In the world of heavy equipment, having a clear grasp of the various elements that constitute your machine is essential for effective maintenance and operation. A comprehensive overview of these components not only aids in troubleshooting but also enhances the longevity and performance of the machinery.

Identifying the intricate relationships between different parts is crucial for ensuring optimal functionality. This knowledge empowers operators and technicians to make informed decisions regarding repairs and replacements, ultimately leading to a smoother workflow and reduced downtime.

Visual representations of these components can serve as valuable tools for both learning and reference. By familiarizing oneself with the layout and interconnections, users can approach maintenance tasks with confidence, knowing exactly where to focus their efforts. Understanding this intricate network is key to unlocking the full potential of your equipment.

Kubota MX5200 Overview

This section provides an insightful look into a robust agricultural machine designed for versatility and efficiency in various farming tasks. Known for its reliability and powerful performance, this equipment is ideal for both small and large-scale operations. Its thoughtful engineering ensures that it meets the diverse needs of users, from routine maintenance to heavy-duty tasks.

With a strong emphasis on user-friendliness, this model features intuitive controls and an ergonomic design, making it accessible for operators of all experience levels. The combination of a durable build and advanced technology ensures longevity and exceptional performance in various conditions.

| Feature | Description |

|---|---|

| Engine Power | High-performance engine delivering excellent torque and efficiency. |

| Transmission | Smooth gear shifts for enhanced control and productivity. |

| Hydraulics | Powerful hydraulic system for effective lifting and attachment operations. |

| Comfort | Spacious operator platform with adjustable seating for reduced fatigue. |

| Versatility | Compatible with a wide range of attachments for diverse applications. |

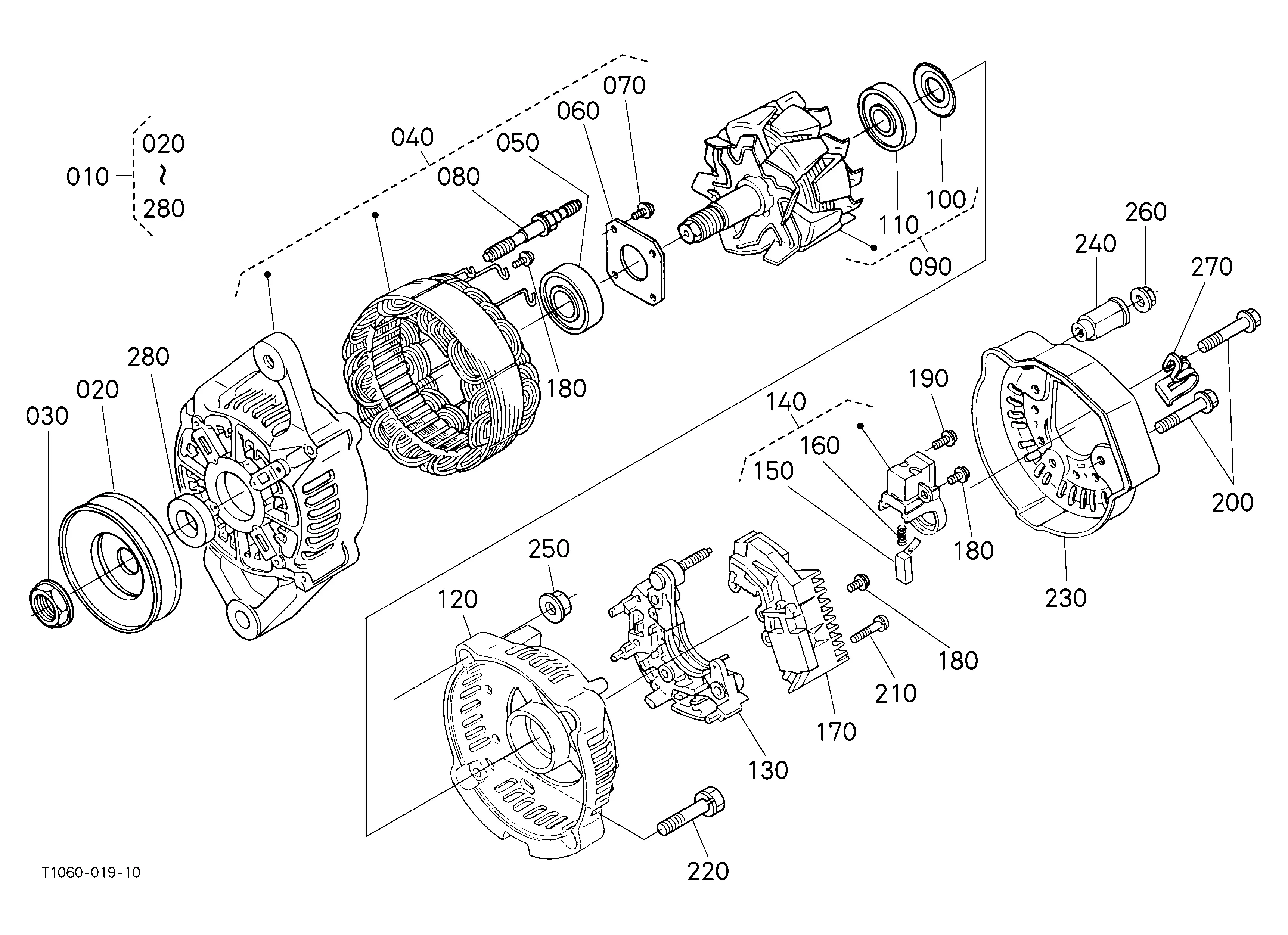

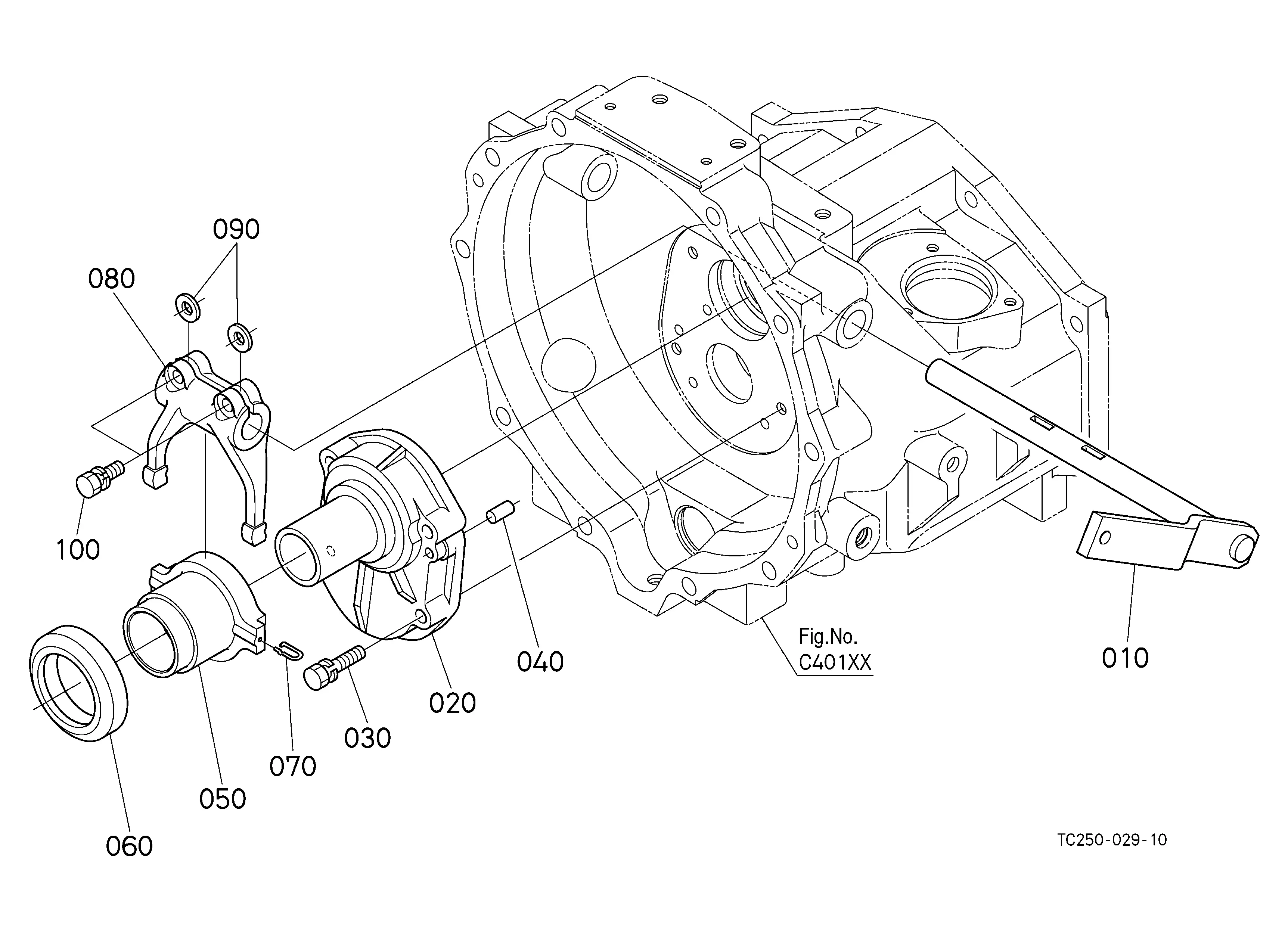

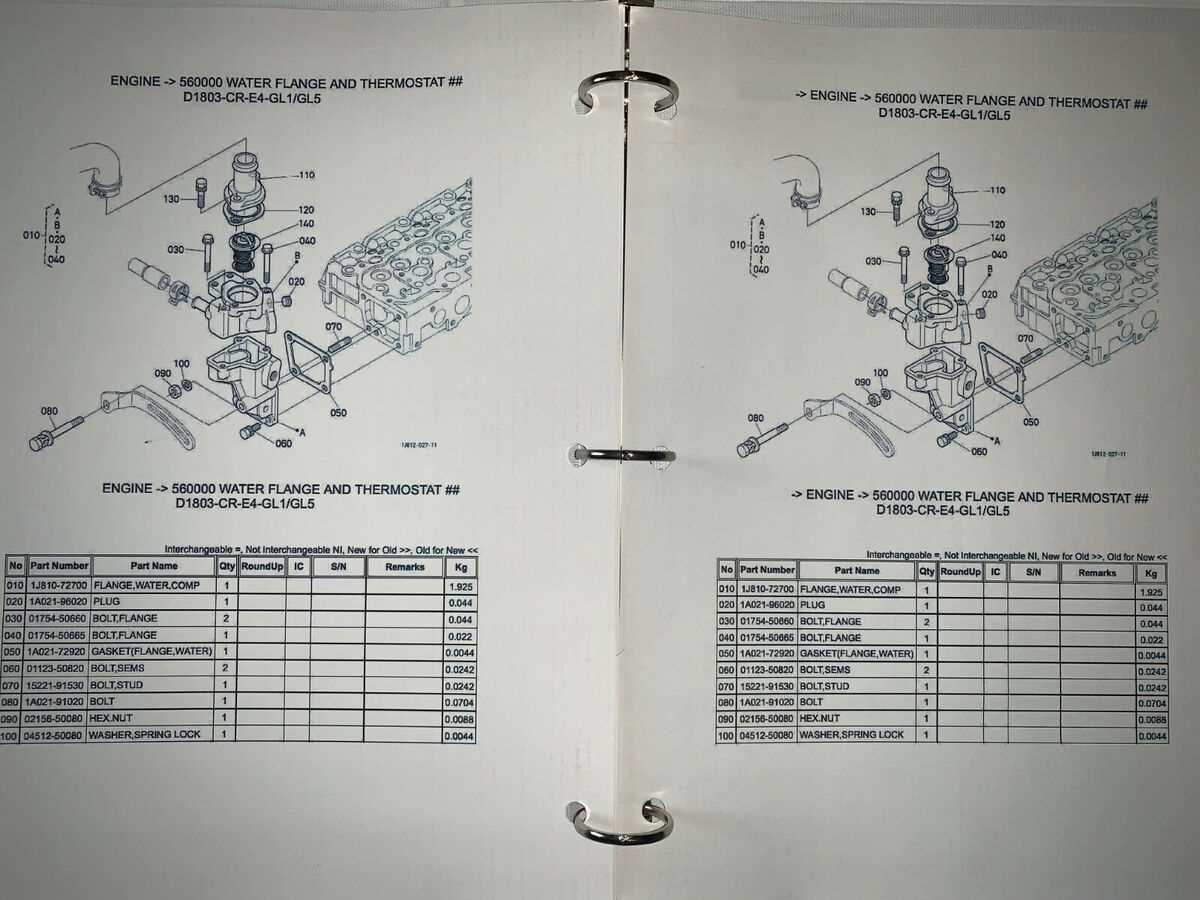

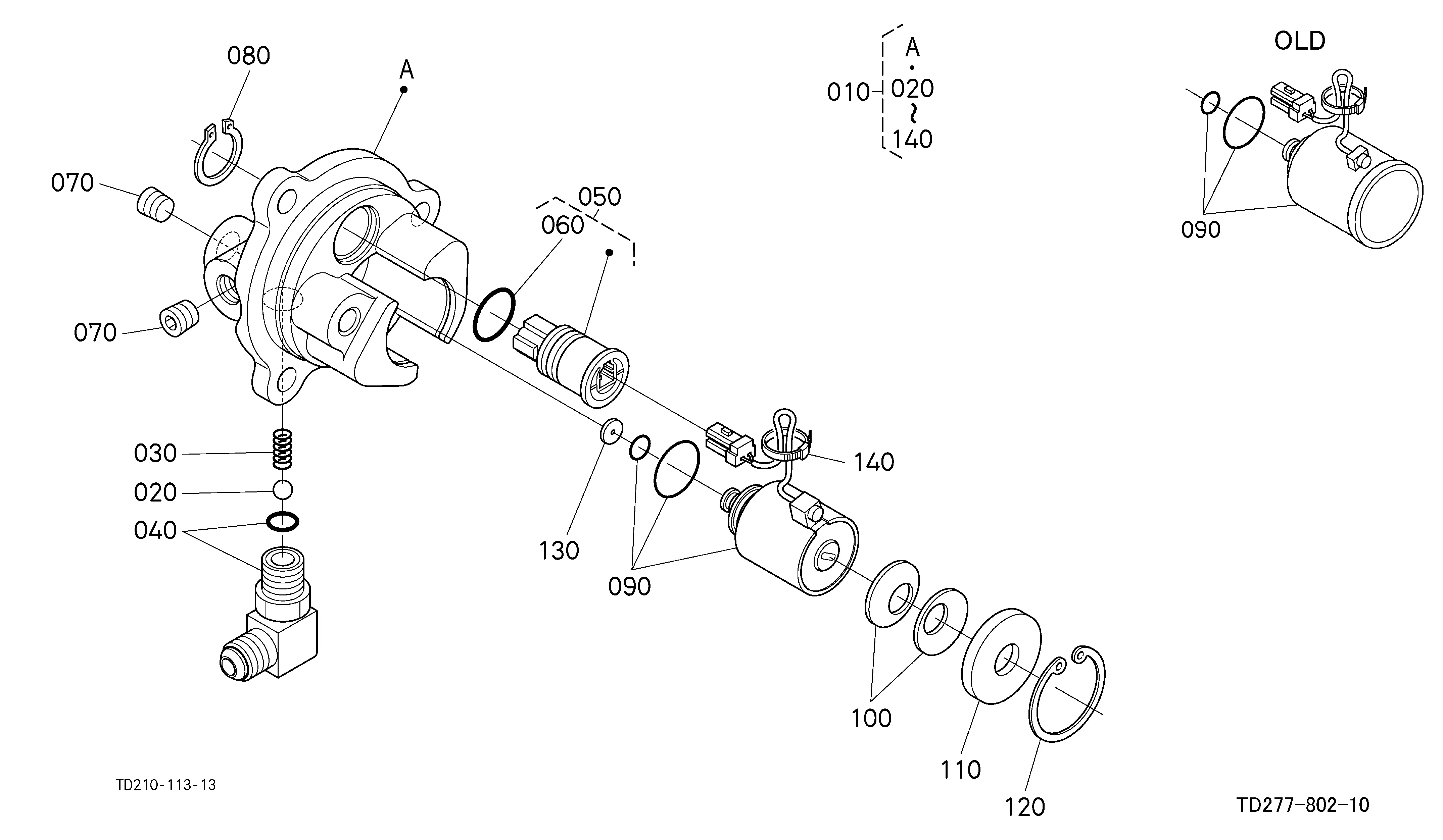

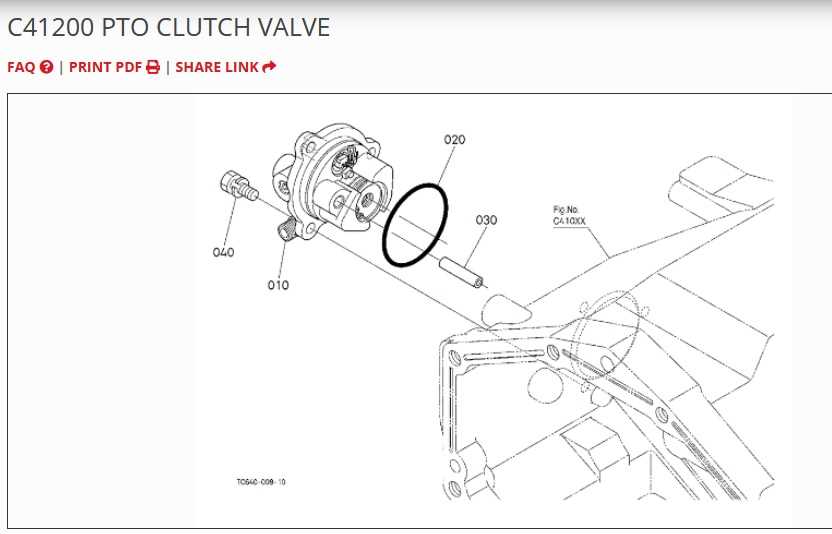

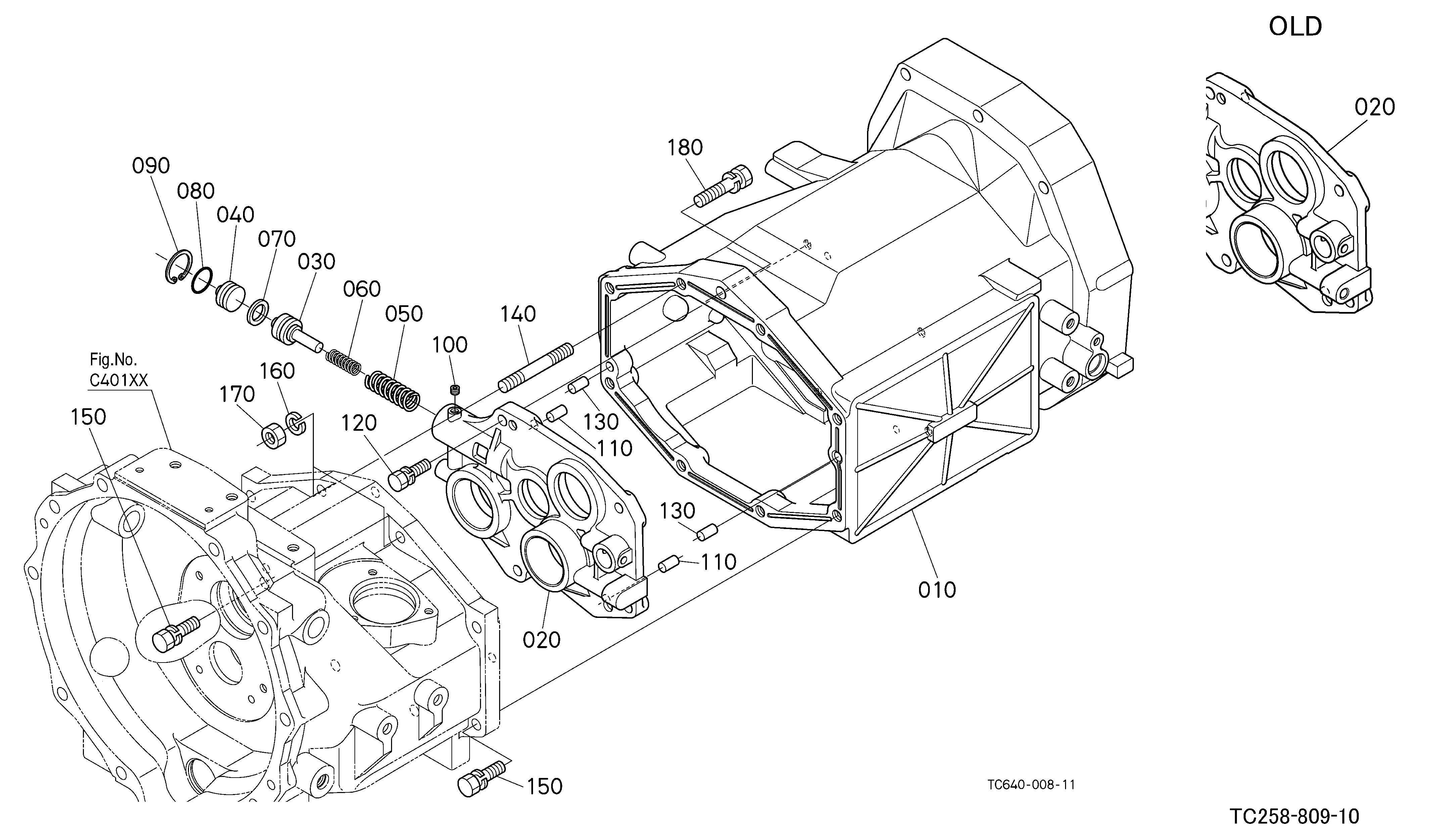

Understanding Parts Diagrams

Grasping the intricacies of assembly schematics is essential for anyone involved in machinery maintenance. These visual aids serve as crucial resources, offering insights into the components that make up a system. By comprehending these illustrations, users can identify individual elements and their relationships within the entire structure.

Breaking down complex machines into manageable parts helps streamline repairs and replacements. Each section typically highlights specific units, allowing for quick reference and facilitating effective troubleshooting. This organized approach ultimately leads to enhanced efficiency and reduced downtime.

Additionally, familiarity with these visuals empowers users to communicate more effectively with suppliers and technicians. Understanding terminology and layouts can lead to more accurate ordering of replacements and a deeper knowledge of the machinery’s functionality.

Key Components of MX5200

This section explores the essential elements that contribute to the functionality and efficiency of this powerful agricultural machine. Understanding these components can enhance performance and facilitate maintenance.

- Engine: The heart of the machine, providing the necessary power for various tasks.

- Transmission: Responsible for transferring power to the wheels, allowing for smooth operation.

- Hydraulic System: Essential for lifting and controlling attachments, enhancing versatility.

- Chassis: The framework that supports the entire structure, ensuring stability and durability.

- Electrical System: Powers the controls and lights, crucial for operation in different conditions.

By delving into these critical components, users can maximize their understanding and utilization of the machinery.

Importance of Genuine Parts

Utilizing authentic components for machinery is crucial for maintaining optimal performance and longevity. High-quality items are specifically engineered to fit perfectly and work seamlessly with the overall system, ensuring that the equipment functions as intended. This commitment to using original pieces enhances reliability and minimizes the risk of malfunctions.

Quality Assurance

One significant advantage of selecting original components is the assurance of quality. These items undergo rigorous testing and adhere to strict manufacturing standards, which are essential for maintaining the integrity of the equipment. By investing in genuine parts, users can trust that they are getting the best materials and craftsmanship available.

Cost-Effectiveness

While counterfeit or generic alternatives may appear attractive due to lower initial costs, they often lead to greater expenses in the long run. Inferior substitutes can result in frequent repairs and replacements, as well as potential damage to other vital parts. In contrast, genuine components may come with warranties, providing additional peace of mind and potential savings over time.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. This guide will help you navigate the intricacies of such illustrations, ensuring you grasp the relationships and functions of each element.

Start by familiarizing yourself with the overall layout, identifying the key sections and categories. Look for labels that provide names or numbers, as these often correlate with specific pieces. Color coding may also indicate different systems or functions, aiding in quicker identification.

Next, pay attention to the reference keys or legends that accompany the visual. These provide essential information about the symbols and notations used, helping you understand what each mark signifies. Make notes of any unfamiliar terms or symbols for further research.

Finally, cross-reference the illustration with an accompanying list of components if available. This will help you confirm your understanding and assist in locating parts during repairs or replacements. With practice, interpreting these visuals will become second nature, enhancing your confidence in tackling maintenance tasks.

Common Issues with MX5200 Parts

Understanding the frequent challenges faced with components of heavy machinery can help ensure optimal performance and longevity. Identifying these issues early can prevent costly repairs and downtime.

Frequent Problems

- Wear and tear on hydraulic seals leading to leaks.

- Electrical failures due to corroded connections.

- Overheating of the engine caused by clogged filters.

Maintenance Tips

- Regularly inspect hydraulic systems for leaks.

- Clean electrical connections to prevent corrosion.

- Change filters as recommended to avoid engine strain.

Where to Find Replacement Parts

Finding components for machinery can be a straightforward process if you know where to look. There are several reliable sources where you can acquire the necessary items to keep your equipment running smoothly. Whether you are seeking genuine or aftermarket options, understanding the best avenues for sourcing can save you time and money.

| Source | Description | Advantages |

|---|---|---|

| Authorized Dealers | Official distributors providing original components. | Guaranteed compatibility and quality assurance. |

| Online Retailers | Websites specializing in machinery supplies. | Wide selection and often competitive pricing. |

| Local Repair Shops | Service providers that may stock essential items. | Convenience and personalized service. |

| Salvage Yards | Places where used components can be purchased. | Cost-effective options for older models. |

| Online Marketplaces | Platforms where individuals sell new and used items. | Potential for finding rare or hard-to-find components. |

By exploring these options, you can find the right solutions to meet your machinery needs, ensuring optimal performance and longevity.

Maintenance Tips for MX5200

Proper upkeep is essential for maximizing the performance and longevity of your machinery. Regular maintenance not only ensures smooth operation but also prevents costly repairs down the line. Here are some key practices to keep in mind.

Regular Inspections

Conduct thorough inspections of all components to identify wear and tear early. Pay close attention to fluids, belts, and filters, as these are critical to optimal functionality. Checking these items regularly can prevent minor issues from escalating into major problems.

Lubrication and Cleaning

Keep moving parts well-lubricated to reduce friction and wear. Additionally, cleaning the machinery after use helps remove dirt and debris that can cause damage. A clean machine not only performs better but also has a longer lifespan.

Upgrading Your Kubota Machine

Enhancing your agricultural equipment can significantly boost its performance and longevity. By implementing strategic upgrades, you can improve efficiency, safety, and productivity on your farm. Whether it’s enhancing power, comfort, or functionality, a thoughtful approach to modifications can yield remarkable results.

Evaluating Your Needs

Before embarking on any enhancements, it’s crucial to assess what specific improvements would benefit your operations the most. Consider factors such as workload, terrain, and the types of tasks you frequently perform. Understanding these elements will help you make informed decisions about which upgrades to prioritize.

Choosing Quality Components

Investing in high-quality components is essential for achieving the ultimate performance. Look for trusted brands and reliable suppliers that offer durable parts designed to withstand rigorous conditions. By opting for superior materials, you can ensure that your modifications will enhance the overall functionality of your machinery.

Cost Considerations for Repairs

When addressing maintenance and restoration of machinery, evaluating expenses is crucial. Understanding the financial implications of repairs can help owners make informed decisions that align with their budget and operational needs.

Labor Costs: One of the primary factors influencing repair expenses is labor. Skilled technicians may charge varying rates depending on their experience and the complexity of the task.

Parts Pricing: The cost of replacement components can vary significantly based on brand, availability, and whether they are OEM or aftermarket. It’s essential to research these options to ensure you’re getting the best value.

Frequency of Repairs: Consider how often certain issues arise. Frequent repairs on specific systems might indicate a need for more extensive troubleshooting or replacement, which could save money in the long run.

Potential Downtime: Factor in the cost of lost productivity while equipment is out of service. Sometimes, spending more on prompt repairs can prevent larger losses associated with downtime.

Ultimately, a thorough analysis of these elements can aid in making strategic repair decisions, ensuring both efficiency and cost-effectiveness.

Resources for Kubota Owners

For individuals who own machinery from this renowned manufacturer, having access to reliable resources is essential for optimal maintenance and operation. These tools and references can enhance the ownership experience, ensuring that every task is performed efficiently and effectively.

Here are some valuable resources to consider:

- Official Manuals: Always refer to the user and service manuals specific to your model. These documents provide detailed information on operation, maintenance, and troubleshooting.

- Online Forums: Engaging with fellow enthusiasts in community forums can offer insights, tips, and shared experiences that are invaluable for problem-solving.

- Parts Suppliers: Reliable suppliers offer a wide range of components necessary for repairs and upgrades. Look for trusted distributors with a strong reputation.

- Video Tutorials: Platforms like YouTube host countless instructional videos that cover a variety of maintenance tasks, making complex procedures easier to follow.

- Local Dealerships: Establishing a relationship with local dealerships can provide access to expert advice and genuine parts that ensure compatibility and reliability.

By utilizing these resources, owners can enhance their knowledge, keep their equipment in peak condition, and extend the lifespan of their machinery.