When it comes to maintaining the aesthetics and health of your green spaces, the machinery involved plays a crucial role. A thorough comprehension of the individual elements that constitute these devices is vital for ensuring their optimal performance. Whether for personal gardens or professional landscapes, familiarity with the structure of this equipment can enhance efficiency and longevity.

In the intricate world of grass management tools, each component serves a distinct function that contributes to the overall operation. By exploring the interrelationships among these various segments, users can better navigate issues related to maintenance and repairs. This understanding not only empowers operators but also fosters a greater appreciation for the technology behind modern landscaping.

As we delve into the specifics of these mechanical systems, the visual representation of their components becomes an invaluable asset. Such illustrations not only aid in identifying individual pieces but also clarify how they work together seamlessly. For both novice and seasoned users, this knowledge serves as a foundation for effective troubleshooting and informed decision-making.

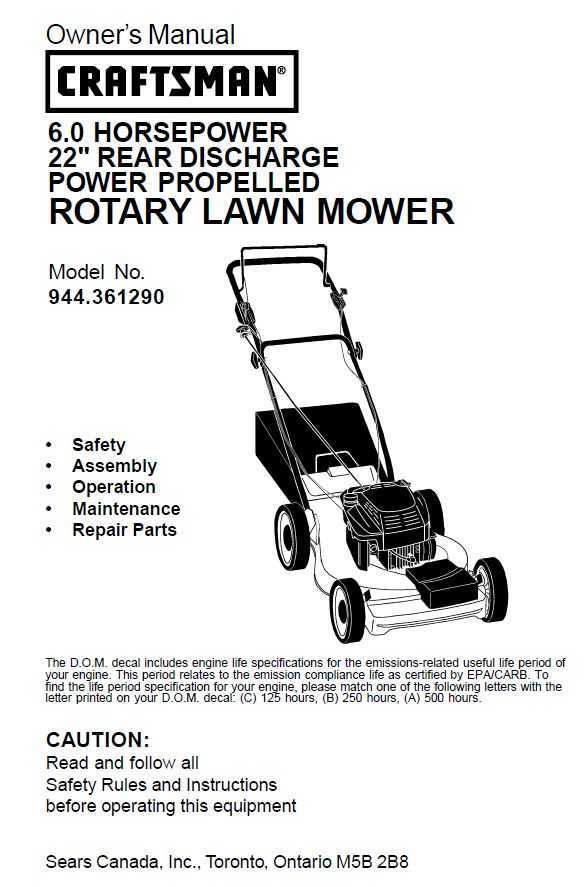

Understanding Lawn Mower Components

Gaining insight into the various elements of grass cutting machinery is essential for effective maintenance and operation. Each component plays a crucial role in the overall functionality, contributing to the efficiency and longevity of the device.

Here are some key elements to consider:

- Engine: The powerhouse that drives the entire system, responsible for generating the necessary force.

- Deck: The housing that protects the blades and houses the cutting mechanism.

- Blades: Sharp elements that perform the cutting action, requiring regular sharpening and replacement.

- Wheels: Allow for mobility, with various sizes impacting maneuverability on different terrains.

- Handle: Provides control and ease of operation, often adjustable for user comfort.

Understanding how these components work together can significantly enhance the user’s ability to perform maintenance tasks and troubleshoot issues effectively.

Importance of Certified Parts

The quality of components used in machinery significantly impacts performance, longevity, and safety. Utilizing authentic and approved elements ensures that devices function at their best and maintain operational efficiency over time. When individuals opt for reliable options, they invest not only in the equipment but also in the overall experience of its use.

Enhanced Performance

Genuine components are designed to meet specific standards set by manufacturers. This guarantees compatibility and optimal functioning, leading to enhanced performance. When devices are equipped with such elements, they operate smoothly and efficiently, reducing the likelihood of breakdowns.

Safety and Reliability

The use of authorized components minimizes risks associated with malfunctioning equipment. Quality assurance in the manufacturing process means that these elements have been rigorously tested for safety. This not only protects the user but also extends the lifespan of the machinery, making it a sound investment in the long run.

Overview of Mower Diagrams

Understanding the layout and functionality of outdoor equipment is essential for effective maintenance and repairs. Visual representations serve as invaluable tools, offering insights into the arrangement and interaction of various components. These illustrations help users identify parts and comprehend their roles within the entire system.

Typically, these visuals highlight critical elements, showcasing how each piece fits together and operates in harmony. Users can quickly locate specific sections, making troubleshooting more straightforward and enhancing their ability to perform repairs efficiently. Moreover, these representations often include notations that provide additional context, such as part numbers or assembly instructions.

Ultimately, familiarity with these visuals empowers individuals to engage confidently with their machinery. Whether for personal use or professional maintenance, having access to detailed illustrations can significantly enhance the repair experience, leading to better performance and longevity of the equipment.

Common Mower Parts Explained

Understanding the various components of a cutting machine is essential for effective maintenance and operation. Each element plays a critical role in ensuring the device functions smoothly, enhancing its efficiency and longevity. Familiarity with these components can aid in troubleshooting and repair, allowing users to keep their equipment in optimal condition.

Key Components

One of the primary elements is the blade, responsible for achieving a clean cut. Regular inspection and sharpening are vital to maintain its performance. The engine is another crucial part, providing the necessary power for operation. Understanding its functionality can help in addressing performance issues.

Additional Elements

The deck serves as the housing for the blade and engine, influencing the overall design and aerodynamics. Belts and cables also play a significant role, connecting various parts and facilitating movement. Regular checks of these elements can prevent potential breakdowns and ensure smooth operation.

How to Read Diagrams Effectively

Understanding visual representations can significantly enhance your ability to grasp complex information quickly. These illustrations serve as guides that translate intricate systems into more accessible formats, allowing you to identify components and their interrelations effortlessly.

Familiarize Yourself with Symbols

Before diving into the interpretation, take a moment to familiarize yourself with the various symbols used in the illustration. Each symbol represents a specific element or action, and recognizing them can streamline your understanding. Consult a legend if available, as it provides crucial insights into what each symbol signifies.

Follow the Flow of Information

Once you are acquainted with the symbols, focus on the direction of lines and connections. These elements often indicate the sequence of operations or the relationship between different components. Pay attention to how elements are linked; this can reveal dependencies and functionalities that are essential for effective operation.

Benefits of Using Original Parts

Utilizing genuine components for maintenance and repairs significantly enhances the performance and longevity of machinery. Original items are designed specifically for particular models, ensuring optimal functionality and reliability.

Quality Assurance

One of the primary advantages of using authentic components is the guarantee of quality. These items undergo rigorous testing to meet industry standards, which helps to:

- Reduce the likelihood of failures.

- Maintain efficiency during operation.

- Ensure compatibility with existing systems.

Cost-Effectiveness in the Long Run

While genuine components may have a higher upfront cost, they often provide better value over time. Consider the following:

- Fewer replacements needed due to durability.

- Lower maintenance costs associated with reliable performance.

- Increased resale value of the equipment.

Investing in original items can ultimately save money and time, leading to enhanced satisfaction and peace of mind.

Identifying Wear and Tear

Recognizing deterioration in your equipment is essential for maintaining optimal performance. Regular inspection can prevent minor issues from escalating into major problems, ensuring longevity and efficiency.

To effectively identify signs of wear, consider the following indicators:

- Visual Inspection: Check for cracks, rust, or corrosion on metal surfaces.

- Performance Issues: Notice any irregular sounds or reduced effectiveness during operation.

- Vibrations: Excessive shaking may indicate imbalance or damage in components.

- Leaking Fluids: Look for any unusual fluid leaks that may signal internal failures.

It’s important to regularly assess key components such as:

- Blades: Ensure they are sharp and free of chips.

- Belts: Check for signs of fraying or stretching.

- Wheels: Inspect for wear and proper alignment.

- Filters: Clean or replace as needed to maintain airflow and efficiency.

By staying vigilant and addressing any signs of degradation promptly, you can enhance the reliability and performance of your equipment.

Maintenance Tips for Lawn Mowers

Regular upkeep of your grass-cutting equipment is essential for ensuring optimal performance and longevity. By following a few straightforward practices, you can keep your machine running smoothly and efficiently, preventing potential issues before they arise.

Regular Cleaning

After each use, it’s important to clean the undercarriage and blades. Grass clippings and debris can accumulate, leading to rust and corrosion. Use a brush or a cloth to wipe down surfaces, and consider rinsing with water if necessary. Always ensure that the equipment is turned off and cool before cleaning.

Routine Inspections

Conducting regular inspections of your equipment can help identify wear and tear before it becomes a major problem. Check the blades for dullness and nicks; sharpen or replace them as needed. Also, examine the belts and cables for signs of damage or fraying, as these can affect performance and safety.

Emphasizing preventive measures not only enhances the efficiency of your device but also saves time and money on repairs in the long run. Remember to follow the manufacturer’s guidelines for specific maintenance recommendations.

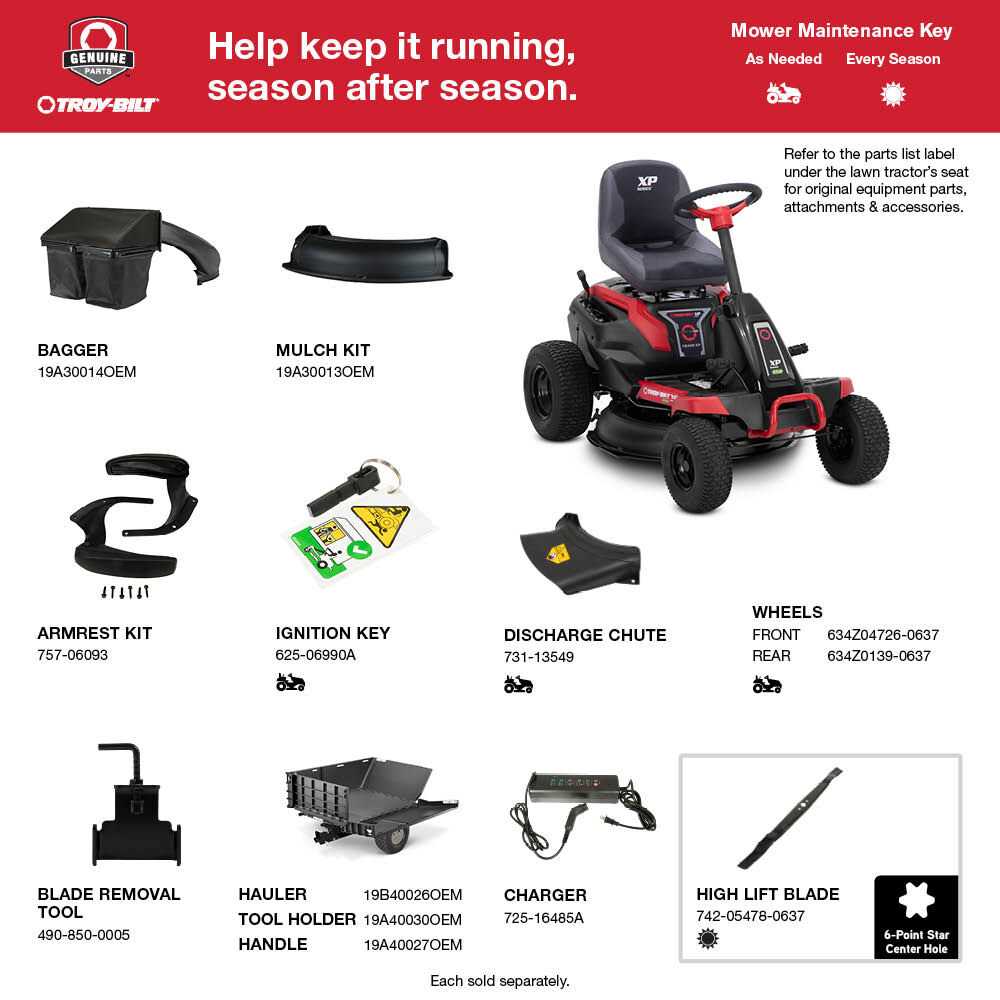

Finding Replacement Parts Online

In today’s digital age, sourcing components for your outdoor equipment has become easier than ever. The internet offers a vast array of options, enabling you to locate the necessary items quickly and efficiently. With just a few clicks, you can access numerous vendors and compare prices, ensuring you find the best deal for your needs.

When searching for specific components online, consider the following steps to streamline the process:

| Step | Description |

|---|---|

| 1 | Identify the Model: Ensure you know the exact model and specifications of your equipment to find compatible items. |

| 2 | Use Reliable Sources: Stick to reputable websites and retailers to avoid counterfeit products. |

| 3 | Compare Prices: Take the time to compare prices across different platforms to ensure you’re getting the best value. |

| 4 | Check Reviews: Read customer reviews to gauge the quality and reliability of the components before making a purchase. |

| 5 | Consider Shipping Options: Look for vendors that offer fast and affordable shipping to minimize downtime. |

By following these steps, you can efficiently navigate the online marketplace and secure the components you need to keep your equipment running smoothly.

Comparing OEM and Aftermarket Parts

When it comes to choosing components for machinery, two main options often arise: original and alternative suppliers. Each category presents its own set of advantages and disadvantages, influencing both performance and cost-effectiveness. Understanding these differences is crucial for making informed decisions.

Original components are manufactured by the same company that produced the original equipment. They typically offer a guaranteed fit and performance, maintaining the integrity of the machine. Users often appreciate the assurance of quality that comes with these items, as they are designed to meet specific standards and specifications.

On the other hand, alternative suppliers provide a wider range of options, often at a lower price point. While these components may vary in quality, they can be an appealing choice for budget-conscious consumers. However, potential drawbacks include the risk of incompatibility or reduced lifespan, which can lead to more frequent replacements.

Ultimately, the decision between original and alternative components hinges on individual priorities. Whether one values reliability over cost savings or vice versa, it is essential to weigh the long-term implications of each choice carefully.

Safety Precautions When Repairing

Engaging in maintenance and repairs of mechanical equipment requires a focus on safety to prevent accidents and injuries. Understanding the inherent risks associated with the task and taking appropriate measures can greatly enhance the safety of the working environment.

Essential Safety Measures

Before starting any repair work, it is crucial to follow these fundamental safety precautions:

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use gloves, goggles, and sturdy footwear to protect against sharp objects and debris. |

| Disconnect Power Source | Ensure that the equipment is turned off and unplugged to prevent accidental activation. |

| Use Proper Tools | Employ the right tools for the job to avoid damaging components and reduce the risk of injury. |

| Work in a Ventilated Area | Ensure adequate ventilation to avoid inhaling harmful fumes or dust. |

| Keep Workspace Organized | A tidy workspace minimizes the chances of tripping or misplacing tools. |

Additional Considerations

In addition to the essential precautions, it is advisable to familiarize yourself with the specific equipment and its repair requirements. Reading the manufacturer’s manual can provide important insights into potential hazards and proper handling techniques.

Resources for DIY Repairs

Engaging in self-repairs can be both rewarding and cost-effective. By utilizing the right resources, you can efficiently troubleshoot issues and restore functionality to your equipment. Whether you’re a novice or have some experience, the following tools and materials can significantly enhance your repair efforts.

Online Guides and Tutorials

The internet is a treasure trove of information. Websites dedicated to home maintenance often feature step-by-step guides, videos, and forums where enthusiasts share their experiences. These resources can provide invaluable insights and practical tips, making the repair process smoother and more understandable.

Community Forums and Support Groups

Participating in community forums can connect you with fellow DIYers who have faced similar challenges. These platforms allow for the exchange of ideas, troubleshooting advice, and even sourcing of components. Engaging with a community can empower you with knowledge and boost your confidence in taking on repairs.

Maintaining Your Lawn Mower’s Longevity

Proper care and regular upkeep are essential for ensuring the extended lifespan of your grass trimming equipment. By following a structured maintenance routine, you can enhance performance and prevent unnecessary wear and tear, ultimately saving time and money on replacements and repairs.

Essential Maintenance Practices

Implementing a few key practices can significantly impact the longevity of your equipment. Regularly checking and changing fluids, inspecting the blades, and cleaning the exterior are fundamental tasks that should not be overlooked. Additionally, seasonal adjustments can ensure optimal performance throughout the year.

Common Maintenance Schedule

| Task | Frequency |

|---|---|

| Change oil | Every 50 hours of use |

| Sharpen blades | Every 20 hours of use |

| Clean air filter | Every season |

| Inspect belts and cables | Every month |

| Check spark plug | Every season |

By adhering to this maintenance schedule, you can ensure your equipment operates efficiently and remains in excellent condition for years to come.