Understanding the various elements that comprise an engine is crucial for effective maintenance and repairs. A thorough exploration of these components can enhance both functionality and longevity. By familiarizing yourself with the intricate relationships and configurations of each part, you can ensure optimal performance and address any issues that may arise.

This section will delve into the essential aspects of engine assembly, highlighting the significance of each individual piece. By analyzing the arrangements and functions, you will gain insights into how these components interact, contributing to the overall efficiency of the machinery.

Moreover, having a detailed visual reference can serve as a valuable tool for both novice and experienced technicians. It can simplify the process of identifying specific parts, thereby streamlining repairs and maintenance tasks. Such resources empower users to take a proactive approach, ensuring that their engines operate smoothly and effectively.

This section provides an introduction to the engine’s essential components, focusing on their functions and interrelationships. Understanding the layout and role of these elements is crucial for efficient maintenance and troubleshooting. Proper knowledge can enhance performance and extend the lifespan of the machinery.

| Component Name | Description |

|---|---|

| Cylinder Head | Responsible for enclosing the combustion chamber and housing the intake and exhaust valves. |

| Crankshaft | Converts the linear motion of the pistons into rotational motion to drive the vehicle. |

| Fuel Injector | Delivers fuel directly into the combustion chamber for efficient ignition. |

| Cooling System | Maintains optimal operating temperature by circulating coolant through the engine. |

| Oil Pan | Holds the lubricating oil, ensuring smooth operation of moving parts. |

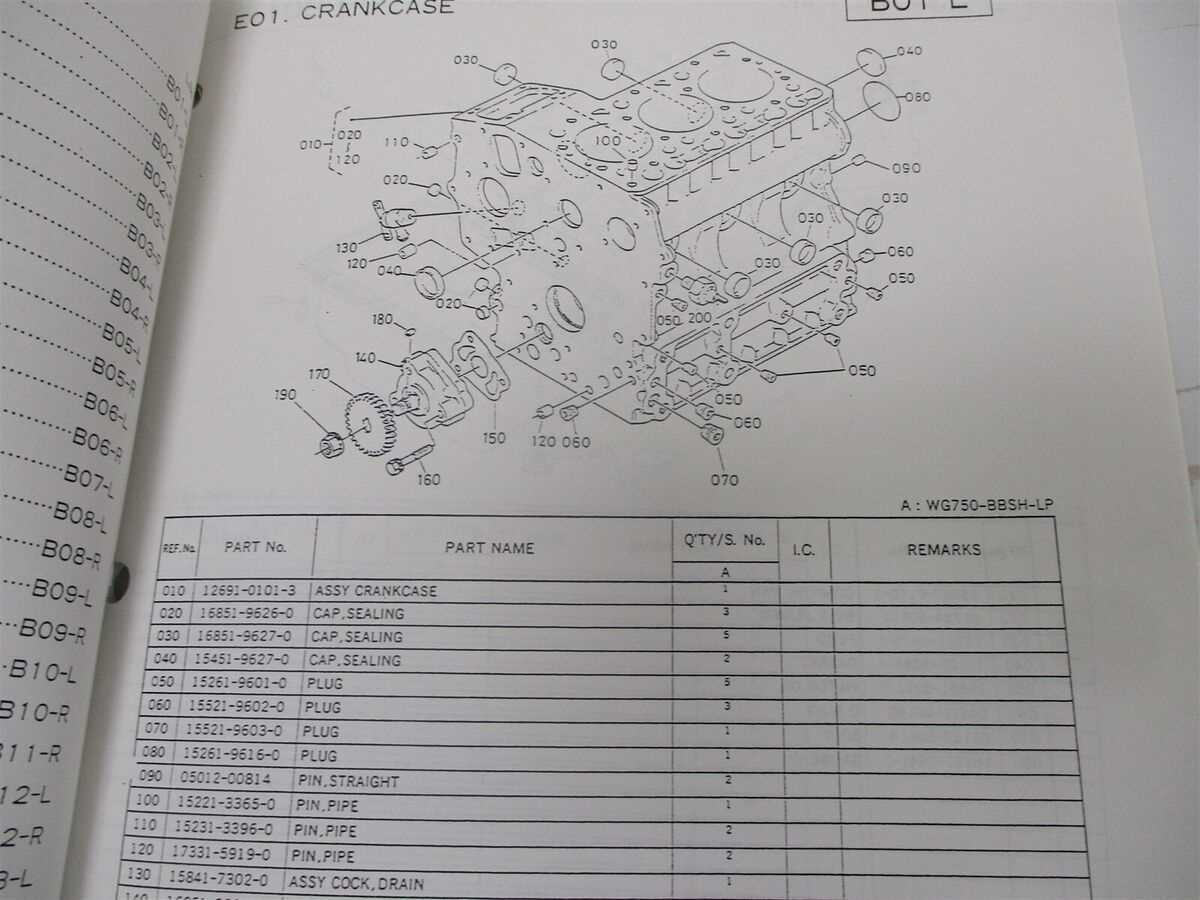

Key Components of the WG750

The internal structure of any machinery plays a crucial role in its overall functionality and performance. Understanding the essential elements that contribute to the operation of a specific engine can enhance maintenance and repair efforts, ensuring optimal efficiency and longevity.

Essential Elements

Among the vital parts are the cylinder block, which houses the pistons and provides the foundation for the engine’s assembly. Additionally, the crankshaft transforms linear motion into rotational energy, driving various systems within the unit. The valve mechanism regulates airflow and fuel intake, crucial for efficient combustion.

Supporting Components

Other significant components include the fuel injection system, which delivers the necessary fuel in precise quantities for combustion, and the cooling system, essential for maintaining optimal operating temperatures. Regular inspection and understanding of these key parts will help in diagnosing issues and performing effective maintenance.

Importance of Parts Diagrams

Understanding the layout and components of machinery is essential for effective maintenance and repair. Visual representations of mechanical assemblies provide valuable insights into the relationships between various elements, ensuring that individuals can accurately identify and address issues. These visual aids serve as crucial references for technicians and operators alike, facilitating smoother troubleshooting processes.

Enhanced Understanding

Having a clear visual guide allows users to comprehend the structure and functionality of equipment more effectively. It aids in recognizing how different components interact, making it easier to identify potential problems and solutions. This clarity ultimately leads to improved efficiency during repairs and maintenance.

Streamlined Repair Process

When dealing with complex machinery, a well-illustrated reference can significantly reduce the time spent diagnosing issues. Technicians can quickly locate specific elements, ensuring that replacements and adjustments are made promptly. This streamlined approach not only minimizes downtime but also enhances overall productivity.

Commonly Replaced Parts List

In the realm of engine maintenance, certain components are frequently exchanged due to wear and tear. Understanding which items are often replaced can help in keeping machinery running smoothly and efficiently. Below is a curated list of commonly swapped elements that operators should be aware of for optimal performance.

Essential Components

- Fuel filters

- Oil filters

- Air filters

- Gaskets

- Belt assemblies

Performance Enhancers

- Spark plugs

- Seals

- Battery connections

- Hoses and clamps

- Thermostats

Regularly checking and replacing these key items can lead to improved reliability and longevity of the machinery. Make sure to consult the maintenance schedule to identify the right time for replacements.

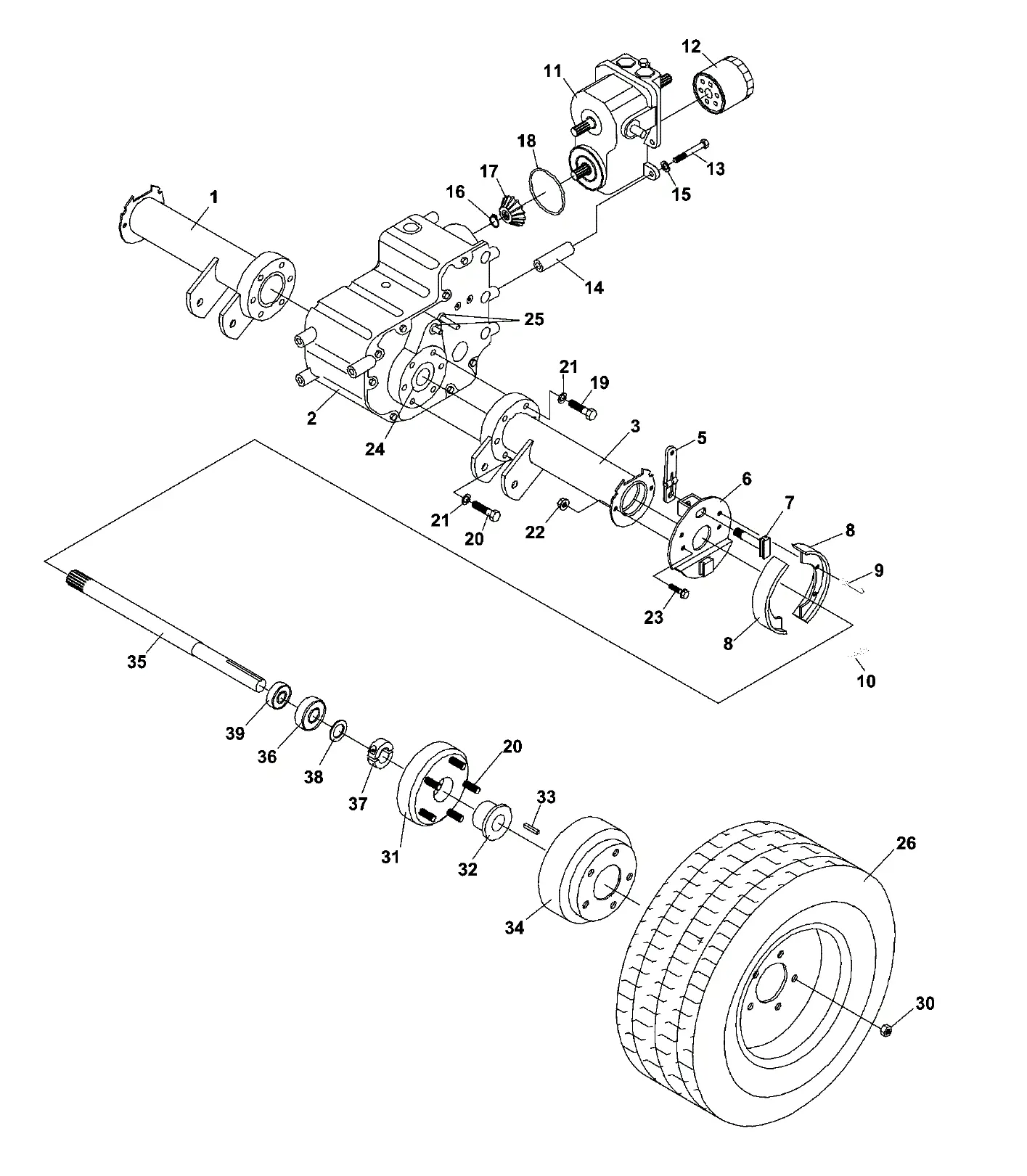

How to Read Parts Diagrams

Understanding component illustrations is crucial for anyone involved in machinery maintenance and repair. These visual guides simplify the identification of individual elements and their connections within a larger assembly. By familiarizing oneself with the layout and symbols used, users can efficiently locate the necessary items for their tasks.

Key Elements to Identify

When examining a component illustration, there are several critical features to pay attention to:

| Element | Description |

|---|---|

| Reference Numbers | Each part is often labeled with a unique reference number that corresponds to a list of items, making it easier to order or identify specific pieces. |

| Connection Lines | These lines indicate how various components are connected or interact, providing insight into the assembly’s overall functionality. |

| Groupings | Parts may be grouped together based on their function or location, helping users understand how they work as a unit. |

Tips for Effective Usage

To maximize the utility of component illustrations, consider the following tips:

- Cross-reference the reference numbers with the parts list to ensure accurate identification.

- Pay attention to the scale of the illustration, which can affect the size perception of each element.

- Use the visual guide in conjunction with a manual to gain a comprehensive understanding of the assembly process.

Troubleshooting Using Diagrams

Visual aids play a crucial role in diagnosing issues within machinery. These illustrations help users understand the complex arrangements of components, allowing for effective identification of problems. Utilizing these visuals can streamline the troubleshooting process, making it easier to pinpoint malfunctioning parts and rectify them efficiently.

Understanding Common Issues

By examining visuals, one can quickly recognize typical faults. For instance, an illustration can highlight areas prone to wear or malfunction, guiding users toward potential trouble spots. This understanding enables proactive maintenance, reducing the risk of severe breakdowns.

Guided Repair Procedures

Visual references provide step-by-step guidance for repairs. Each component’s placement and function can be clearly depicted, simplifying the disassembly and reassembly processes. Following these guided procedures ensures that repairs are conducted correctly, minimizing the likelihood of errors that could lead to further complications.

Where to Find Replacement Parts

Locating high-quality components for machinery is essential for maintaining optimal performance and longevity. Various resources are available for individuals seeking replacements, ranging from online platforms to local suppliers. Exploring these avenues can lead to efficient solutions for equipment repairs and upgrades.

Online Marketplaces

Numerous websites specialize in providing a wide array of components for various machines. These platforms often feature user-friendly search options, allowing buyers to quickly find the required items. Additionally, customer reviews and ratings can guide decisions, ensuring reliable purchases.

Local Distributors and Dealerships

Visiting nearby distributors or authorized dealerships is another effective way to source necessary components. These establishments typically offer expert advice and may have specific items in stock. Building relationships with local suppliers can also lead to personalized service and potential discounts on future orders.

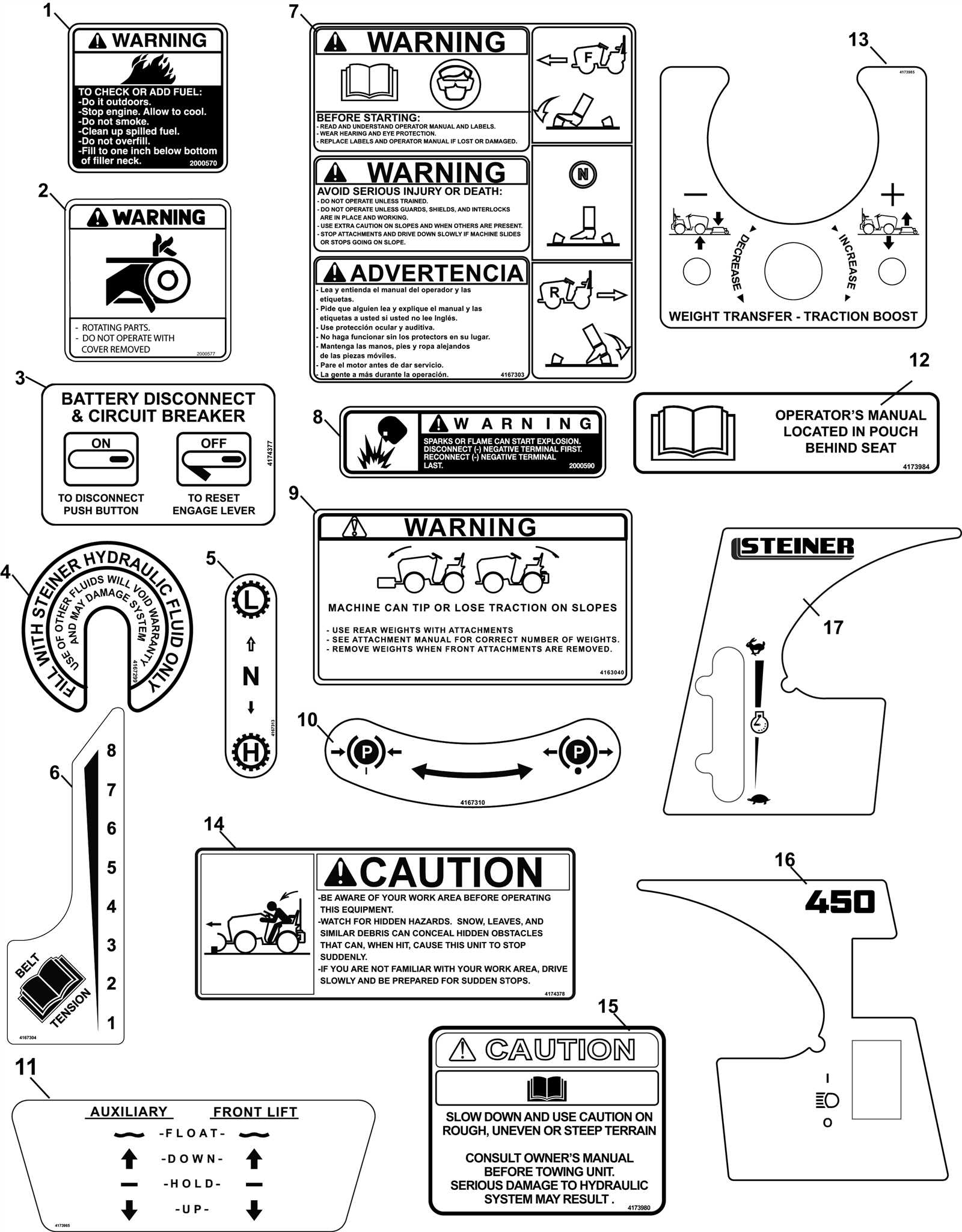

Maintenance Tips for WG750

Regular upkeep is crucial for ensuring optimal performance and longevity of any engine. By adhering to a consistent maintenance schedule, you can prevent potential issues and enhance efficiency. Below are some essential practices to keep your unit running smoothly.

- Routine Inspection: Conduct frequent checks for leaks, cracks, or wear. Addressing small issues early can prevent more significant problems down the line.

- Fluid Levels: Regularly monitor and top off fluids, including oil and coolant. Proper fluid levels are vital for effective operation.

- Air Filter Maintenance: Clean or replace the air filter as needed to ensure adequate airflow and prevent contaminants from entering the engine.

- Fuel System Care: Use high-quality fuel and consider adding a fuel stabilizer to prevent degradation when the unit is not in use for extended periods.

- Regular Cleaning: Keep the exterior and surrounding areas clean to avoid dirt and debris buildup, which can lead to overheating and other issues.

Following these guidelines will help maintain peak performance and extend the lifespan of your engine. Remember, investing time in maintenance now can save significant costs in repairs later.

Understanding Engine Specifications

Engine specifications play a crucial role in determining the performance, efficiency, and compatibility of an engine with various applications. By examining these details, one can assess how well an engine meets the demands of specific tasks. This section aims to explore the essential characteristics that define an engine’s capabilities.

Several key parameters contribute to a comprehensive understanding of an engine’s performance:

- Displacement: Refers to the total volume of all the cylinders in the engine. It impacts power output and fuel efficiency.

- Horsepower: A measure of the engine’s ability to perform work over time, indicating how much power is produced.

- Torque: The rotational force generated by the engine, crucial for tasks requiring substantial pulling or lifting capacity.

- Compression Ratio: The ratio of the maximum to minimum cylinder volume, affecting efficiency and power.

- Fuel Type: Indicates the kind of fuel the engine is designed to use, influencing its operation and efficiency.

Understanding these specifications helps users make informed decisions regarding engine selection, maintenance, and upgrades, ensuring optimal performance for various applications. Knowledge of an engine’s capabilities fosters a better appreciation of its design and intended use.

Resources for Parts Information

Accessing accurate information regarding components and their specifications is crucial for effective maintenance and repairs. A variety of resources are available to assist in identifying and sourcing the necessary elements for machinery. Utilizing these tools can streamline the process and ensure that replacements or upgrades meet the required standards.

Manufacturer Websites

Visiting the official websites of manufacturers provides valuable resources, including catalogs, specifications, and contact information for authorized dealers. These platforms often feature online tools that allow users to search for specific components by model or category, making it easier to find what is needed.

Online Forums and Communities

Engaging with online forums and communities can be incredibly beneficial. These platforms allow enthusiasts and professionals to share insights, experiences, and recommendations regarding various components. Members often post valuable information, including troubleshooting tips and recommended sources for purchasing specific items.

FAQs About WG750 Parts

This section addresses common inquiries related to components and their functionalities for a specific engine model. Understanding these elements is crucial for maintaining optimal performance and ensuring longevity.

What are the essential components for engine maintenance?

Regular upkeep requires a few vital elements, such as filters, gaskets, and spark plugs. Ensuring these items are in good condition can significantly enhance efficiency and prevent potential issues.

How do I identify the correct replacement components?

To find suitable replacements, consult the manufacturer’s specifications or trusted suppliers. Using the right specifications ensures compatibility and optimal operation, leading to a more reliable engine performance.