The maintenance of outdoor equipment is essential for ensuring optimal performance and longevity. This section delves into the various elements that comprise such machinery, highlighting their significance in the overall functionality. By gaining insight into these components, users can enhance their understanding and improve their maintenance practices.

Identifying each section of this machinery allows operators to troubleshoot issues effectively and make informed decisions when it comes to repairs or replacements. Knowledge of these features not only aids in resolving problems but also empowers users to engage with their equipment more confidently.

Furthermore, recognizing how these individual parts interact fosters a deeper appreciation for the design and engineering behind the machinery. This understanding can lead to better care and optimization, ensuring that the equipment performs at its best throughout its lifespan.

Understanding Sabre Lawn Mower Components

Every machine comprises various essential elements that work together to ensure optimal functionality. Familiarizing oneself with these components is crucial for effective maintenance and troubleshooting. Each section plays a specific role, contributing to the overall performance and efficiency of the equipment.

Engines serve as the heart of the equipment, providing the necessary power for operation. A well-functioning engine guarantees smooth performance and longevity. Regular checks on its condition can prevent significant issues.

Blades are fundamental in achieving a clean and even finish. Sharp and well-aligned blades enhance cutting efficiency and minimize strain on the engine. Routine inspection and sharpening are vital to maintain their effectiveness.

Chassis forms the structural framework, supporting all other components. It is essential for stability and durability, ensuring that the machine can withstand various working conditions. Regular checks for wear and tear can help in prolonging its life.

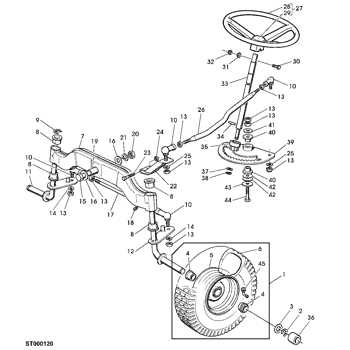

Wheels play a significant role in mobility. They should rotate freely and be adequately inflated to provide smooth navigation across different terrains. Maintenance of tires is crucial for ensuring optimal maneuverability and preventing accidents.

In summary, understanding these integral components aids in effective care and management, enhancing performance and prolonging the life of the equipment.

Key Features of Sabre Models

The models from this brand are designed with a focus on performance, efficiency, and user-friendly features. Each variant brings a range of attributes that enhance functionality and durability, making them suitable for various outdoor tasks. Understanding these key features is essential for users to make informed decisions and maximize the utility of their equipment.

| Feature | Description |

|---|---|

| Powerful Engine | Equipped with high-performance engines that provide reliable power for optimal cutting. |

| Adjustable Height Settings | Offers multiple height adjustments for customized cutting lengths to suit different terrains. |

| Ergonomic Design | Features comfortable grips and controls that enhance user comfort during operation. |

| Durable Construction | Built with high-quality materials to withstand harsh weather conditions and prolonged use. |

| Easy Maintenance | Designed for straightforward upkeep, ensuring longevity and consistent performance. |

Importance of Regular Maintenance

Consistent upkeep is essential for ensuring the longevity and efficiency of equipment. By prioritizing routine care, users can prevent potential breakdowns, enhance performance, and extend the lifespan of their machinery.

Benefits of Routine Care

- Improved Performance: Regular inspections and servicing can lead to optimal functionality, ensuring that machines operate at their best.

- Cost Savings: By identifying and addressing minor issues early, significant repairs and replacements can be avoided, leading to substantial financial savings over time.

- Enhanced Safety: Regular checks can help identify safety hazards, reducing the risk of accidents and ensuring a safer operating environment.

Key Maintenance Practices

- Regularly check and replace filters to ensure optimal airflow and efficiency.

- Keep all moving parts lubricated to reduce friction and wear.

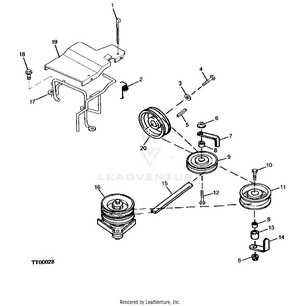

- Inspect belts and cables for signs of wear or damage and replace them as needed.

- Clean the equipment after each use to prevent debris buildup that can hinder performance.

By following these essential maintenance practices, users can significantly enhance the reliability and performance of their machines, ensuring they remain in peak condition for years to come.

Common Issues with Lawn Mowers

Operating outdoor equipment often leads to a variety of complications that can hinder performance and efficiency. Understanding these frequent problems can help users troubleshoot effectively and maintain optimal functionality.

Typical Problems Encountered

- Engine Does Not Start

- Uneven Cutting

- Excessive Vibration

- Clogged Blades

- Fuel Leaks

Maintenance Tips

- Regularly check and replace the fuel.

- Inspect and clean the cutting blades frequently.

- Ensure proper oil levels are maintained.

- Examine and replace air filters as needed.

- Store equipment in a dry and secure location.

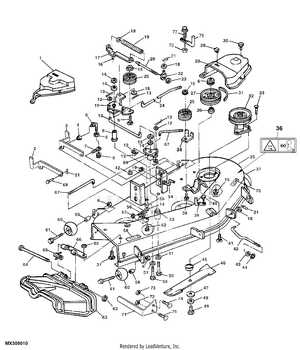

How to Identify Replacement Parts

When maintaining outdoor equipment, understanding how to recognize components that may require substitution is crucial. This ensures optimal performance and longevity of your machine. Identifying these elements can save time and effort in the repair process.

Start by examining the owner’s manual, as it typically contains detailed information about the various elements and their specifications. Manuals often provide part numbers, which can be invaluable when searching for replacements. If the manual is not available, look for labels or tags on the equipment itself that may list model numbers or other identifying details.

Visual inspection is also important. Take note of any worn or damaged areas. Comparing these with online resources or reference guides can help you find the correct replacements. Many websites and forums provide images and descriptions of components, aiding in the identification process.

Consult with experts at local retailers or service centers. These professionals can assist in identifying the right components based on your equipment’s model and condition. They may also offer insights on compatible alternatives that could improve performance.

Lastly, consider using online marketplaces that specialize in outdoor machinery. These platforms often categorize items by brand and model, making it easier to locate what you need. Utilize customer reviews and ratings to ensure you choose reliable replacements.

Tools Needed for Repairs

When undertaking maintenance or fixing machinery, having the right tools is essential for a smooth and efficient process. Proper equipment ensures that tasks are completed accurately and safely, minimizing the risk of damage and personal injury.

Essential tools for these tasks often include a variety of hand tools, power tools, and specialized instruments. Common items such as wrenches, screwdrivers, and pliers form the foundation of any repair toolkit. Additionally, power tools like drills and impact drivers can greatly enhance efficiency, especially for more complex repairs.

It’s also crucial to have safety equipment on hand, including gloves, goggles, and ear protection, to safeguard against potential hazards during repairs. Lastly, maintaining an organized workspace with a sturdy workbench and adequate lighting can significantly improve focus and productivity.

Step-by-Step Repair Guide

This section provides a comprehensive approach to addressing common issues that may arise with your equipment. By following the outlined steps, you can efficiently diagnose and resolve problems, ensuring optimal performance and longevity.

-

Start by gathering the necessary tools and equipment for the repair process.

-

Carefully examine the machine to identify visible signs of wear or damage.

-

Refer to the manual for troubleshooting tips specific to your model.

-

Disassemble the components as needed, taking care to note the order of removal for easier reassembly.

-

Inspect each component thoroughly, replacing any that show significant wear or failure.

-

Clean all parts to remove debris and buildup that may affect performance.

-

Reassemble the equipment, ensuring that all parts are securely fastened.

-

Test the machine to confirm that the issues have been resolved and it operates smoothly.

Following these steps will help maintain the efficiency of your device and extend its operational life.

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring personal safety is paramount. Proper precautions can help prevent accidents and injuries while handling equipment. Familiarity with safe practices not only protects the individual performing the repairs but also enhances the overall efficiency of the task.

Essential Safety Guidelines

Before beginning any maintenance or repair work, it is crucial to follow these essential guidelines:

- Always wear appropriate personal protective equipment, including gloves and safety goggles.

- Disconnect power sources before starting any repair tasks to avoid unexpected activation.

- Work in a well-ventilated area to prevent inhalation of harmful fumes or dust.

- Keep tools organized and within reach to minimize the risk of accidents.

Emergency Procedures

In case of an emergency, knowing the right steps to take can make a significant difference. Follow these procedures:

| Situation | Action |

|---|---|

| Injury | Administer first aid and seek medical attention immediately. |

| Equipment Malfunction | Disconnect the power source and notify a qualified technician. |

| Fire | Evacuate the area and use a fire extinguisher if trained to do so. |

Where to Find Genuine Parts

Obtaining authentic components for your equipment is essential for optimal performance and longevity. Ensuring that you source high-quality replacements can make a significant difference in the reliability of your machine. Here are several options to consider when searching for trustworthy items.

- Authorized Dealers: Visiting an official dealer is one of the best ways to find genuine replacements. They offer a wide range of products and have knowledgeable staff to assist you.

- Manufacturer’s Website: Many brands provide direct sales through their websites, allowing you to browse and order authentic components online.

- Local Retailers: Check local hardware or home improvement stores that might carry genuine items. Staff can often help you find what you need or order it for you.

- Online Marketplaces: Websites such as Amazon or eBay can be useful, but ensure to check seller ratings and reviews to avoid counterfeit products.

- Repair Shops: Local repair shops may have access to genuine components or can assist in sourcing them for you.

When searching for replacements, always verify the authenticity of the components to ensure compatibility and quality. Taking the time to find the right sources will pay off in the long run.

Benefits of Using Original Parts

Utilizing authentic components in equipment maintenance ensures optimal performance and longevity. These original elements are designed specifically for each model, providing a perfect fit and function that aftermarket alternatives may lack.

Quality Assurance

Original components undergo rigorous testing and quality control processes, guaranteeing reliability. Here are some key advantages:

- Superior materials and construction.

- Consistency in performance and durability.

- Lower risk of failure or malfunction.

Enhanced Performance

Using genuine components contributes significantly to the overall efficiency of the equipment. Consider the following points:

- Improved compatibility with existing systems.

- Maintained operational standards set by the manufacturer.

- Optimized functionality, leading to better user experience.

Tips for Enhancing Performance

Improving the efficiency and longevity of your equipment is essential for optimal functionality. By implementing several practical strategies, you can significantly boost performance while ensuring a smoother operation. This section provides actionable insights to help maintain and enhance the overall effectiveness of your machinery.

Regular Maintenance

Consistent upkeep is crucial for any machine’s performance. Regularly check and clean components, including air filters, blades, and belts. This will prevent the buildup of debris that can hinder functionality and lead to more significant issues. Additionally, lubricating moving parts reduces friction, allowing for smoother operation and prolonging the life of the equipment.

Proper Storage Practices

Storing your machinery correctly can greatly affect its performance. Ensure that it is kept in a dry and sheltered area to avoid exposure to harsh weather conditions. When not in use, consider using a cover to protect against dust and debris. Maintaining the right temperature and humidity levels can also help prevent rust and corrosion, keeping your equipment in top condition.