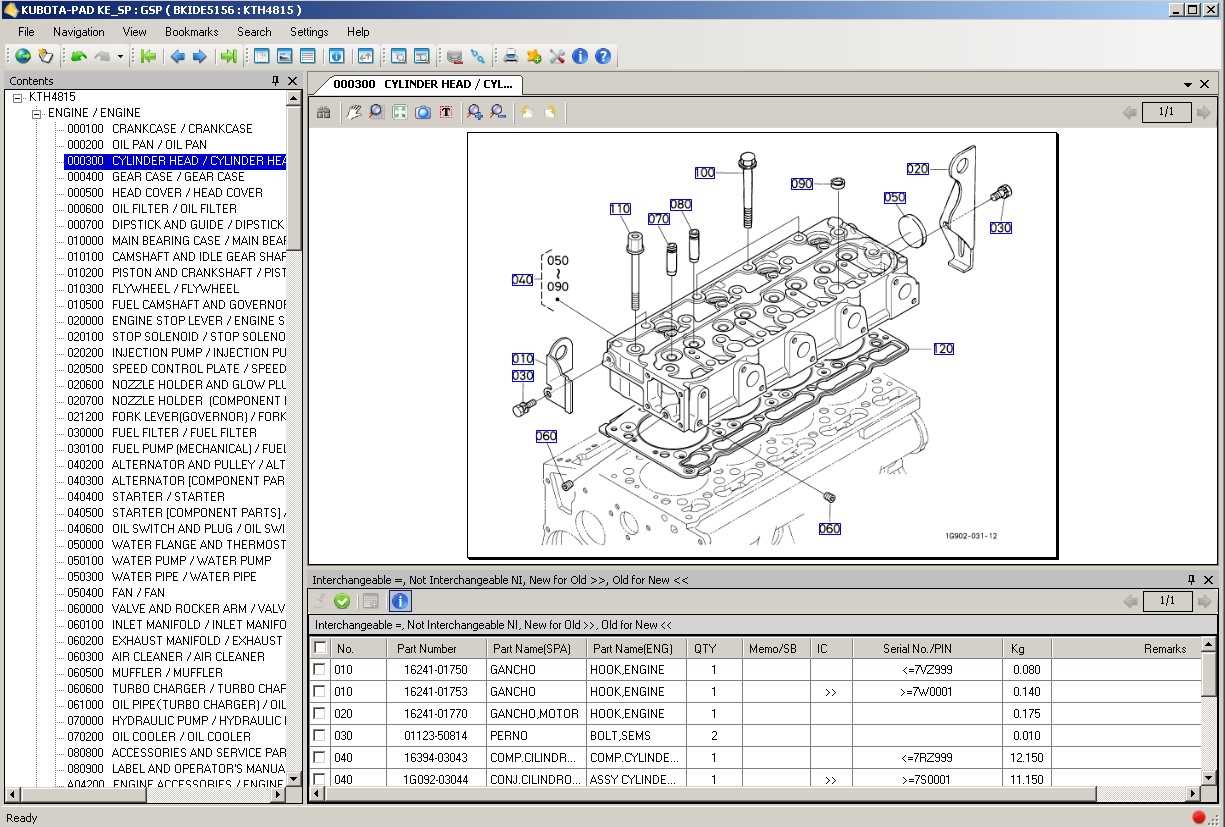

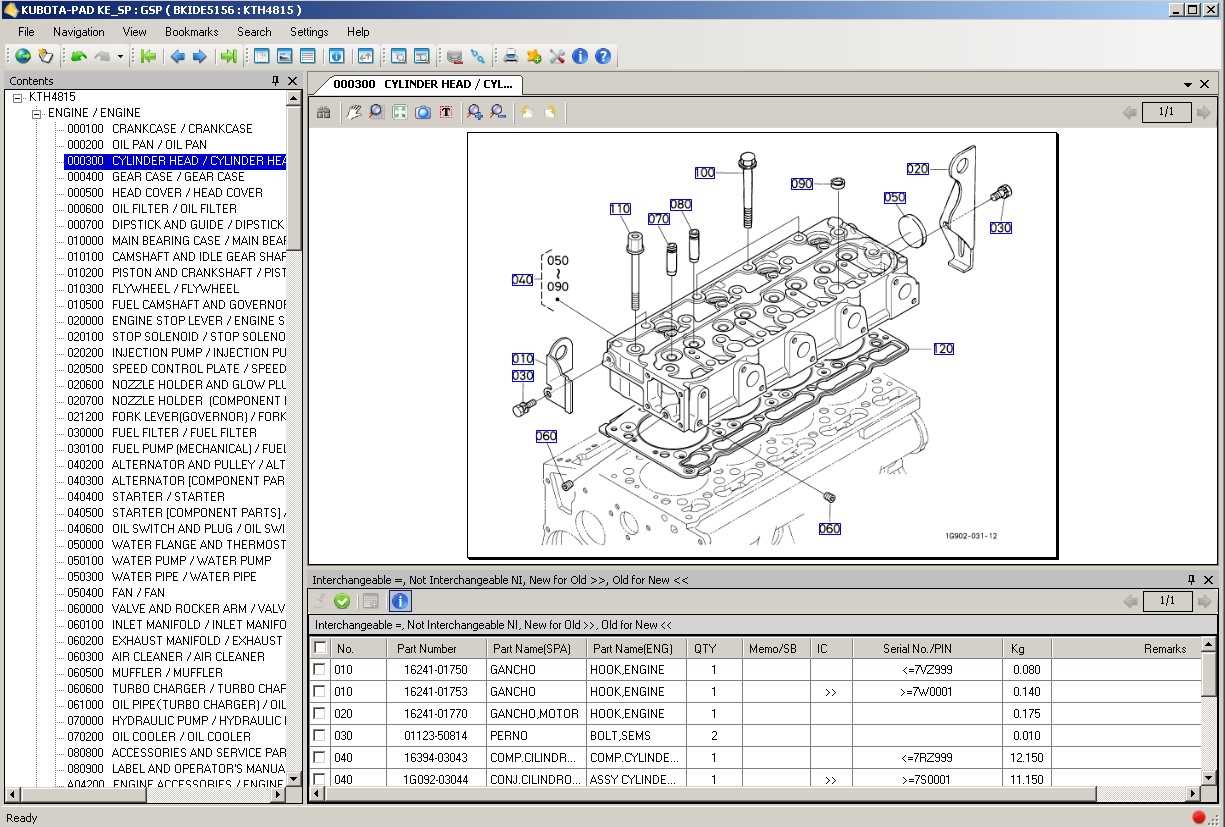

Key Engine Components for Kubota M9000

The engine of this robust agricultural machine relies on various interconnected elements that ensure its seamless operation. Understanding the essential mechanical parts can greatly aid in maintaining its performance and longevity. Each component plays a critical role in keeping the engine running smoothly, providing the necessary power to handle demanding tasks.

Major Engine Parts

The heart of this heavy-duty machine features several primary components that work together to generate and regulate power. From the central combustion chamber to the intricate fuel injection system, each piece is carefully designed to ensure optimal functionality. Below is a summary of the main elements responsible for smooth engine performance.

| Component |

Function |

| Cylinder Block |

Houses the pistons and ensures proper alignment for smooth movement. |

| Crankshaft |

Converts linear motion of pistons into rotational force. |

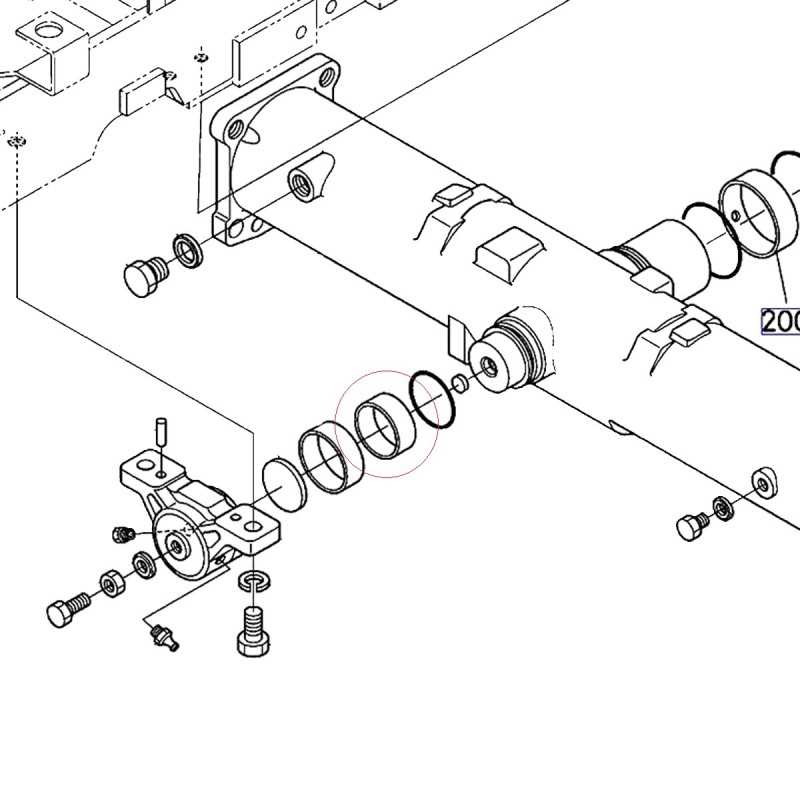

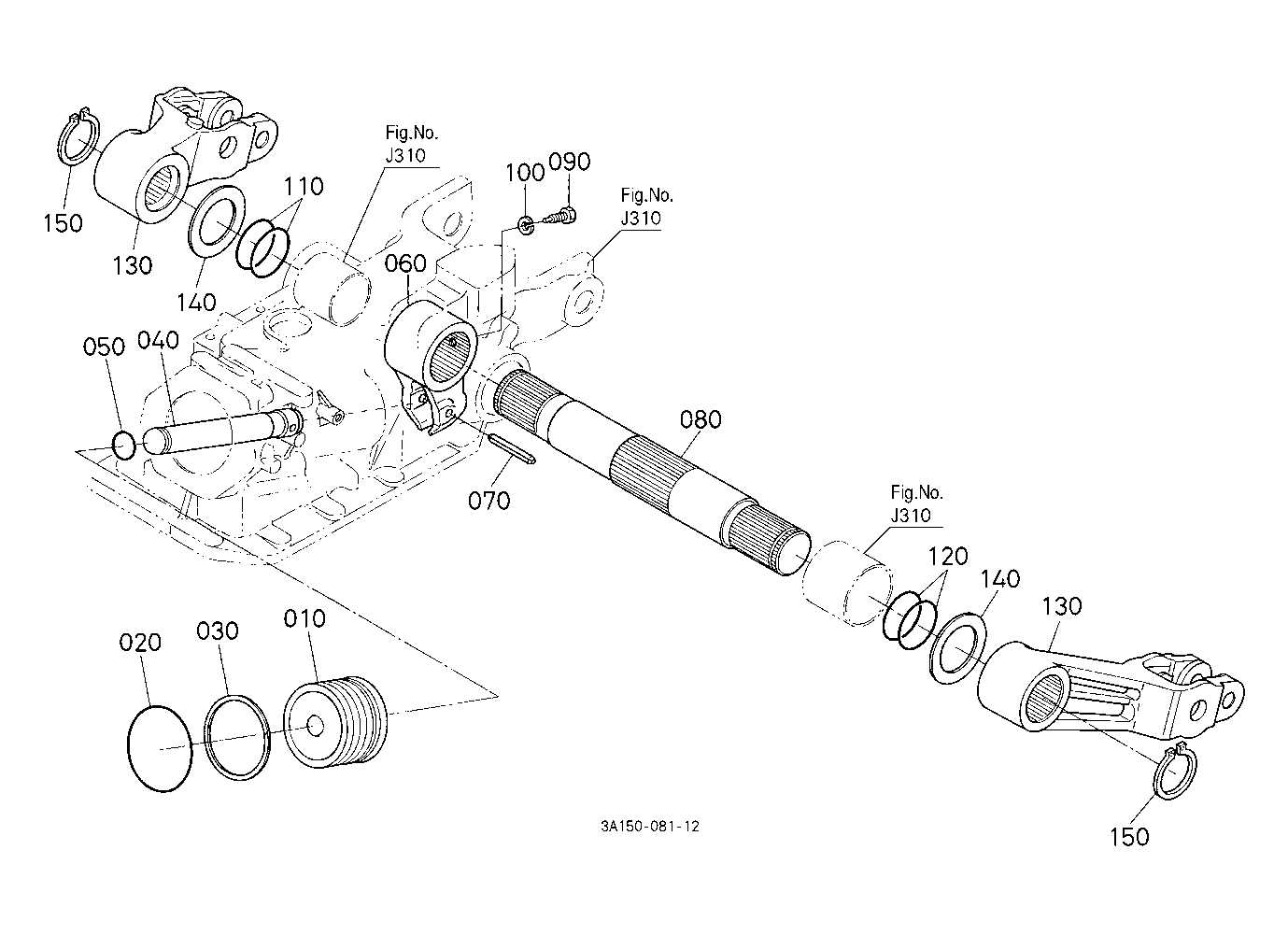

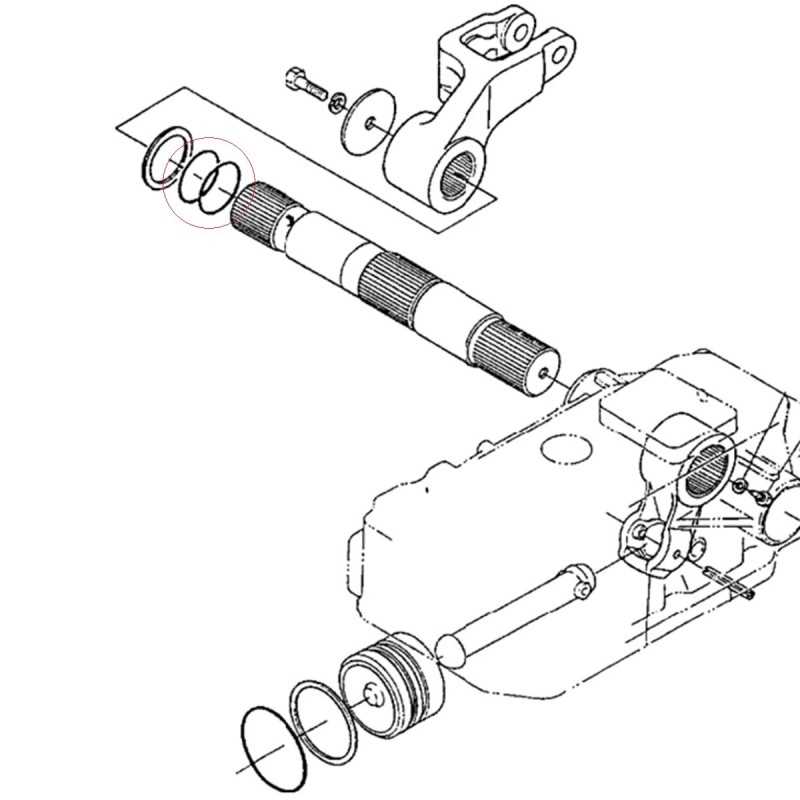

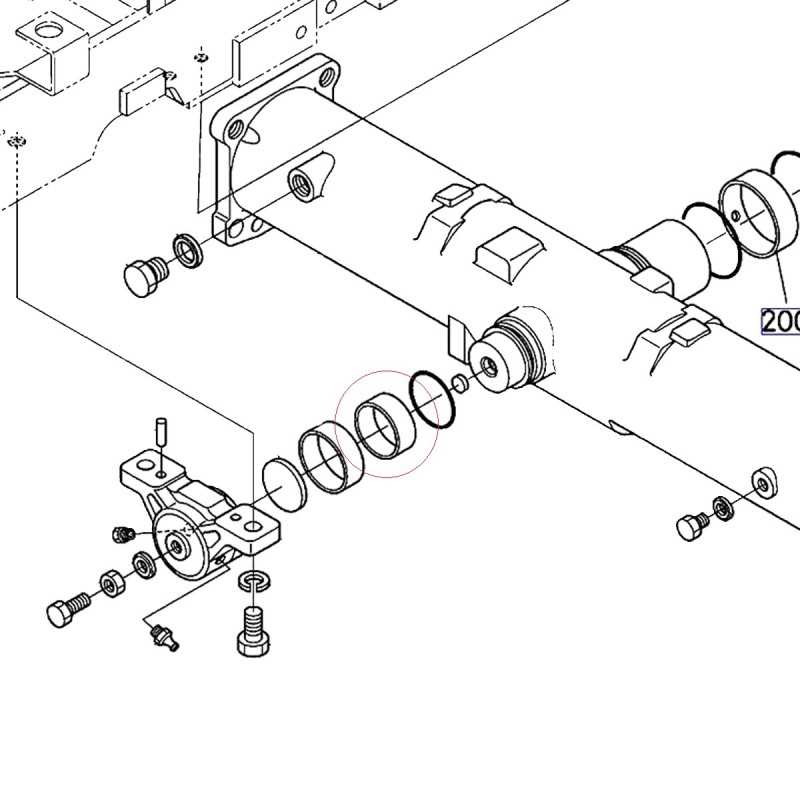

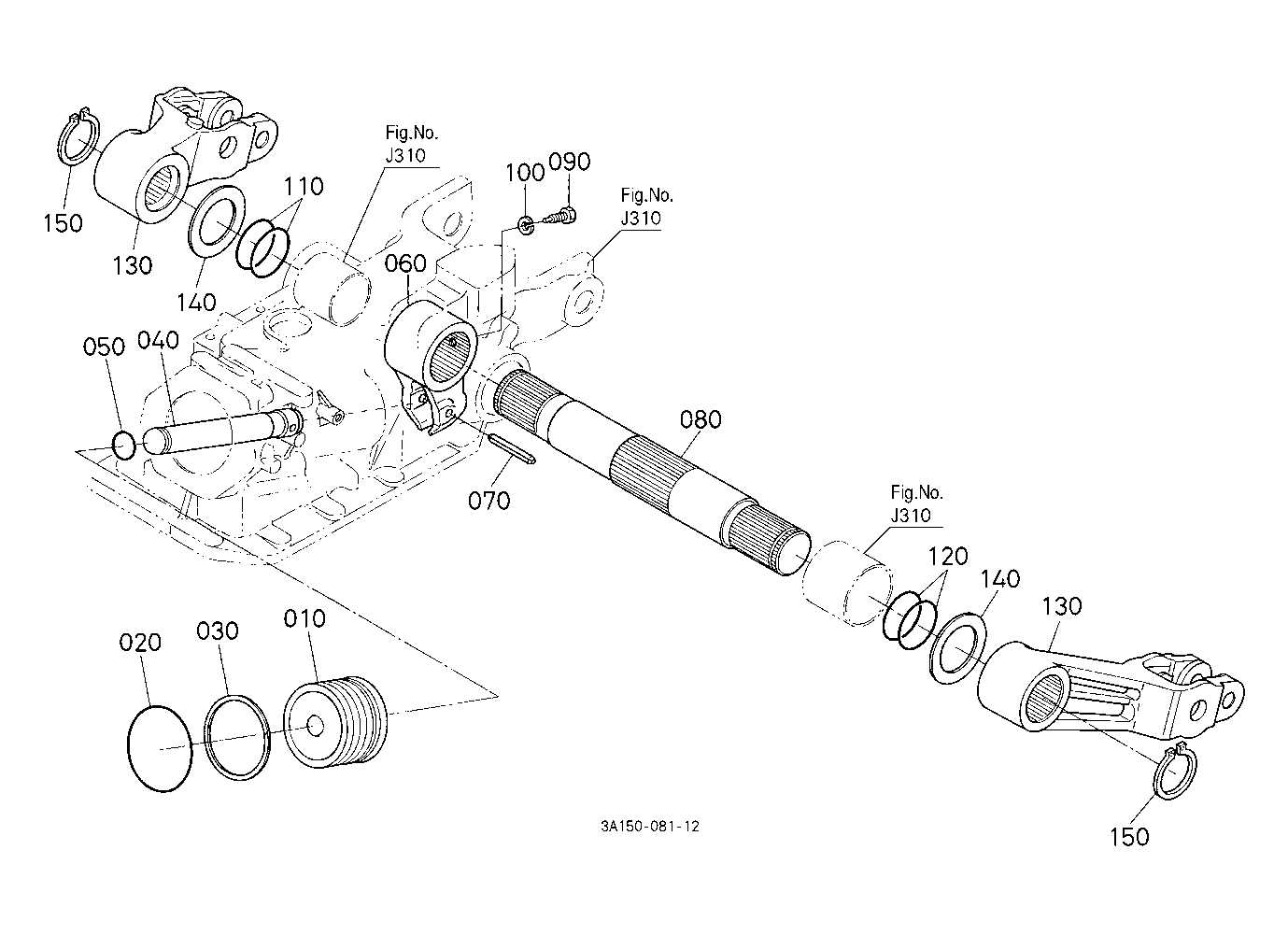

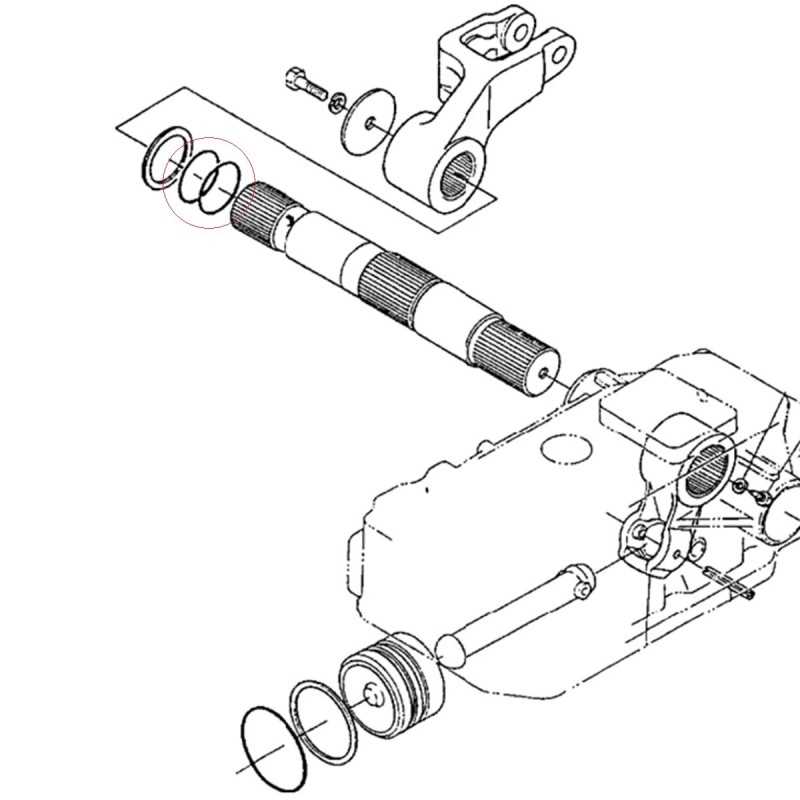

Hydraulic System Breakdown of the Kubota M9000

The fluid-driven mechanics of this powerful machine are essential for ensuring smooth operation and reliable performance in various tasks. These mechanisms allow the transfer of energy through pressurized liquids, making it easier to control and move different components effectively.

At the core of this system lies a series of interconnected channels and devices that manage the flow of hydraulic fluid. Pumps, valves, and cylinders work together to convert this fluid energy into mechanical motion, allowing the machine to handle heavy loads with precision. Key elements like control levers and pressure regulators ensure that operations are safe and efficient, adjusting the flow as needed.

Proper maintenance of these systems ensures long-term reliability. By regularly inspecting the lines and connections, as well as monitoring fluid levels, one can prevent common issues such as leaks and pressure drops. Understanding how these components function is vital for troubleshooting and keeping operations running smoothly.

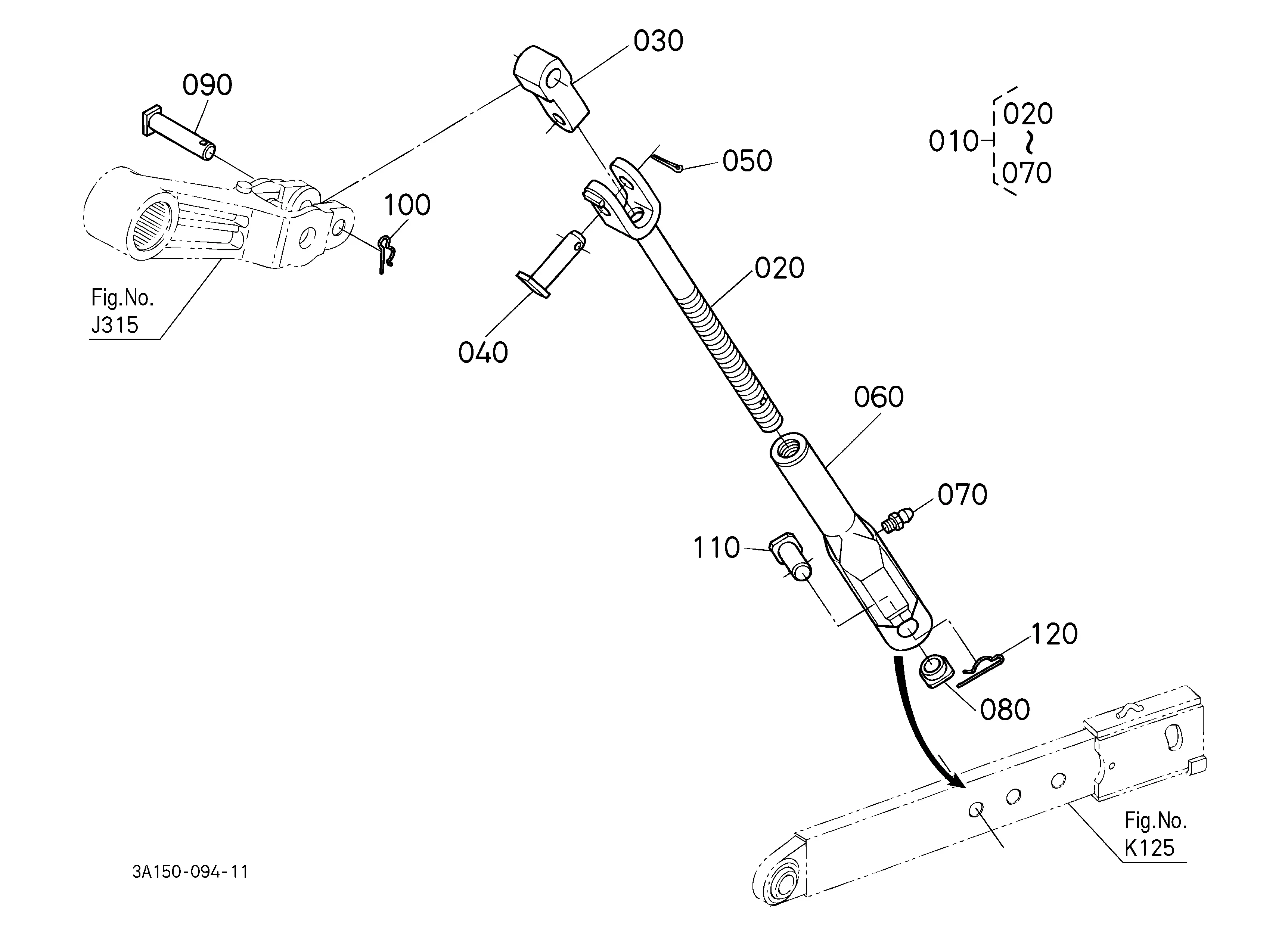

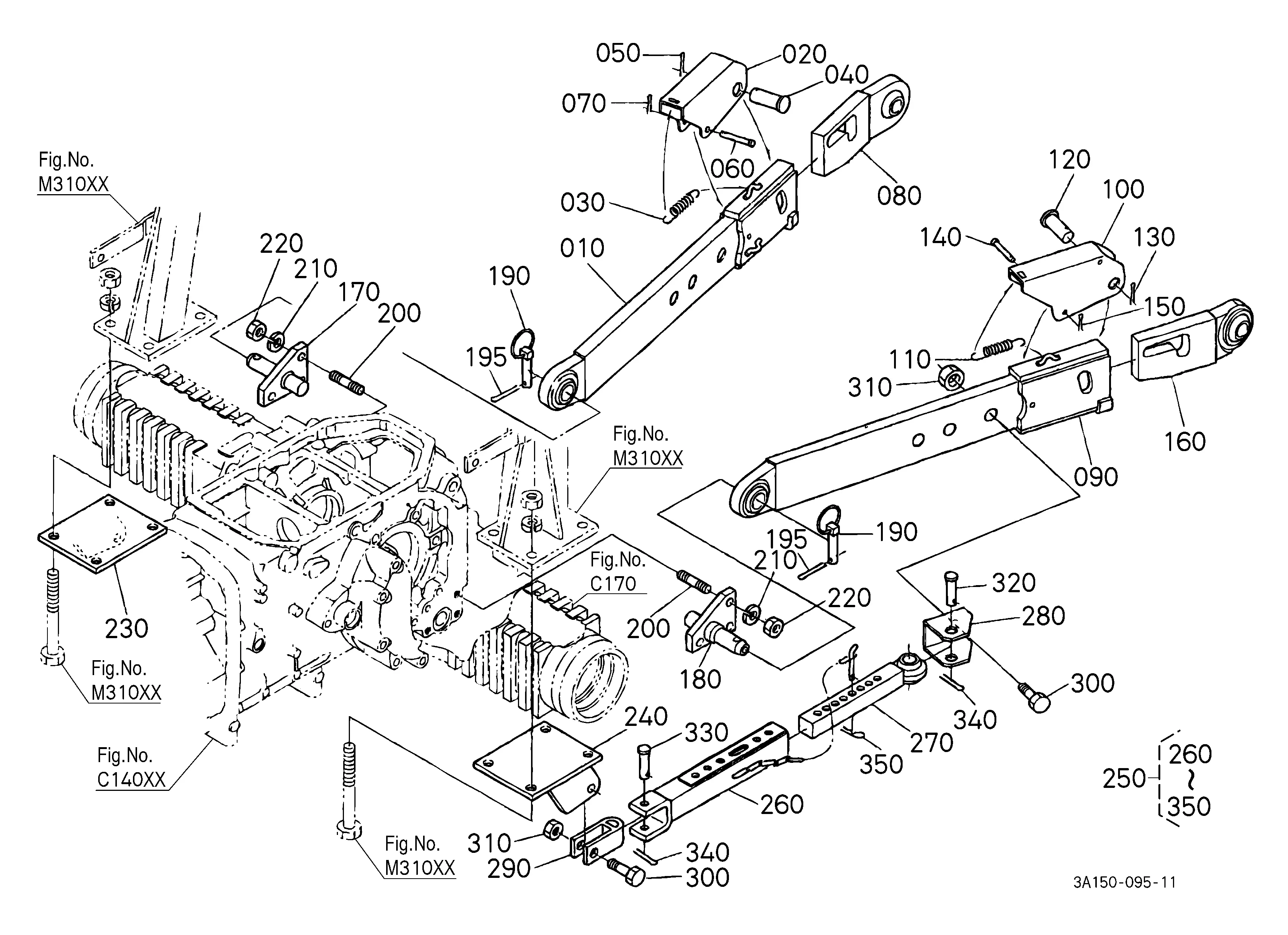

Transmission Parts and Their Functionality

The transmission system plays a crucial role in ensuring smooth power delivery from the engine to the wheels. Its core components work in unison to regulate speed and torque, adapting to different operational demands. Understanding how these elements work together can enhance the overall performance of any mechanical system.

Main Components and Their Roles

The central part of this system is the gearbox, which manages the shifting of gears to adjust the vehicle’s speed. Another critical element is the clutch, responsible for engaging and disengaging the engine’s power during gear changes. These components ensure smooth transitions and prevent damage caused by abrupt shifts in power.

Additional Mechanisms for Efficiency

Other important mechanisms include the drive shaft, which transfers the engine’s output to the differential, and the differential itself, which allows the wheels to rotate at different speeds, particularly when navigating turns. Together, these elements maintain optimal balance and precision in handling, ensuring efficiency and reliability during operation.

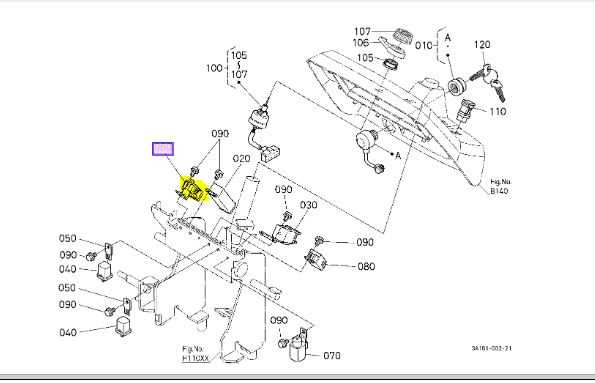

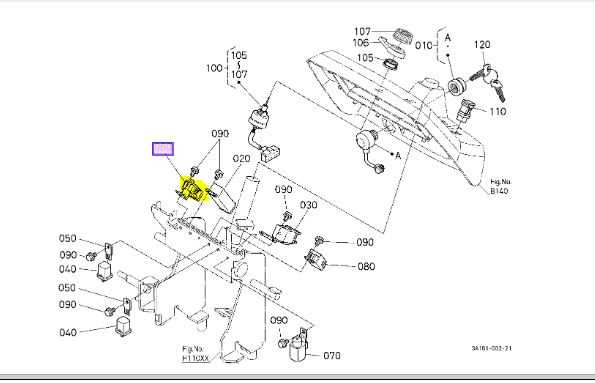

Exploring the Electrical System Components

Understanding the essential elements of the electrical framework is crucial for ensuring smooth operation and maintenance. This system powers various functions, controlling everything from illumination to critical electronic controls. Each component within this system plays a unique role, contributing to overall efficiency and reliability.

Battery and Wiring Network

The energy source provides the necessary power to operate multiple devices. Through a network of wiring, energy is distributed to different sections, allowing the machinery to perform its functions seamlessly. Proper maintenance of this network ensures consistent and dependable performance.

Control Modules and Relays

Electronic modules are responsible for managing and regulating the performance of various subsystems. Relays, on the other hand, serve as switches, directing electrical flow where it’s needed, ensuring that different parts of the system receive the appropriate power when required.

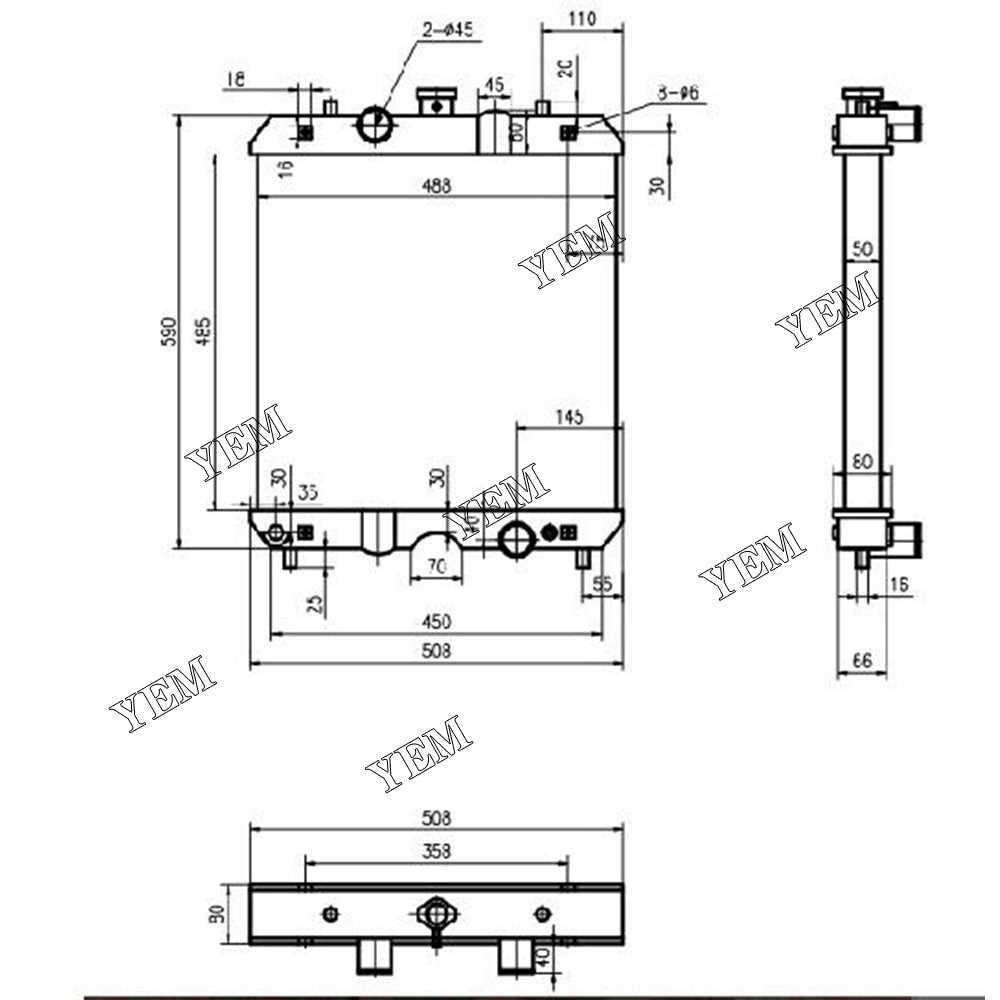

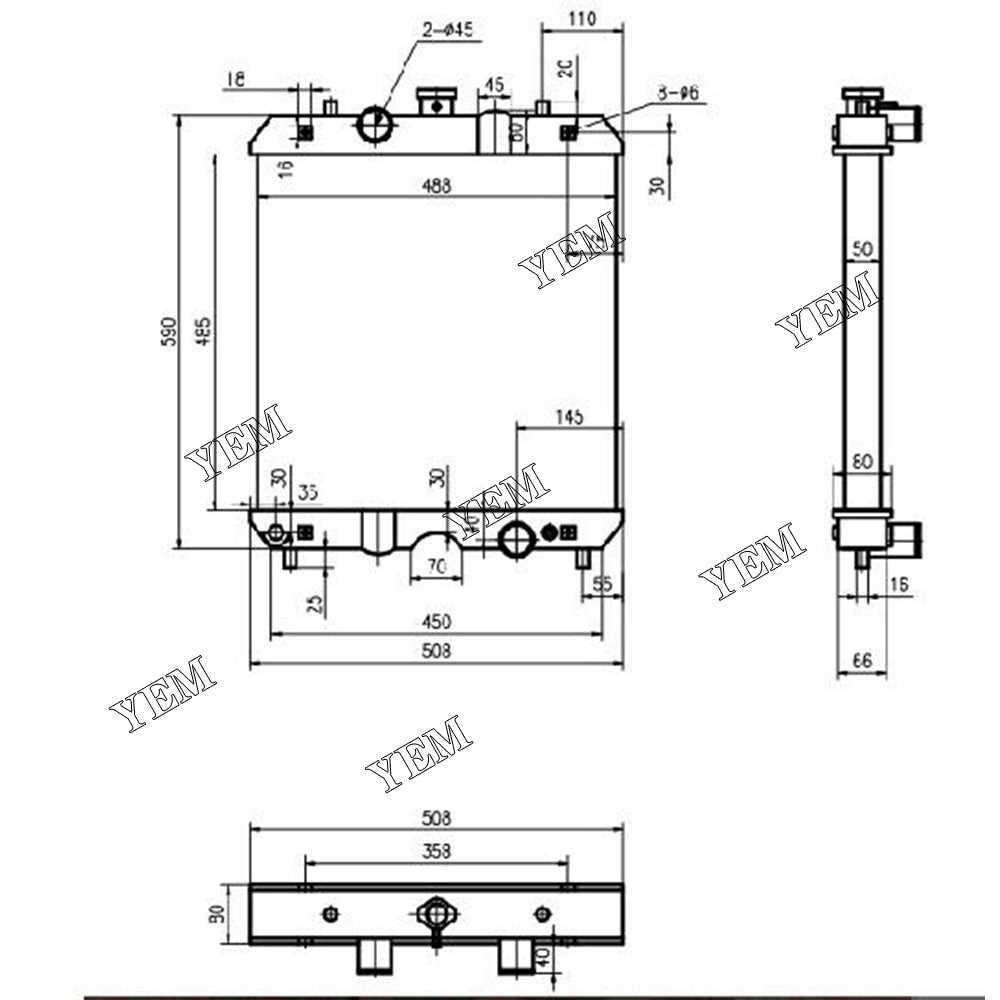

Cooling System Overview for the Kubota M9000

The cooling system plays a crucial role in maintaining the engine’s optimal operating temperature, preventing overheating and ensuring efficient performance. It ensures that the engine runs smoothly, even during extended periods of use, by regulating the heat generated from internal combustion.

- Radiator: The central component responsible for dissipating heat. It transfers the excess warmth from the engine to the outside air, using a series of metal fins to increase surface area for effective cooling.

- Water Pump: Circulates the coolant throughout the system, ensuring that the liquid flows consistently between the engine block and radiator.

- Thermostat: A temperature-sensitive valve that controls the flow of coolant based on the engine’s temperature. It helps the engine warm up quickly and prevents overheating by adjusting coolant flow.

- Hoses and Piping: Flexible tubes that transport coolant between components. These parts are designed to withstand pressure and high temperatures, ensuring the system remains sealed and functional.

- Cooling Fan: Located near the radiator, the fan aids in air circulation, especially when the vehicle is stationary or moving slowly, ensuring consistent a

Detailed Look at the Fuel System

The fuel delivery setup in this machine is designed to ensure optimal performance and reliability. This section delves into the various elements involved in supplying energy, focusing on how each component works in harmony to maintain smooth operation. By understanding this system, you can appreciate the critical role each part plays in keeping the engine running efficiently.

The following table provides a breakdown of key components and their respective functions within the fuel system:

| Component |

Function |

| Fuel Pump |

Transfers liquid from the tank to the injection system, ensuring a consistent flow. |

| Fuel Filter |

Removes contaminants from the liquid to prevent damage to the injection system. |

Injection No

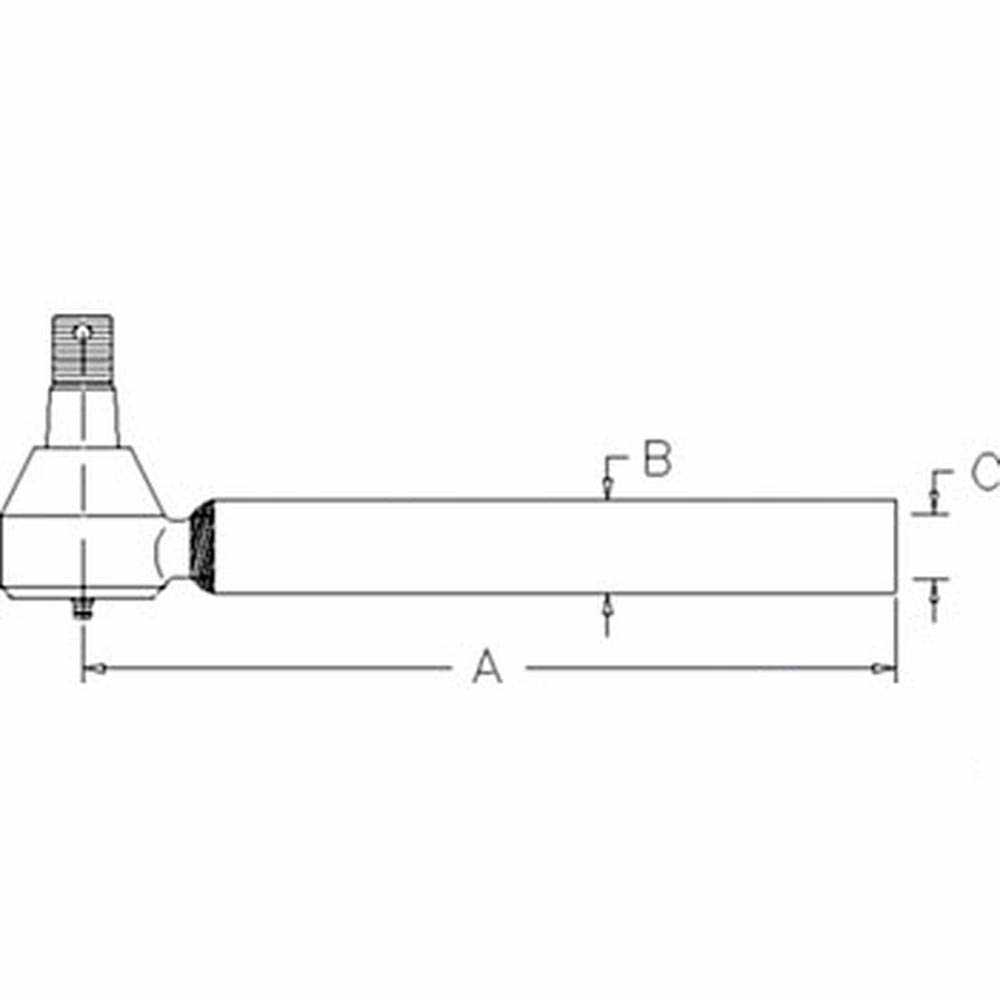

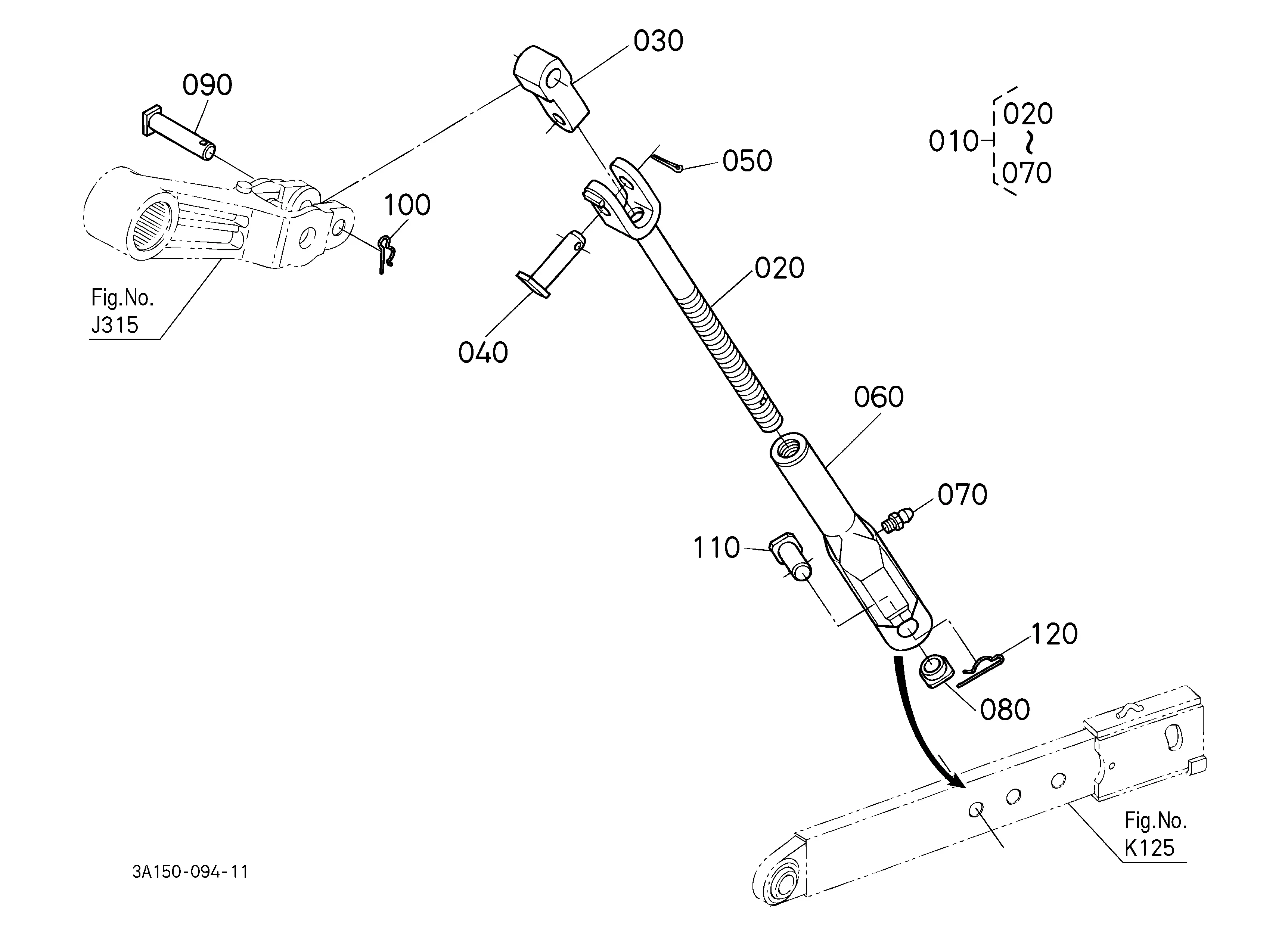

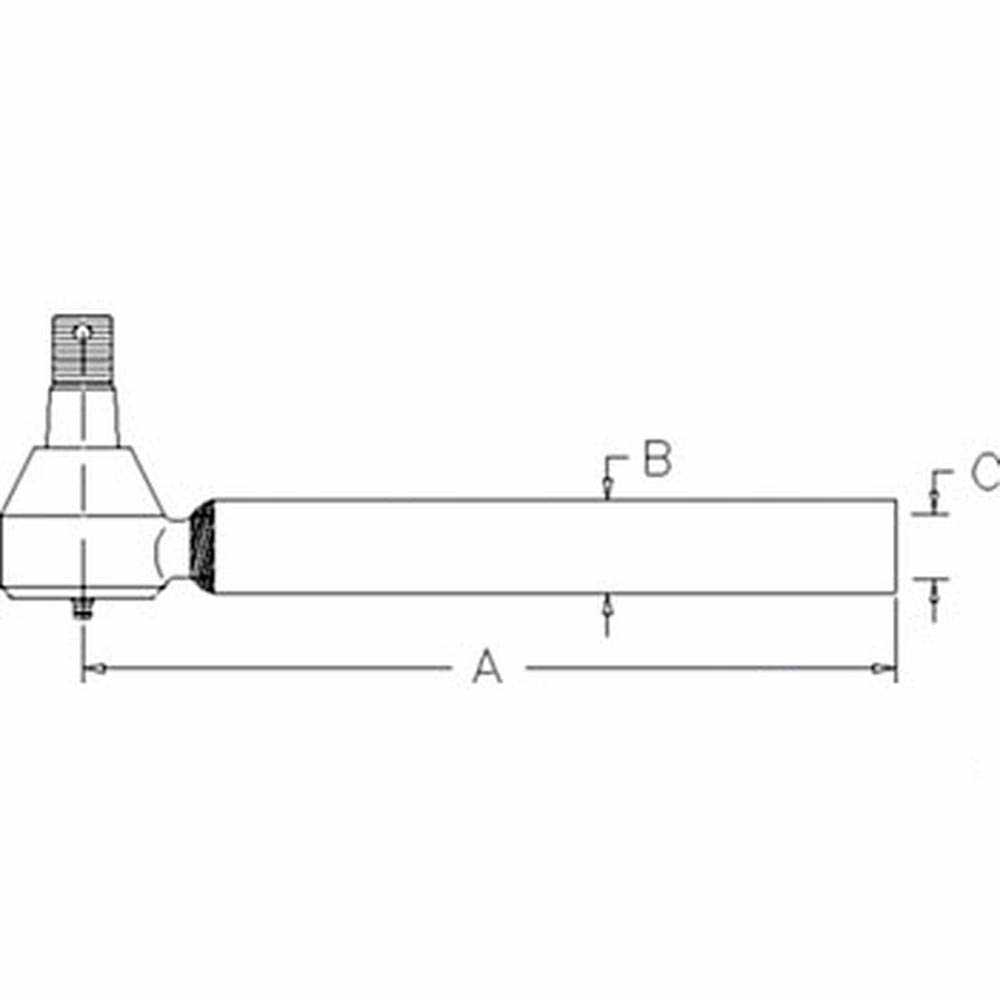

Suspension and Steering Mechanisms Explained

The efficiency and comfort of any heavy-duty vehicle depend heavily on the functionality of its suspension and steering systems. These interconnected mechanisms play a crucial role in maintaining balance, ensuring smooth handling, and absorbing shocks during operation. Understanding how these systems work together can provide valuable insights into maintaining stable performance across diverse terrains.

Key Components of the Suspension System

The suspension system consists of several vital elements that work in unison to cushion the vehicle and protect it from harsh impacts. These components are designed to improve traction, enhance stability, and ensure a smooth ride, regardless of surface conditions.

- Springs: Designed to absorb and dissipate energy fr

Brake System Components in the Kubota M9000

The braking mechanism of a heavy-duty agricultural vehicle is crucial for ensuring safety and control during operation. This section explores the essential elements that make up the braking assembly, focusing on their functions and significance in maintaining optimal performance.

At the heart of the system is the master cylinder, which generates hydraulic pressure to activate the brake components. It is connected to the brake lines that transport this pressure to each wheel assembly. Additionally, the brake calipers play a pivotal role in clamping the brake pads against the rotors, effectively slowing down or stopping the machine.

Another vital component is the brake booster, designed to amplify the force applied to the brake pedal, making it easier for the operator to engage the brakes. The system also includes the brake pads and rotors, which are responsible for friction generation, ensuring reliable stopping power. Regular maintenance of these components is essential to ensure longevity and efficiency in operation.

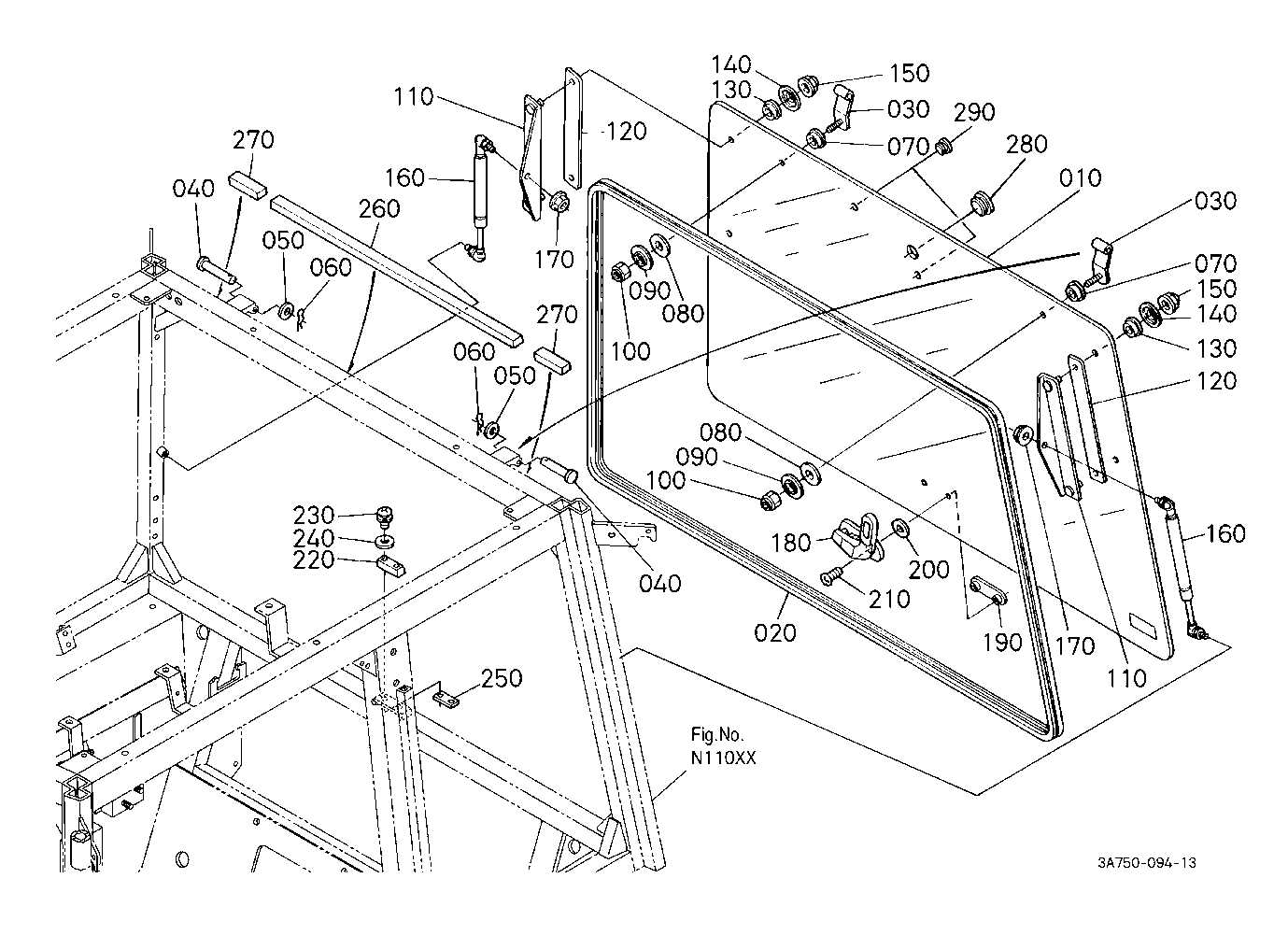

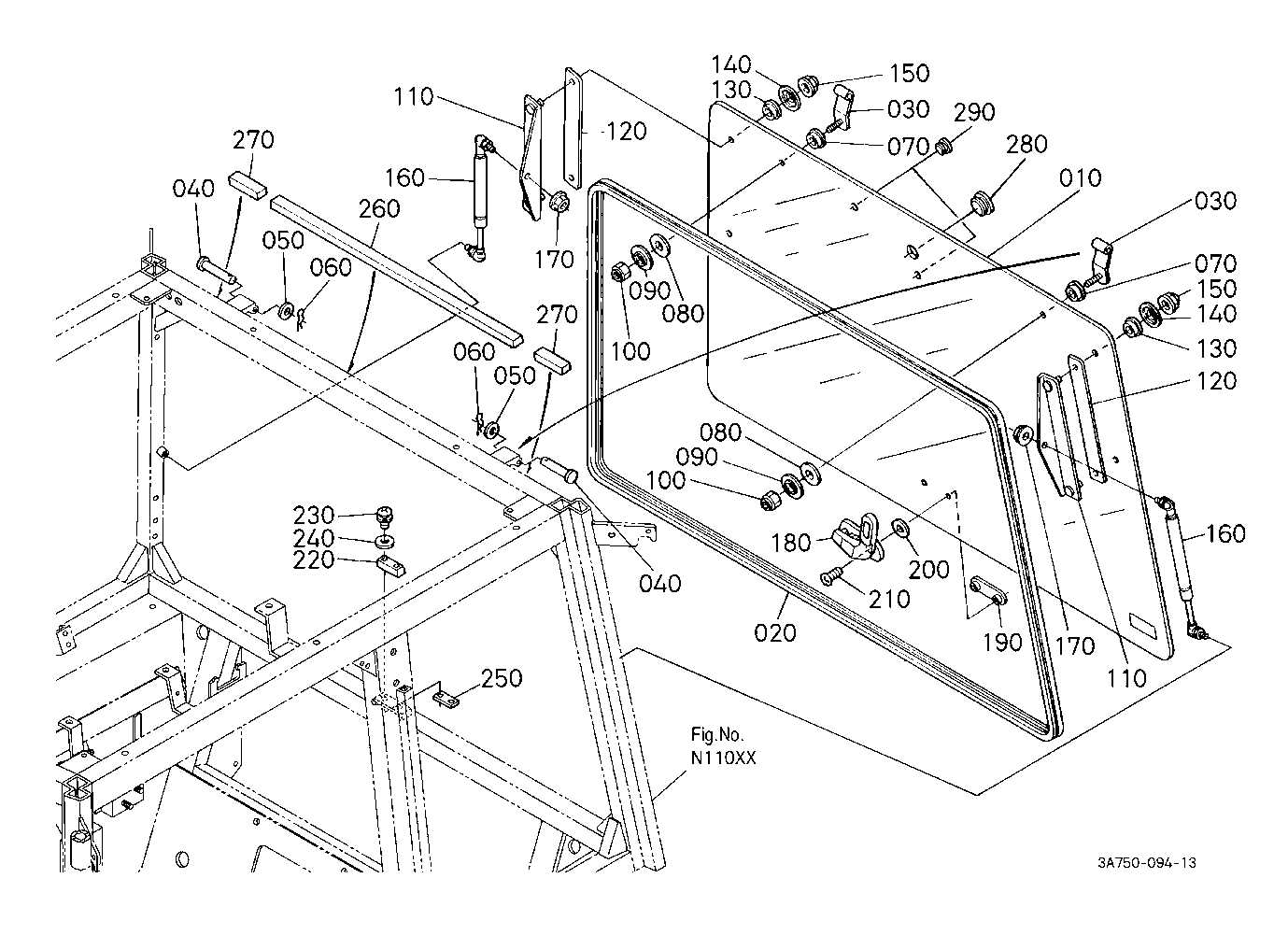

Interior Cabin Parts and Features

The interior of agricultural machinery is designed to enhance comfort and functionality for the operator. This section explores the various components and attributes that contribute to an efficient working environment. Understanding these elements can improve the overall experience while navigating through different tasks.

Seating and Controls

The seating arrangement is crafted for comfort during long hours of operation, often featuring adjustable options to accommodate different user preferences. Controls are intuitively positioned for ease of access, allowing the operator to manage functions effortlessly. Ergonomic design principles are employed to minimize fatigue and enhance productivity.

Instrumentation and Visibility

Instrumentation panels provide vital information at a glance, ensuring the operator can monitor essential metrics effectively. High-quality visibility is achieved through well-placed windows and mirrors, allowing for a clear view of the surrounding area. This setup is crucial for safe maneuvering and operational efficiency, particularly in expansive fields.

Maintenance Essentials: Filters, Belts, and More

Effective upkeep of machinery is crucial for optimal performance and longevity. Key components such as filtration systems and drive belts play vital roles in ensuring that equipment operates smoothly. Regular inspection and timely replacement of these elements can significantly enhance efficiency and reduce the risk of unexpected breakdowns.

Importance of Filters

Filtration systems are essential for maintaining clean fluids and preventing contaminants from entering critical areas. Regular checks and changes of air, oil, and fuel filters ensure that the engine remains free from harmful particles, promoting better combustion and overall performance. Neglecting filter maintenance can lead to decreased efficiency and increased wear.

Significance of Belts

The role of drive belts cannot be overstated, as they are integral to the operation of various systems within the equipment. These components transmit power from the engine to other parts, such as the alternator and hydraulic pump. Routine inspection for signs of wear or damage is essential; replacing frayed or cracked belts promptly can prevent further complications and downtime.

|