When it comes to maintaining the efficiency of your marine engine, familiarity with its individual components is essential. Having a clear visual reference can significantly enhance your ability to troubleshoot issues and perform regular upkeep. This guide aims to provide you with an insightful look at the essential elements that make up a 20 HP engine, allowing you to understand how they interact and function together.

Each element plays a crucial role in the overall performance and reliability of the engine. From the ignition system to the cooling mechanisms, recognizing each component’s purpose will empower you to handle maintenance tasks with confidence. Whether you’re a seasoned enthusiast or a newcomer to marine engines, grasping these fundamentals will help you keep your vessel running smoothly.

In the following sections, we will delve into a detailed overview of these vital components, featuring visual aids that will enhance your comprehension. With the right knowledge, you’ll be better equipped to ensure your engine operates at its best, maximizing both performance and longevity.

Overview of 20 HP Mercury Outboards

This section provides an essential look into the 20 HP engine designed for marine applications, highlighting its significance in various boating activities. Understanding its construction and functionality can enhance performance and maintenance for users.

Key Features

With a compact design, this engine delivers remarkable power and efficiency. The innovative technology integrated into its mechanics ensures smooth operation and reliability, making it a preferred choice for both recreational and professional use.

Applications

These engines are ideal for small boats, providing the ultimate balance between speed and fuel economy. Whether for fishing, leisure cruising, or water sports, their versatility allows for enjoyable experiences on the water.

Common Parts of Mercury Outboards

Understanding the essential components of a marine propulsion system is crucial for maintenance and performance. Each element plays a significant role in ensuring smooth operation and reliability. Familiarity with these key components can aid in troubleshooting and repairs, ultimately enhancing the boating experience.

Key Components

- Powerhead: This is the heart of the engine, housing the combustion chamber and necessary components for fuel ignition.

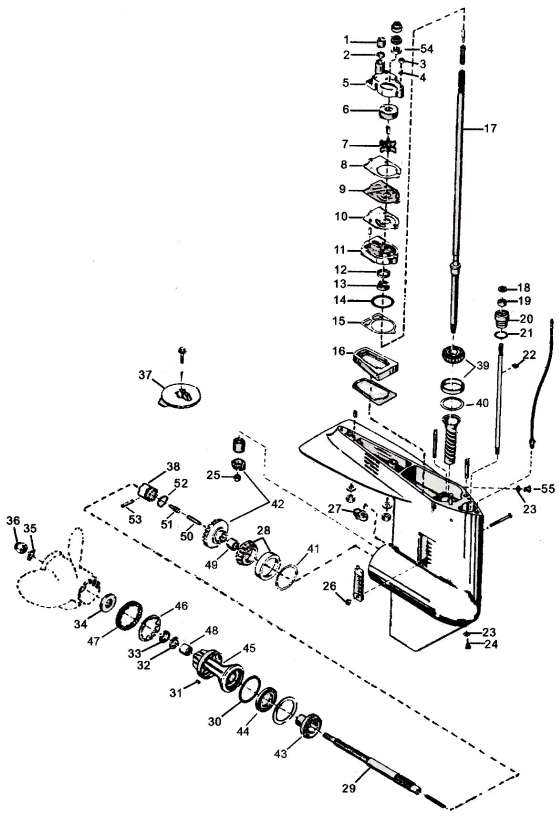

- Lower Unit: Contains the gears and shaft responsible for transferring power to the propeller, enabling propulsion.

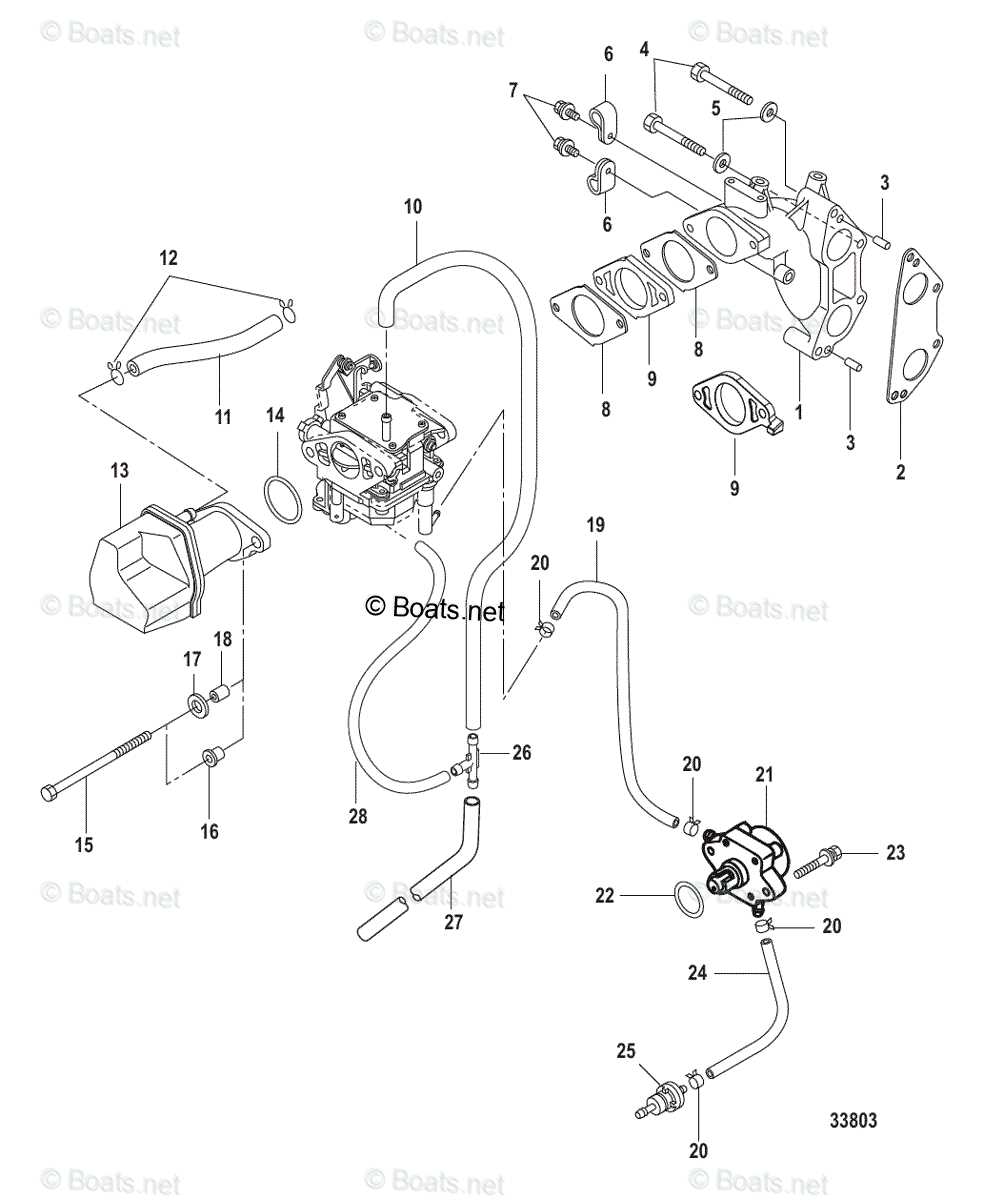

- Fuel System: Comprises the fuel tank, lines, and injectors that deliver fuel to the engine for combustion.

- Cooling System: Ensures the engine operates at optimal temperatures, preventing overheating through water circulation.

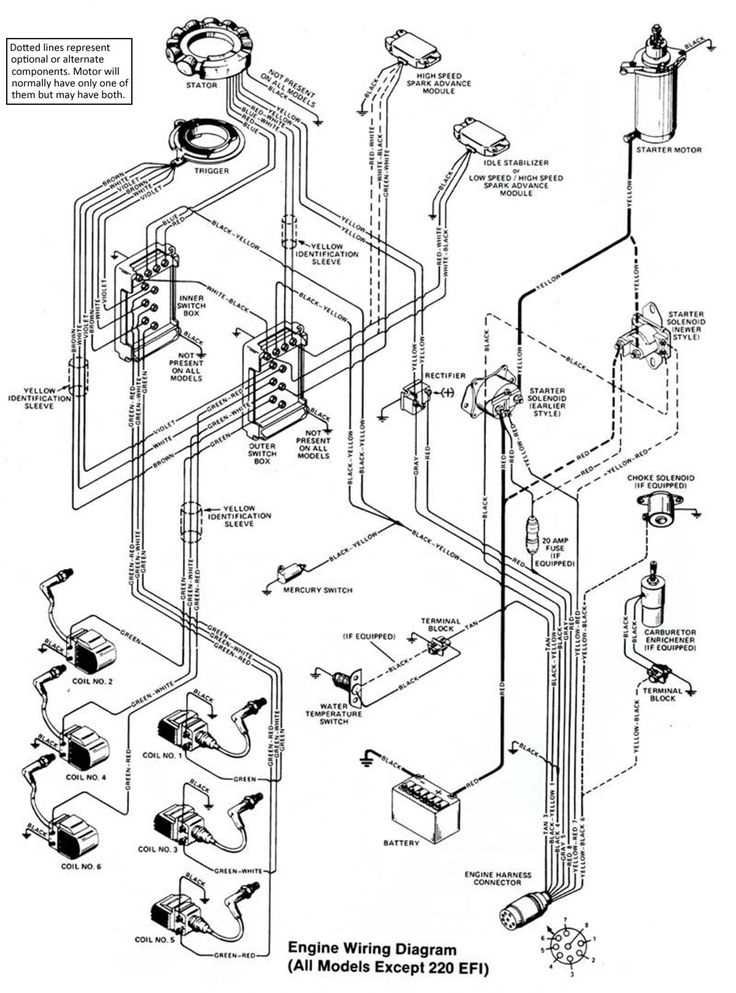

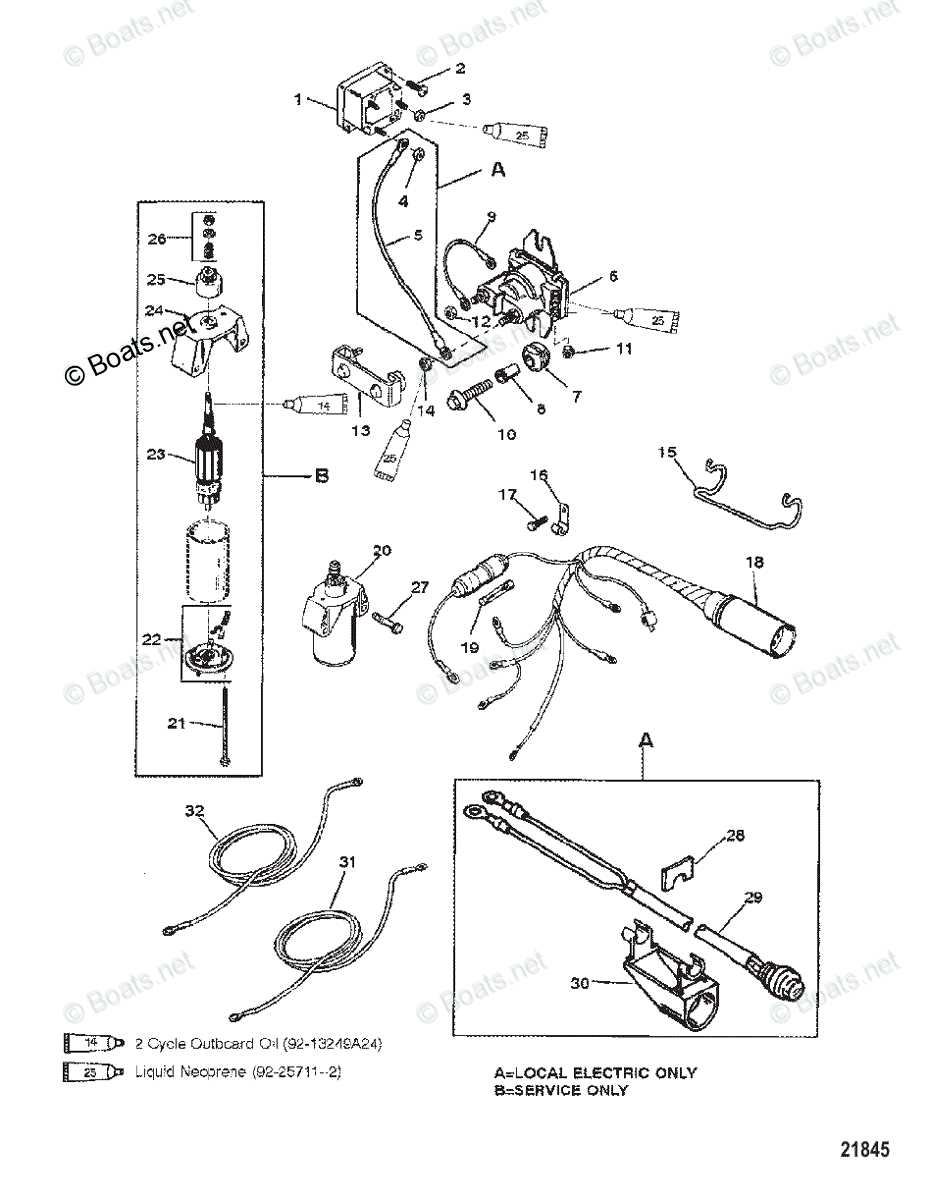

- Ignition System: Generates the spark required for combustion, typically involving coils, plugs, and wiring.

Maintenance Tips

- Regularly check the oil levels and replace fluids as needed to ensure smooth operation.

- Inspect the fuel system for leaks or blockages that could affect performance.

- Clean or replace the spark plugs to maintain efficient combustion.

- Ensure the cooling system is free of debris to prevent overheating.

- Examine the lower unit for signs of wear or damage, addressing any issues promptly.

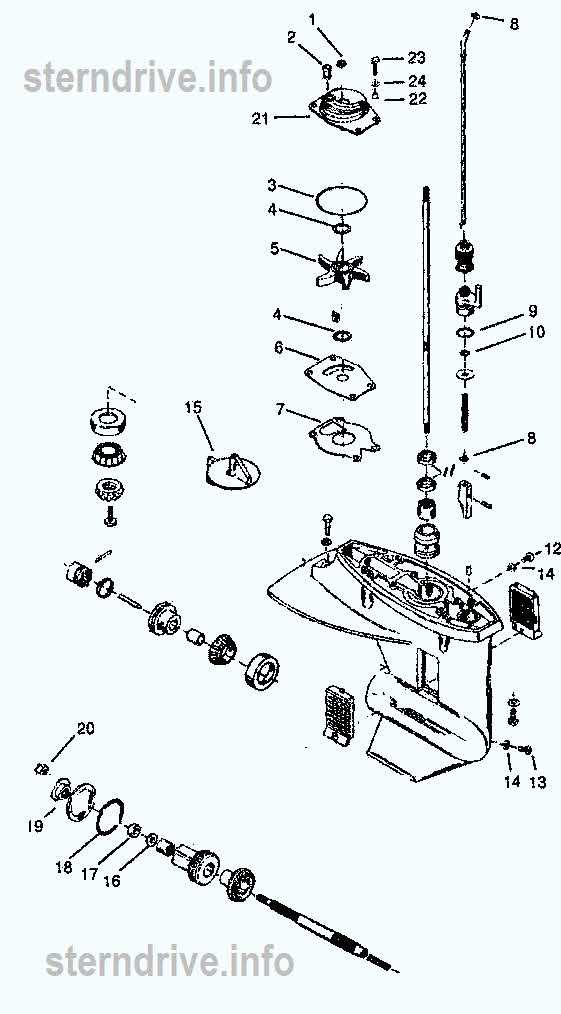

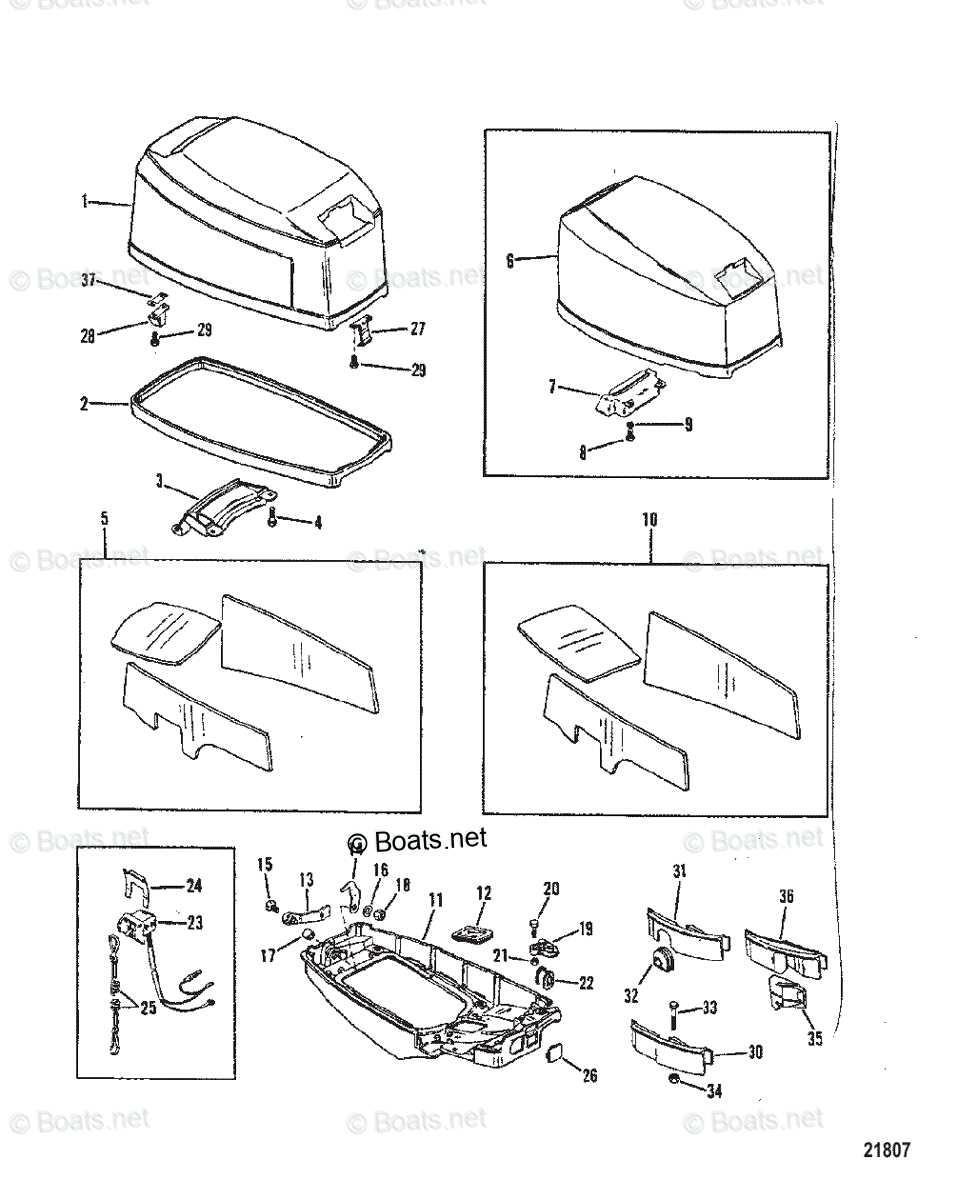

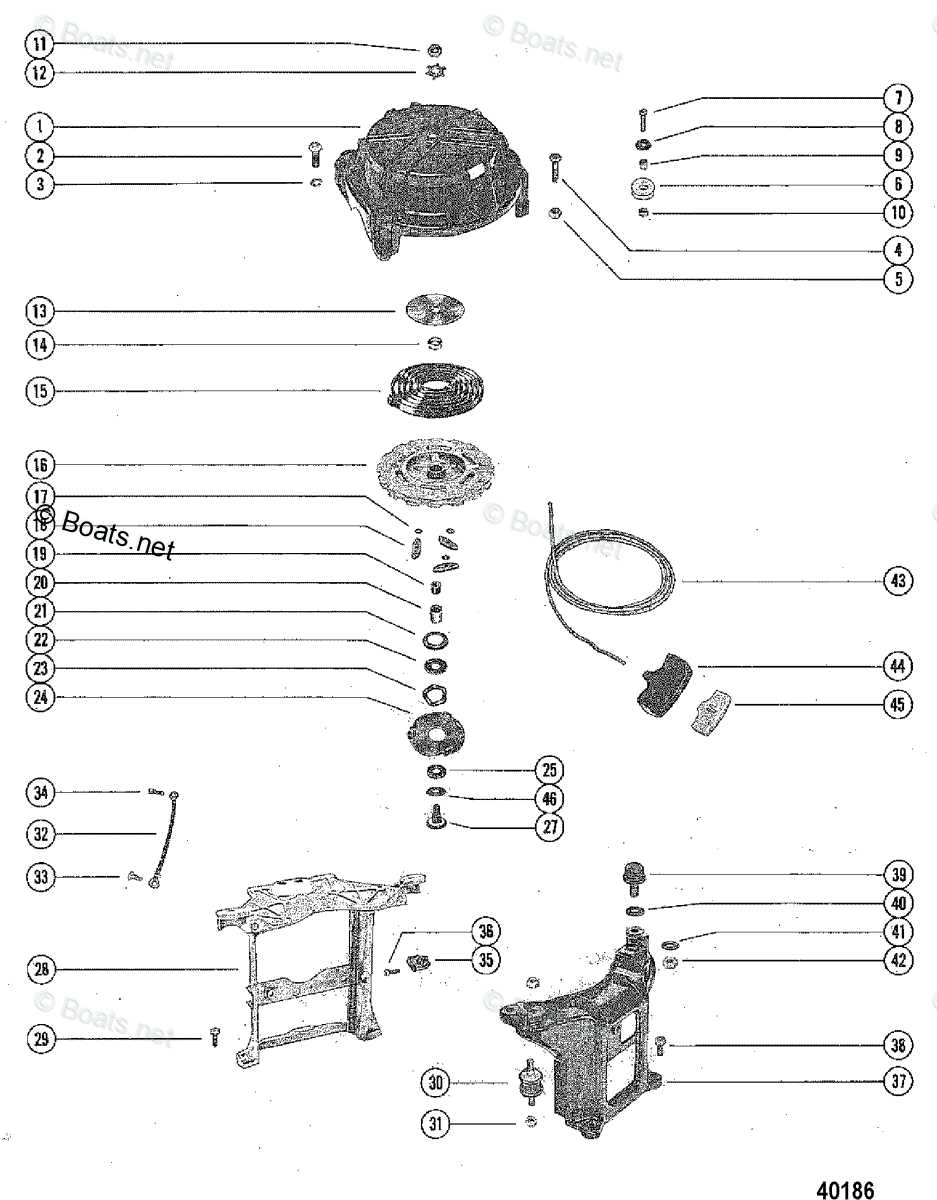

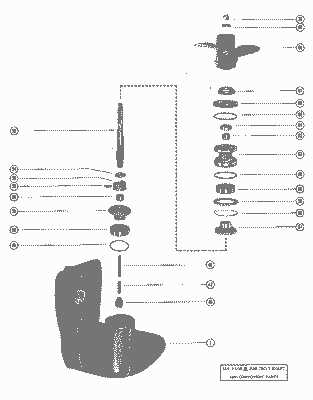

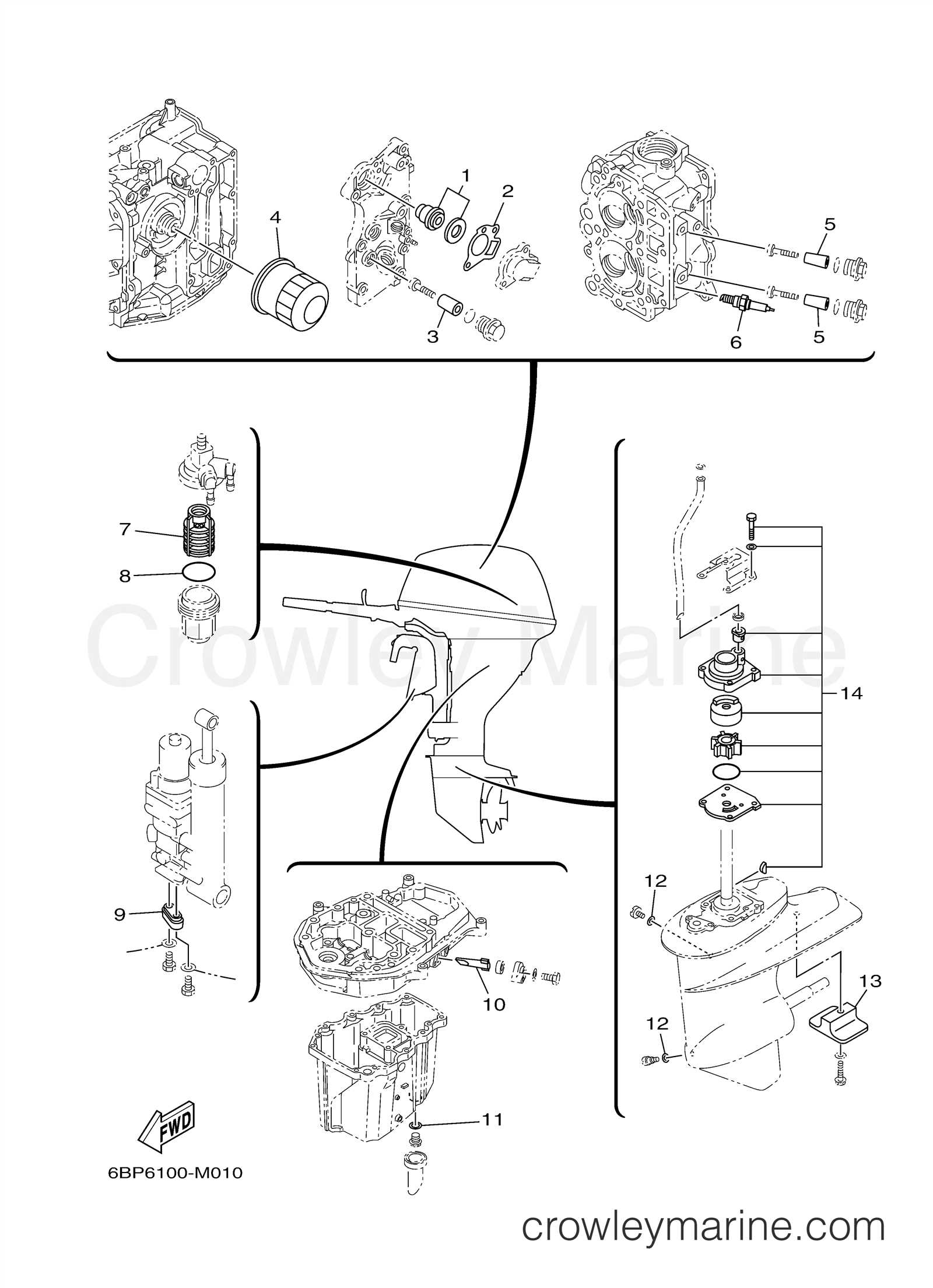

Understanding the Parts Diagram

Comprehending the visual representation of components is essential for effective maintenance and repair. This illustration serves as a guide to identify and locate various elements, ensuring smooth operation and troubleshooting.

Key benefits of utilizing such representations include:

- Enhanced clarity in identifying individual components.

- Streamlined assembly and disassembly processes.

- Efficient troubleshooting and repairs.

When analyzing the illustration, consider the following:

- Familiarize yourself with the layout and symbols used.

- Note the connections and relationships between different elements.

- Refer to the corresponding manual for detailed descriptions.

Ultimately, mastering this visual guide empowers users to delve deeper into their understanding of mechanical systems, promoting longevity and optimal performance.

Essential Maintenance for Outboard Motors

Proper upkeep is crucial for ensuring longevity and optimal performance of marine engines. Regular maintenance can prevent costly repairs and enhance reliability during use.

Key Maintenance Tasks

- Check fuel levels and quality.

- Inspect and replace the spark plugs as needed.

- Examine the cooling system for blockages or leaks.

- Clean or replace the air filter regularly.

- Inspect the propeller for damage and ensure proper alignment.

Seasonal Maintenance Tips

- Drain fuel before long periods of inactivity.

- Apply a protective coating to the engine and exposed components.

- Perform a thorough cleaning to remove salt and debris.

- Test the battery and connections for corrosion.

- Store in a dry, sheltered location to avoid moisture damage.

How to Identify Parts Quickly

Recognizing components swiftly can save time and enhance efficiency during maintenance or repairs. By familiarizing yourself with various elements, you can streamline your work process and ensure proper functionality.

Visual Guides and Resources

Utilizing visual references is crucial for quick identification. Many resources are available, including manuals and online images, which depict different components clearly.

Common Identifiers

| Identifier | Description |

|---|---|

| Serial Number | A unique code that provides specific information about the unit. |

| Model Name | The name associated with the particular type or design. |

| Color Coding | Different colors may indicate specific functions or features. |

Tools Needed for Repairs

Proper maintenance and repairs require a selection of essential instruments to ensure efficiency and effectiveness. Having the right tools on hand can make the process smoother and more manageable, whether you are fixing a minor issue or conducting a thorough examination. An organized toolkit allows for quick access and minimizes the risk of damage during repairs.

First and foremost, a comprehensive set of wrenches is crucial for loosening and tightening various components. Socket sets with different sizes can also provide versatility for reaching tight spaces. Additionally, screwdrivers of varying types and sizes are indispensable for handling different fasteners.

Other important tools include pliers, which assist in gripping and manipulating parts, and a multimeter for electrical diagnostics. A torque wrench ensures that connections are secure without over-tightening, while a diagnostic tool can help identify performance issues efficiently. Finally, a clean workspace and a sturdy workbench enhance the overall repair experience.

Replacement Parts: What to Consider

When it comes to maintaining the performance and longevity of your marine engine, selecting the right components is crucial. Understanding the specifics of what you need can make a significant difference in ensuring smooth operation and preventing future issues.

First and foremost, compatibility is essential. Always verify that the new items you are considering will work seamlessly with your existing setup. This includes checking model numbers and specifications to avoid mismatches that could lead to inefficient functioning.

Quality is another vital aspect. Opting for high-grade alternatives can enhance durability and reduce the frequency of replacements. Researching trusted brands and reading user reviews can guide you towards reliable options that stand the test of time.

Cost should also be weighed carefully. While it may be tempting to choose the cheapest available option, consider the long-term implications. Investing a little more initially in superior quality can often save you money down the line through decreased maintenance and replacement costs.

Lastly, it’s beneficial to consult with experts or community forums. Engaging with those who have experience in the field can provide invaluable insights and recommendations that help you make informed decisions. This collaborative approach can lead to more satisfactory outcomes and a well-functioning engine.

Common Issues with 20 HP Models

When operating smaller marine engines, several frequent challenges may arise, impacting performance and reliability. Understanding these issues can help users maintain their equipment effectively and ensure a smoother experience on the water.

- Fuel Problems:

- Stale fuel can lead to starting difficulties and reduced efficiency.

- Clogged fuel filters may cause poor engine performance.

- Ignition System Failures:

- Worn spark plugs can result in misfires and inconsistent power.

- Faulty ignition coils may lead to complete engine shutdown.

- Cooling Issues:

- Overheating can occur if the cooling system is blocked or malfunctioning.

- Low water flow may indicate a clogged intake or impeller failure.

- Electrical Concerns:

- Battery-related problems can prevent starting and lead to electrical failures.

- Corroded connections may hinder overall electrical performance.

- Wear and Tear:

- Regular use can lead to component degradation, requiring replacements.

- Vibration and impacts may cause loose fittings and misalignments.

Addressing these common issues promptly can extend the life of the engine and enhance overall reliability, ensuring enjoyable outings on the water.

Where to Find OEM Parts

Locating original equipment manufacturer components can be a straightforward process if you know where to look. Many enthusiasts and professionals seek reliable sources to ensure the quality and compatibility of the items they need for their machinery. Access to authentic components is crucial for maintaining performance and longevity.

One of the best places to start your search is through official manufacturer websites. They often have dedicated sections for replacement components, allowing you to browse by model or part number. Additionally, authorized dealers can provide a wealth of information and stock various components, ensuring you receive genuine items.

Online marketplaces also offer a vast selection of components, but it is essential to verify the seller’s reputation and confirm that the items are original. Forums and community groups dedicated to enthusiasts can be invaluable resources, as members frequently share their experiences and recommendations for trusted suppliers.

Lastly, local marine supply stores often carry a range of original components or can order them for you. Building relationships with knowledgeable staff can help you find what you need while receiving expert advice on installation and maintenance.

Benefits of Regular Maintenance

Routine upkeep is essential for ensuring longevity and optimal performance of marine engines. Consistent checks and services can prevent minor issues from escalating into significant problems, ultimately saving time and money. By prioritizing maintenance, users can enhance reliability and efficiency, leading to a more enjoyable experience on the water.

Enhanced Performance

Regular attention to an engine ensures that all components function at their best. Regular servicing keeps systems clean and free from blockages, which contributes to improved fuel efficiency and overall power output. This proactive approach allows enthusiasts to truly enjoy their time without unexpected interruptions.

Increased Safety

Neglecting maintenance can lead to unforeseen failures that pose safety risks. By performing scheduled inspections, users can identify and rectify potential hazards before they arise. Prioritizing upkeep not only protects the equipment but also ensures a safer experience for everyone on board.

Step-by-Step Repair Guide

This section provides a comprehensive approach to fixing your engine efficiently. Whether you are a seasoned mechanic or a novice, following these organized steps will help you troubleshoot and resolve common issues effectively.

1. Gather Your Tools: Before starting any repair, ensure you have all necessary tools and replacement components at hand. This includes wrenches, screwdrivers, and any specialized equipment required for your specific model.

2. Review the Manual: Consult the user manual to understand the specifications and assembly of your device. Familiarizing yourself with the layout will make the repair process smoother and more straightforward.

3. Inspect for Damage: Carefully examine the engine for any visible wear or damage. Look for signs such as leaks, cracks, or corrosion that may indicate underlying problems that need addressing.

4. Disassemble with Care: When disassembling components, keep track of all screws and parts. It is beneficial to organize them in a manner that makes reassembly easy, perhaps by using labeled containers.

5. Clean and Replace: Clean all parts thoroughly to remove dirt and debris. Replace any worn or damaged components with new ones to ensure optimal performance.

6. Reassemble and Test: Carefully put everything back together, following the steps in reverse order. Once reassembled, conduct a test run to ensure that everything functions as intended.

7. Regular Maintenance: After repairs, establish a routine maintenance schedule to prevent future issues. Regular checks will prolong the life of your engine and enhance its efficiency.

Tips for Extended Engine Life

Ensuring the longevity of your marine engine requires regular maintenance and attention to detail. By following a few key practices, you can significantly enhance performance and minimize the risk of costly repairs. A proactive approach will keep your equipment running smoothly for years to come.

Regular Maintenance Checks: Schedule routine inspections to identify potential issues before they escalate. Check fluid levels, filters, and connections regularly to ensure everything is in optimal condition.

Use Quality Fuel: Always opt for high-quality fuel to prevent clogging and ensure efficient combustion. Contaminated or subpar fuel can lead to serious complications down the line.

Keep the Cooling System Clean: Overheating can be detrimental to engine health. Regularly inspect and clean the cooling system to prevent blockages and ensure adequate heat dissipation.

Monitor Operating Temperature: Keep an eye on the temperature gauge. If you notice any unusual readings, investigate immediately to avoid overheating and potential damage.

Proper Storage: When not in use, ensure the engine is stored properly. Use appropriate covers and consider draining fluids to prevent corrosion and deterioration.

Follow Manufacturer Guidelines: Always adhere to the recommended maintenance schedule provided by the manufacturer. This includes oil changes, filter replacements, and any specific checks tailored to your model.

By implementing these strategies, you can significantly extend the life of your engine and maintain its performance, allowing for enjoyable and worry-free experiences on the water.