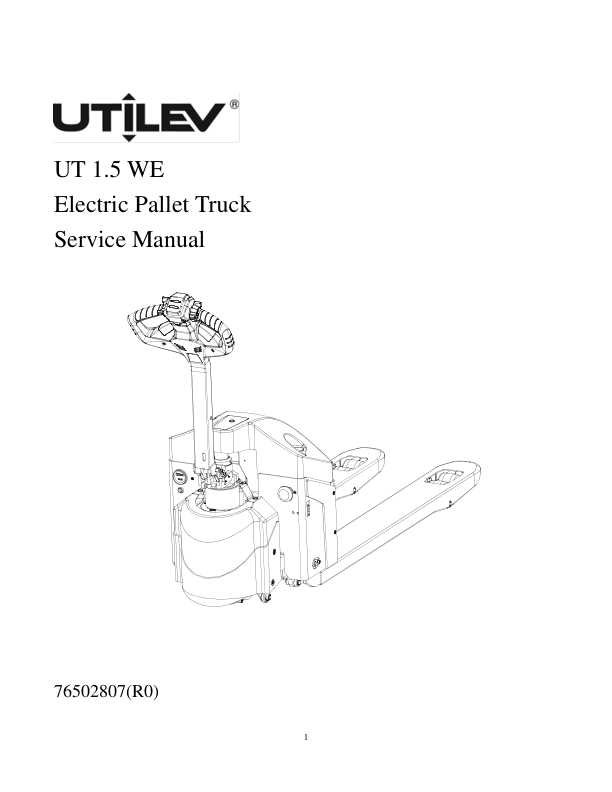

In any warehouse or storage setting, efficient lifting tools play a crucial role in daily operations. These devices are designed to handle heavy loads with ease, offering a practical solution for transporting goods over short distances. The structure and functionality of such equipment involve several key elements that work in harmony to ensure smooth operation.

Each element of this lifting tool is carefully engineered to contribute to its overall performance. From the base structure that ensures stability to the lifting mechanism responsible for movement, every part serves an important function. By exploring these various components, it becomes easier to grasp how they contribute to the overall effectiveness of the tool.

In this section, we will break down the most important elements of this equipment, offering insights into their specific roles and how they work together. This knowledge is valuable not only for understanding the operation of the device but also for identifying any necessary maintenance or replacements.

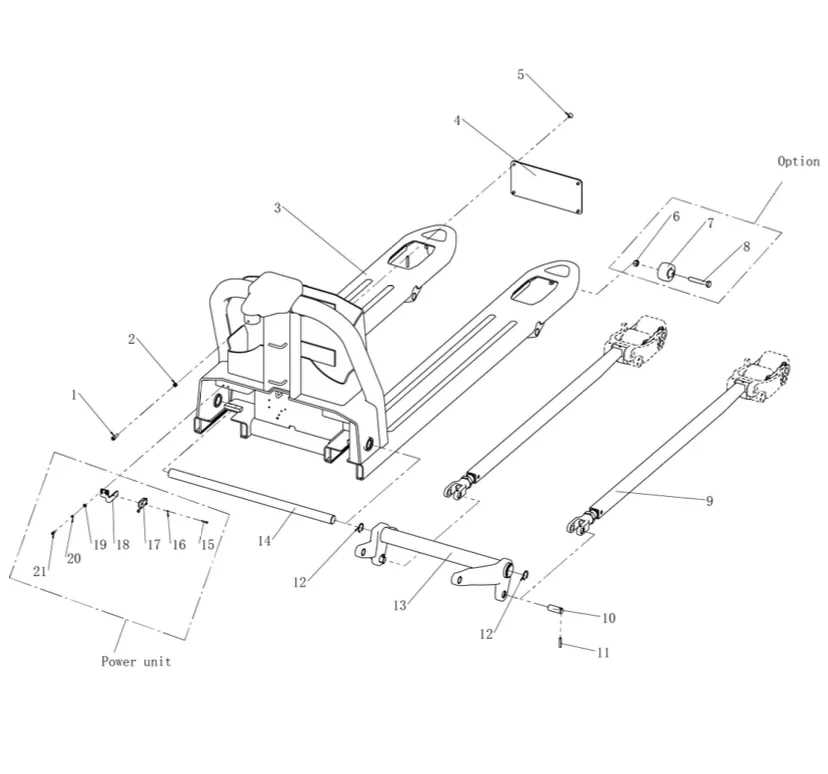

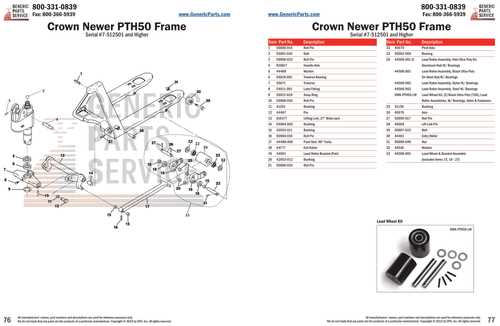

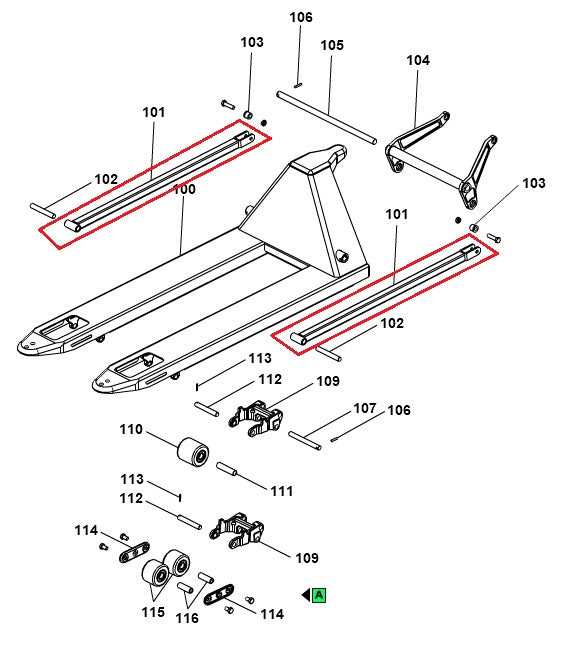

Overview of Manual Pallet Jack Components

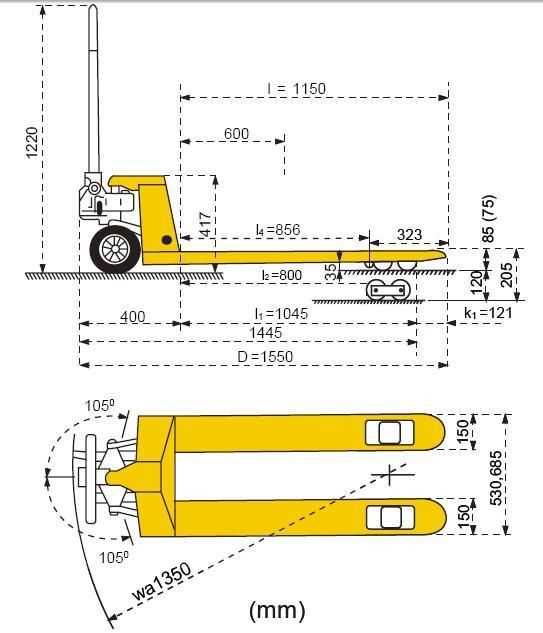

Understanding the structure of this lifting tool helps ensure efficient operation and quick identification of essential elements. Each component plays a critical role in the overall functionality, allowing smooth and reliable lifting and transportation.

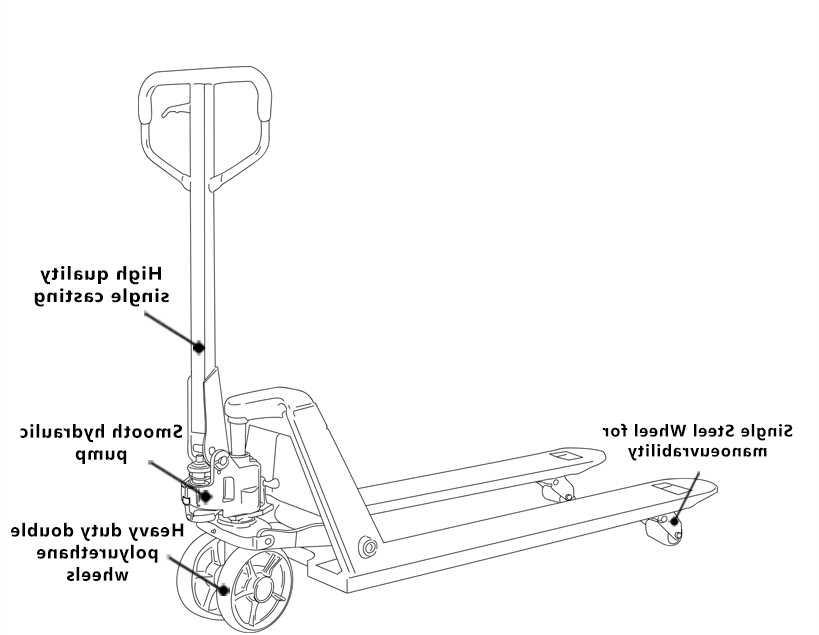

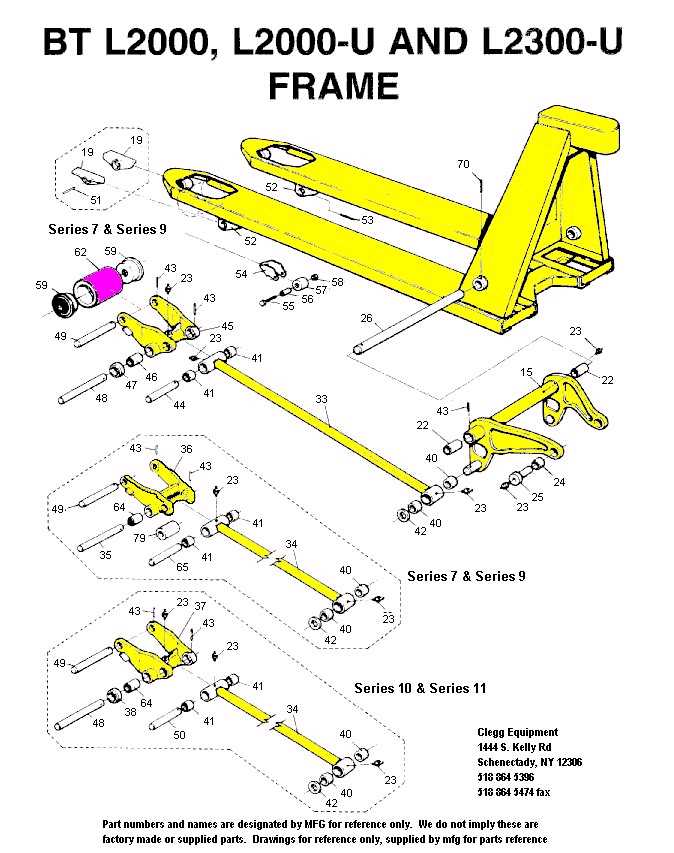

- Frame: The main structure supporting the rest of the equipment, providing stability and balance during use.

- Handle Assembly: Designed for maneuverability, this part allows operators to control direction and apply lifting force with ease.

- Wheels: Positioned both at the front and back, these enable movement across different surfaces while reducing friction.

- Hydraulic Unit: This system provides the necessary lift mechanism, converting manual effort into vertical motion through fluid pressure.

- Load Forks: Long prongs extend beneath the item to be lifted, distributing weight evenly and ensuring secure transport.

Understanding the Role of Hydraulic Pump

In a lifting mechanism, one of the most critical components is responsible for generating the force required to elevate loads efficiently. This section explores how pressure-driven systems convert energy into mechanical action, making it possible to handle weights with minimal effort. The hydraulic pump serves as the heart of this system, ensuring smooth and controlled motion.

The hydraulic pump operates by using fluid dynamics to create pressure. When activated, it transfers liquid from one chamber to another, resulting in a force that pushes or pulls the load upward or downward. Below is a simple representation of the key elements involved:

| Component | Function |

|---|---|

| Reservoir | Stores the liquid required for pressure generation |

| Piston | Moves within the chamber to create displacement |

| Valve | Handle Assembly: Function and Design

The handle is a crucial component that ensures effective control and maneuverability in various lifting equipment. It plays a vital role in facilitating the user’s interaction with the machine, offering both comfort and precision during use. The design of this part is typically crafted to balance strength, ergonomics, and functionality, enhancing the overall efficiency of the equipment. Let’s explore the essential aspects of this element, highlighting its key functional characteristics and design choices.

In conclusion, the handle assembly combines both technical precision and user-centered design to deliver an effective interface for controlling the machinery. Importance of Load Wheels in Operation

Efficient movement of heavy items relies heavily on the performance of key components, and among them, the role of ground-contact mechanisms is crucial. These small yet vital elements ensure stability, smooth motion, and support while handling various tasks. Understanding their function can significantly enhance equipment longevity and user experience. Below are key reasons why ground-contact elements play a critical role in material handling equipment:

Ensuring regular maintenance and choosing durable ground-contact mechanisms can make a significant Forks and Their Contribution to LiftingThe lifting mechanism relies heavily on the two parallel arms that form the primary support for elevating and moving loads. These arms are engineered to withstand significant weight while maintaining stability, ensuring smooth operations in various handling environments. Structural Integrity

Built to offer both strength and durability, the arms are designed from reinforced materials that prevent bending under heavy pressure. The balance between their weight and toughness allows them to function efficiently, even with high-capacity loads. Precision and AlignmentPrecision in the alignment of these arms is critical for maintaining balance during the elevation process. The exact placement allows for even distribution of weight, reducing the risk of tipping or uneven lifting, ensuring safe and reliable operation. Maintenance Tips for Pallet Jack Bearings

Ensuring optimal performance and longevity of critical components requires regular attention and care. Proper maintenance of these elements not only enhances efficiency but also prevents costly repairs and replacements. The following guidelines will help you keep these components in excellent condition. Regular Inspection

Lubrication Practices

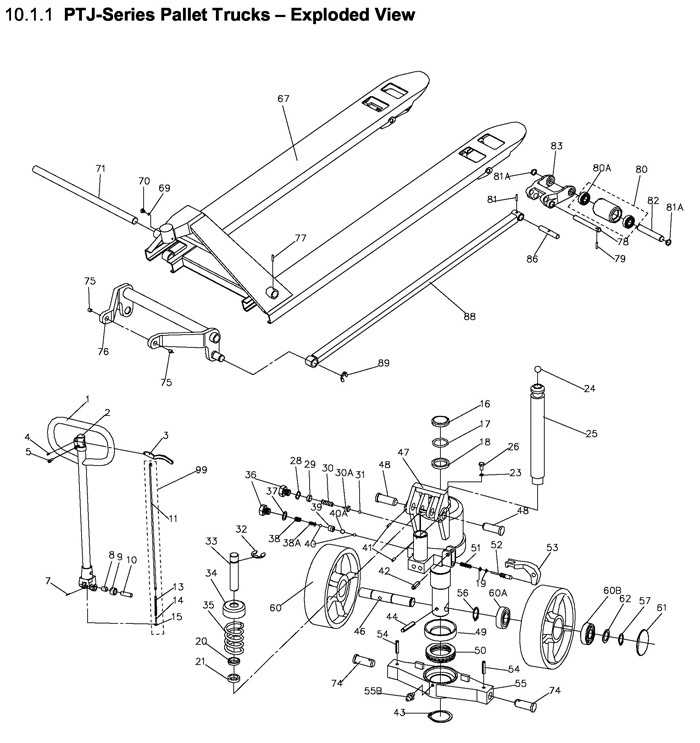

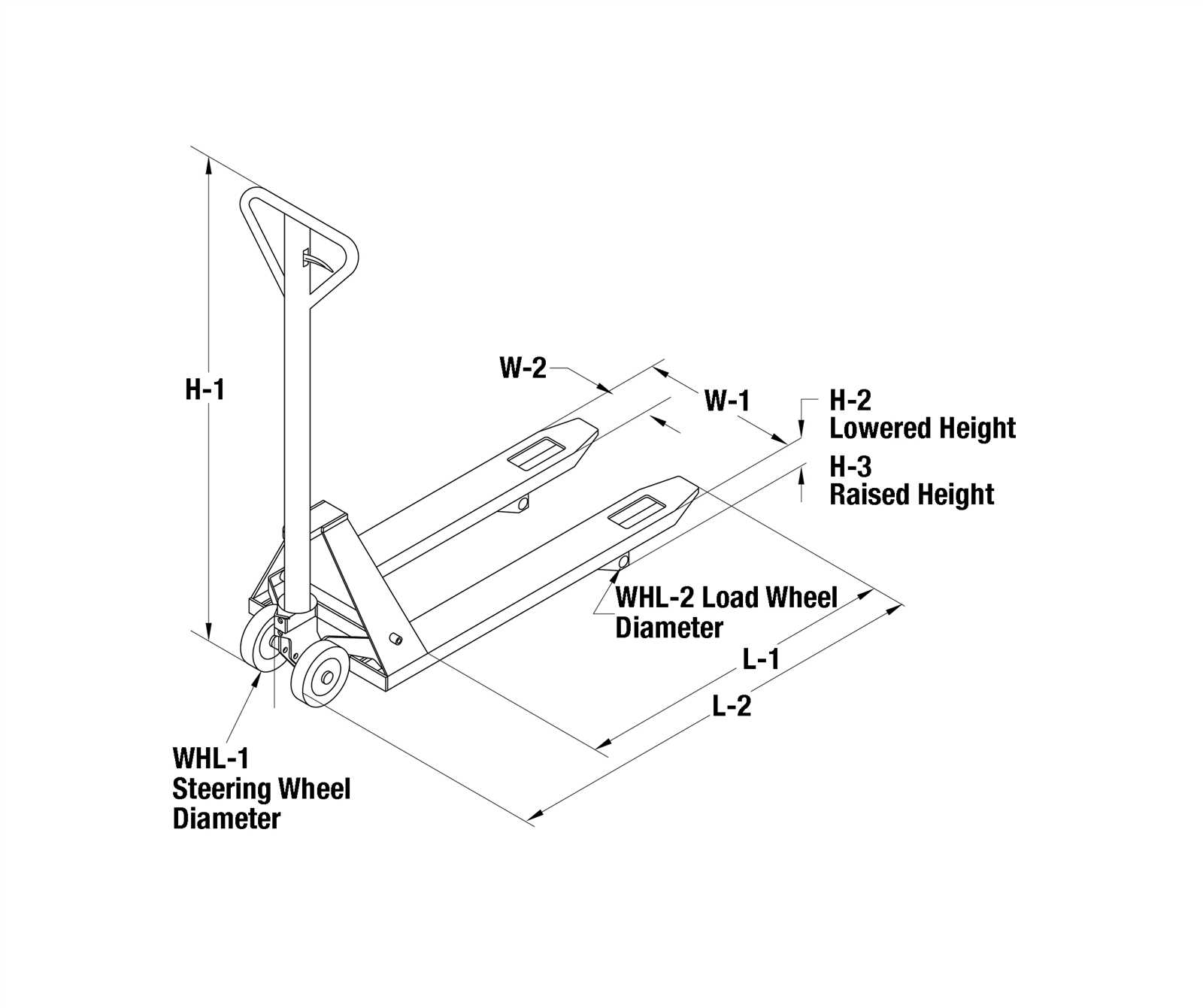

Following these maintenance practices will contribute significantly to the overall performance and lifespan of essential components, ensuring reliable operation in various applications. Steering Mechanism and Wheel Alignment

The steering apparatus and the alignment of wheels are crucial components in the operation of wheeled equipment. These elements ensure precise maneuverability and stability, allowing for effective navigation in various environments. A well-designed steering system, paired with correctly aligned wheels, significantly enhances the efficiency and safety of handling tasks. Importance of Proper Alignment

Correct alignment of the wheels contributes to several key aspects of functionality:

Components of the Steering MechanismThe steering system comprises several vital elements that work together to facilitate movement:

Regular maintenance and inspection of these components are essential to ensure optimal performance and longevity. Proper adjustments can prevent issues that may arise from misalignment or wear, thus maintaining the overall efficiency of the equipment. Hydraulic Cylinder: Key Features and UsageThe hydraulic cylinder is a vital component in various lifting mechanisms, converting fluid pressure into linear motion. Its design and functionality are crucial for enabling heavy loads to be maneuvered with ease and precision. Understanding its features can significantly enhance operational efficiency. Key Features: One of the most notable characteristics of hydraulic cylinders is their power-to-weight ratio. They can generate substantial force relative to their size, making them ideal for applications requiring strength without excessive bulk. Additionally, the sealing systems incorporated in these cylinders ensure minimal leakage and optimal performance under pressure. Another important aspect is the stroke length, which defines how far the cylinder can extend. This feature is essential for achieving the desired lift or push in various tasks. Furthermore, the choice of materials used in construction influences durability and resistance to environmental factors, enhancing the cylinder’s longevity in demanding settings. Usage: Hydraulic cylinders are commonly employed in industries such as construction, manufacturing, and logistics. They are instrumental in lifting and moving heavy equipment, facilitating smooth operations. Proper maintenance and understanding of the cylinder’s limitations are key to maximizing its effectiveness and ensuring safety in the workplace. Brake Systems in Manual Pallet JacksEffective stopping mechanisms are crucial in enhancing the safety and functionality of handling equipment. These systems ensure smooth deceleration and prevent unintended movements, thus protecting both operators and the surrounding environment. Understanding the components and operations of these systems is essential for optimal performance. Typically, these mechanisms consist of several key elements:

Maintaining these systems is vital for the longevity and reliability of the equipment. Regular inspection of the following is recommended:

In conclusion, a well-maintained braking system enhances both safety and efficiency in operations involving handling equipment. Proper understanding and care of these components can prevent accidents and ensure seamless workflows. Common Wear and Tear Points to Monitor

Regular observation of specific components is essential to ensure the longevity and optimal performance of any lifting device. Identifying areas that experience significant stress or friction can help prevent malfunctions and costly repairs. Monitoring these elements will contribute to the overall efficiency and safety of operations. Wheels and RollersThe wheels and rollers are critical in providing smooth mobility. Over time, they may wear down or become damaged due to constant use on various surfaces. Inspecting them regularly for signs of deformation or excessive wear is crucial. Replacing worn wheels promptly can enhance maneuverability and prevent further issues. Hydraulic System

The hydraulic system is vital for lifting and lowering loads effectively. Leaks, degraded seals, and low fluid levels can significantly affect functionality. It’s important to check for any signs of hydraulic fluid leakage and ensure that the system maintains the appropriate pressure. Regular maintenance can prevent performance loss and extend the lifespan of the device. Safety Features and Their Practical Benefits

Ensuring the well-being of operators and maintaining a secure working environment are paramount in any industry that utilizes lifting equipment. Various enhancements contribute to safety, helping to mitigate risks and improve overall efficiency in material handling tasks. Implementing robust safety mechanisms provides numerous advantages:

In addition to these benefits, specific elements can further enhance security:

By prioritizing safety, organizations can protect their workforce and optimize productivity while ensuring that material handling remains effective and efficient. |