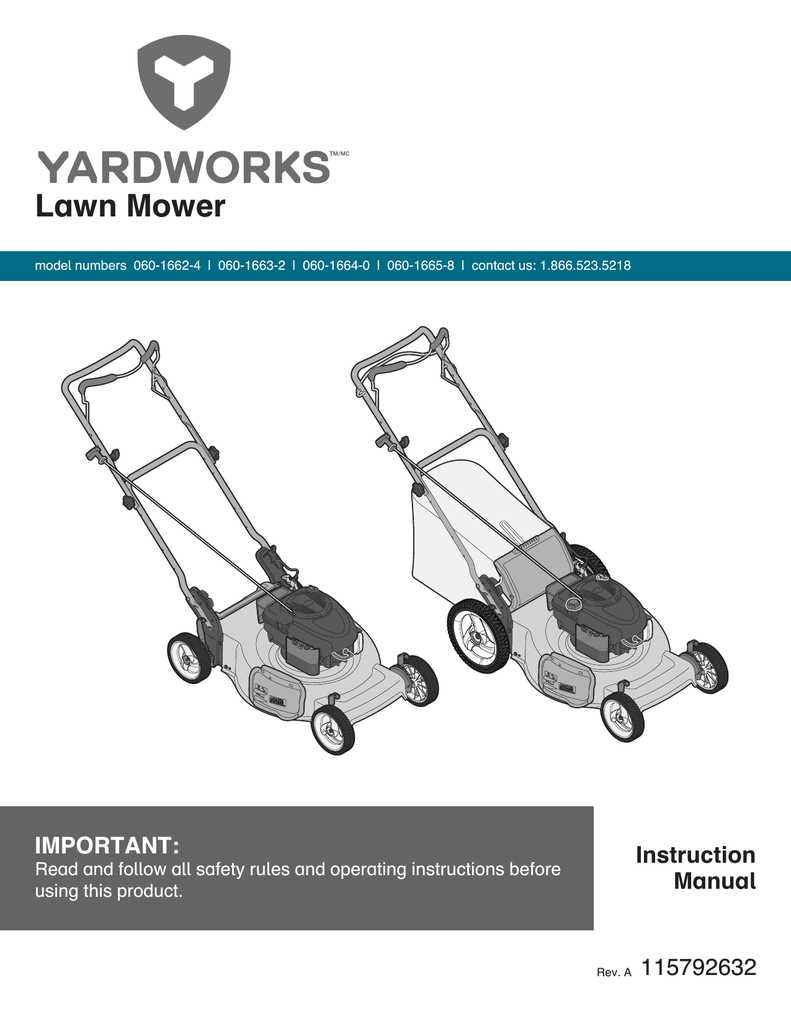

Every machine designed for maintaining outdoor spaces comprises a series of interconnected elements that ensure optimal functionality. A comprehensive understanding of these components is essential for effective troubleshooting and maintenance. Familiarity with the structure allows users to quickly identify issues and address them efficiently.

By examining the configuration of each element, one can appreciate how they interact to deliver peak performance. This knowledge empowers operators to make informed decisions about repairs and replacements, ultimately extending the life of their equipment. A detailed exploration of these arrangements reveals not only the individual functions but also the overall synergy required for successful operation.

In this section, we will delve into the various components, highlighting their roles and importance in the machinery’s functionality. Whether for routine upkeep or more significant repairs, understanding these layouts is invaluable for anyone looking to optimize their outdoor maintenance tools.

Understanding Lawn Mower Components

Familiarizing oneself with the various elements of garden equipment is essential for effective maintenance and operation. Each component plays a specific role in ensuring the machine functions smoothly and efficiently. Grasping the function of these components can greatly enhance performance and troubleshooting capabilities.

The following table outlines key components typically found in garden equipment, along with their primary functions:

| Component | Function |

|---|---|

| Engine | Powers the machine and drives the cutting mechanism. |

| Deck | Houses the cutting blade and provides structural support. |

| Blade | Cuts grass and maintains desired height. |

| Wheels | Facilitate movement and maneuverability across different terrains. |

| Handle | Allows the user to control and guide the equipment. |

| Fuel Tank | Holds fuel necessary for engine operation. |

| Air Filter | Prevents dirt and debris from entering the engine. |

Identifying Key Replacement Parts

Understanding the essential components of your equipment is crucial for maintaining its efficiency and performance. Recognizing which elements may require attention or replacement can significantly extend the lifespan of your machine. This section focuses on highlighting the main components that often need servicing, ensuring you can keep your device in optimal condition.

Common Components to Inspect

Begin by examining the engine, as it is the heart of your device. Regular checks on the filters and spark plugs can prevent performance issues. Additionally, pay attention to the blades, as sharp and undamaged blades are vital for effective operation. Regular maintenance of these items can enhance cutting efficiency.

Importance of Regular Maintenance

Routine evaluation of the drive system is also necessary. Components like belts and wheels are crucial for smooth operation, and any wear or damage should be addressed promptly. Keeping track of these essential elements can help avoid unexpected breakdowns and costly repairs, ensuring reliable performance throughout the season.

Exploring Common Assembly Features

Understanding the typical components of garden equipment can enhance both maintenance and functionality. Familiarity with various elements allows for better troubleshooting and performance optimization.

Several assembly characteristics are often found across different models:

- Frame Structure: The backbone of any equipment, providing stability and support.

- Cutting Mechanism: A crucial feature designed for efficient trimming, varying in design depending on intended use.

- Power Source: Different options, such as gas or electric, influencing performance and environmental impact.

- Handle Configuration: Ergonomically designed to ensure comfort and control during operation.

- Wheels and Mobility: Essential for maneuverability, with variations in size and material for different terrains.

Recognizing these assembly traits contributes to informed decisions regarding repairs and upgrades, ensuring optimal operation of the equipment.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring efficiency and longevity of your equipment. By following a few straightforward guidelines, you can enhance functionality and reduce the risk of unexpected breakdowns.

Regular Inspection

- Check for wear and tear on components.

- Ensure all fasteners are secure and not loose.

- Inspect the cutting mechanism for any damage or dullness.

Cleaning Practices

- Clean debris from the exterior after each use.

- Remove grass clippings to prevent rust buildup.

- Wipe down surfaces to maintain a pristine appearance.

Tools Needed for Part Replacement

Replacing components in machinery requires specific instruments to ensure the process is efficient and effective. Proper tools not only facilitate quick replacements but also prevent potential damage to the equipment. Below is a comprehensive list of essential tools that will assist in the replacement of various elements.

Essential Tools

- Wrenches: Different sizes for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips types for various screws.

- Socket Set: For removing nuts and bolts quickly.

- Pliers: Useful for gripping and bending wires or small parts.

- Utility Knife: Handy for cutting materials as needed.

Safety Equipment

- Safety Goggles: Protect eyes from debris during repairs.

- Gloves: Ensure a firm grip while safeguarding hands.

- Dust Mask: Recommended when working with potentially harmful materials.

Equipping yourself with the right tools and safety gear will streamline the replacement process, ensuring a smoother and safer experience.

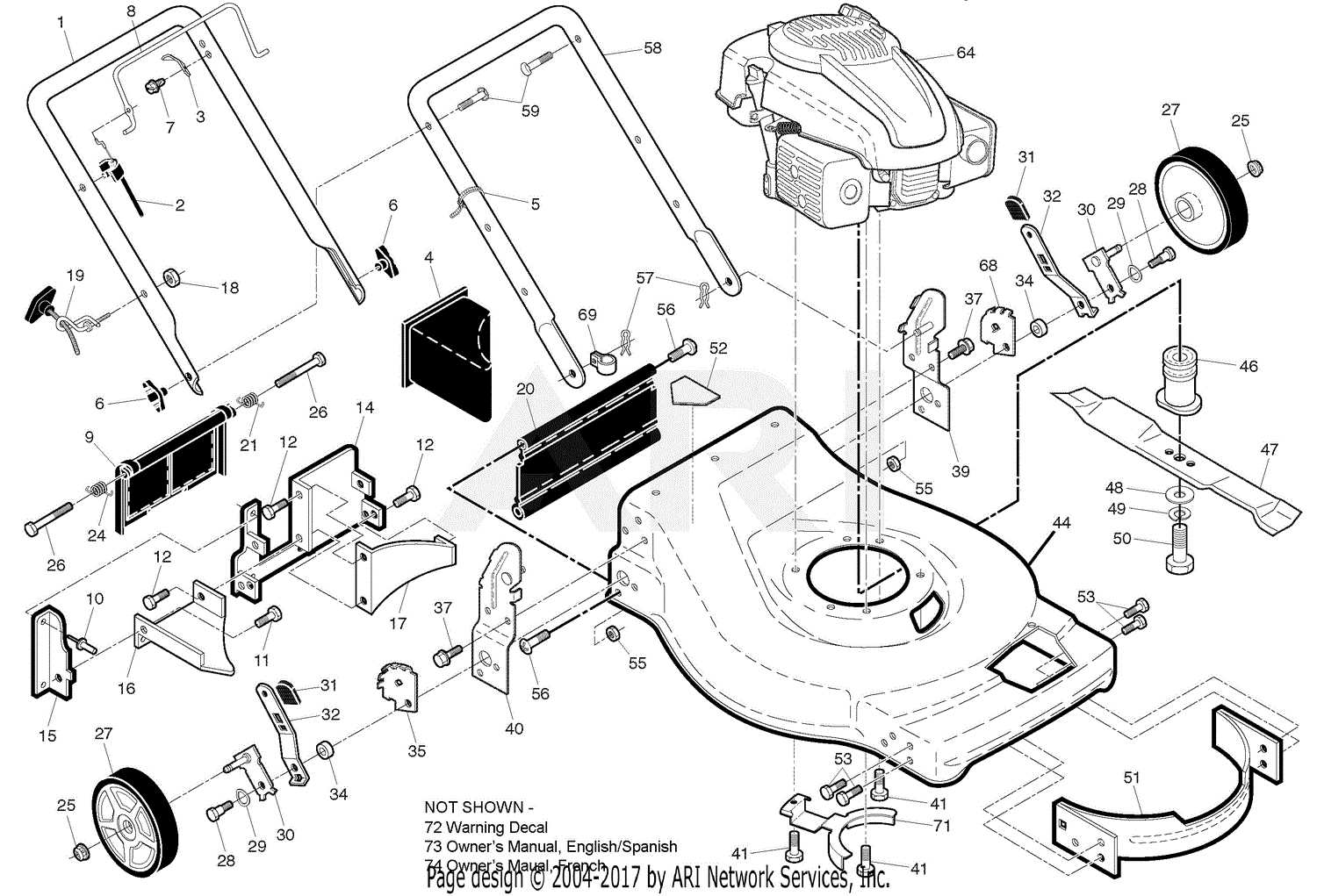

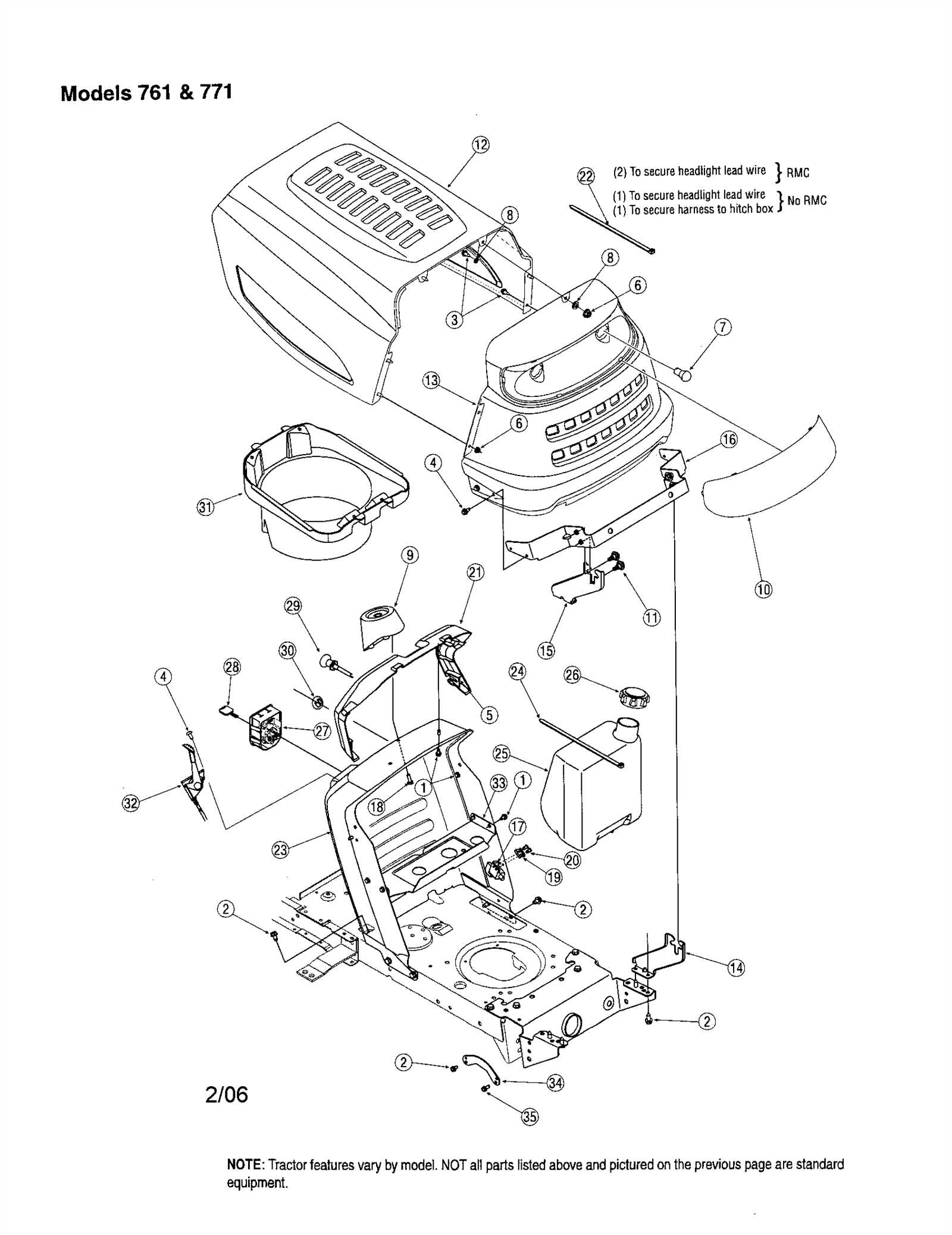

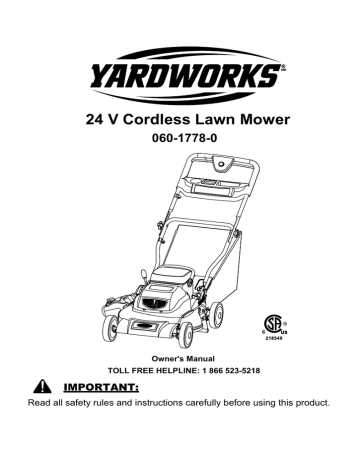

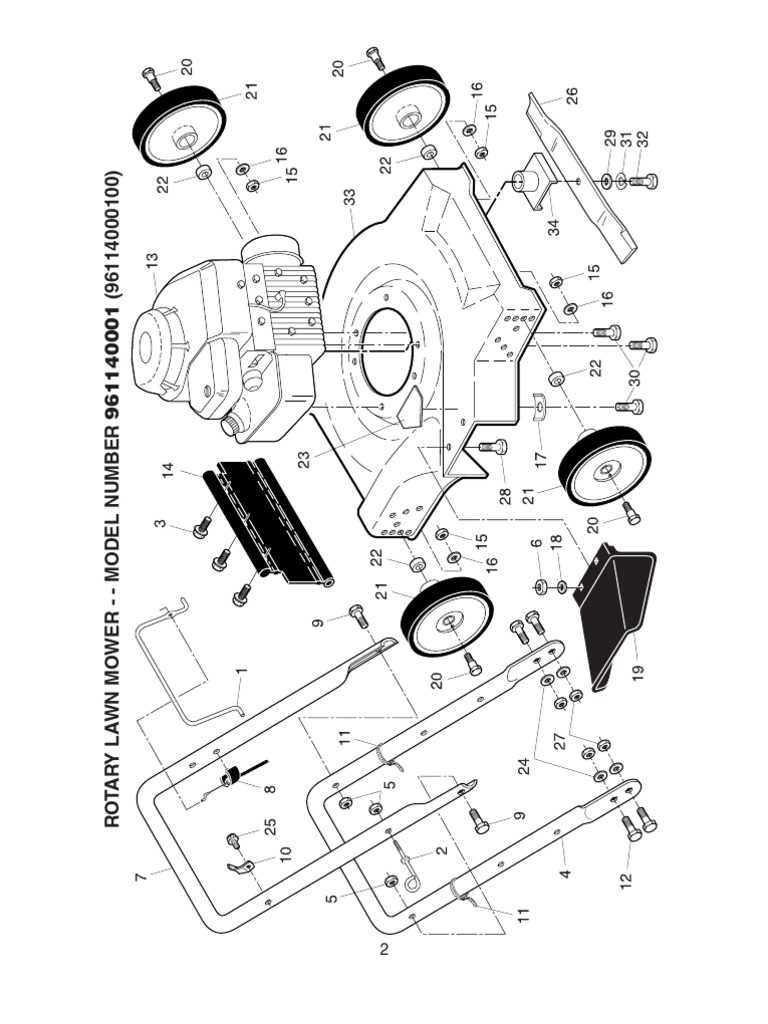

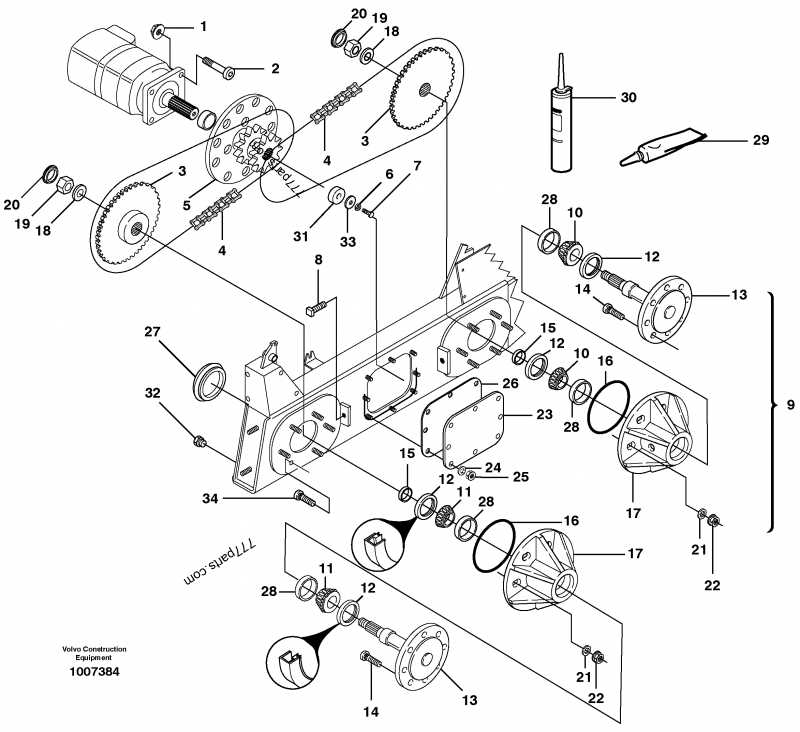

How to Read Diagrams Effectively

Understanding visual representations is crucial for successful assembly and maintenance. Whether you’re troubleshooting or assembling equipment, clear comprehension of these illustrations can significantly enhance your efficiency. Familiarity with common symbols and layouts is essential for decoding information accurately.

Familiarize Yourself with Symbols

Every visual representation employs specific icons to convey various components and functions. Take time to learn what each symbol signifies. This knowledge will empower you to interpret the content with greater ease, reducing confusion and errors.

Follow Logical Sequences

Diagrams typically follow a structured flow, guiding you through connections and relationships. Pay attention to the order in which elements are presented. This approach will help you grasp the overall structure and facilitate a smoother understanding of how everything fits together.

Common Issues with Mower Parts

Understanding the frequent challenges associated with machine components can significantly enhance performance and longevity. Identifying and addressing these concerns early on is crucial for efficient operation.

- Wear and Tear: Over time, various elements may degrade due to regular usage, leading to decreased functionality.

- Clogs: Debris accumulation can hinder smooth operation, causing interruptions during use.

- Misalignment: Improper positioning of components can result in ineffective operation and potential damage.

- Corrosion: Exposure to moisture can lead to rusting, affecting the integrity of metal parts.

- Electrical Issues: Faulty connections or damaged wiring may disrupt power flow, impairing functionality.

Addressing these common challenges proactively can lead to more reliable performance and reduce the need for extensive repairs.

Steps for Safe Disassembly

Disassembling equipment requires careful planning and adherence to safety protocols. Following the correct procedures can prevent accidents and ensure that all components are handled properly during the process. Understanding the necessary steps is essential for a smooth and safe disassembly experience.

Preparation and Safety Gear

Before starting, ensure you have the appropriate tools and protective equipment. Safety goggles and gloves are essential to protect against debris and sharp edges. Additionally, review the manual for specific instructions related to the equipment, as this can provide valuable insights into potential hazards.

Systematic Approach

Begin the disassembly by clearly marking each component as you remove it. This practice not only aids in reassembly but also minimizes the risk of losing crucial parts. Take your time and avoid rushing through the process; meticulousness is key to maintaining safety and integrity throughout the disassembly.

Comparing Original vs. Aftermarket Parts

When considering replacement components for your equipment, it’s crucial to evaluate the differences between genuine and third-party options. Each category offers distinct advantages and potential drawbacks, which can significantly impact performance and longevity.

Original components are typically produced by the manufacturer, ensuring compatibility and reliability. These pieces are designed specifically for your device, providing the following benefits:

- Guaranteed fit and function

- High-quality materials

- Manufacturer warranty support

On the other hand, aftermarket components can offer a more cost-effective solution. While these alternatives may vary in quality, they often appeal to consumers looking for budget-friendly options. Some key considerations include:

- Potential savings on purchase price

- Variety of options available

- Possibility of varying quality and durability

Ultimately, the choice between original and alternative components depends on your specific needs and budget. Weighing the pros and cons can lead to a more informed decision that suits your equipment requirements.

Where to Find Replacement Components

Locating the right components for your equipment is essential for maintaining its performance and longevity. Fortunately, there are numerous sources available for acquiring these essential items, ensuring that your device remains in optimal condition.

Online Retailers

- Specialty websites that focus on outdoor equipment often provide a wide range of replacement options.

- Major e-commerce platforms typically have sections dedicated to replacement items, offering competitive pricing and customer reviews.

- Manufacturer websites may also list authorized dealers and online shops where components can be purchased directly.

Local Stores and Service Centers

- Local hardware stores often carry a selection of commonly needed items.

- Authorized service centers can be a valuable resource for obtaining specific components and may offer installation services.

- Salvage yards or thrift shops occasionally stock used items that can serve as affordable alternatives.

Understanding Warranty and Returns

When purchasing outdoor equipment, it’s essential to be aware of the policies regarding protection and product exchanges. This section highlights key aspects that consumers should consider to ensure they make informed decisions and receive the appropriate support if issues arise.

Warranty Coverage: Generally, warranties serve as a promise from the manufacturer to repair or replace defective items within a specified time frame. It’s crucial to read the details carefully, as coverage can vary significantly between products.

Return Policies: Understanding the terms for returning items is vital for consumer satisfaction. Retailers typically have specific guidelines on how long customers have to initiate a return and under what conditions refunds or exchanges are granted.

Documentation: Keeping the original receipt and any warranty information is important. These documents are often required when filing claims or returning products, ensuring a smoother process for consumers.

Seasonal Maintenance for Longevity

Regular upkeep is essential for extending the lifespan of any outdoor machinery. By implementing a routine schedule that aligns with the changing seasons, users can ensure optimal performance and prevent potential issues before they arise. This proactive approach not only enhances efficiency but also saves time and money in the long run.

Spring Preparations

As temperatures rise, it’s crucial to inspect the equipment for any wear and tear. Cleaning the exterior and checking fluid levels are foundational steps. Additionally, sharpen blades to guarantee a clean cut, which promotes healthy growth in the surrounding area.

Autumn Adjustments

With the arrival of cooler months, it’s time to prepare for storage. Draining fuel and cleaning components helps prevent corrosion. A thorough inspection allows for timely repairs, ensuring that the machinery is ready for use when the season changes again.

FAQs About Lawn Mower Parts

This section addresses common inquiries related to the components of grass-cutting machines. Understanding these elements can enhance your maintenance and repair efforts, ensuring optimal performance.

1. What should I do if a component breaks? It’s advisable to consult the manual for your specific model. Often, replacement parts can be ordered directly from manufacturers or authorized dealers.

2. How can I identify the right component for my machine? Look for the model number and reference it in the user manual. This information will guide you to the correct specifications and replacements.

3. Are there universal components available? While some items are designed to fit various models, it’s best to use parts that are specifically engineered for your machine to ensure compatibility and safety.

4. How often should I replace components? Regular maintenance checks can help determine wear and tear. Generally, it’s a good practice to replace items that show significant signs of damage or decreased functionality.

5. Can I perform repairs myself? Many repairs can be undertaken by the user, provided they have the necessary tools and knowledge. However, for complex issues, seeking professional assistance is recommended.