When it comes to marine propulsion systems, having a clear understanding of the essential elements is crucial for optimal performance and maintenance. This section aims to illuminate the intricate workings of a 50 HP engine, highlighting the various components that contribute to its efficiency and reliability.

By exploring the layout and functionality of these mechanical parts, enthusiasts and technicians alike can enhance their knowledge and skills. Whether you’re looking to troubleshoot an issue or simply deepen your appreciation for these powerful machines, this guide will provide valuable insights.

In the following sections, we will delve into each component, offering a comprehensive overview that serves as an ultimate resource for both novices and seasoned professionals. Understanding how these elements interact can significantly impact your overall experience on the water.

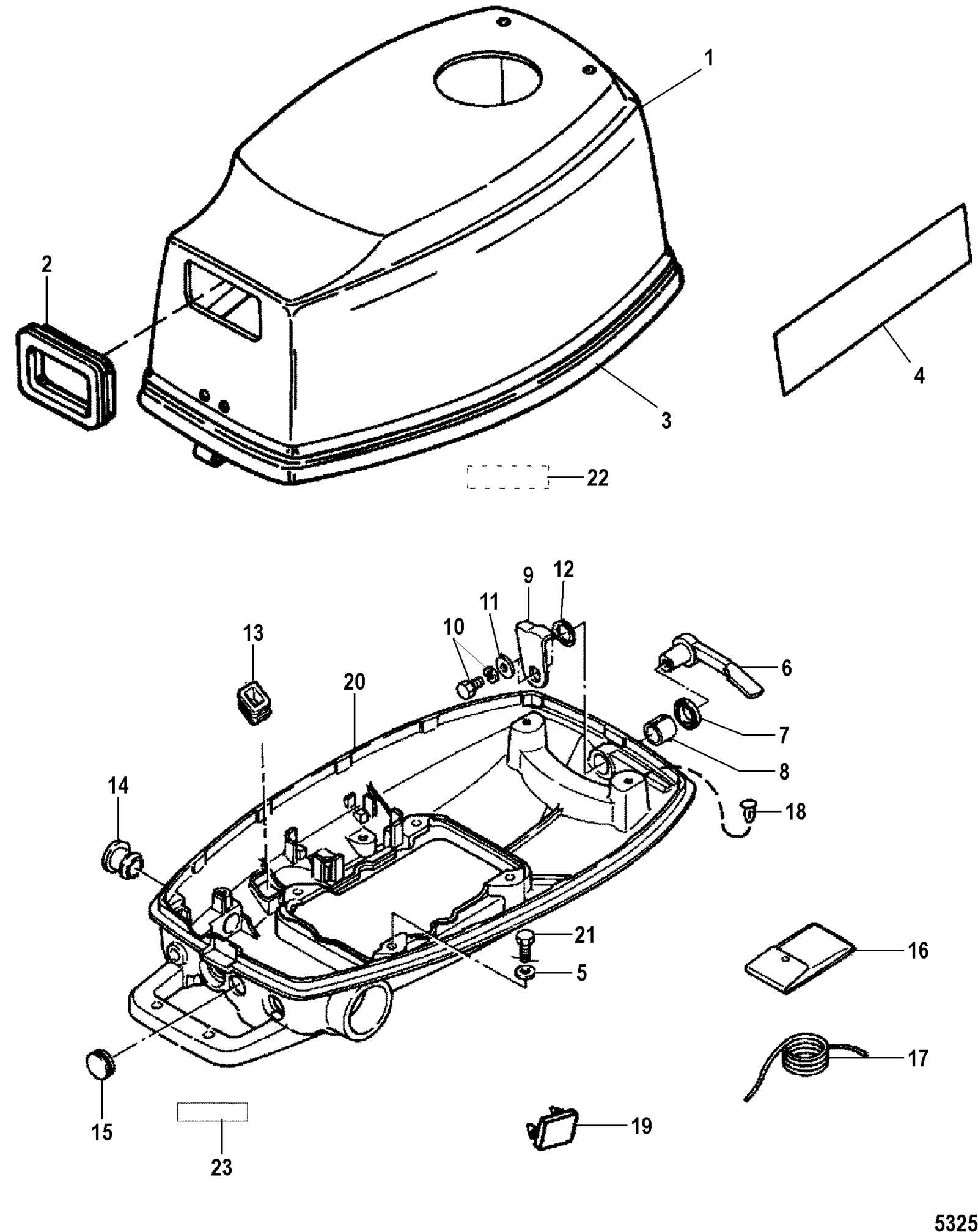

Overview of 50 HP Mercury Outboard

This section explores the essential features and functionalities of a 50 HP marine engine, focusing on its design, performance, and common applications. Understanding these aspects is crucial for users seeking to optimize their boating experience.

Key Features

- Efficient fuel consumption

- Robust build quality

- Compact and lightweight design

- Easy maintenance and serviceability

Common Applications

- Fishing boats

- Small recreational vessels

- Workboats in shallow waters

- Water sports activities

In summary, this power unit stands out for its reliability and versatility, making it a popular choice among marine enthusiasts.

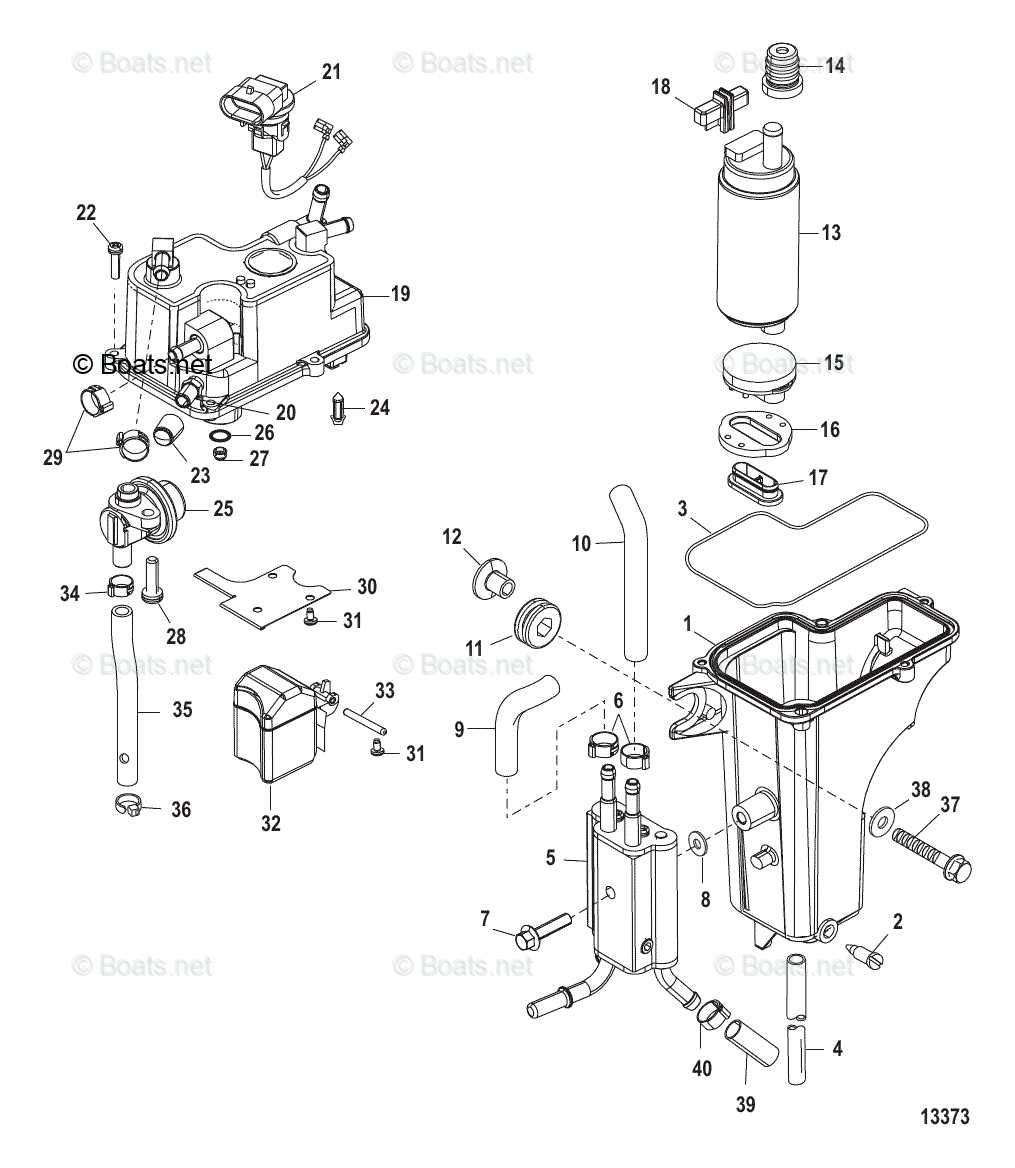

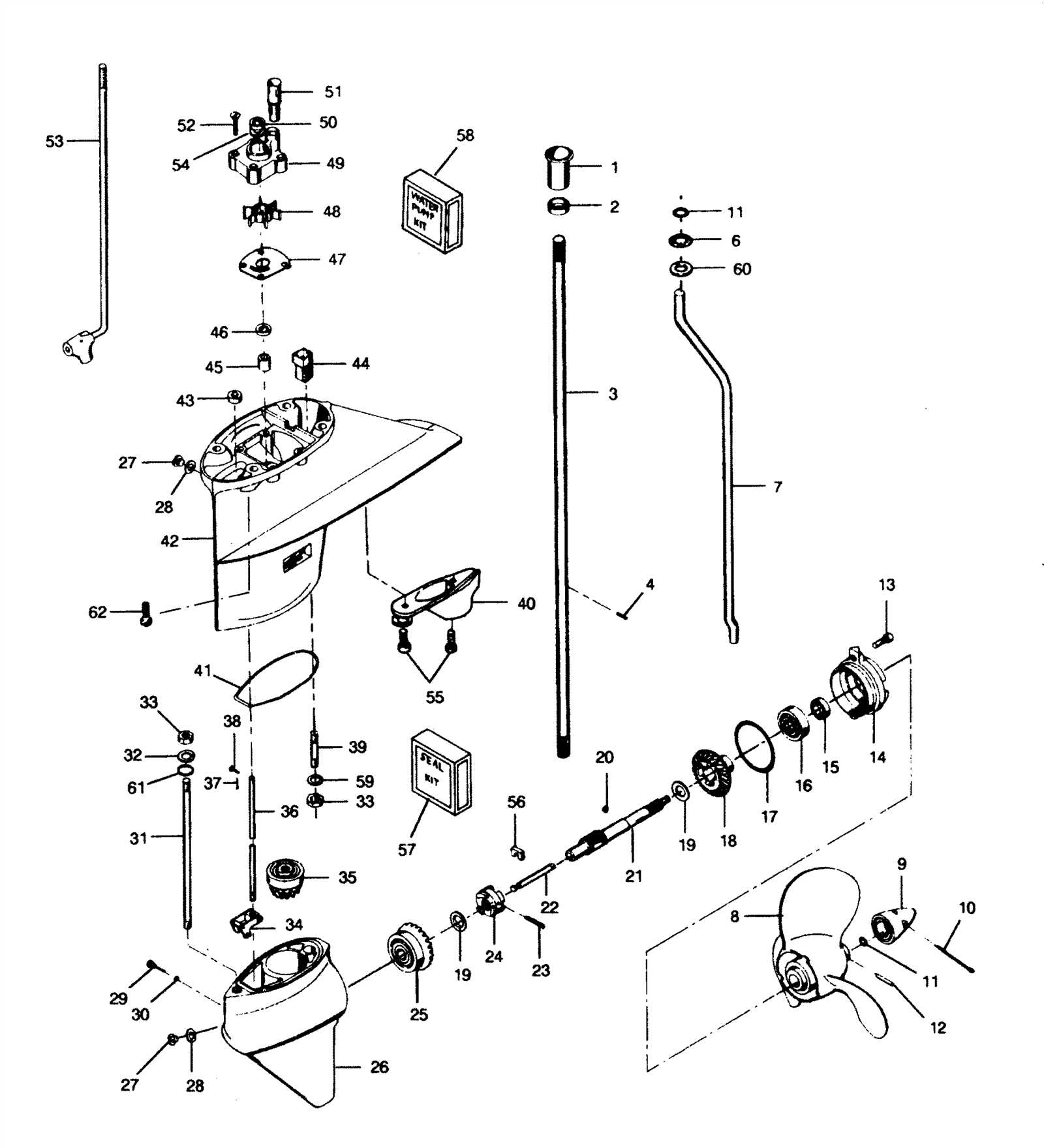

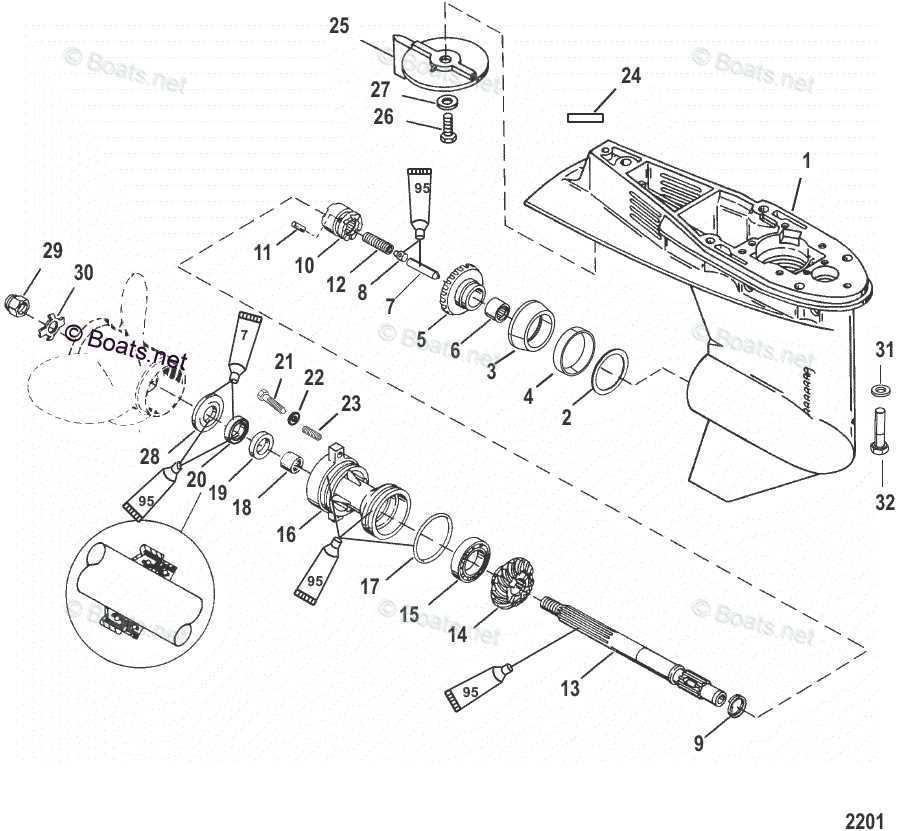

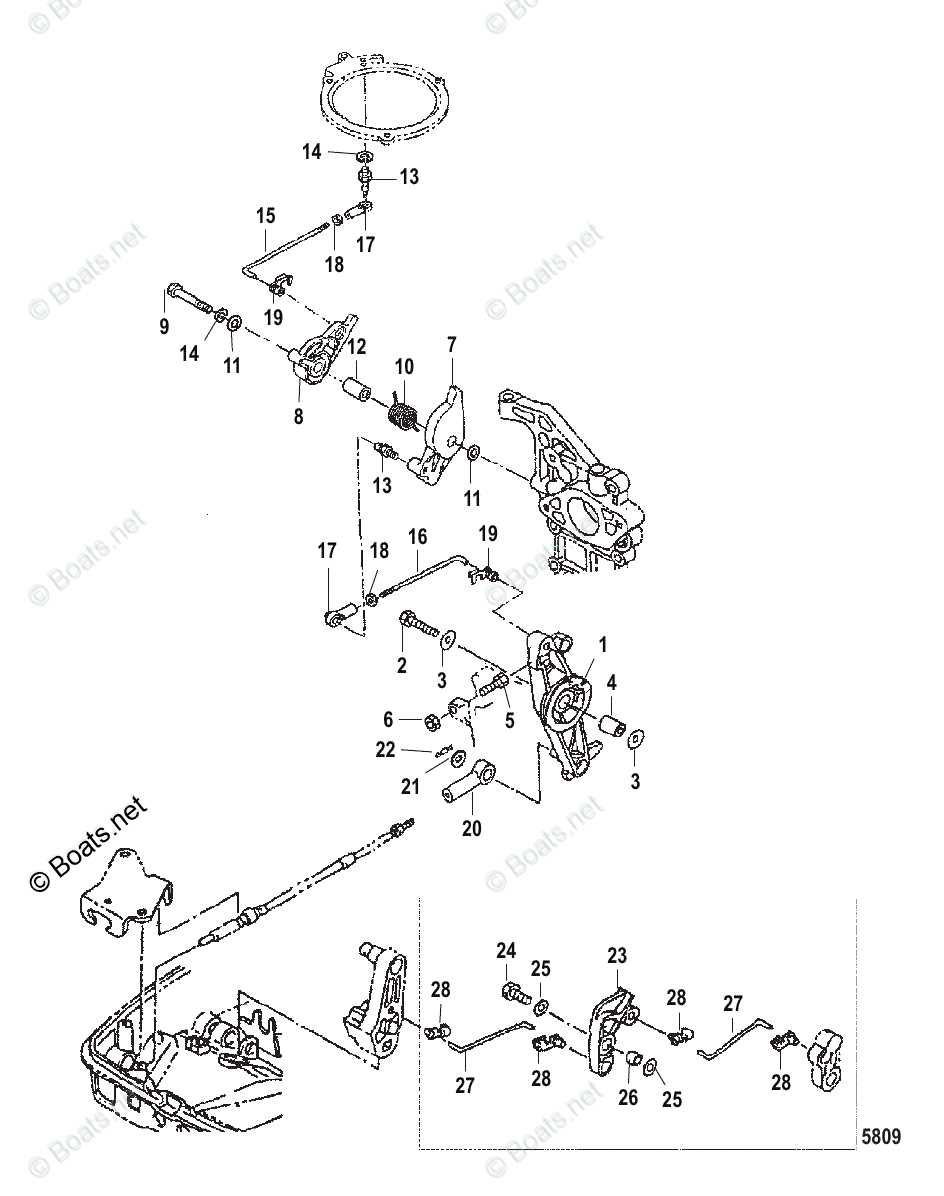

Importance of Accurate Parts Diagrams

Having precise illustrations of components is crucial for effective maintenance and repair. These visuals not only facilitate identification but also streamline the reassembly process, ensuring that everything fits perfectly. Without clarity in these representations, users may face significant challenges, leading to potential errors and inefficiencies.

| Benefits | Description |

|---|---|

| Enhanced Understanding | Clear visuals improve comprehension of how parts interact. |

| Time Efficiency | Accurate schematics reduce the time spent on repairs. |

| Reduced Errors | Minimized risk of misplacement or incorrect assembly. |

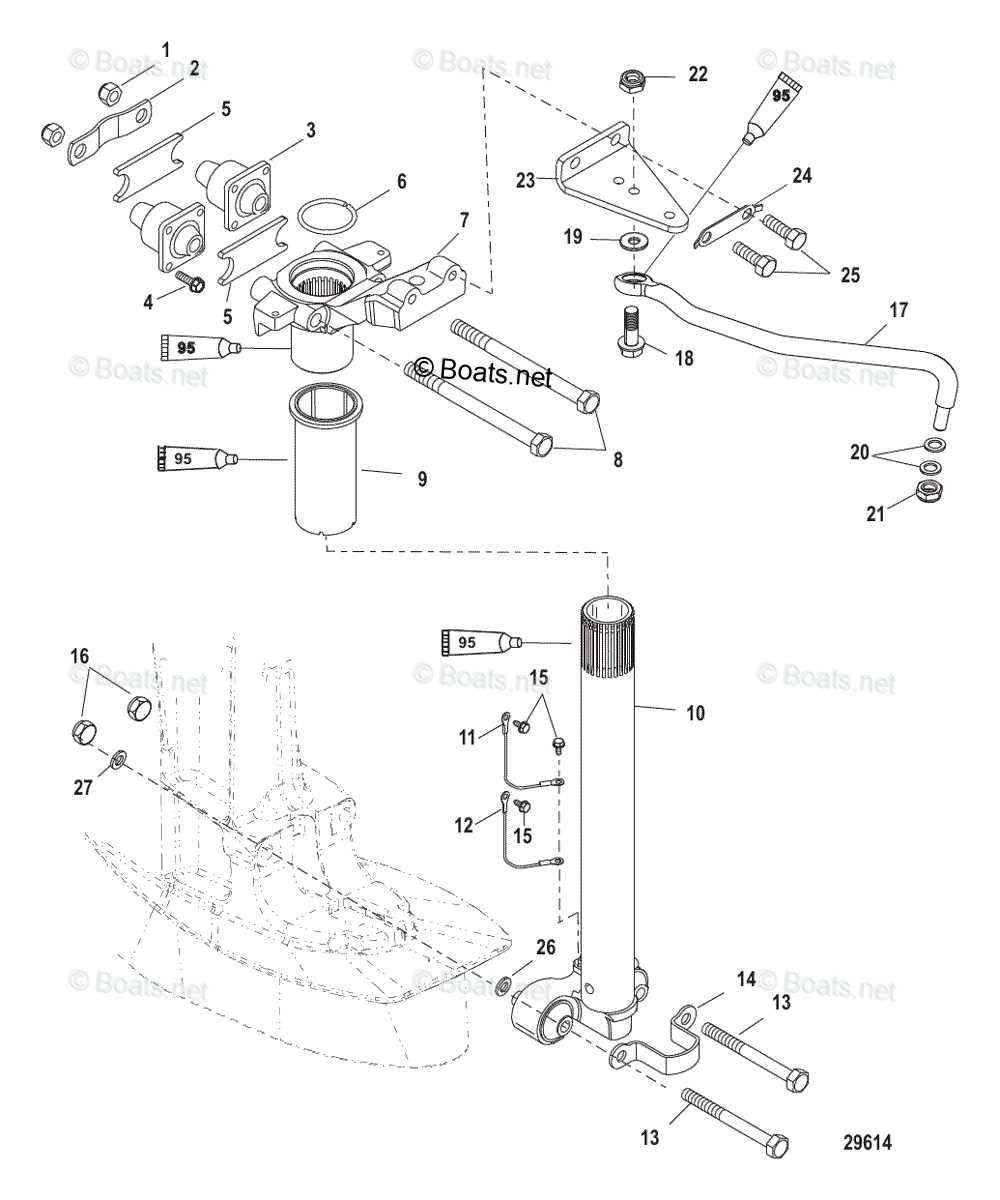

Common Parts in Mercury Outboards

Understanding the key components of marine engines is essential for maintenance and performance. These elements work together to ensure smooth operation and reliability on the water. Familiarity with these features can significantly enhance the boating experience.

Key Components

Powerhead: This is the core of the engine, housing the combustion chamber and crucial mechanisms. Its efficiency directly impacts overall performance.

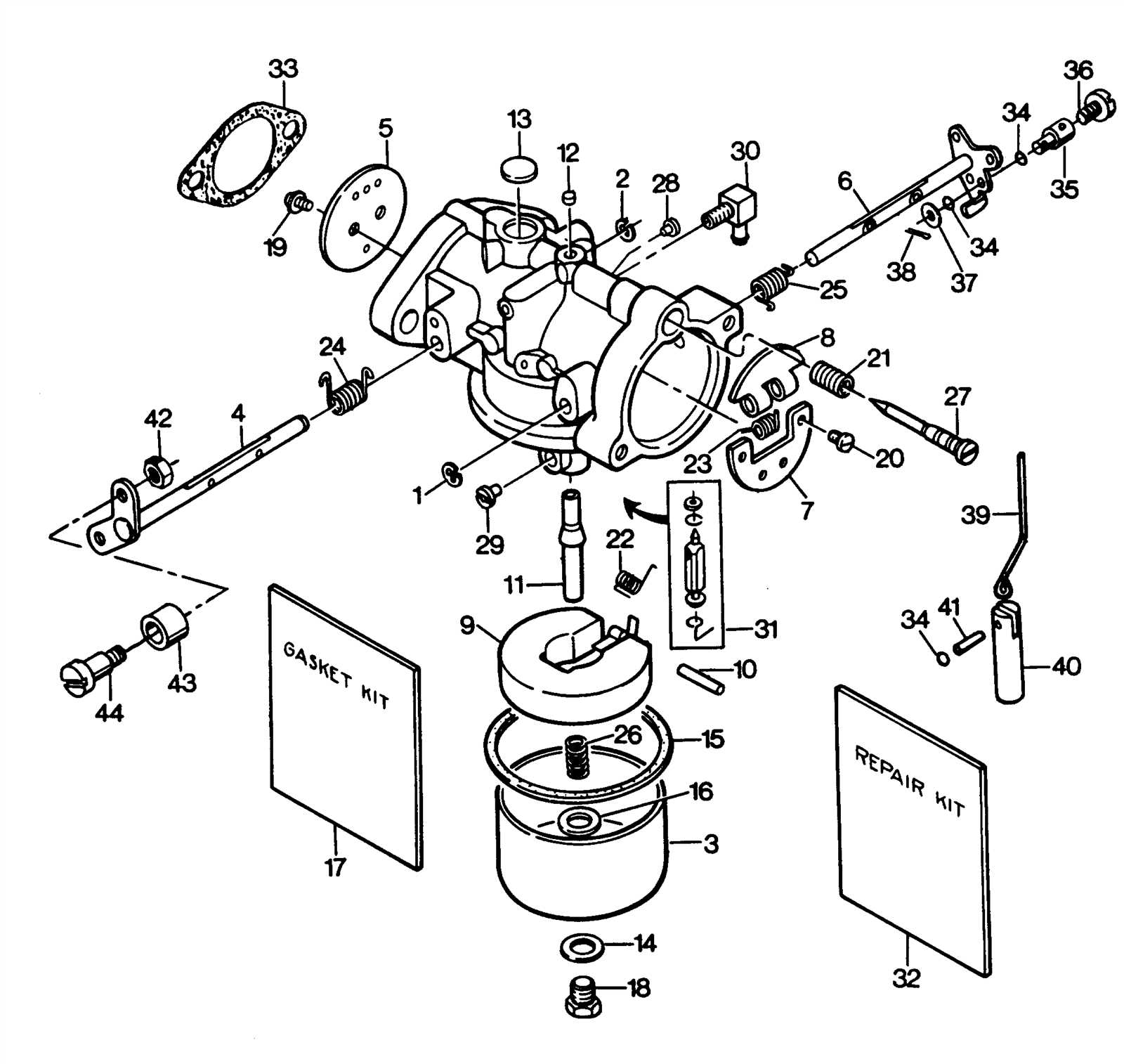

Fuel System

Fuel Pump: Responsible for delivering the necessary fuel to the engine, this element is vital for optimal functioning. Regular checks can prevent common issues.

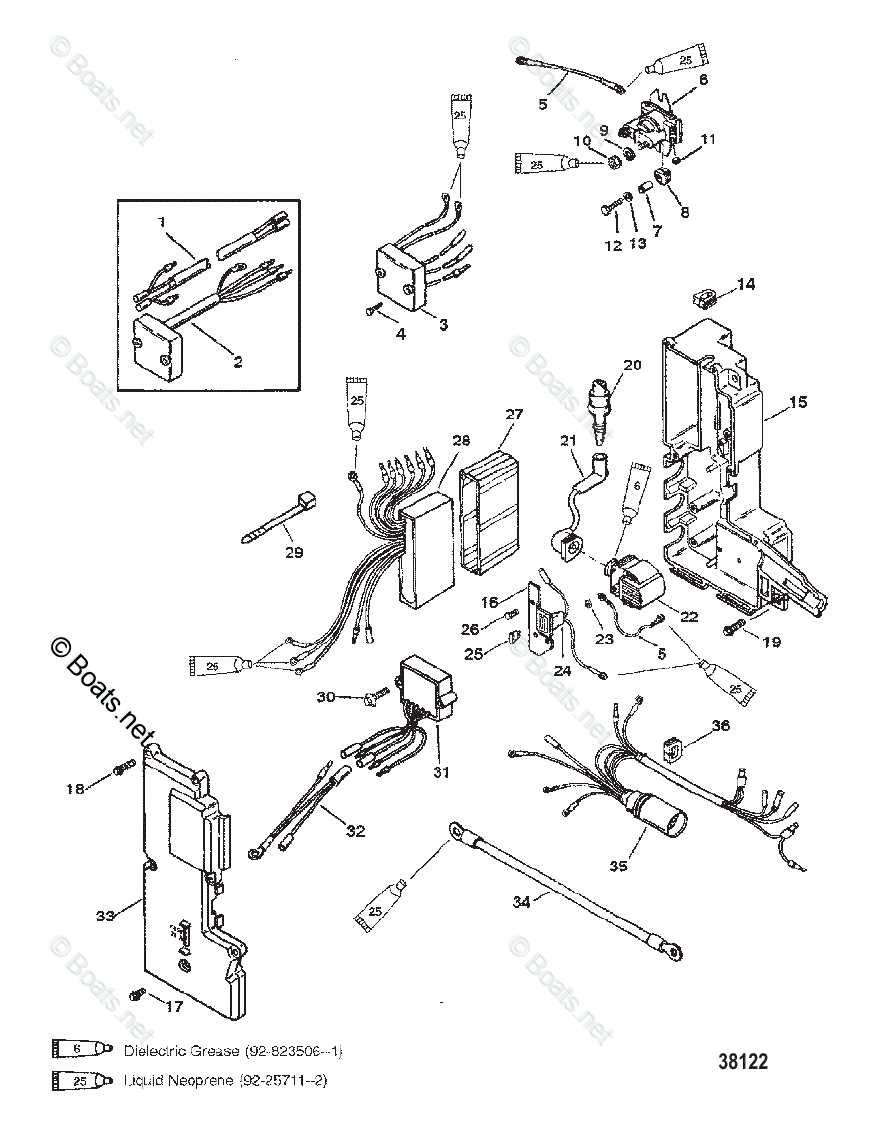

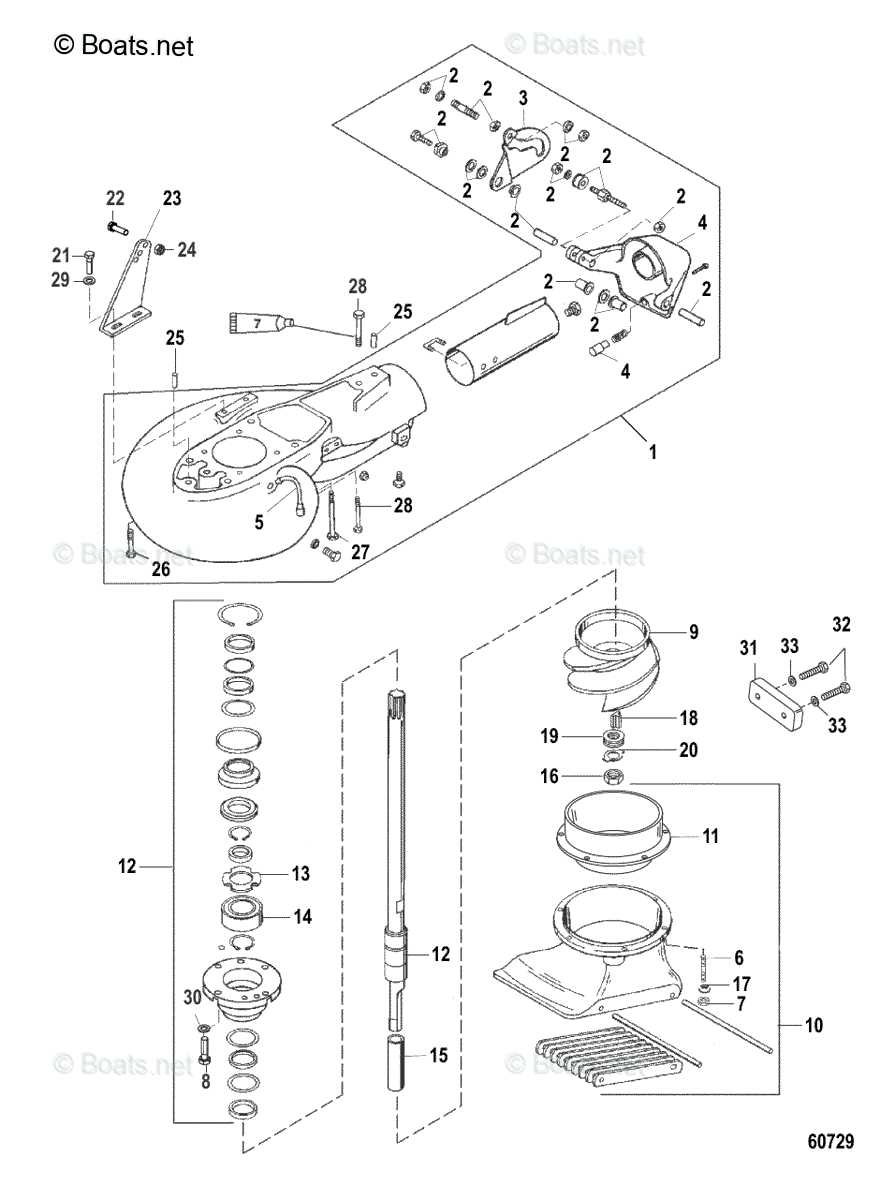

Identifying Key Components Visually

Understanding the essential elements of a marine engine is crucial for effective maintenance and troubleshooting. Visual identification helps in recognizing the functions and relationships of various components, facilitating smoother operations and repairs. This section aims to provide insights into distinguishing these vital parts through visual cues.

Main Elements to Recognize

- Engine Block

- Fuel System

- Ignition Components

- Cooling Mechanism

- Exhaust System

Tips for Effective Identification

- Familiarize yourself with each component’s layout and design.

- Utilize color coding and labels if available.

- Take note of the size and shape variations among similar parts.

- Refer to manuals for reference images when necessary.

- Practice recognizing components during routine inspections.

By enhancing your visual identification skills, you can significantly improve your understanding and maintenance of your marine engine, ensuring optimal performance on the water.

Maintenance Tips for Outboard Motors

Regular upkeep is essential for ensuring the longevity and optimal performance of your marine engine. By following a few key practices, you can prevent common issues and enhance reliability on the water.

- Check and replace the fuel filter regularly to maintain clean fuel flow.

- Inspect the propeller for damage and ensure it is securely attached.

- Monitor the cooling system and flush it periodically to remove debris.

- Change the oil and oil filter as recommended to keep the engine lubricated.

- Examine electrical connections for corrosion and secure fit.

By implementing these practices, you can significantly improve your engine’s performance and reduce the risk of unexpected failures.

Finding Replacement Parts Easily

Locating suitable components for your marine engine can be a straightforward process with the right approach. Utilizing reliable resources and tools can significantly streamline your search, ensuring that you find the exact items you need without unnecessary hassle.

Start by exploring online retailers that specialize in marine equipment. These platforms often provide comprehensive catalogs, making it easier to navigate through various options. Additionally, using search filters can help narrow down choices based on specifications, enhancing your efficiency.

Don’t overlook the value of community forums and discussion groups. Engaging with fellow enthusiasts can yield valuable insights and recommendations. These networks often share experiences regarding sourcing components, which can guide you toward reliable suppliers.

Lastly, consider contacting local dealerships or service centers. They can offer expert advice and may have inventory that aligns with your needs. Establishing a relationship with these professionals can also facilitate future purchases and maintenance.

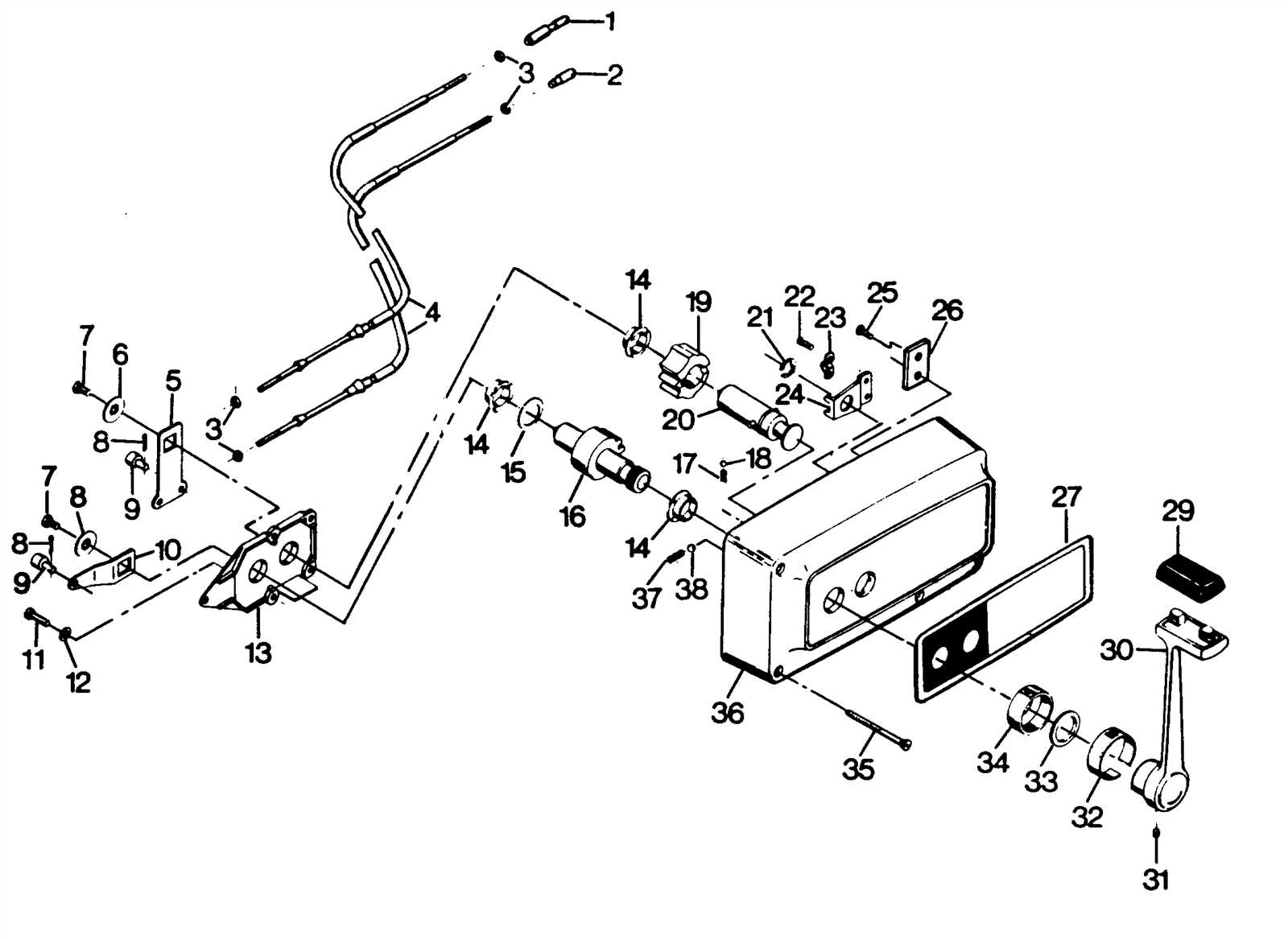

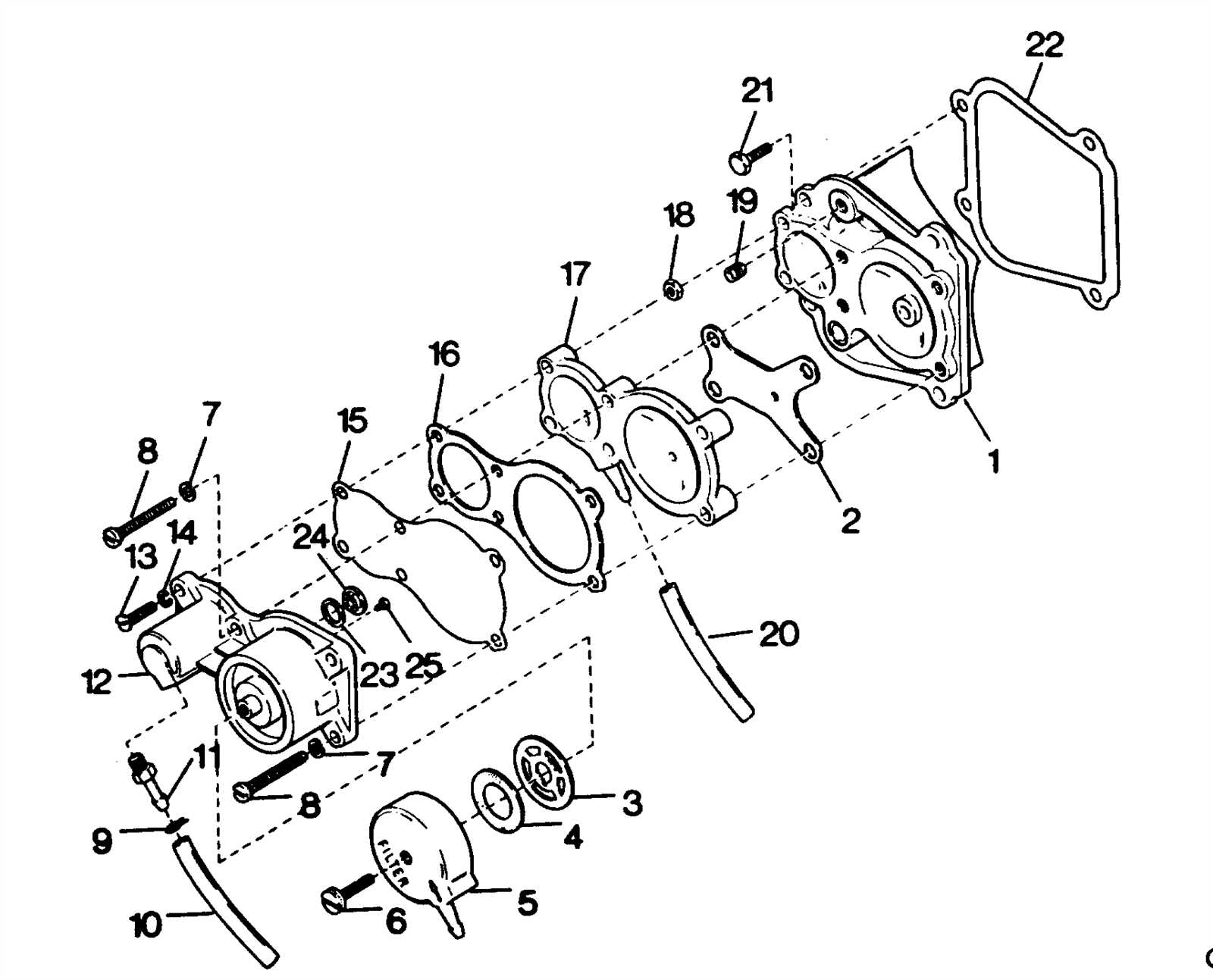

Understanding Engine Assembly Basics

Grasping the fundamentals of engine construction is essential for anyone involved in marine machinery. This knowledge not only enhances maintenance skills but also improves troubleshooting capabilities. A well-assembled engine operates efficiently, ensuring longevity and reliability.

Key Components of Engine Assembly

- Crankshaft: The heart of the engine that converts linear motion into rotational energy.

- Pistons: Components that move up and down within the cylinders, creating the necessary pressure for combustion.

- Cylinders: The chambers where the fuel-air mixture ignites and drives the pistons.

- Valves: Mechanisms that control the intake of fuel and the expulsion of exhaust gases.

- Camshaft: Responsible for opening and closing the valves at the right times during the engine cycle.

Assembly Process Overview

- Begin with the crankcase, ensuring all surfaces are clean and free of debris.

- Install the crankshaft, aligning it properly within the designated mounts.

- Position the pistons within the cylinders, ensuring they are correctly oriented.

- Attach the cylinder head, securing it with the appropriate bolts to maintain compression.

- Integrate the timing components, ensuring synchronization between the crankshaft and camshaft.

- Finish with the installation of valves, intake, and exhaust systems, double-checking for proper sealing.

Understanding these elements and their assembly is crucial for effective engine management and repair. Mastery of these basics leads to improved performance and reduced downtime.

Benefits of OEM vs Aftermarket Parts

When it comes to maintaining and repairing equipment, choosing the right components can significantly impact performance and longevity. Original components are crafted by the manufacturer and often come with specific advantages, while alternative options can offer cost savings and broader availability. Understanding these distinctions is crucial for making informed decisions.

| Feature | OEM Components | Aftermarket Options |

|---|---|---|

| Quality | Manufactured to precise specifications | Varied quality; not always guaranteed |

| Warranty | Often includes manufacturer’s warranty | May have limited or no warranty |

| Fit | Designed for perfect compatibility | Possible fitment issues |

| Price | Generally higher cost | Usually more affordable |

| Availability | May require specific ordering | Widely available from multiple sources |

Ultimately, the choice between original and alternative components depends on individual needs and priorities, making it essential to delve into both options before deciding.

Common Issues with 50 HP Outboards

Boating enthusiasts often encounter a range of challenges when operating 50 horsepower engines. Understanding these common complications can help in timely troubleshooting and maintenance, ensuring smooth performance on the water. Below, we outline frequent issues and potential solutions that can enhance the longevity and reliability of your marine engine.

Fuel System Problems

One of the primary areas where issues can arise is the fuel system. Clogged filters, stale fuel, or malfunctioning pumps can lead to poor performance or starting difficulties. Regular inspection and maintenance are crucial to prevent these problems.

| Issue | Symptoms | Solutions |

|---|---|---|

| Clogged Fuel Filter | Difficulty starting, rough idling | Replace filter, clean fuel lines |

| Stale Fuel | Loss of power, hard starting | Drain old fuel, refill with fresh |

| Malfunctioning Pump | Inconsistent power, sputtering | Inspect pump, replace if necessary |

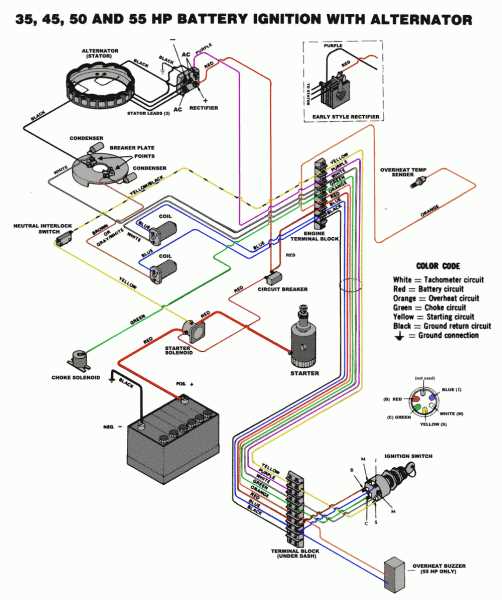

Electrical Failures

Electrical issues can also hinder performance. Faulty wiring, dead batteries, or corroded connections may prevent the engine from starting or cause intermittent failures. Regular checks can mitigate these risks.

| Issue | Symptoms | Solutions |

|---|---|---|

| Dead Battery | Engine won’t start, dim lights | Charge or replace battery |

| Corroded Connections | Intermittent issues, erratic performance | Clean connections, apply anti-corrosion spray |

| Faulty Wiring | Engine stalling, no response | Inspect wiring, repair or replace as needed |

Tools Needed for Repair and Maintenance

Effective upkeep and repair of marine engines require a specific set of instruments to ensure precision and efficiency. Having the right tools at hand not only streamlines the process but also enhances the quality of work performed. Understanding what is essential can make all the difference in achieving optimal performance.

Basic Tools: A quality wrench set is vital for loosening and tightening various components. Additionally, a screwdriver set will be necessary for accessing smaller screws in tight spaces. Don’t forget about pliers for gripping and manipulating parts during repairs.

Specialty Instruments: A compression tester is crucial for assessing engine health, while a multimeter helps in diagnosing electrical issues. Consider investing in a torque wrench to ensure bolts are tightened to the manufacturer’s specifications.

Maintenance Supplies: Stock up on lubricants, cleaners, and sealants to maintain and protect components from wear and corrosion. Regular maintenance can significantly extend the lifespan of the engine.

Equipping yourself with these essential tools will ultimately lead to more successful repairs and a better understanding of your marine equipment.

How to Read Parts Diagrams Effectively

Understanding visual representations of components can greatly enhance your ability to identify and manage individual elements. By familiarizing yourself with the layout and symbols used, you can streamline your maintenance and repair processes. This knowledge not only helps in locating specific items but also aids in comprehending how they interact within a larger assembly.

Start by examining the overall layout, noting how components are grouped and labeled. Look for a key or legend that explains the symbols used, as these can vary significantly. Pay attention to the orientation and numbering of elements, which often indicates their position in the assembly.

As you explore further, make a habit of cross-referencing the visual guide with written instructions. This dual approach ensures clarity and helps avoid mistakes during reassembly. Additionally, keeping a notebook for personal annotations can be beneficial for future reference.

Lastly, practice makes perfect. The more you engage with these visuals, the better you’ll become at interpreting them. Over time, this skill will ultimately save you time and effort in any repair or maintenance task.

Repair vs. Replace: Making the Decision

When faced with malfunctioning equipment, the choice between fixing or swapping out components can be daunting. Each option has its own set of advantages and drawbacks, making it essential to evaluate the situation carefully. Understanding the implications of your decision can lead to more efficient outcomes and cost savings.

Factors to Consider

Several key elements should guide your decision-making process. These include the age of the unit, availability of components, cost of repairs, and overall performance. Each factor plays a vital role in determining whether a repair will restore functionality or if a replacement is the ultimate solution.

| Factor | Repair | Replace |

|---|---|---|

| Cost | Often cheaper if minor issues | Higher initial investment |

| Time | May take longer for parts | Typically quicker installation |

| Longevity | Limited lifespan post-repair | New model offers better durability |

Making the Choice

Ultimately, weigh the benefits against the costs to make an informed decision. Consider consulting with experts or performing a thorough analysis of your specific circumstances to ensure optimal results.

Where to Source Quality Parts

Finding reliable components for your marine engine is crucial for optimal performance and longevity. Various sources offer a range of options, ensuring that you can obtain high-quality items suited to your needs. Whether you prefer shopping online or visiting local retailers, it’s essential to know where to look for the best selections.

| Source Type | Description | Pros | Cons |

|---|---|---|---|

| Online Retailers | Websites specializing in marine supplies. | Convenient, extensive selection, competitive pricing. | Shipping times may vary, risk of receiving incorrect items. |

| Local Marine Shops | Brick-and-mortar stores focusing on marine equipment. | Personalized service, immediate pickup. | Limited stock, potentially higher prices. |

| Manufacturer Direct | Purchasing straight from the manufacturer. | Guaranteed authenticity, access to the latest models. | Higher costs, may lack variety. |

| Second-Hand Market | Used components from online marketplaces or auctions. | Cost-effective, unique finds. | Quality uncertainty, potential for wear. |