Understanding the various elements of a cooling device is crucial for maintaining its efficiency and longevity. Each section plays a vital role in ensuring optimal functionality and performance. By familiarizing yourself with the layout and interaction of these components, you can enhance the overall operation of the system.

Identification of individual components aids in troubleshooting and repairs. A clear grasp of how each element fits within the larger assembly allows for quicker diagnosis of issues. This knowledge is invaluable for anyone involved in the upkeep of refrigeration systems.

Moreover, recognizing the relationships between different sections can facilitate more effective maintenance practices. Regular inspection and understanding of these connections can prevent minor issues from escalating into major problems, ensuring consistent performance over time. Effective management of these aspects will lead to improved reliability and efficiency.

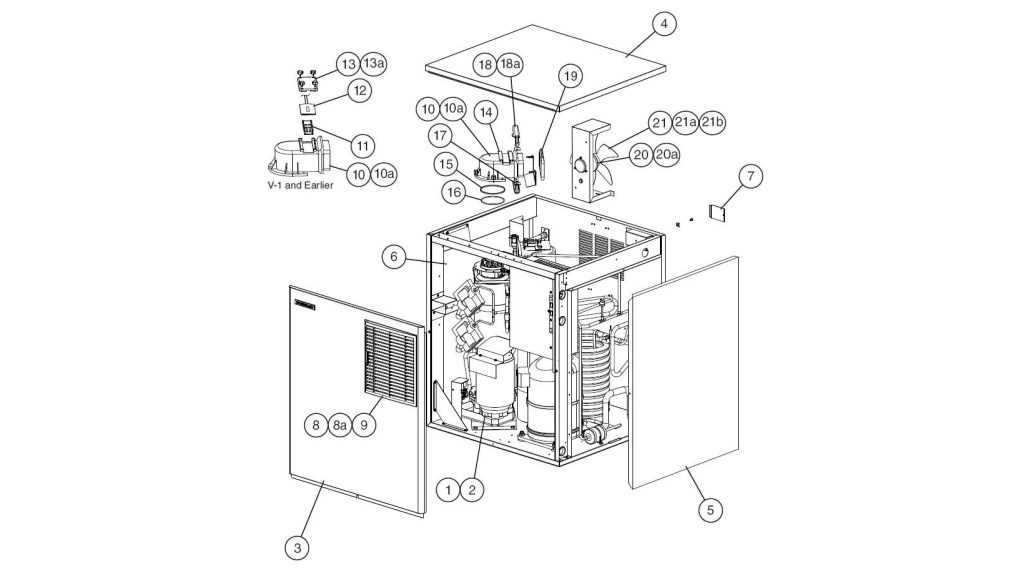

Hoshizaki Ice Machine Components Overview

This section provides an insightful overview of the various elements that contribute to the functionality and efficiency of an advanced refrigeration system. Understanding these components is crucial for effective maintenance and optimal performance, ensuring the device operates smoothly and reliably.

Key Elements

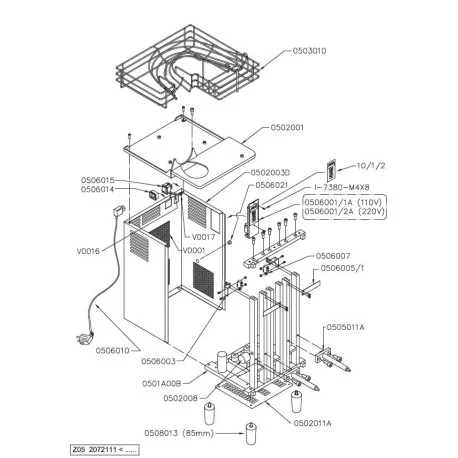

The system comprises several key components that play a vital role in its operation. Among them are the refrigeration unit, which cools the internal environment, and the water supply mechanism, essential for generating the final product. Additionally, the control panel allows for user interaction and regulation of settings, making it easier to monitor and adjust the unit’s performance.

Importance of Maintenance

Regular maintenance of these critical elements is essential to prolonging the life of the device and preventing potential issues. Routine checks on the cooling system, water lines, and electrical components help identify wear and tear, ensuring the unit operates at peak efficiency. Proper upkeep not only enhances performance but also reduces the likelihood of costly repairs.

Understanding Ice Machine Functionality

The operation of refrigeration units designed for producing frozen water is intricate yet fascinating. These devices rely on various components working in harmony to create and deliver solidified water in a consistent manner. A thorough comprehension of how these systems function can enhance maintenance efforts and extend their lifespan.

At the heart of these systems lies a cycle that involves multiple stages, each playing a crucial role in the overall process. From water intake to the final freezing stage, understanding each phase helps in troubleshooting and optimizing performance.

| Stage | Description |

|---|---|

| Water Intake | In this stage, the unit draws water from a reservoir or direct supply, preparing it for freezing. |

| Freezing | Water is subjected to low temperatures, causing it to solidify into the desired form. |

| Harvesting | Once frozen, the solidified water is released from the freezing surface, making it available for use. |

| Storage | The final product is kept in a designated area, maintaining the necessary temperature until needed. |

Common Issues with Ice Machines

In the world of refrigeration, there are several challenges that users frequently encounter. Understanding these common problems can help in diagnosing issues and ensuring optimal performance. From mechanical failures to environmental factors, various elements can impact the functionality of these cooling units.

Frequent Mechanical Failures

Mechanical components are prone to wear and tear over time. Issues such as compressor failure or condenser blockages can lead to insufficient cooling. Regular maintenance and inspections can help identify these issues early, preventing costly repairs.

Environmental and Operational Factors

External conditions also play a significant role in performance. High ambient temperatures can affect the unit’s efficiency, while inadequate ventilation may lead to overheating. Ensuring proper airflow and optimal installation conditions is crucial for longevity and effectiveness.

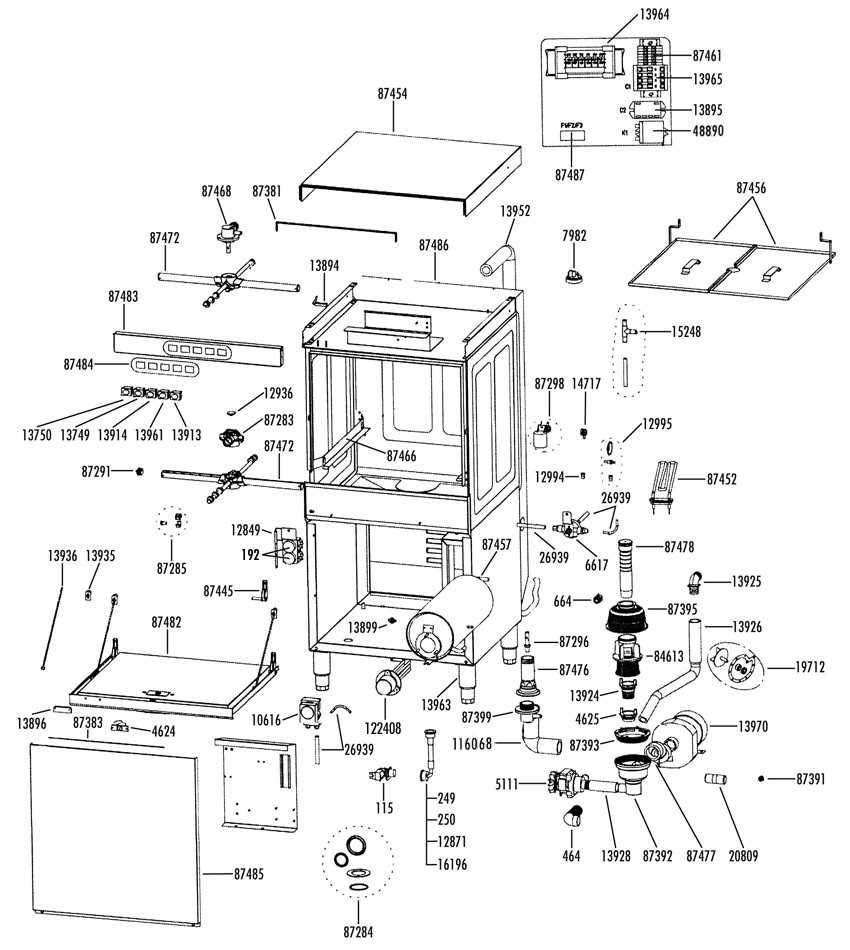

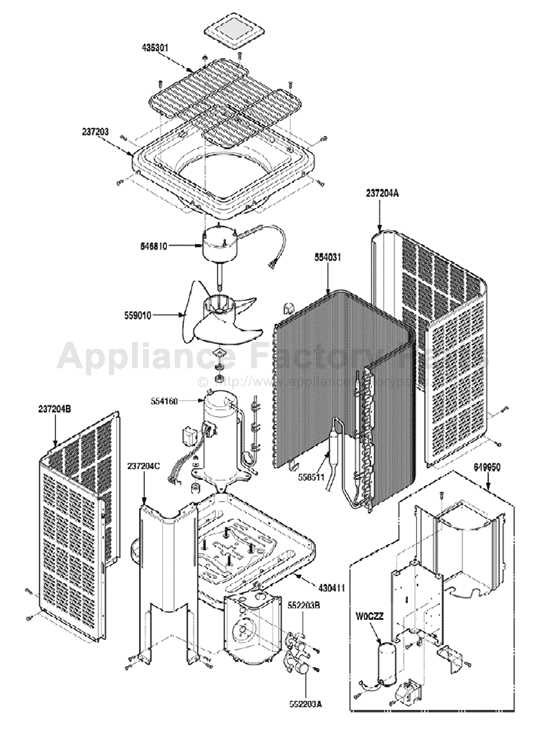

Replacement Parts for Hoshizaki Models

Maintaining optimal performance in refrigeration units often requires the timely replacement of various components. These essential elements play a crucial role in ensuring that the system operates efficiently and effectively. Understanding the various components available can help users make informed decisions about their upkeep and functionality.

Commonly replaced components include condenser coils, compressors, and control boards. Each of these elements contributes significantly to the overall performance and longevity of the unit. When selecting replacements, it is vital to choose high-quality options that are compatible with specific models to ensure proper functionality.

Additionally, regular maintenance checks can identify wear and tear before it becomes a major issue. Keeping a supply of essential components on hand can minimize downtime and enhance the reliability of your refrigeration system. Users should consult the manufacturer’s recommendations for the best practices regarding replacements and maintenance to extend the lifespan of their units.

Maintenance Tips for Ice Machines

Proper upkeep of your refrigeration equipment is essential for optimal performance and longevity. Regular maintenance not only enhances efficiency but also prevents costly breakdowns. Implementing a few straightforward practices can ensure your equipment operates smoothly over time.

Regular Cleaning

Routine sanitation of your unit is crucial. Residue buildup can lead to poor functionality and flavor contamination. Use a suitable cleaner to eliminate any deposits, ensuring all components are thoroughly rinsed and dried after cleaning.

Inspect Components Frequently

Routine inspections are vital to identify potential issues before they escalate. Check for signs of wear in critical components such as fans and compressors. Addressing minor repairs promptly can save you from more significant expenses down the line.

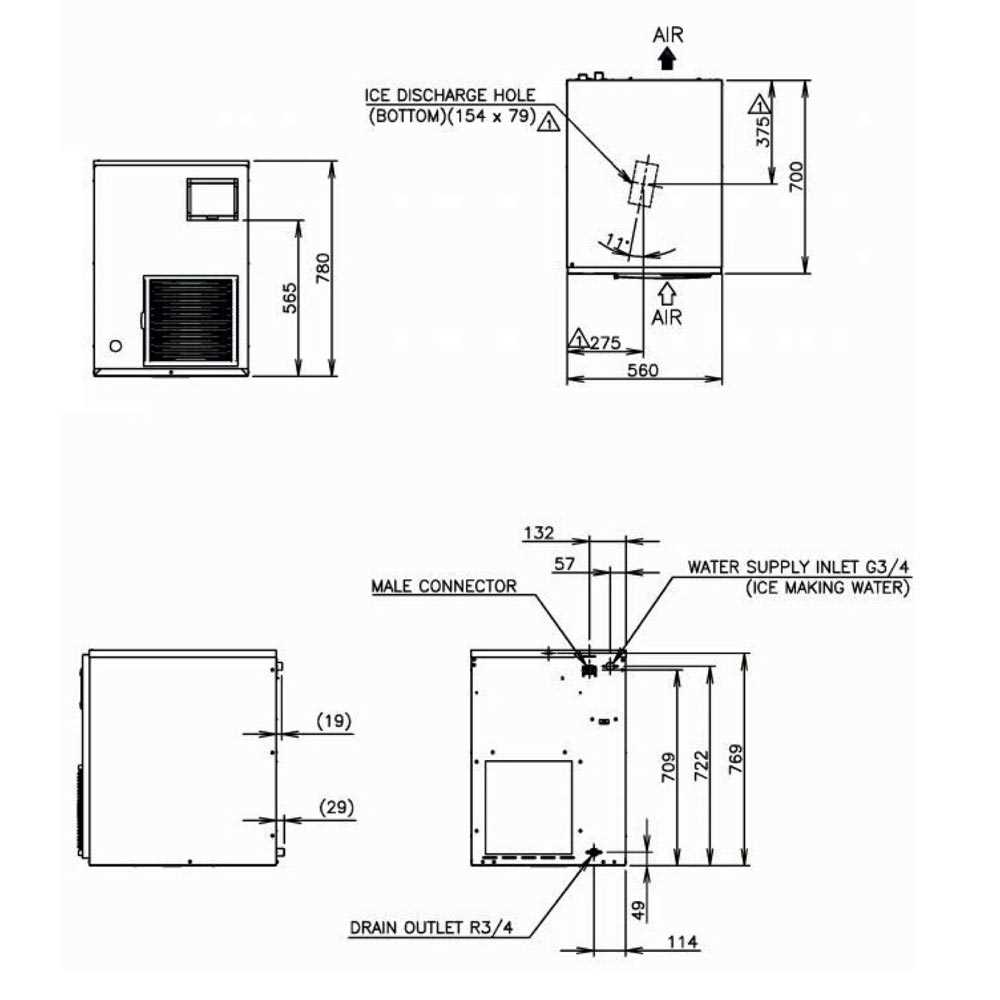

Identifying Hoshizaki Ice Machine Models

Recognizing different models of commercial refrigeration equipment is essential for effective maintenance and operation. Each model comes with distinct specifications and features that cater to various business needs. Understanding these variations allows users to select the most suitable unit for their requirements.

To accurately identify specific models, users should examine the manufacturer’s labels typically located on the unit’s exterior. These labels often include crucial information such as the model number, serial number, and production details. Familiarity with this information streamlines the process of sourcing replacement components and technical support.

Additionally, consulting the user manual or the manufacturer’s website can provide in-depth insights into the equipment’s specifications. Various resources, such as online forums and customer support, can also assist in understanding the unique aspects of each model. This knowledge is vital for ensuring optimal functionality and longevity of the equipment.

Importance of Proper Ice Production

Ensuring high-quality frozen water production is essential for various industries, including hospitality and food service. Reliable production not only meets the demands of customers but also enhances operational efficiency and safety. Understanding the significance of optimal creation techniques helps in maintaining the desired standards and consistency.

Quality Output: Adequate production techniques guarantee that the resulting frozen elements are clean and suitable for consumption. This is vital for maintaining health standards and preventing contamination.

Operational Efficiency: Effective production processes can significantly reduce downtime and maintenance costs. When the production system operates smoothly, it minimizes interruptions, allowing for uninterrupted service.

Customer Satisfaction: In industries where customer experience is paramount, the availability of properly produced frozen elements directly influences client satisfaction. Consistent quality and supply ensure that businesses can meet the expectations of their patrons.

Resource Management: Proper production methods lead to better resource utilization, including water and energy. Efficient practices can contribute to sustainability efforts by reducing waste and lowering energy consumption.

Safety Precautions When Servicing

Maintaining and servicing equipment requires careful attention to safety protocols. Adhering to these guidelines not only protects the technician but also ensures the longevity and efficient operation of the apparatus. Proper safety measures help prevent accidents and injuries during the servicing process.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) when performing maintenance tasks. This includes gloves, safety goggles, and sturdy footwear to minimize the risk of injury. Depending on the nature of the service, additional protective gear, such as face shields or respirators, may be necessary.

Lockout/Tagout Procedures

Implement lockout/tagout procedures to ensure that the equipment is properly shut down and cannot be accidentally restarted during servicing. This practice is crucial for preventing electrical shock or unintended operation while maintenance is being performed. Always verify that the equipment is de-energized before beginning any work.

Cleaning Techniques for Ice Machines

Maintaining optimal hygiene and functionality is essential for equipment that produces frozen products. Regular cleaning ensures the longevity of the unit and the quality of the output. Understanding effective techniques for cleaning is vital for operators to keep their appliances in top condition.

One effective approach involves utilizing a mixture of water and a specialized cleaning solution. This mixture can help break down mineral deposits and contaminants. It is important to follow the manufacturer’s guidelines for the proper dilution and application of cleaning agents.

Another method is to conduct routine checks on critical components, including water filters and storage areas, to prevent the buildup of bacteria. Regular maintenance can include rinsing surfaces with a sanitizer to eliminate any residual impurities.

| Cleaning Method | Description |

|---|---|

| Water and Cleaning Solution | Mix a specific solution to remove buildup and contaminants. |

| Regular Component Checks | Inspect filters and storage areas to prevent bacterial growth. |

| Surface Sanitization | Rinse surfaces with a sanitizer to maintain cleanliness. |

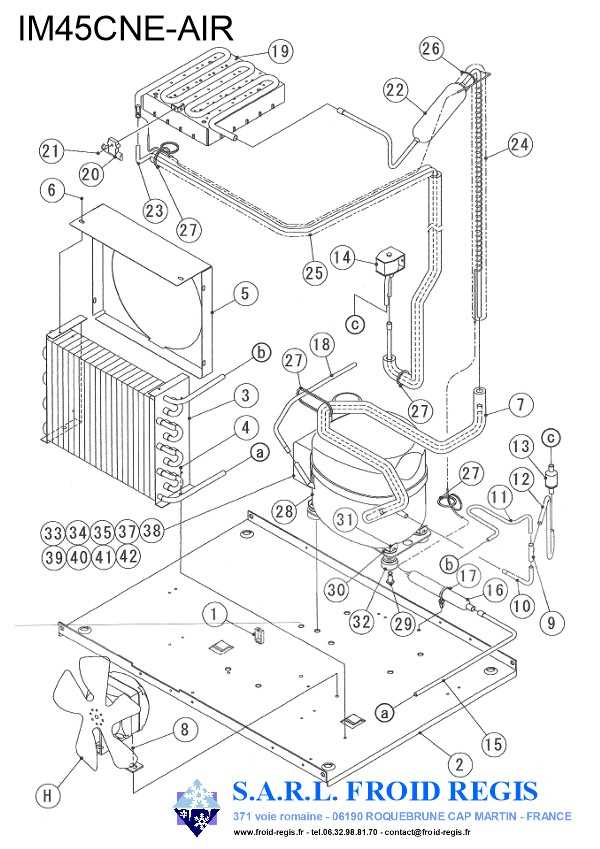

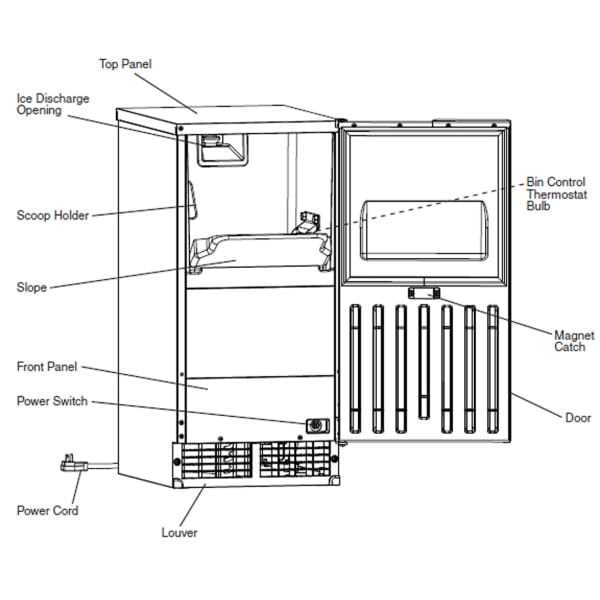

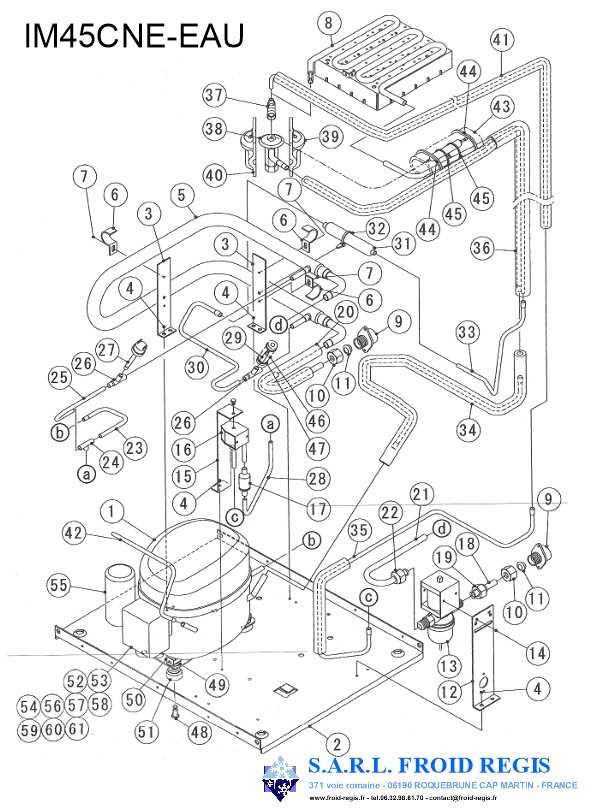

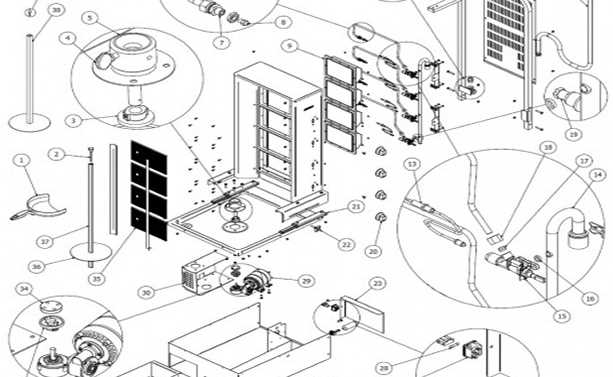

How to Read Parts Diagrams

Understanding component illustrations is essential for effective maintenance and repair tasks. These visual representations provide vital information about the various elements of a system, their arrangements, and their relationships. By familiarizing yourself with these graphics, you can enhance your troubleshooting skills and streamline your repair processes.

Here are some key points to consider when interpreting these illustrations:

- Familiarize Yourself with Symbols: Each component is represented by specific symbols. Learn what each symbol means to easily identify different parts.

- Pay Attention to Labels: Components often have labels indicating their names or functions. These labels can provide crucial context when analyzing the layout.

- Understand the Layout: Diagrams are organized in a way that reflects the physical arrangement of components. Grasping this layout helps in understanding how parts interact with one another.

- Refer to a Key or Legend: Many illustrations include a key or legend that explains the symbols and notations used. Consult this section for clarity.

- Follow the Flow: If applicable, observe the flow of processes represented in the illustration. This can aid in troubleshooting issues effectively.

By mastering these techniques, you can efficiently navigate through component illustrations and improve your maintenance strategies.

Ordering Parts for Ice Machines

When it comes to maintaining your equipment, sourcing components efficiently is crucial. Understanding how to navigate the ordering process can save time and ensure optimal functionality.

Here are some essential steps to consider:

- Identify the specific component needed.

- Gather model and serial numbers for accurate identification.

- Research reputable suppliers or manufacturers.

After identifying potential vendors, it’s important to:

- Compare prices and availability.

- Check customer reviews and ratings.

- Inquire about return policies and warranty options.

Once you select a supplier, follow these steps to complete your order:

- Confirm the correct component details.

- Provide necessary shipping information.

- Review payment options and place your order.

Finally, keep track of your orders and shipping confirmations to ensure timely delivery and address any issues promptly.

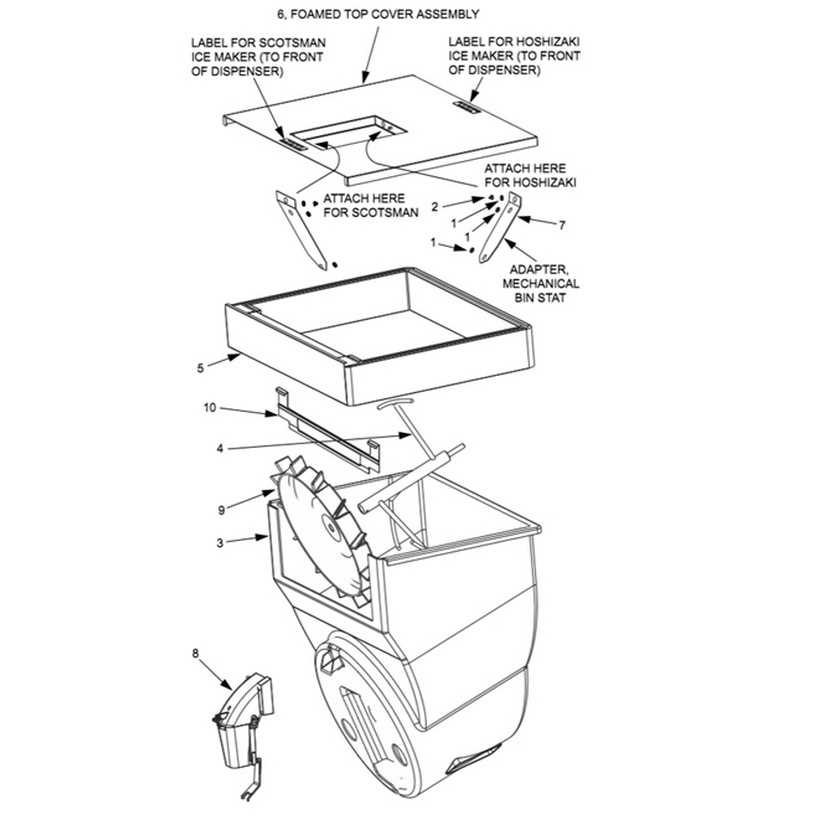

Exploring Ice Machine Accessories

In the realm of refrigeration technology, various components play a crucial role in enhancing functionality and efficiency. Understanding these elements can significantly impact performance and user experience. Each accessory contributes uniquely to the overall system, ensuring optimal operation and longevity.

Accessories often include storage bins, filtration systems, and dispensing units. Storage bins are designed to hold the frozen products, maintaining their quality and accessibility. Filtration systems improve water quality, reducing impurities that may affect the final output. Additionally, dispensing units facilitate easy access, allowing users to retrieve the product conveniently.

Investing in high-quality components is essential for maintaining performance. Regular maintenance and timely replacement of worn accessories can prevent costly repairs and enhance the efficiency of the entire system. Understanding the role of each accessory ensures that operators can make informed decisions for optimal functionality.

Enhancing Efficiency in Ice Production

Improving productivity in the creation of frozen products is crucial for businesses aiming to meet consumer demands while minimizing operational costs. Effective strategies can lead to significant gains in both output and energy conservation.

Key Strategies for Improvement

- Regular Maintenance: Ensuring that all equipment is well-maintained can prevent breakdowns and inefficiencies.

- Optimized Workflow: Streamlining processes helps in reducing unnecessary steps, leading to faster production cycles.

- Energy Management: Implementing energy-saving technologies can greatly reduce consumption while maintaining production quality.

- Training Staff: Well-trained personnel can operate equipment more efficiently and identify issues quickly.

Benefits of Enhanced Efficiency

- Increased production volume.

- Lower energy costs.

- Improved product quality.

- Higher customer satisfaction.

By focusing on these strategies, businesses can create a more effective environment for producing frozen products, ultimately leading to greater profitability and sustainability.