In the realm of outdoor equipment, having a comprehensive overview of the various elements that contribute to functionality is crucial for maintenance and repair. A well-structured representation of these components enables users to identify and address potential issues effectively. This knowledge not only enhances operational efficiency but also extends the lifespan of the machinery.

When it comes to intricate machinery, familiarity with individual segments can significantly reduce downtime. An organized visual reference facilitates quick identification and replacement of worn-out or faulty items, ensuring that the equipment remains in peak condition. Understanding how each part interconnects allows operators to perform necessary tasks with confidence and precision.

By delving into the specifics of each element, users can gain insights into the assembly and disassembly processes, which are essential for effective troubleshooting. This knowledge empowers owners to take proactive measures, ultimately leading to smoother operations and greater satisfaction with their equipment.

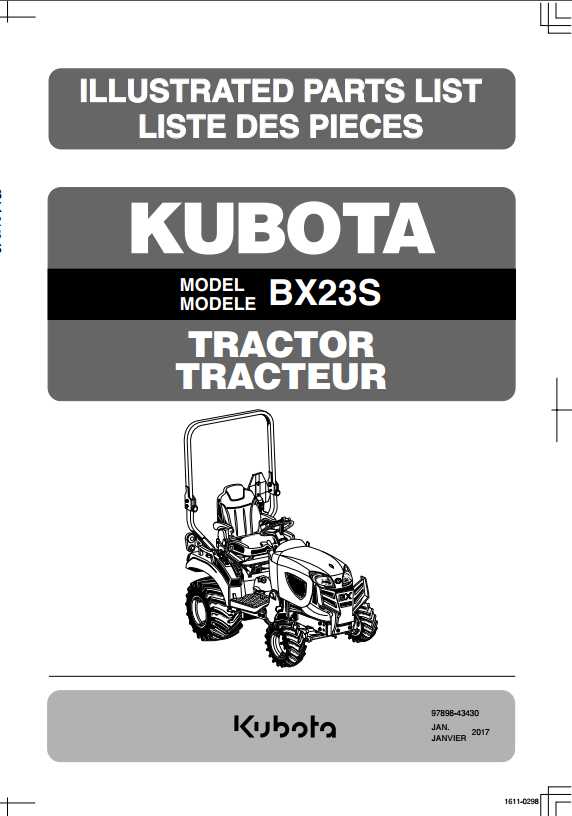

Kubota Z125S Overview

This section provides a comprehensive look at a popular model in the landscaping equipment sector, highlighting its features, benefits, and overall functionality. Designed for efficiency and ease of use, this machine is ideal for both residential and commercial applications.

Engine Performance: Equipped with a robust engine, this unit delivers reliable power for various mowing tasks. Its efficient design ensures optimal fuel consumption while maintaining high performance.

Maneuverability: The compact size of this equipment allows for exceptional agility, making it easy to navigate through tight spaces and complex terrains. Operators appreciate its responsiveness and control during operation.

Durability: Built with high-quality materials, this model is designed to withstand the rigors of frequent use. Its sturdy construction contributes to a longer lifespan and lower maintenance needs.

User Experience: With an ergonomic design, this machine offers comfort during prolonged use. The intuitive controls make it accessible for users of all skill levels, enhancing the overall mowing experience.

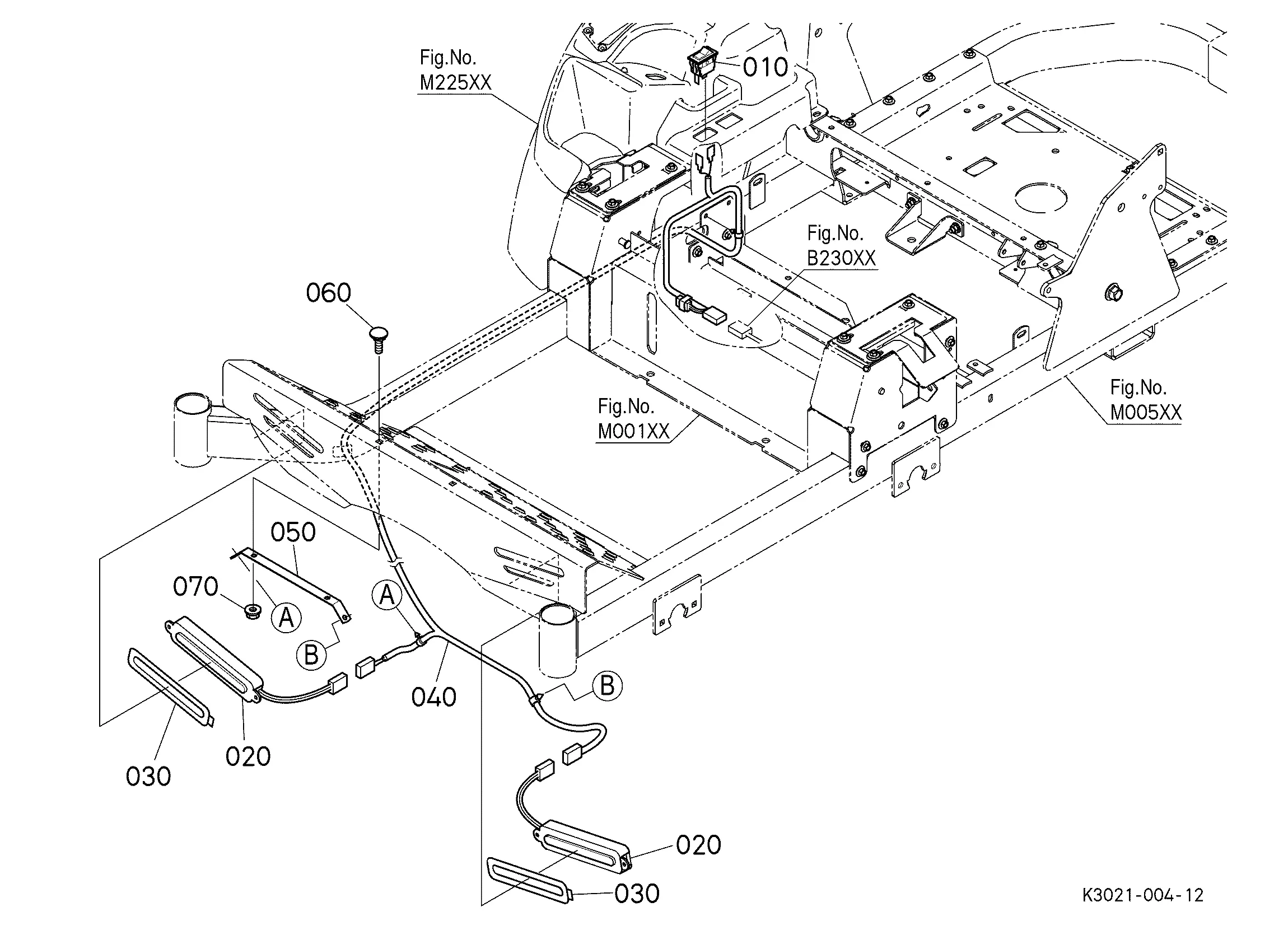

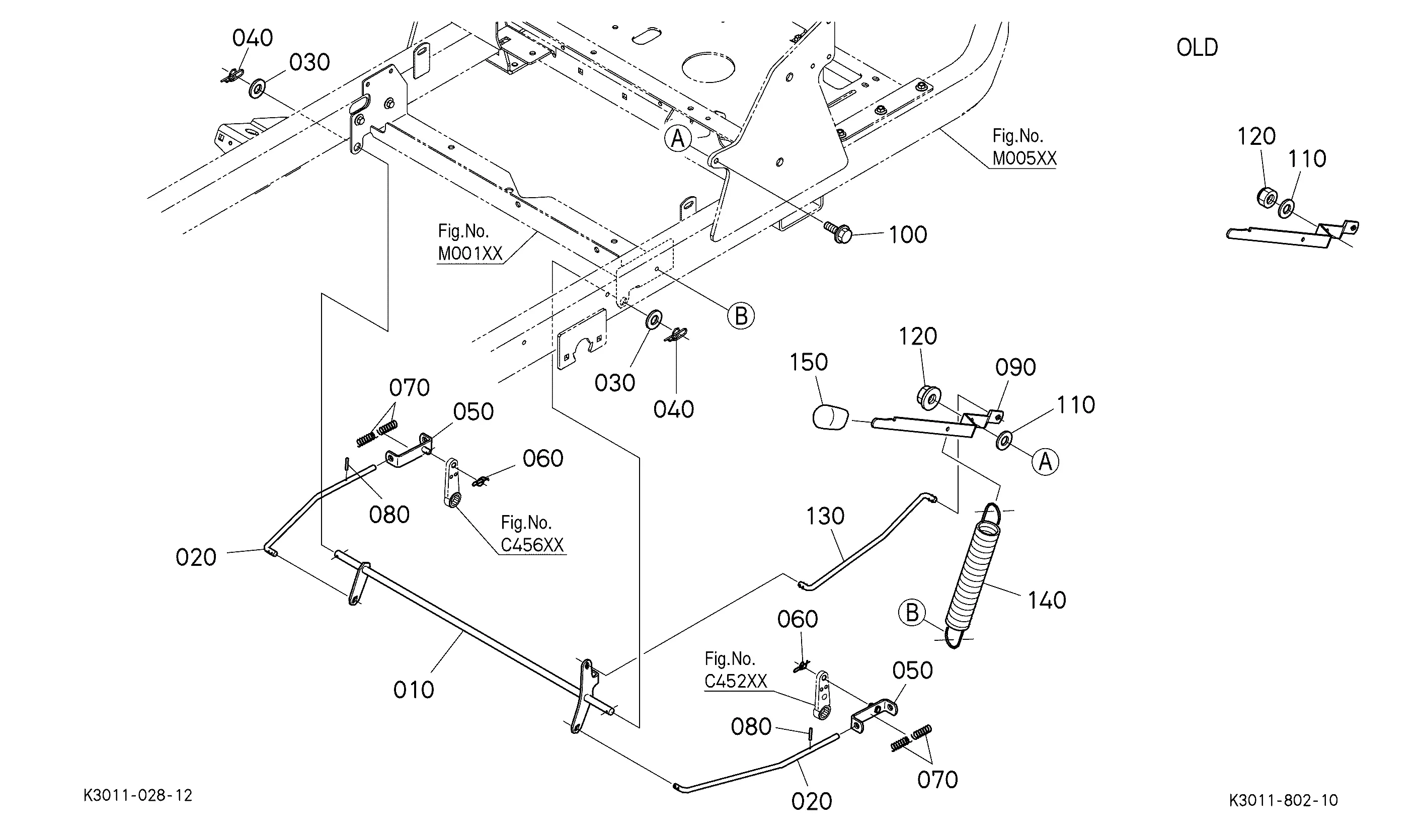

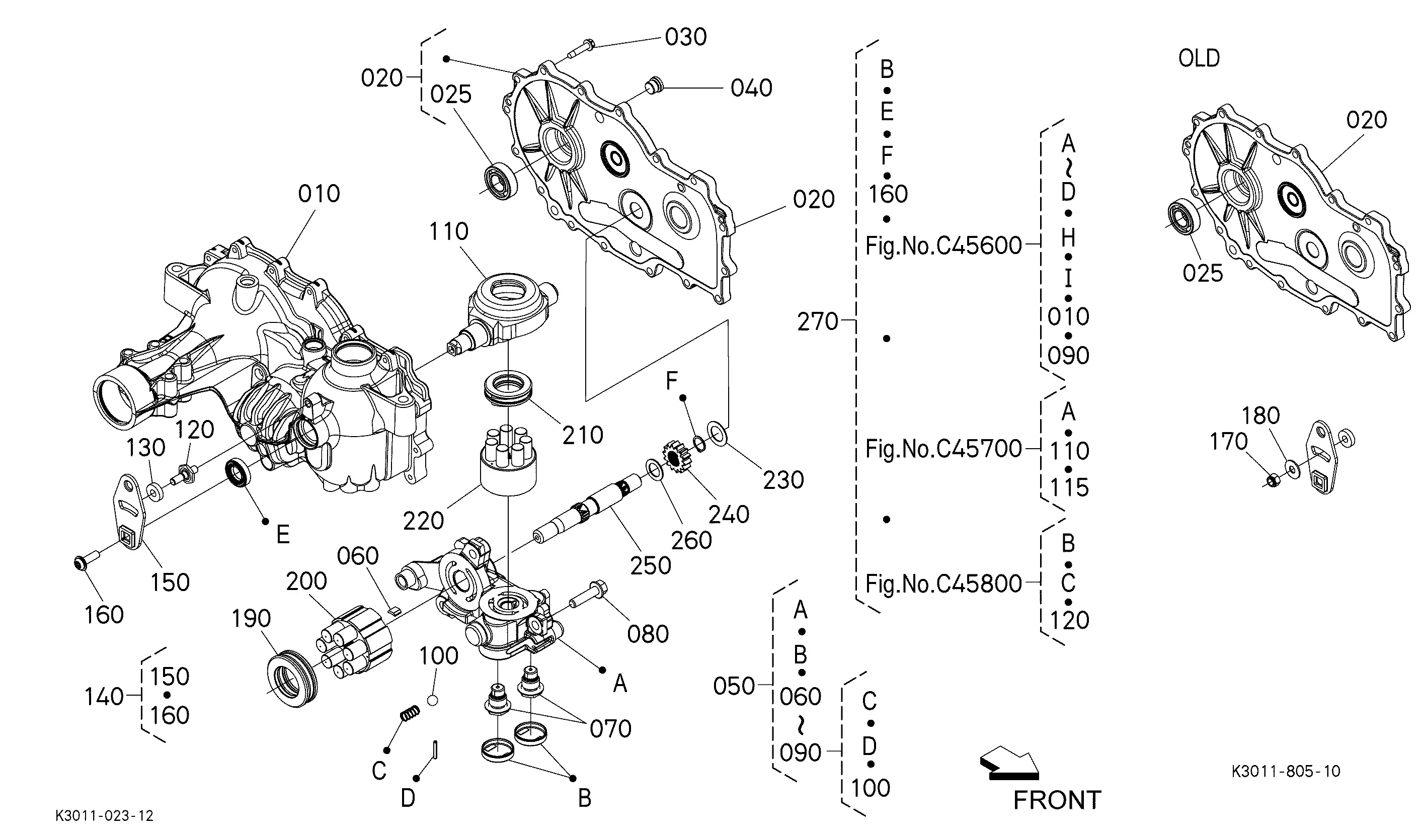

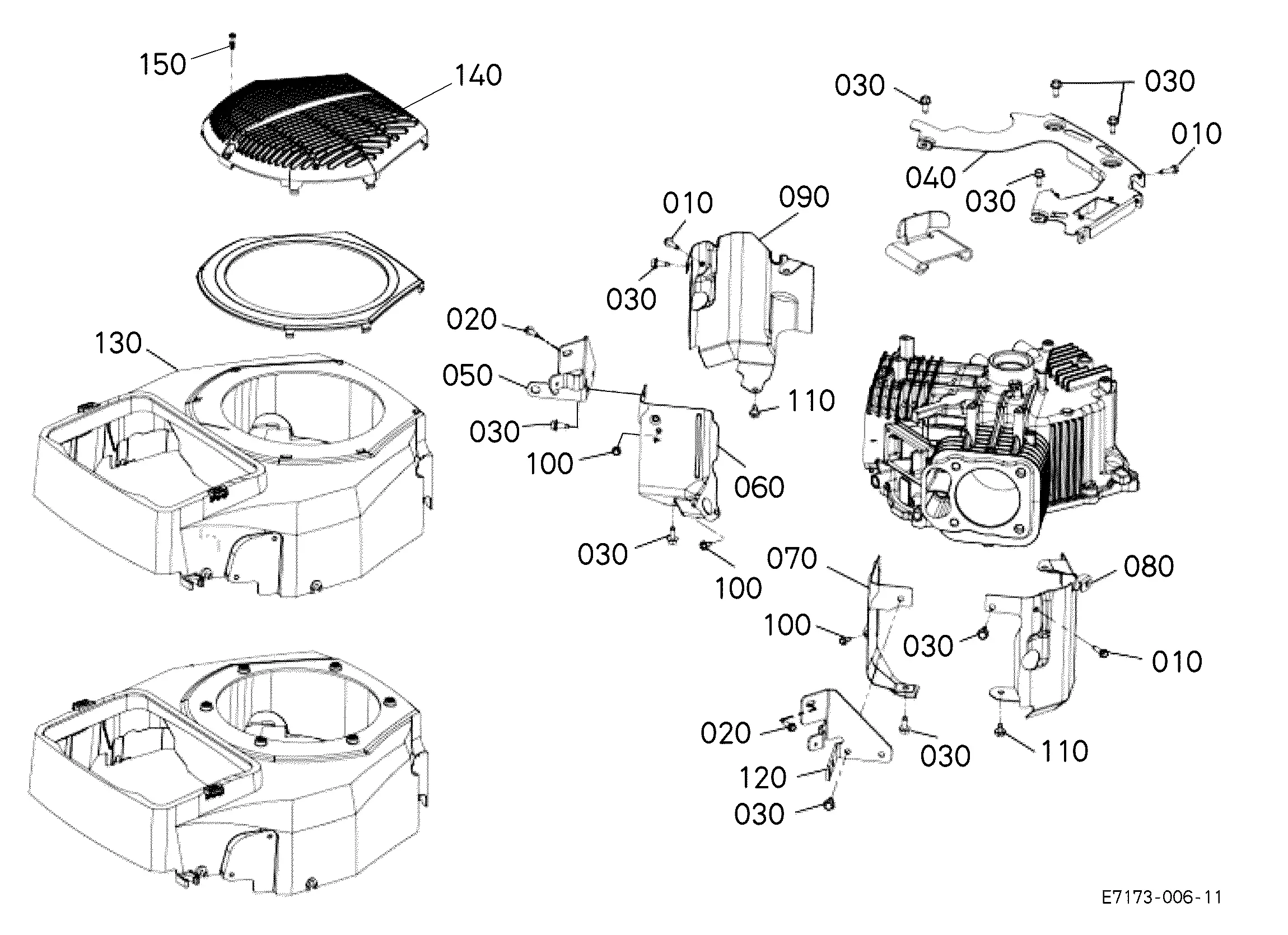

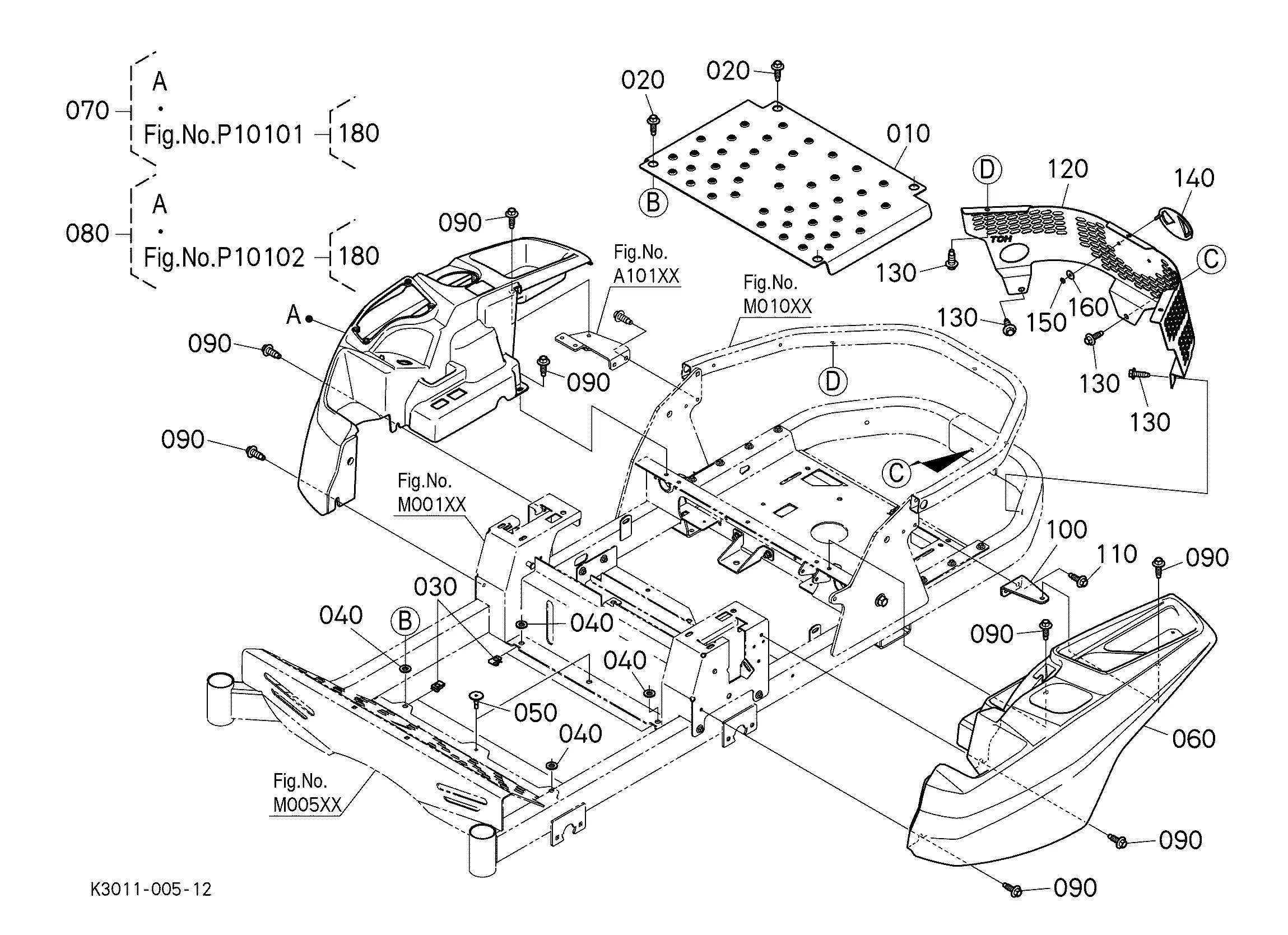

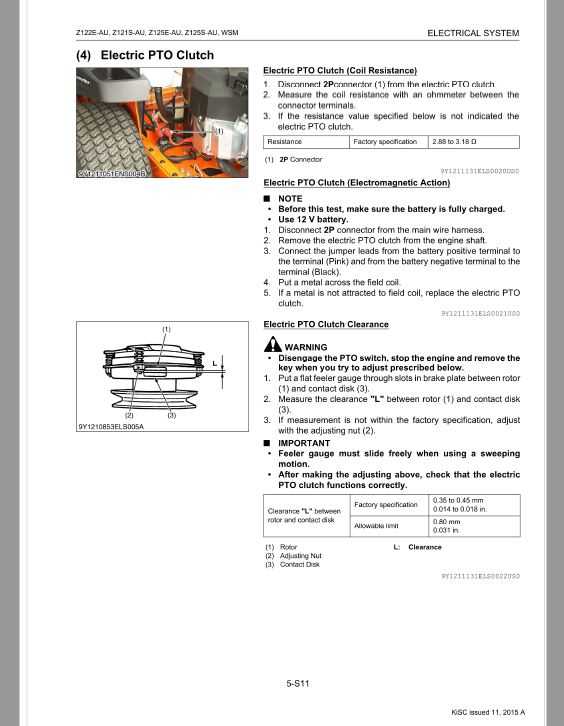

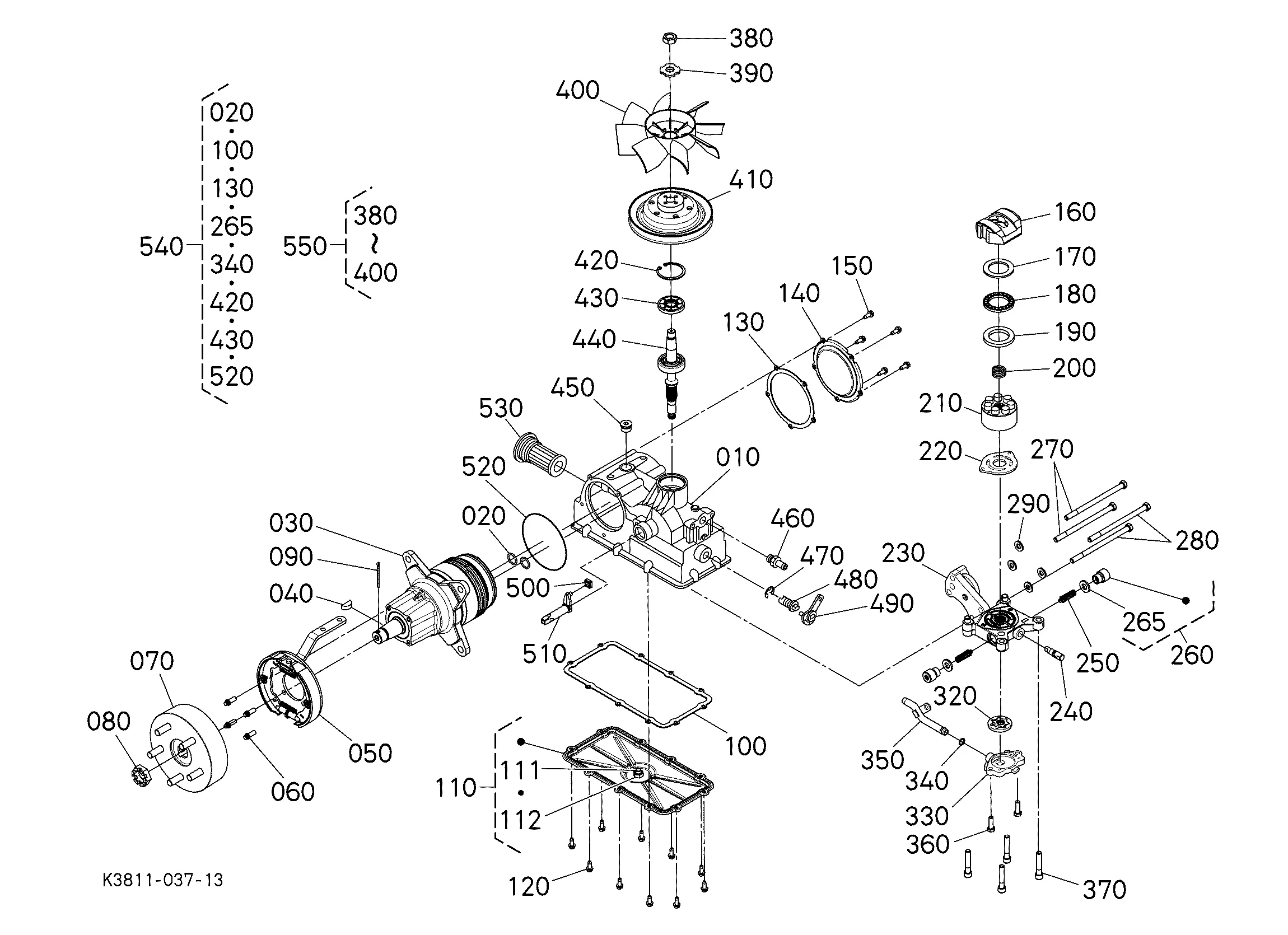

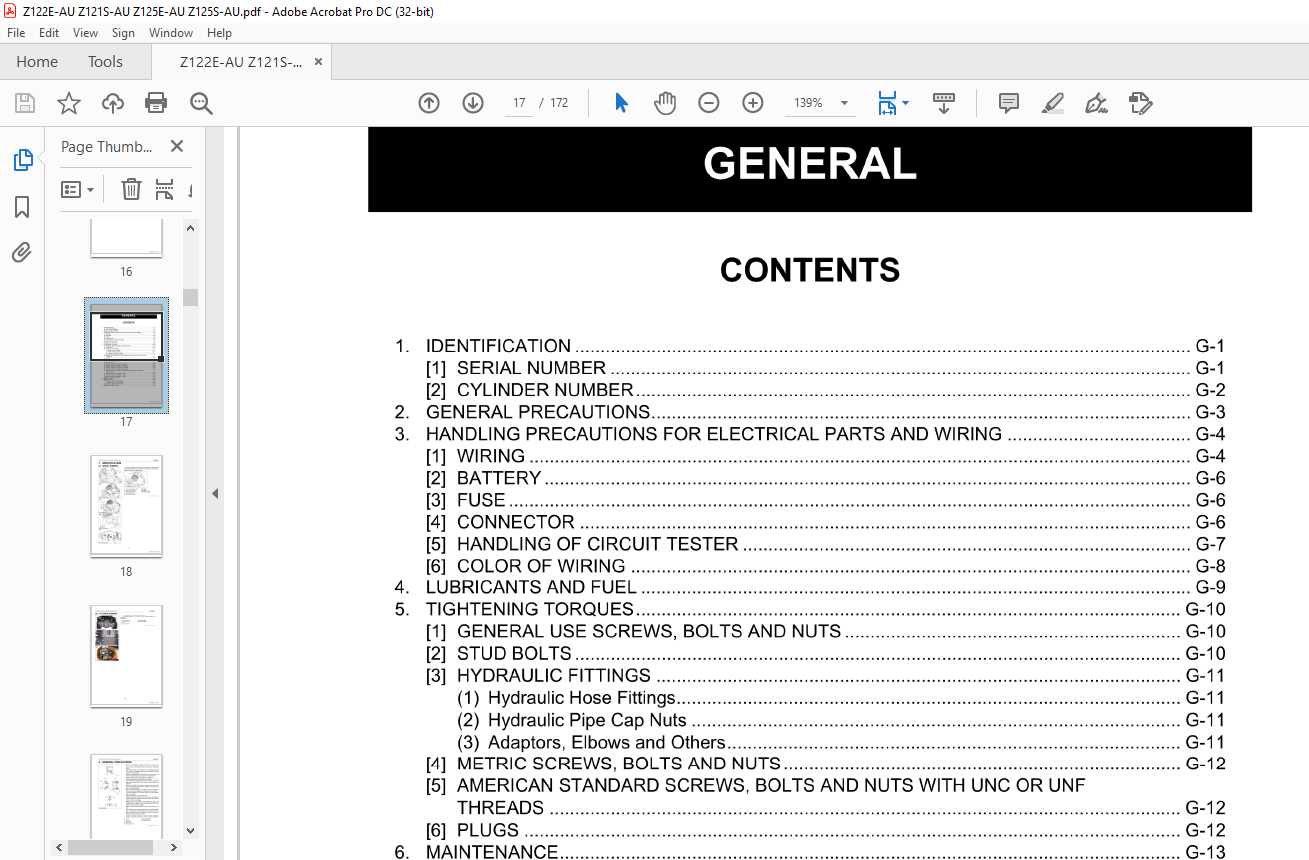

Understanding Parts Diagrams

Interpreting visual representations of mechanical components is essential for maintenance and repair. These illustrations provide a clear overview of how individual elements fit together, enabling users to identify and locate specific items efficiently. Grasping the structure and labeling within these visuals simplifies the process of ordering replacements and performing repairs.

Key Elements of Visual Representations

Each illustration typically includes various symbols and annotations that indicate the function and relationship of parts. Familiarity with these elements enhances the user’s ability to navigate through the assembly effectively.

Benefits of Utilizing Visual Aids

Utilizing these visuals streamlines the repair process, reduces errors, and saves time. A comprehensive understanding can lead to improved performance and longevity of machinery.

| Component | Description |

|---|---|

| Labeling | Identification of parts with corresponding numbers or letters. |

| Connection Lines | Indications of how parts interact or connect. |

| Exploded View | A three-dimensional representation showcasing part arrangement. |

Importance of Accurate Diagrams

Precision in visual representations is crucial for effective maintenance and assembly processes. Accurate illustrations serve as essential tools, aiding users in understanding complex systems and ensuring proper functionality.

- Enhances clarity in identifying components.

- Facilitates efficient troubleshooting and repairs.

- Reduces the risk of errors during assembly.

- Promotes a better understanding of operational mechanisms.

When individuals can clearly see the relationships between parts, they can delve into more intricate tasks confidently. The ultimate goal is to achieve seamless operation and longevity of equipment.

Main Components of Kubota Z125S

The efficiency and performance of any machinery heavily rely on its essential elements. Understanding these critical components not only enhances maintenance practices but also aids in troubleshooting potential issues. Each part plays a specific role in ensuring the overall functionality of the equipment.

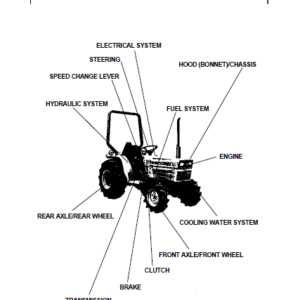

One of the primary features includes the engine, which serves as the powerhouse, converting fuel into mechanical energy. Alongside the engine, the transmission system is vital for transferring power to the wheels, allowing for smooth movement and control. The chassis, which houses the framework, supports various components and provides stability during operation.

Another significant element is the cutting deck, designed for precise grass trimming and ensuring a clean finish. The drive system, encompassing wheels and axles, is crucial for mobility and maneuverability across different terrains. Additionally, the electrical system, which includes batteries and wiring, powers lights and ignition, enabling seamless operation.

Finally, understanding the role of safety features, such as brakes and protective shields, ensures operator security and equipment longevity. Collectively, these components form the backbone of the machine, making it essential to grasp their functions for optimal performance.

Where to Find Parts Diagrams

Finding visual representations of components for machinery can be essential for maintenance and repairs. These illustrations provide clarity on assembly and assist in identifying the right elements needed for various tasks.

Online Resources

- Manufacturer Websites: Many official sites offer downloadable resources.

- Specialty Forums: Enthusiast communities often share links and files.

- Retailer Platforms: Online shops sometimes include schematics in product listings.

Print Resources

- Service Manuals: Printed guides may contain detailed images and breakdowns.

- Local Dealers: Authorized dealers can provide physical copies upon request.

- Library Archives: Public libraries may have access to maintenance manuals.

How to Read a Parts Diagram

Understanding a visual representation of components can significantly enhance your ability to identify and locate individual pieces within a larger assembly. This skill is crucial for maintenance, repairs, and ensuring optimal functionality of equipment.

To effectively interpret such a visual aid, follow these guidelines:

- Familiarize Yourself with the Layout:

- Identify the sections that categorize different types of components.

- Look for labels that indicate various groups or assemblies.

- Study the Symbols:

- Learn what each symbol or number represents.

- Refer to a legend or key if available, which explains the markings used.

- Follow the Flow:

- Trace the connections between components to understand how they interact.

- Note any directional indicators that show the orientation of parts.

- Cross-reference with Documentation:

- Use user manuals or service guides to gain additional context.

- Check for part numbers and descriptions to ensure accuracy.

By applying these strategies, you will improve your comprehension of the visual guide and enhance your ability to manage and maintain your machinery effectively.

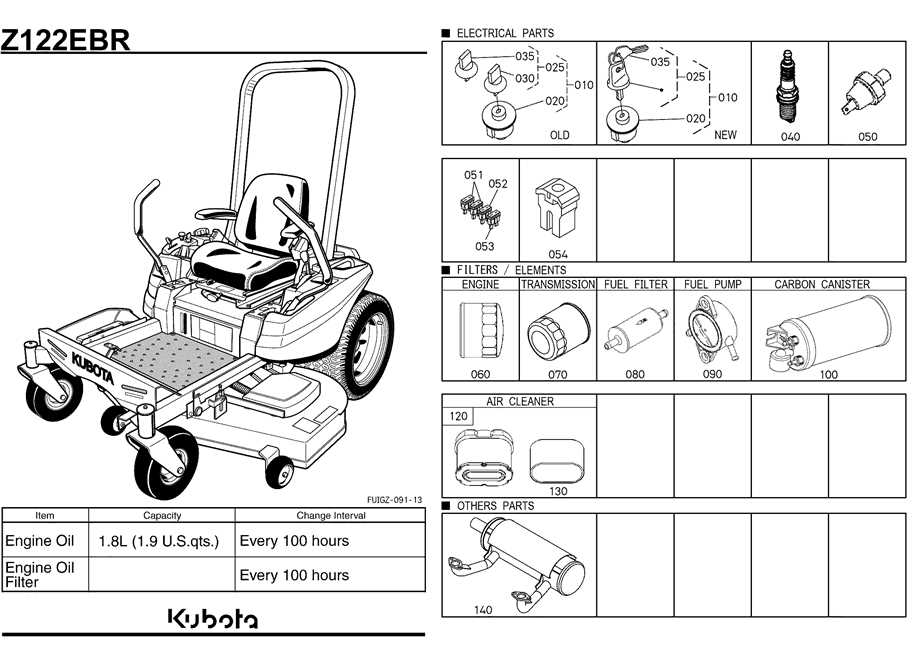

Common Replacement Parts for Z125S

Maintaining optimal performance requires awareness of key components that may need frequent replacement. Understanding these essential elements can enhance longevity and efficiency, ensuring smooth operation over time.

- Blades: Essential for effective cutting, dull or damaged blades should be replaced regularly to maintain a clean lawn.

- Air Filter: A clean air filter is crucial for engine performance, preventing dirt and debris from entering and ensuring efficient operation.

- Oil Filter: Regular replacement of the oil filter helps to maintain engine cleanliness and extends its life by removing contaminants.

- Battery: A reliable power source is vital; replacing an old or weak battery ensures consistent starting and operation.

- Tires: Worn or damaged tires can affect traction and stability, making timely replacement essential for safety and efficiency.

By keeping these components in good condition, operators can avoid unnecessary downtime and costly repairs, leading to a more enjoyable and effective experience.

Maintenance Tips for Kubota Mowers

Regular upkeep is essential for ensuring the longevity and efficiency of your mowing equipment. Implementing a consistent maintenance routine not only enhances performance but also prevents costly repairs down the line. Here are some key practices to keep in mind.

| Task | Frequency | Description |

|---|---|---|

| Check Oil Level | Weekly | Ensure the engine oil is at the recommended level to promote smooth operation. |

| Sharpen Blades | Monthly | Keep blades sharp for clean cuts and improved grass health. |

| Clean Air Filter | Every 25 hours | Inspect and clean the air filter to maintain optimal airflow. |

| Inspect Belts | Every season | Check belts for wear and replace if necessary to avoid malfunction. |

| Fuel System Check | Every season | Inspect the fuel lines and replace old fuel to ensure proper engine performance. |

Identifying Genuine Parts vs. Imitations

When it comes to machinery components, distinguishing authentic items from replicas is crucial for maintaining performance and longevity. Authentic components often come with quality assurance and specific standards, while imitations may compromise functionality.

Visual Inspection: Start by examining the packaging and labeling. Genuine items usually have clear branding and specific identifiers, whereas replicas may lack detail or clarity.

Material Quality: Authentic components are made from high-grade materials, ensuring durability. In contrast, imitations may use inferior materials, resulting in quicker wear and potential failures.

Performance Testing: When possible, testing the functionality of the components can reveal discrepancies. Genuine items are designed for optimal performance, while imitations may not meet these standards.

Supplier Reputation: Always consider the supplier’s credibility. Established vendors are more likely to offer authentic items, whereas unknown sources may provide imitations.

By delving into these aspects, one can make informed decisions and ensure the longevity and reliability of their machinery.

Step-by-Step Repair Process

This section outlines a systematic approach to tackling maintenance tasks effectively. Following a structured method ensures that all aspects of the repair are addressed, minimizing the chances of overlooking critical components.

Preparation and Safety

Before beginning any repair work, it’s essential to gather the necessary tools and safety equipment. Always ensure the machine is turned off and cool to the touch.

Disassembly Steps

Start by removing the outer covers and any components obstructing access to the parts that need attention. Keep track of screws and small parts for easy reassembly.

| Step | Action |

|---|---|

| 1 | Gather tools and safety gear. |

| 2 | Turn off the machine and let it cool. |

| 3 | Remove covers and obstructing components. |

| 4 | Inspect parts for wear or damage. |

| 5 | Replace or repair necessary components. |

| 6 | Reassemble all parts securely. |

Following these steps will help ensure a successful repair, prolonging the lifespan of the equipment.

Cost Considerations for Replacement Parts

When it comes to maintaining equipment, understanding the financial implications of component replacements is essential for effective budgeting and planning. Various factors influence the overall expense associated with obtaining new components, making it crucial to evaluate these elements before making any decisions.

Here are some key factors to consider:

- Quality vs. Price: Higher quality components often come at a premium. It’s important to weigh the long-term benefits against the initial costs.

- Brand Reputation: Well-known brands may charge more, but they often provide reliability and warranties that can save money in the long run.

- Availability: Rare or specialized components may incur additional shipping and handling fees, increasing overall costs.

- Compatibility: Ensure that replacements fit the specific model. Incompatible components can lead to further expenses due to damage or additional modifications.

Additionally, consider the following strategies to manage costs effectively:

- Research: Take time to compare prices from various suppliers to find the best deals.

- Buy in Bulk: If possible, purchasing multiple components at once can lead to discounts.

- Explore Used Options: Certified pre-owned parts can be a cost-effective alternative without sacrificing quality.

By carefully analyzing these considerations, one can make informed decisions that align with both immediate needs and long-term sustainability. Proper financial planning ensures that the maintenance of equipment remains efficient and affordable.

Resources for Kubota Owners

For enthusiasts and owners of outdoor machinery, having access to reliable resources is essential for maintenance and repairs. Whether you’re seeking manuals, community forums, or trusted suppliers, these tools can greatly enhance your ownership experience and ensure your equipment remains in optimal condition.

Online Manuals and Guides: Many manufacturers offer downloadable resources that provide detailed instructions on operation and maintenance. These manuals are invaluable for understanding your machine’s specifications and troubleshooting common issues.

Community Forums: Engaging with fellow owners through dedicated online platforms can provide support and shared experiences. These communities often share tips, tricks, and solutions that can help you resolve problems more efficiently.

Parts Suppliers: Finding quality components is crucial for repairs. Reliable suppliers, both online and local, offer a variety of parts that meet the standards needed for your machinery. Look for those with good reviews and customer support to assist in your purchase decisions.

Video Tutorials: Visual learning can be particularly effective when tackling repairs. Numerous platforms host tutorials that guide you step-by-step through various maintenance tasks, from basic upkeep to more complex repairs.

Workshops and Training: Participating in local workshops can enhance your skills and knowledge. These sessions often cover essential maintenance techniques and safety practices, ensuring you’re well-equipped to handle your machinery.