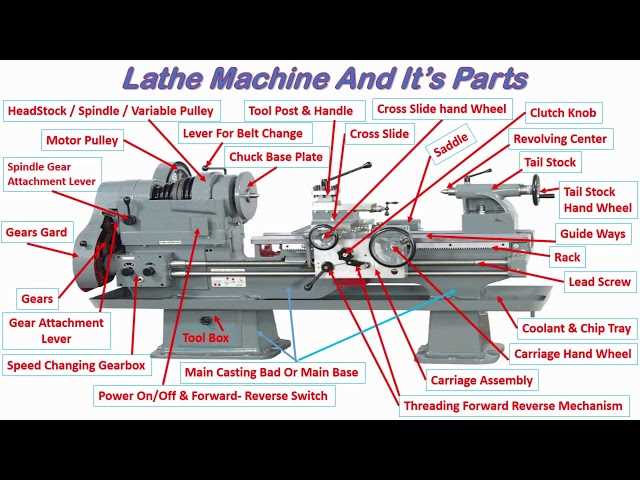

This section delves into the intricate elements that constitute a pivotal tool in various manufacturing processes. Each component plays a significant role in achieving precision and efficiency in transforming raw materials into finished products.

Familiarity with these elements enhances comprehension of their functions and interactions, providing valuable insights for both beginners and experienced operators. Recognizing the distinct characteristics and applications of each component fosters a deeper appreciation of their engineering and design.

As we explore the various components, we will highlight their importance and interrelation, offering a comprehensive overview that underscores their collective contribution to successful operations.

This section provides an introductory exploration into the fundamental concepts surrounding a specific type of equipment commonly used in manufacturing and fabrication processes. Understanding the essential components and their functionalities is vital for both beginners and experienced operators.

The following table outlines various elements associated with this type of tool, emphasizing their roles and significance in the overall operation.

| Component | Description |

|---|---|

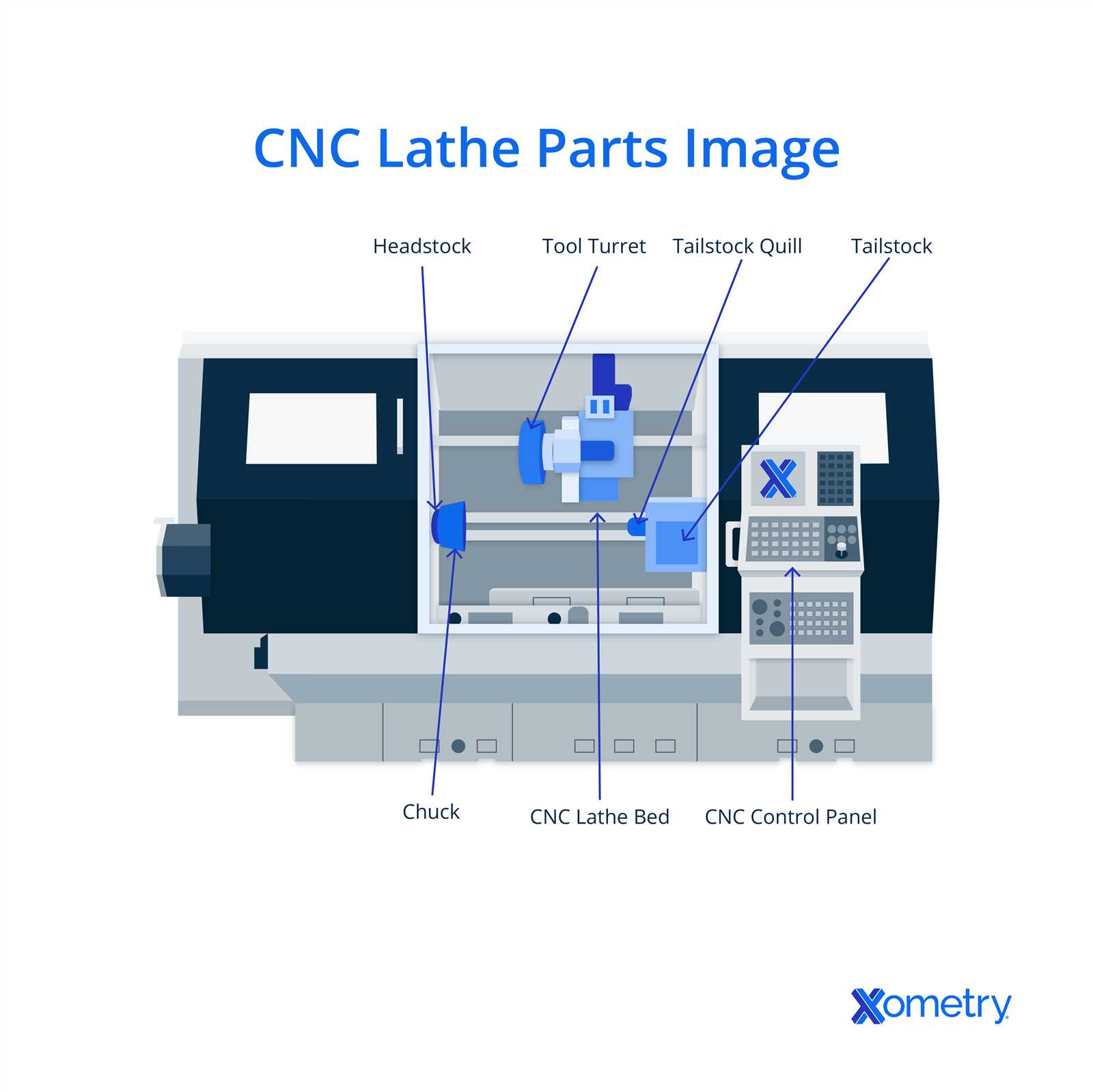

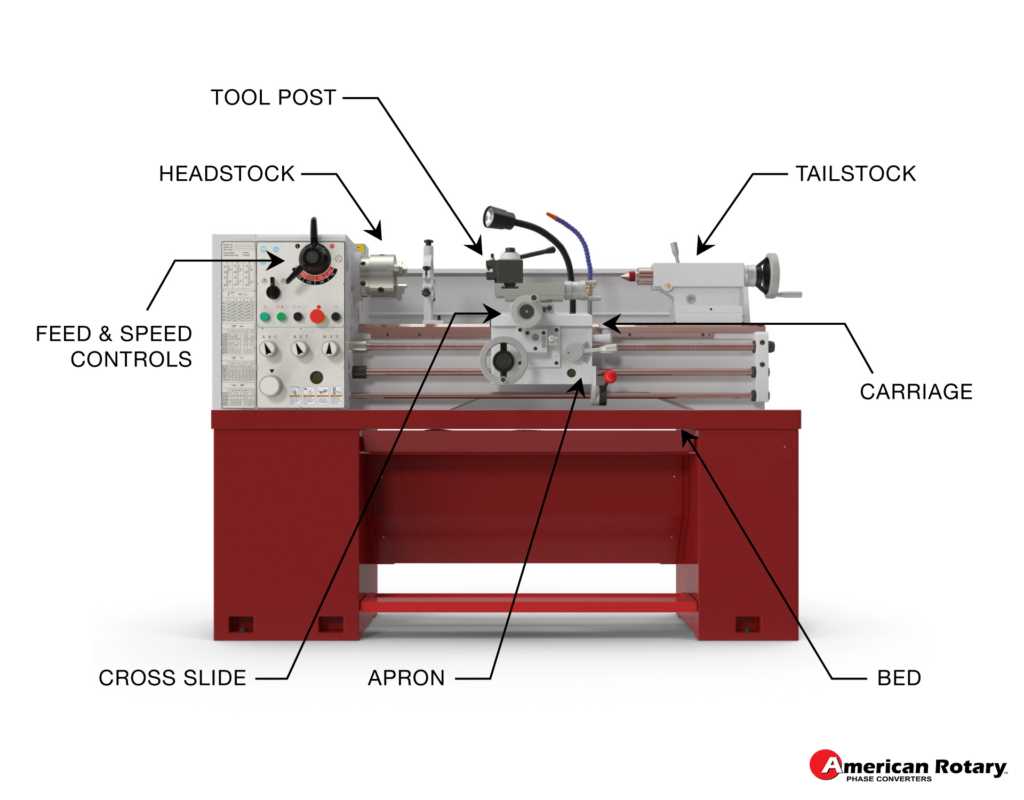

| Headstock | Houses the main spindle and motor, facilitating the rotation of workpieces. |

| Tailstock | Provides support for the opposite end of the workpiece and allows for adjustments. |

| Bed | Serves as the foundation, ensuring stability and alignment during operations. |

| Cross Slide | Allows lateral movement of cutting tools for precise shaping. |

| Tool Post | Holds the cutting tool securely in place for effective material removal. |

| Carriage | Enables the movement of the tool and workpiece along the length of the bed. |

| Apron | Controls the carriage’s movement and includes various levers and mechanisms. |

| Spindle | Responsible for rotating the workpiece, typically driven by a motor. |

| Lead Screw | Facilitates the longitudinal movement of the carriage, allowing for threading operations. |

| Feed Rod | Drives the carriage for automatic or manual feeding of the tool. |

| Chuck | Secures the workpiece to the spindle for accurate rotation and processing. |

| Tailstock Quill | Adjustable part that enables fine-tuning of the workpiece support. |

Main Components of Lathe Equipment

This section explores the fundamental elements that make up a pivotal tool used in various manufacturing processes. Understanding these key features is essential for grasping how this tool operates effectively and efficiently in shaping materials.

Essential Features

Each component plays a significant role in the functionality and precision of the equipment. These features work together to facilitate the movement and manipulation of the workpiece while ensuring accurate results during operations.

Overview of Key Elements

| Component | Description |

|---|---|

| Headstock | Houses the main drive motor and other gears that provide power to the system. |

| Tailstock | Supports the opposite end of the workpiece and can be adjusted for various lengths. |

| Bed | The base that provides stability and alignment for other components. |

| Carriage | Moves along the bed and carries the cutting tool, enabling precise adjustments. |

| Cross Slide | Allows for lateral movement of the cutting tool for shaping and contouring. |

| Tool Post | Secures the cutting tool in place and allows for easy replacement. |

Understanding the Headstock Assembly

The headstock assembly serves as a critical component in various machining setups, providing essential functions that influence performance and precision. This section will explore the primary features and roles associated with this crucial element, highlighting its importance in achieving optimal results during the shaping and forming processes.

Key Functions

- Power Transmission: The headstock is responsible for transferring energy from the motor to the spindle, ensuring efficient operation.

- Speed Control: It often includes mechanisms for adjusting the rotational speed, allowing for versatility in machining different materials.

- Support Structure: This assembly provides stability and alignment for the workpiece, maintaining precision throughout the cutting process.

Main Components

- Spindle: The central axis that holds and rotates the workpiece.

- Motor: Powers the headstock, enabling movement and rotation.

- Gearbox: Facilitates speed adjustments and torque variations.

- Bearings: Support the spindle, minimizing friction and wear.

Exploring the Tailstock Features

The tailstock is a vital component that enhances the versatility and functionality of a precision tool. Its design allows for effective support and positioning of various workpieces, ensuring stability during the fabrication process. Understanding its features can significantly impact the efficiency of operations and the quality of the finished products.

One of the primary attributes of the tailstock is its ability to adjust for different lengths and diameters. This adaptability is crucial for accommodating various materials and shapes, making it an indispensable tool in any workshop. Additionally, the incorporation of a quill mechanism allows for fine adjustments, enabling users to achieve precise alignment with the cutting tools.

Moreover, the tailstock often features a locking system that secures it in place once the desired position is achieved. This stability is essential for maintaining accuracy during machining operations, especially when dealing with intricate designs. Furthermore, many tailstocks come equipped with interchangeable accessories, such as live centers and drill chucks, which expand their functionality and enhance the overall productivity of the setup.

In summary, the tailstock plays a pivotal role in ensuring precision and versatility in machining processes. By leveraging its features, operators can improve their workflow and achieve superior results in their projects.

Importance of the Bed Structure

The bed structure serves as the foundational element in any precision equipment, providing stability and support for all operational components. Its design and construction play a crucial role in ensuring accurate functionality and overall performance. Without a robust base, the entire system may suffer from inaccuracies and operational failures.

Key Functions of the Bed Structure

- Stability: A solid base minimizes vibrations, which can adversely affect the precision of the work being performed.

- Alignment: It ensures proper alignment of various components, allowing for smooth operation and accurate results.

- Support: The structure provides essential support for heavy parts, distributing weight evenly to prevent deformation.

Materials and Design Considerations

The choice of materials used in the bed construction is vital. Typically, heavy-duty materials are preferred to enhance rigidity and durability. Additionally, the design should incorporate features that facilitate maintenance and adjustment, ensuring longevity and consistent performance.

Functionality of the Carriage System

The carriage system serves as a crucial component in precision machining, facilitating the movement and positioning of workpieces and cutting tools. This arrangement enables controlled travel along the length of the workpiece, allowing for accurate shaping and finishing processes. Its design contributes to the efficiency and effectiveness of operations, ensuring that various machining tasks are executed with precision.

Key Components and Their Roles

Within this framework, several essential elements collaborate to achieve desired outcomes. The bed provides a stable foundation, while the cross slide allows for lateral adjustments, enhancing versatility in operations. Additionally, the apron plays a vital role in controlling the feed mechanisms, which determine the depth and speed of cutting.

Operational Efficiency

The operational efficiency of this system is largely attributed to its ability to accommodate various machining techniques. By enabling smooth and precise movements, the carriage system enhances productivity and minimizes errors. Moreover, the integration of advanced features, such as automated feeds and digital readouts, further optimizes performance, making it an indispensable aspect of modern machining.

Role of the Tool Post Mechanism

The tool post mechanism plays a vital role in securing and positioning the cutting tool during the machining process. It serves as the interface between the tool and the workpiece, allowing for precise control and adjustment. This component is essential for achieving the desired shape and finish on the material being worked on.

Functionality and Adjustability

This assembly allows for various angles and depths of cut, providing flexibility in operations. By adjusting the position of the cutting tool, users can perform different tasks such as turning, facing, or threading. The mechanism’s ability to maintain stability under pressure is crucial for ensuring accuracy and consistency throughout the machining process.

Types and Configurations

There are several types of tool posts, each designed for specific applications. Some common variations include fixed, quick-change, and rotating types. The choice of configuration can greatly influence the efficiency and effectiveness of the cutting operations, making it imperative to select the right type for the intended task.

Details on the Chuck Types

Various gripping mechanisms play a crucial role in the securing of workpieces during machining operations. Understanding these mechanisms is essential for optimizing performance and ensuring precision. Each type serves specific functions and is designed to accommodate different workpiece shapes and sizes.

Three-Jaw Chucks are among the most common types used in this context. They provide a self-centering grip, making them ideal for cylindrical objects. Their design allows for the simultaneous adjustment of all three jaws, ensuring that the workpiece is held securely and uniformly.

Four-Jaw Chucks offer versatility and greater customization. Each jaw can be adjusted independently, enabling the user to hold irregularly shaped materials or perform precision tasks. This type is particularly useful for setups requiring fine alignment and adjustment.

Collet Chucks are specialized gripping devices that utilize a sleeve mechanism to secure cylindrical workpieces. They offer high accuracy and are often preferred for smaller parts, especially in applications demanding tight tolerances. The quick-change capability of collets enhances workflow efficiency.

Understanding the distinctions between these gripping mechanisms can significantly impact the effectiveness of the setup. Each type brings unique advantages, allowing users to select the most suitable option for their specific requirements, ultimately enhancing productivity and precision in the overall process.

Examining the Spindle Characteristics

The spindle serves as a crucial element in rotating tools, playing an essential role in the overall functionality of machining operations. Its design and specifications directly impact precision, efficiency, and the quality of the finished product. Understanding the various attributes of this component allows for better selection and optimization in manufacturing processes.

Types of Spindles

Spindles can be classified into several categories based on their construction and intended application. Each type possesses unique characteristics that influence its performance. For instance, belt-driven spindles provide flexibility in speed adjustment, while direct-drive spindles ensure higher torque and accuracy during operation.

Key Performance Indicators

When assessing spindle performance, certain metrics come into play. Factors such as rotation speed, stiffness, and thermal stability are critical for maintaining optimal functionality. Higher rotation speeds often lead to improved machining efficiency, but they also require careful consideration of the spindle’s design to prevent overheating and wear.

Analysis of the Feed Mechanism

The feed mechanism plays a crucial role in the operation of precision equipment, ensuring consistent and controlled movement during various machining processes. This component is essential for achieving the desired depth and quality of cut, significantly impacting the overall efficiency and accuracy of the production process.

Functionality and Design

At its core, the feed mechanism facilitates the movement of the workpiece or the cutting tool along designated axes. This movement can be achieved through various methods, including manual adjustment or automated systems. Mechanical linkages and gear systems are commonly employed to translate rotational motion into linear movement, allowing for precise control over the machining parameters.

Types of Feed Mechanisms

There are several variations of feed mechanisms, each tailored to specific applications. For instance, automatic systems utilize sensors and motors to achieve high levels of precision, while manual systems often rely on handwheels and levers for adjustments. Understanding the characteristics of each type is essential for optimizing performance and ensuring compatibility with various operations.

Identifying the Apron Assembly Parts

The apron assembly plays a crucial role in the functionality of a precision tool, facilitating various operations. Understanding the components within this assembly is essential for effective maintenance and troubleshooting. Each element contributes to the overall performance, ensuring smooth movement and control during operations.

Main Components

Within the apron assembly, several key elements work in unison to support its operation. Familiarity with these components will enhance the user’s ability to manage the equipment efficiently.

| Component | Description |

|---|---|

| Handwheel | Used for manual adjustment and positioning of the cutting tool. |

| Clutch Lever | Engages or disengages the drive mechanism for precise control. |

| Cross Slide | Facilitates lateral movement of the cutting tool for shaping operations. |

| Feed Rod | Controls the automatic feed mechanism for consistent material removal. |

Understanding Each Component

Each item within the apron assembly serves a unique purpose. The handwheel allows for fine adjustments, enabling the user to achieve the desired positioning with accuracy. The clutch lever is vital for transitioning between operations, while the cross slide ensures that lateral movements are precise. The feed rod plays a significant role in automating processes, contributing to efficiency and consistency.

Utilizing the Power Transmission System

The effective application of a power transmission framework is crucial for the seamless operation of various tools and devices in the manufacturing sector. This system is responsible for delivering energy from the source to the operational components, enabling them to perform their functions efficiently. Understanding its intricacies allows for better management and optimization of performance.

Power transmission components include belts, gears, and pulleys, each playing a vital role in transferring energy. These elements work in harmony to ensure that rotational force is converted and delivered accurately, facilitating precise movements and operations.

Furthermore, monitoring and maintenance of the transmission system is essential for longevity and reliability. Regular checks can prevent potential failures and ensure that all components operate at optimal levels. By focusing on these aspects, users can enhance productivity and reduce downtime significantly.