Understanding the layout and structure of specialized equipment is crucial for proper maintenance and efficient operation. Each element within these devices plays a key role in ensuring smooth and reliable functionality, which can greatly affect performance over time. By knowing how different elements interact and work together, users can better address potential issues and ensure longevity.

The arrangement of various operational elements is designed to simplify processes and make adjustments easier. Having a clear view of how the components are organized helps technicians and operators identify key areas for optimization, ultimately ensuring that maintenance is streamlined and repairs are straightforward.

Regular inspections and knowledge of component positioning also aid in minimizing downtime. With a deeper understanding of how everything fits together, handling the equipment becomes much more efficient and reduces the likelihood of unexpected failures.

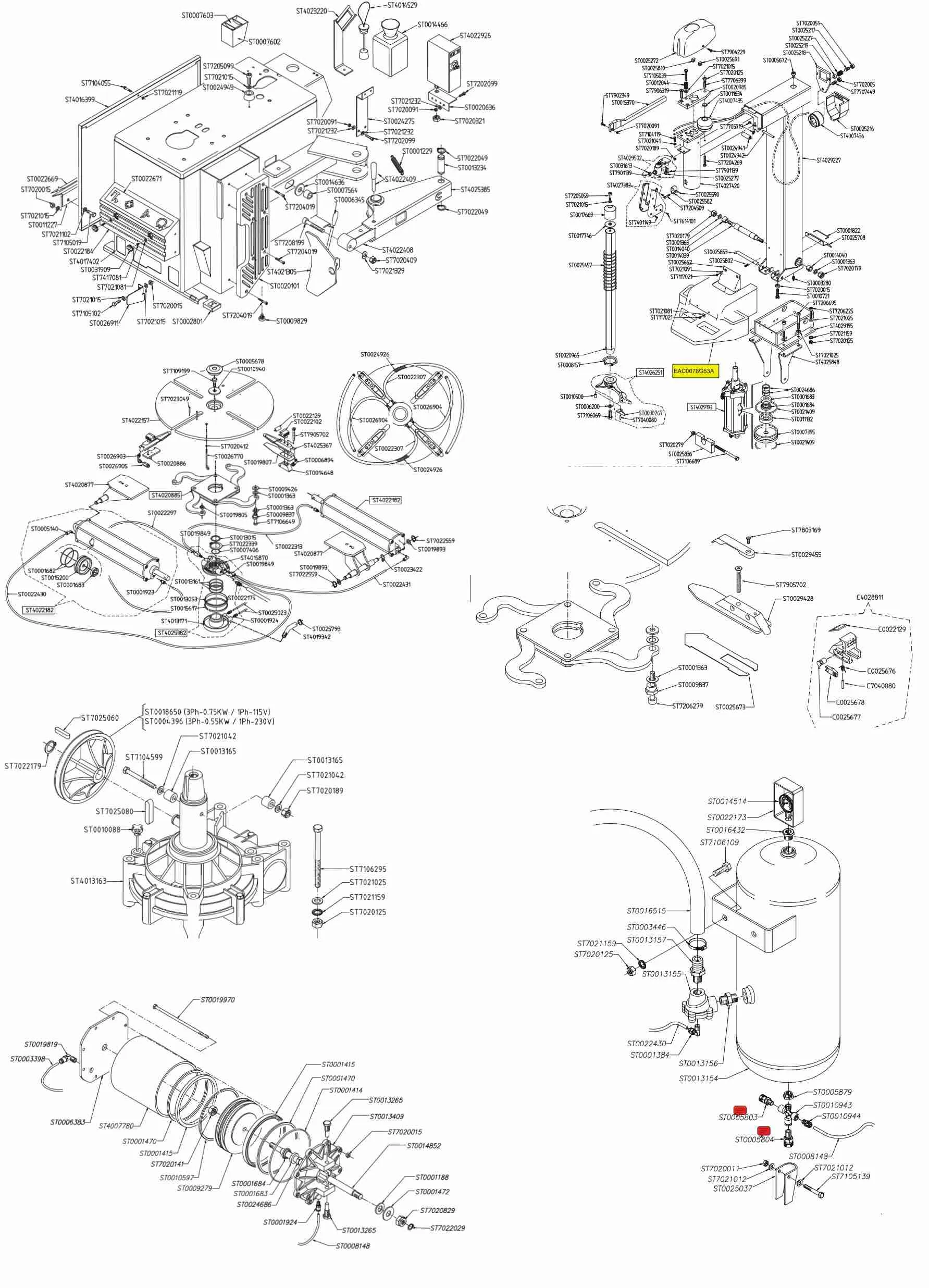

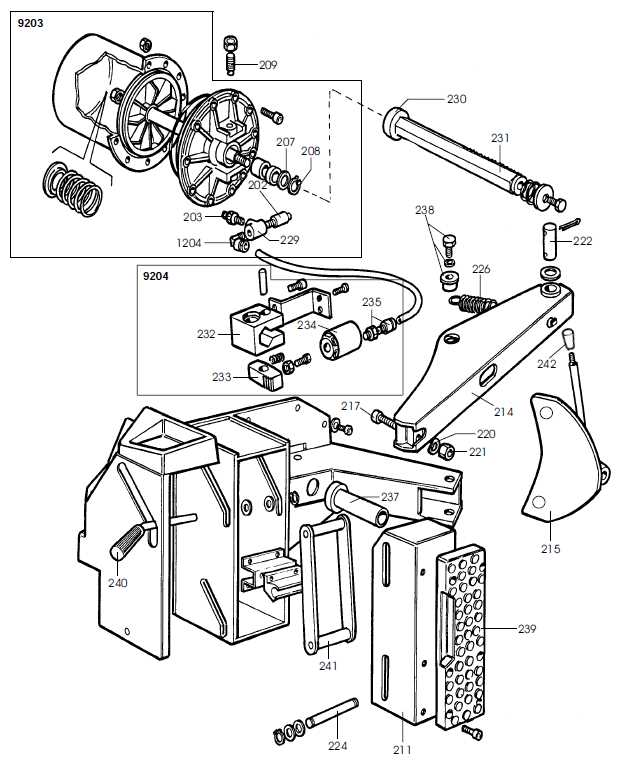

Corghi Tire Machine Components Overview

Understanding the different elements that make up a tire changing system is crucial for efficient use. Each component plays a specific role, contributing to the overall performance and reliability of the equipment. This section will provide a detailed breakdown of the key parts involved in the process, helping you become familiar with the function and maintenance of this essential equipment.

Main Structural Elements

- Base Frame: The foundation that supports the entire assembly, providing stability during operation.

- Mounting Arm: Designed to hold and guide the tools needed for mounting and dismounting wheels.

- Foot Pedals: Controls used to engage and disengage various functions of the equipment, ensuring ease of operation.

Supportive Mechanisms

Main Structural Parts of Corghi Tire Machines

The core components of equipment designed for handling vehicle wheels are built with precision and functionality in mind. These elements ensure the overall structure is stable and capable of withstanding the demands of frequent use, offering seamless performance in various operational settings.

Key Functional Elements

- Frame: A sturdy base that provides support and balance to the entire structure, maintaining stability during operations.

- Mounting Arm: An adjustable arm that allows the operator to position and secure the wheel with precision.

- Bead Breaker: This element applies controlled pressure to separate the tire from the rim, ensuring efficiency in the process.

Support and Safety Mechanisms

- Clamps: Designed to grip and hold the wheel securely, preventing movement during procedures.

- Pedals: Foot-operated controls that offer hands-free operation, enhancing user safety and

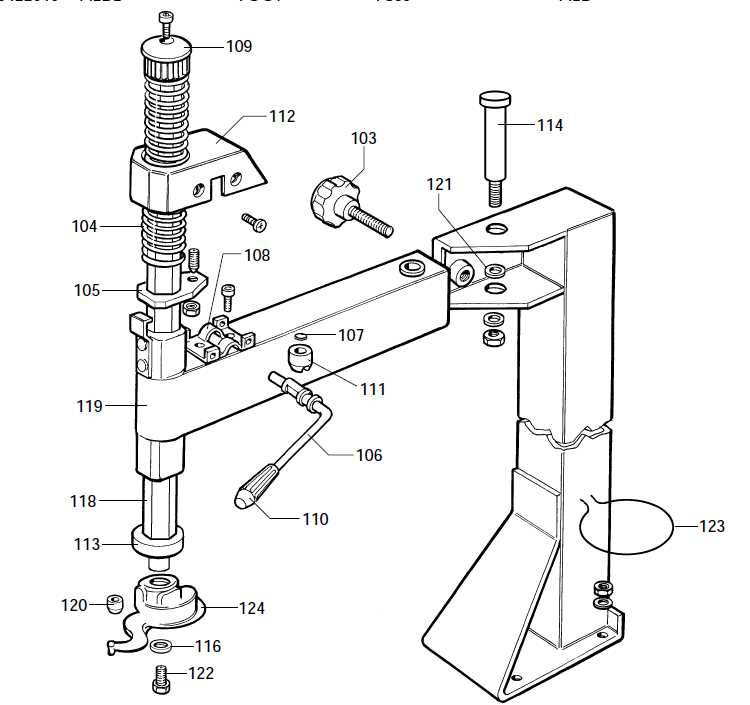

Detailed Look at the Mounting Arm Mechanism

The mounting arm is a crucial element in handling various operations, ensuring that the system can grip and position items efficiently. This section will provide an in-depth view of how the arm functions and what makes it an essential part of the overall mechanism.

Core Functionality of the Arm

The arm operates through a combination of precise movements, driven by hydraulic or pneumatic power, allowing for accurate placement and manipulation. Its ability to maintain stability and control during operation is key to achieving the desired results efficiently.

Adjustment and Flexibility

One of the main advantages of this mechanism is its flexibility. The arm can be adjusted to accommodate various sizes and shapes, making it adaptable to different tasks. This flexibility ensures versatility while maintaining optimal performance.

Key Features of the Bead Breaker System

The bead breaker system is designed to enhance efficiency and precision in separating the rubber edge from the metal surface. Its functionality is critical in ensuring minimal damage during the process, while delivering smooth and consistent performance. This section explores the key characteristics that make the system reliable and user-friendly.

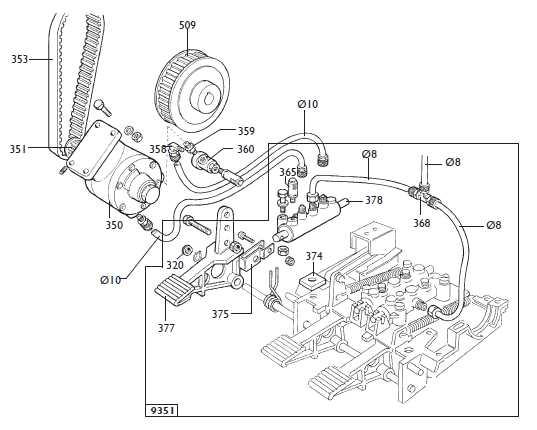

Feature Description High Force Application Allows controlled power to break the seal between the components without causing excessive stress. Adjustable Arm Provides flexibility in adapting to different sizes and angles, ensuring proper fit for various setups. Ergonomic Design Improves user comfort by offering easy control and reducing strain during operation. Air Pressure Control Components Explained

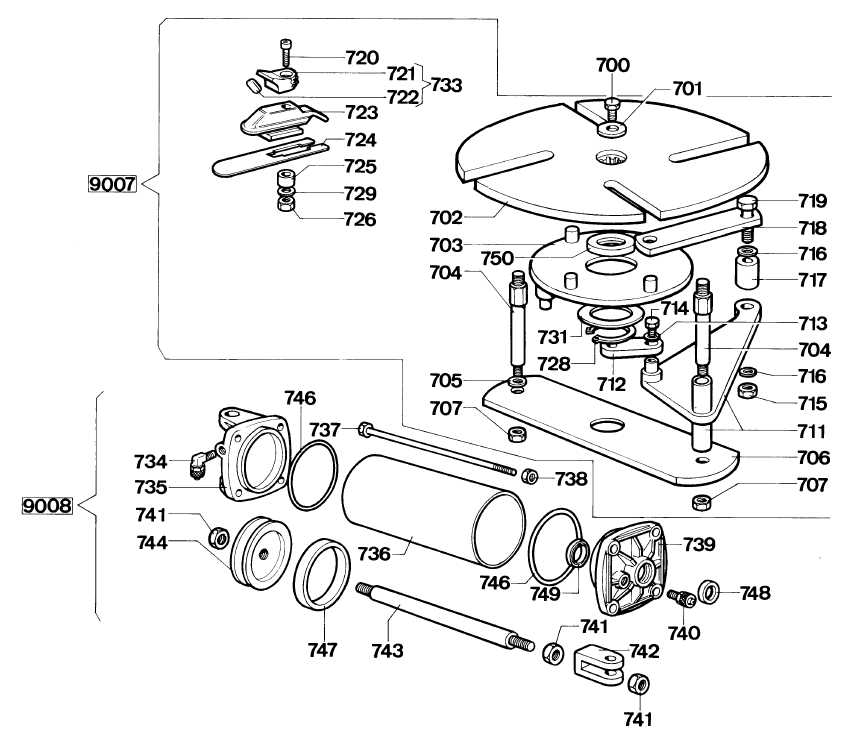

Air pressure regulation is essential for the smooth operation of various mechanical systems. The control elements responsible for maintaining stable pressure ensure that air flow is managed effectively, preventing fluctuations that could disrupt performance.

Key components in these systems include regulators, valves, and sensors. These parts work together to monitor and adjust air flow, ensuring that pressure levels remain within the desired range. Proper functioning of these elements is crucial to maintaining consistency and avoiding any operational issues caused by overpressure or leaks.

Regulators help maintain a steady output, while valves manage the direction and intensity of air flow. Sensors play a critical role in providing real-time data, allowing for quick adjustments to ensure safety and

Understanding the Tire Clamping System

The clamping mechanism is crucial in ensuring the secure positioning of the wheel during servicing. It is designed to hold the rim firmly while various operations are performed, such as mounting or dismounting the rubber. A well-functioning clamping system enhances efficiency and accuracy in the process.

Components of the Clamping Mechanism typically include several essential elements that work together to achieve a tight grip. These components can vary in design but generally involve adjustable arms or jaws that adapt to different rim sizes. The operation of these parts is often assisted by pneumatic or hydraulic systems, providing the necessary force for secure engagement.

Proper Maintenance of the clamping system is vital for optimal performance. Regular inspections and timely replacements of worn-out components can prevent potential issues and ensure smooth operations. Understanding how each part contributes to the overall functionality helps technicians perform effective maintenance and troubleshooting when needed.

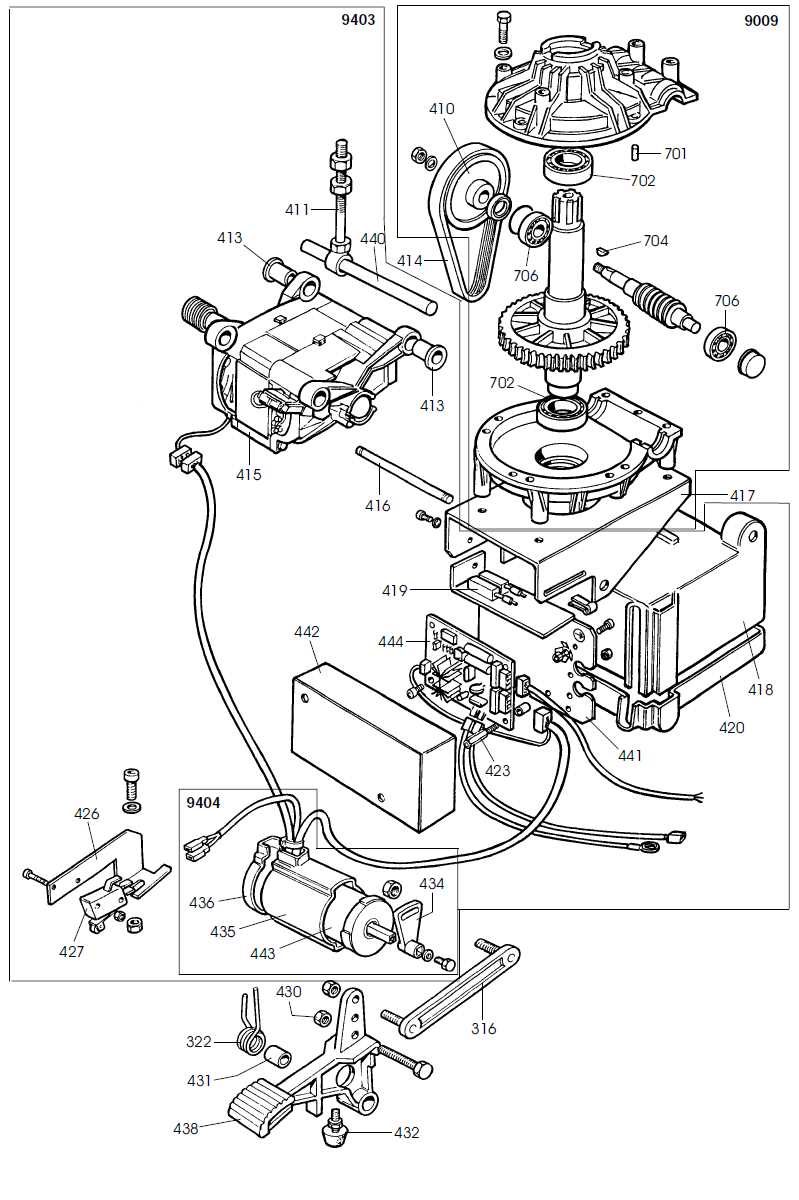

Electrical System Layout in Corghi Machines

The electrical configuration within these types of equipment plays a crucial role in their overall functionality and efficiency. A well-organized arrangement of electrical components ensures that operations are smooth and reliable, allowing users to perform their tasks effectively.

Key Components of the Electrical System

- Control Units

- Power Supply Units

- Wiring Harnesses

- Safety Switches

- Signal Relays

Importance of Proper Layout

Having a systematic electrical setup enhances both safety and performance. It minimizes the risk of malfunctions and optimizes the workflow. Regular maintenance of these components is essential to ensure longevity and reliability in operations.

Safety Mechanisms and Their Importance

Ensuring the safety of equipment is crucial in any operational environment. The implementation of reliable protective features can significantly reduce the risk of accidents and enhance overall performance. These mechanisms are designed to prevent malfunctions and protect users from potential hazards.

There are several key benefits of incorporating safety features into equipment:

- Accident Prevention: Effective safeguards minimize the likelihood of injuries.

- Operational Reliability: Well-designed protective systems ensure that the equipment functions smoothly.

- Regulatory Compliance: Adhering to safety standards helps avoid legal issues and promotes workplace safety.

- User Confidence: Knowing that safety measures are in place increases operator trust in the equipment.

In conclusion, prioritizing protective features not only safeguards users but also contributes to the efficiency and longevity of equipment.

Lubrication and Maintenance Parts Overview

Proper upkeep is essential for optimal performance and longevity of equipment. Regular maintenance ensures that all components function smoothly, reducing wear and tear while enhancing efficiency. This section provides insights into the key elements involved in the upkeep process, focusing on lubrication and essential maintenance features.

Key Components for Lubrication

- Grease fittings: Critical for providing lubricant to moving parts.

- Oil reservoirs: Essential for storing lubricants and ensuring an adequate supply.

- Seals: Important for preventing leaks and maintaining proper lubrication levels.

Maintenance Practices

- Regularly check and refill lubrication levels as needed.

- Inspect seals for any signs of wear or damage.

- Ensure grease fittings are accessible for easy maintenance.

- Follow a scheduled maintenance routine to enhance equipment lifespan.

Maintaining these aspects not only improves functionality but also minimizes the risk of unexpected breakdowns, ensuring that operations run smoothly and efficiently.

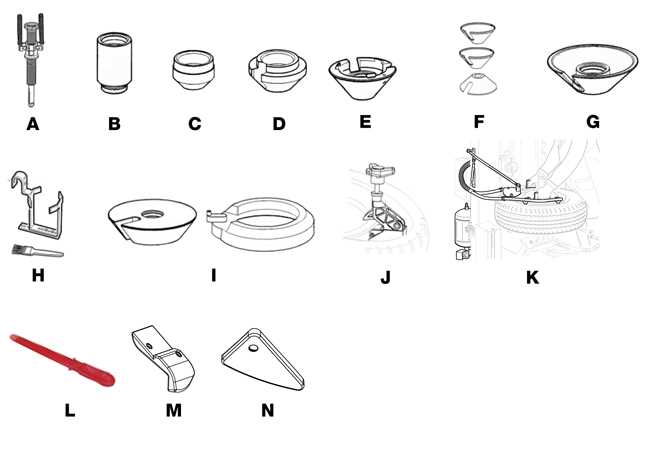

Optional Attachments and Accessories Guide

This section offers an overview of supplementary tools and enhancements designed to optimize functionality and efficiency. Understanding the available options can significantly improve performance and adaptability to various tasks.

Enhancements for Improved Efficiency

Supplementary tools can elevate the overall effectiveness of your setup. Options such as specialized adapters and extensions allow for greater versatility, enabling the user to handle a wider range of tasks with ease. Implementing these enhancements can result in time savings and improved workflow.

Maintenance and Safety Tools

Integrating additional safety and maintenance accessories is crucial for ensuring longevity and reliability. Tools such as protective covers and calibration gauges can help maintain optimal performance while safeguarding against potential hazards. Prioritizing these accessories enhances both safety and operational stability.

Troubleshooting Common Part Failures

When dealing with mechanical equipment, it’s not uncommon to encounter issues related to specific components. Identifying the symptoms and understanding potential causes can significantly expedite the repair process. This section aims to provide insights into common failures, their indications, and suggested solutions to restore optimal functionality.

Failure Type Symptoms Possible Solutions Worn Components Unusual noises, vibrations, decreased efficiency Inspect and replace affected elements Fluid Leaks Puddles beneath the equipment, low fluid levels Check seals and connections; tighten or replace as necessary Electrical Issues Inconsistent performance, error messages, or no power Inspect wiring and connections; replace faulty parts Calibration Errors Inaccurate readings, inconsistent results Recalibrate according to the manufacturer’s guidelines Upgrade Kits for Corghi Tire Machines

Enhancing the performance of vehicle servicing equipment is essential for maintaining efficiency in any workshop. Upgrade kits play a crucial role in this process, offering improved functionality and advanced features. These kits can significantly boost the capabilities of existing systems, allowing for better handling of various tasks and ensuring a smoother workflow.

Benefits of Upgrade Kits

Investing in these enhancement packages provides numerous advantages. First, they can extend the lifespan of your equipment by introducing high-quality components that are designed to withstand rigorous use. Additionally, upgrades can lead to faster operations, reducing waiting times for customers and increasing overall productivity.

Choosing the Right Upgrade Kit

When selecting an enhancement package, it is essential to consider compatibility with your existing setup. Assessing the specific needs of your workshop and understanding the capabilities of various options will help ensure that you make an informed decision. By selecting the appropriate upgrades, you can maximize performance and meet the demands of a dynamic automotive service environment.

Replacement Parts Availability and Options

When it comes to ensuring the longevity and efficiency of equipment, having access to suitable replacement components is crucial. Users often seek reliable alternatives to keep their systems running smoothly. This section delves into the various options available for securing these essential items, highlighting sources and considerations for selection.

Types of Alternatives

There are multiple avenues to explore when looking for compatible components. Original equipment manufacturers typically offer authentic replacements, but third-party suppliers can also provide cost-effective solutions without sacrificing quality. Understanding the differences between these choices can guide users in making informed decisions based on their specific needs.

Where to Find Components

Finding the right replacements can be done through various channels. Authorized dealers, online retailers, and local repair shops often stock a range of items suited for different models. It is advisable to compare prices and availability across these platforms to secure the best deals.

Source Type of Components Price Range Authorized Dealers Genuine Items Higher Online Retailers Aftermarket Options Varied Local Repair Shops Refurbished Items Moderate