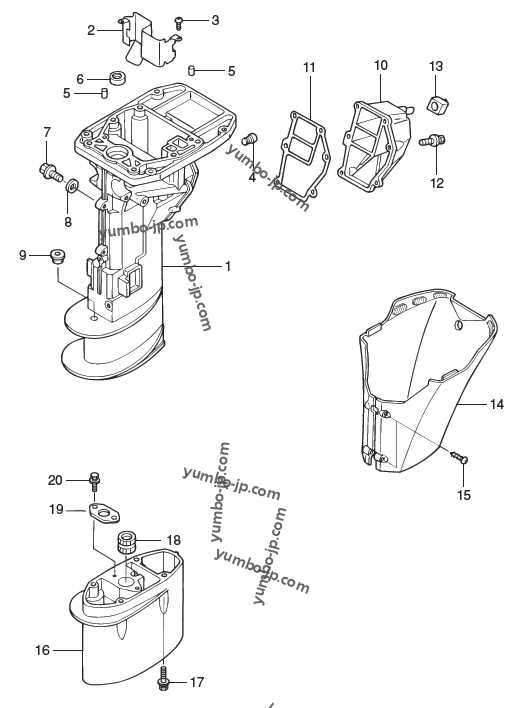

Understanding the internal structure of small marine propulsion systems is essential for proper maintenance and troubleshooting. These engines consist of various interconnected elements that work together to ensure smooth and efficient operation. Whether you’re a seasoned sailor or a novice, having a clear overview of the system can be extremely helpful when performing repairs or replacements.

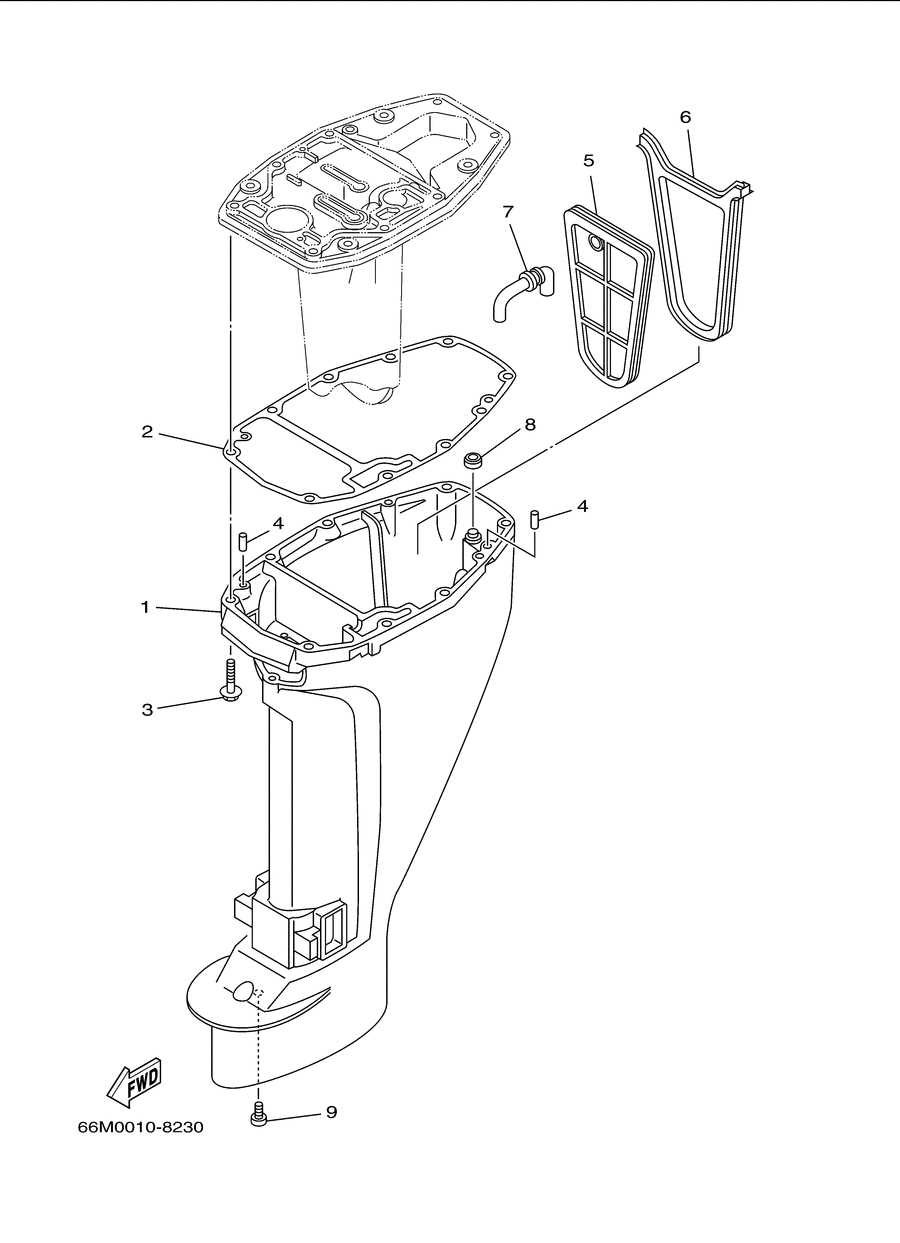

Detailed schematics provide a visual guide to the mechanical layout, offering a breakdown of the individual components. Each element plays a crucial role, from fuel delivery to cooling mechanisms, and understanding how they fit together can streamline the process of identifying any potential issues.

This guide aims to present an organized look into these essential systems, helping you become more familiar with the intricate details. Having access to accurate illustrations and information will give you the confidence to address common challenges with ease.

Understanding the Mercury 9.8 Outboard Engine Structure

To truly grasp how this motor operates, it is essential to break down its mechanical framework. Each component, from the ignition system to the cooling mechanism, plays a vital role in ensuring smooth performance on the water. By understanding the core structure, you can maintain and troubleshoot your machine more effectively.

Key Mechanical Components

The heart of the motor lies in its powerhead, which converts fuel into mechanical energy. Attached to it is the drive shaft, responsible for transferring this power to the propeller, allowing the vessel to move efficiently. In addition, the gearbox is a crucial part that manages speed and torque, ensuring optimal performance in various conditions.

Cooling and Exhaust Systems

The cooling system prevents overheating, circulating water through the engine. Paired with it is the exhaust system, which removes gases generated during combustion. Together, these systems help maintain operational

Key Components of the 9.8 Mercury Motor

This section focuses on the main elements that ensure smooth operation and optimal performance of the propulsion system. Each part works in harmony, contributing to the overall functionality of the engine, making it reliable for various marine activities.

- Power Unit: The central mechanism responsible for generating energy, driving the system forward.

- Fuel System: A network that manages the intake and delivery of fuel, ensuring efficient combustion and energy production.

- Cooling System: A vital component that regulates temperature, preventing overheating and maintaining engine health.

- Ignition System: This system controls the spark generation, which ignites the fuel-air mixture for propulsion.

- Exhaust System: Facilitates the expulsion of gases after

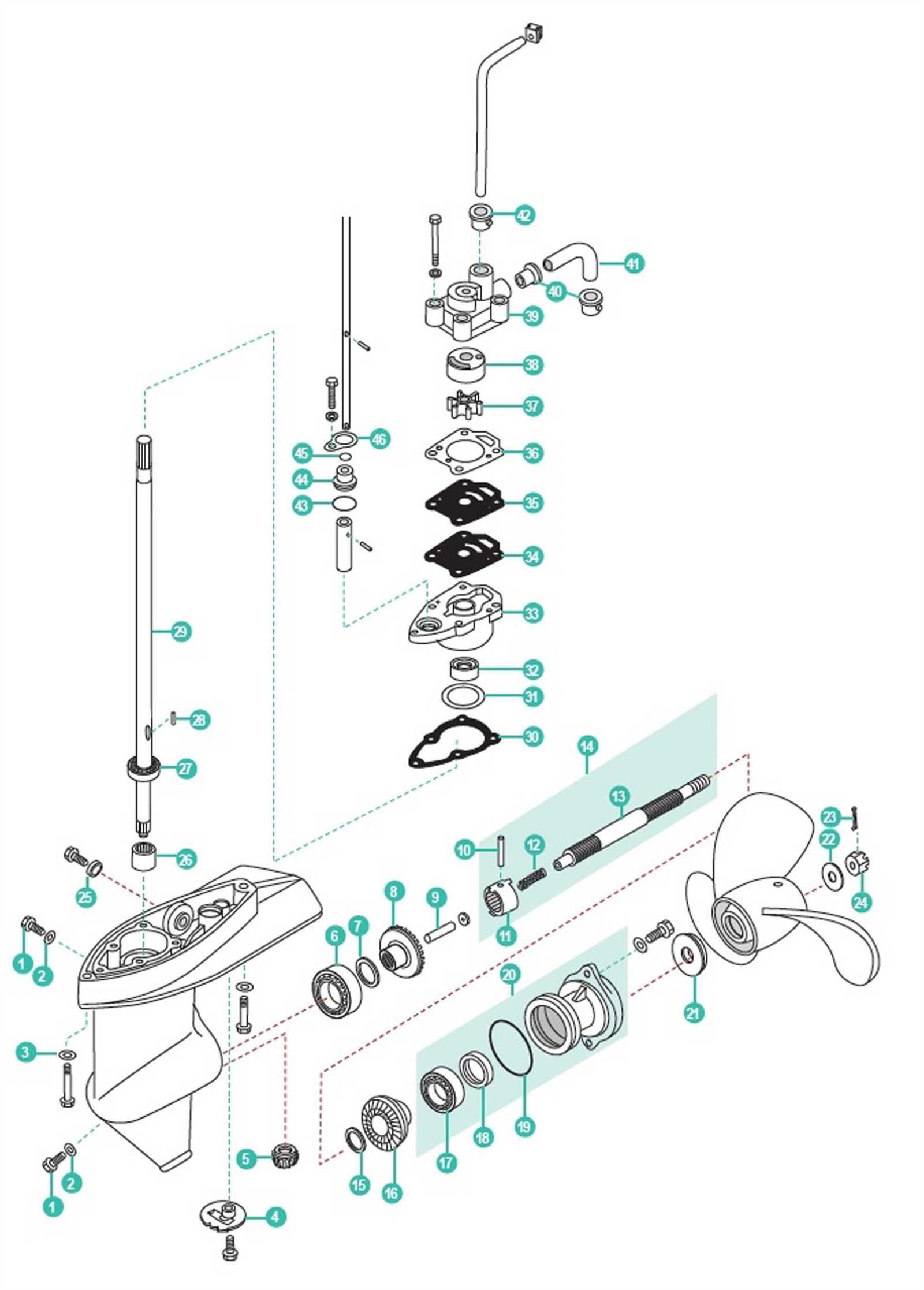

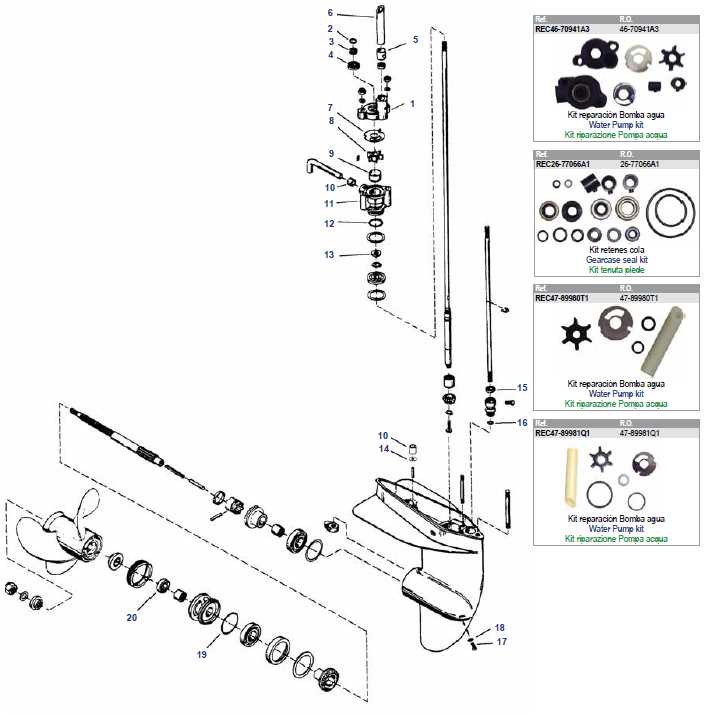

Mercury 9.8 Cooling System Overview

The cooling system in this model is designed to maintain optimal engine temperatures during operation. It ensures that the internal components are protected from overheating, extending the engine’s lifespan and enhancing overall performance. Understanding how the system functions can help identify potential issues early on, ensuring smoother operation and timely maintenance.

At the core of this mechanism is a water intake, which draws in external water to regulate the engine’s temperature. This flow of water passes through various channels within the engine, absorbing excess heat and allowing the motor to run efficiently without overheating. The system is engineered to automatically adjust based on the engine’s needs, ensuring consistent cooling during varying speeds and environmental conditions.

Proper maintenance of this cooling process is essential to prevent buildup of debris or blockages, which could lead to overheating and potential damage. Regular checks of the intake, water pump, and thermostat are recommended to keep everything in optimal condition.

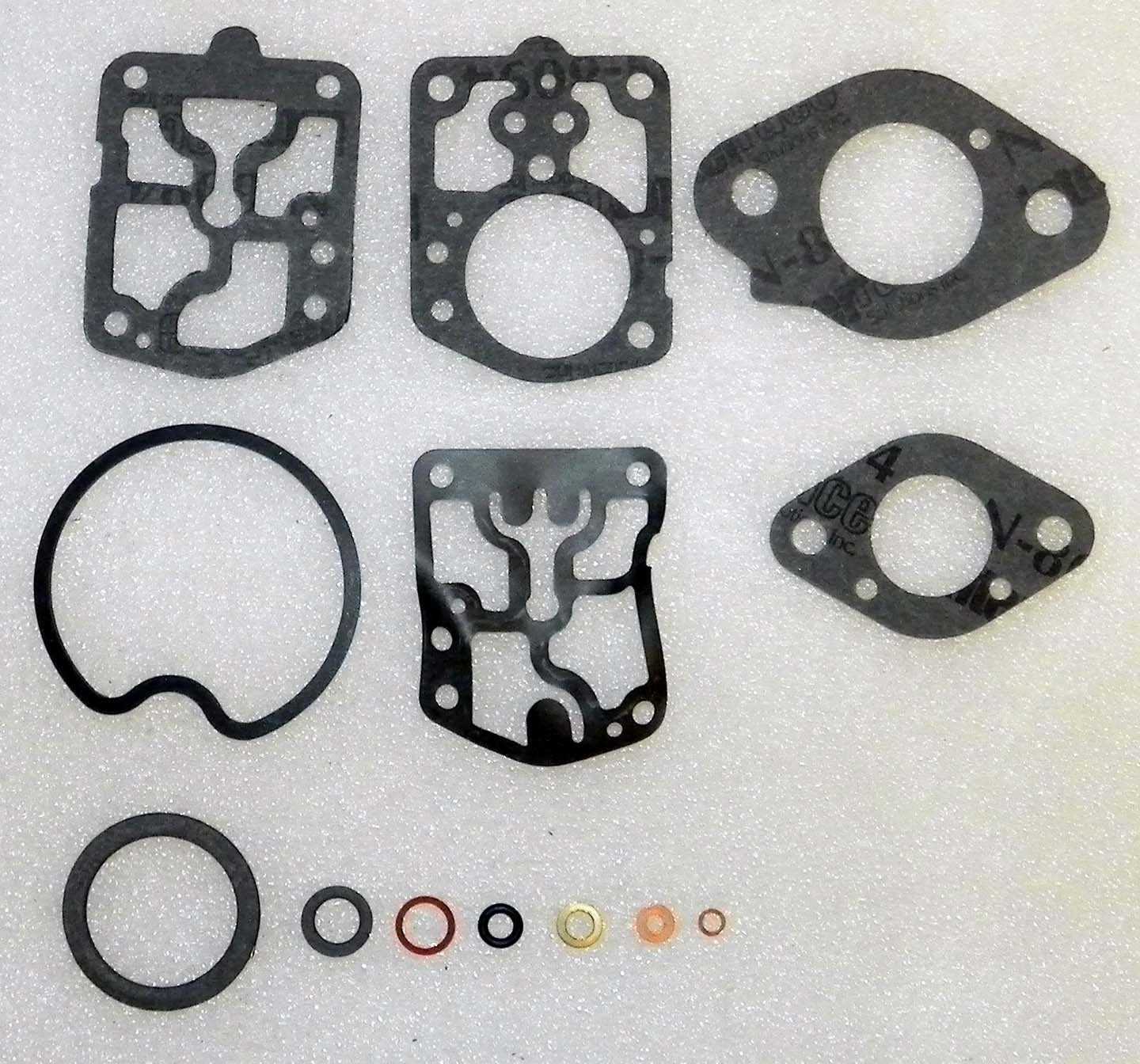

Fuel System Parts for Mercury 9.8

The fuel delivery system in this engine model is essential for ensuring smooth operation and optimal performance. The components responsible for handling fuel must function correctly to prevent issues such as poor efficiency, rough idling, or starting difficulties. This section will cover the main elements of the fuel delivery system, focusing on their roles in maintaining reliability and performance.

Main Components

The primary elements include the fuel pump, which ensures a consistent flow to the engine, and the filter that removes contaminants. These parts work in harmony to prevent blockages and deliver clean fuel, enhancing engine longevity. Without these, fuel flow can be restricted, leading to operational failures.

Maintenance and Care

Regular inspection and cleaning of the lines and connectors are crucial to avoid clogs or leaks. Periodically replacing worn elements can prevent breakdowns

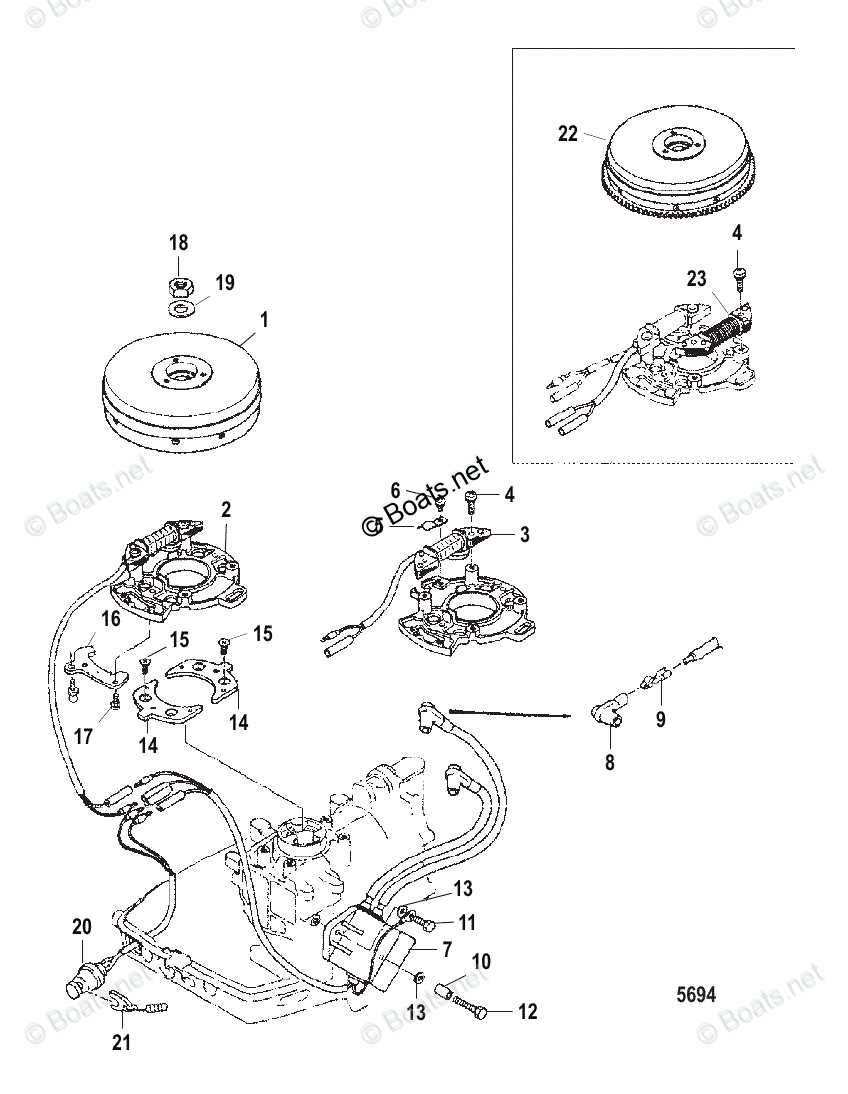

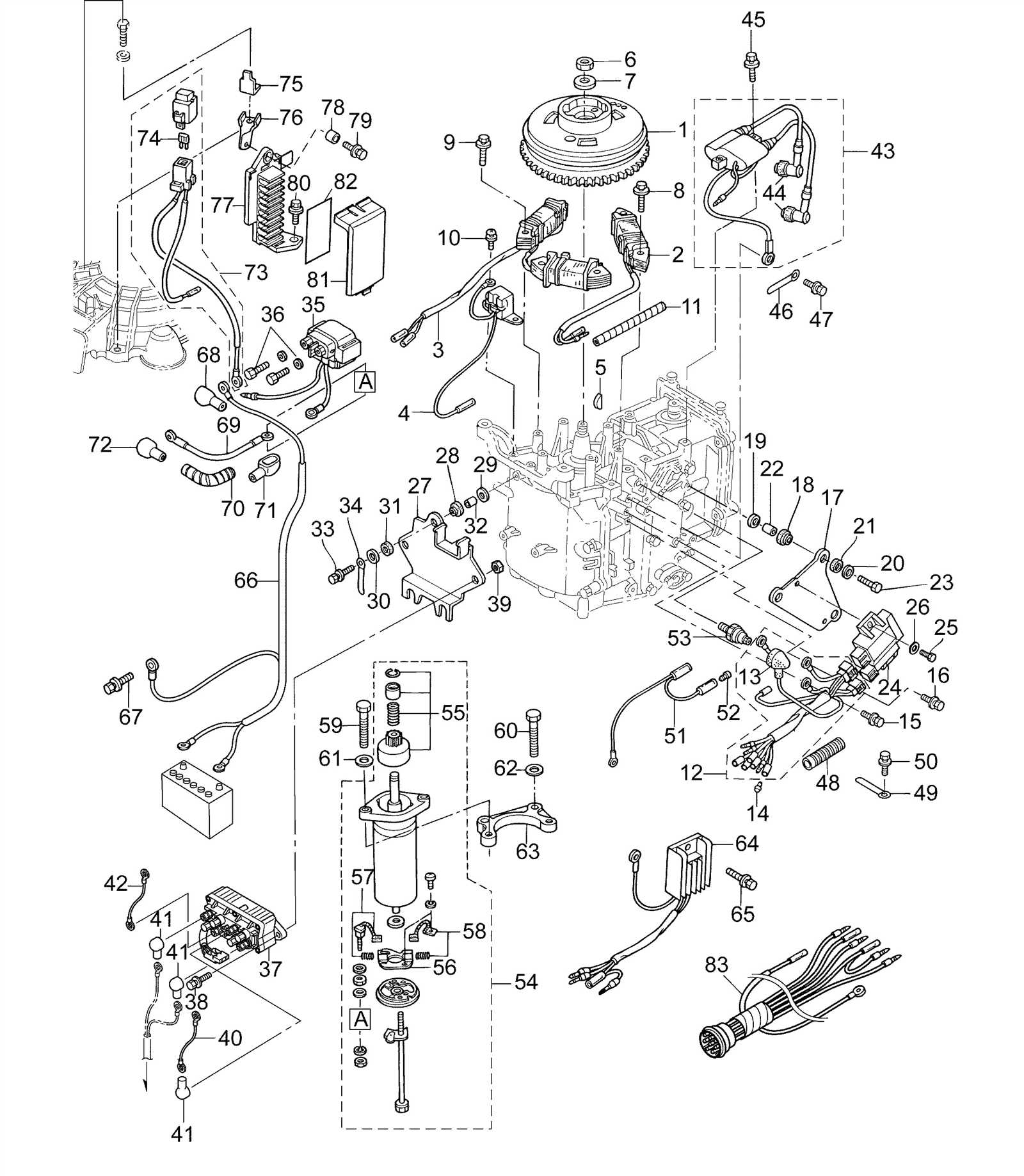

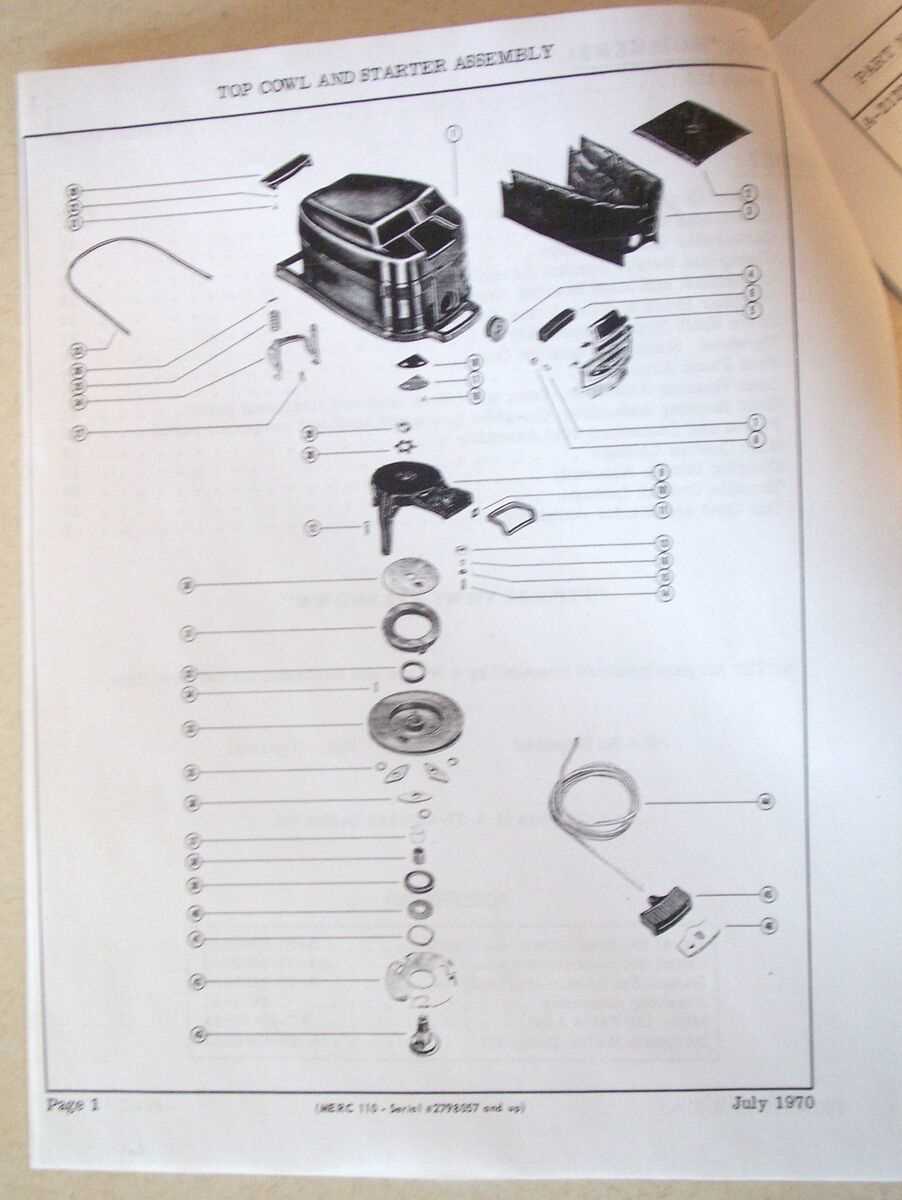

Electrical Components in the Mercury 9.8 Engine

The electrical system in this marine engine plays a vital role in ensuring smooth operation and reliable performance. It manages various functions, including power generation, ignition, and control, by utilizing a set of interconnected elements designed for efficiency and durability.

Ignition System: The ignition setup ensures that the engine starts reliably and operates efficiently by delivering a consistent spark. Key components such as the spark plugs, wires, and control modules contribute to stable performance.

Charging Mechanism: A charging unit maintains battery power during operation, ensuring that all electronic devices, including navigation lights or other onboard systems, remain functional.

Wiring and Connectors: Properly routed wires and connectors ensure seamless communication between various electrical elements, providing safe and dependable performance. These connections help maintain the integrity of the overall system, preventing

Ignition System Breakdown for Mercury 9.8

The ignition mechanism is a crucial component that ensures the proper functioning of a marine propulsion unit. Understanding its elements and their interactions can enhance maintenance practices and improve overall performance. This section delves into the fundamental aspects of the ignition assembly, highlighting key elements that contribute to the system’s efficiency.

Component Function Ignition Coil Transforms low voltage from the battery to high voltage for creating a spark. Spark Plug Ignites the fuel-air mixture in the combustion chamber through a spark. Flywheel Stores rotational energy and aids in producing voltage through the ignition coil. Trigger Signals the ignition coil to release high voltage at the correct time. Wiring Harness Connects various components of the ignition system, ensuring proper electrical flow. Regular inspection and maintenance of these components are essential for optimal engine performance. By understanding how each part functions, operators can troubleshoot issues effectively and ensure the longevity of their marine equipment.

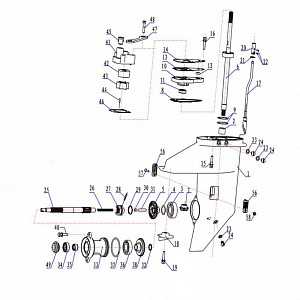

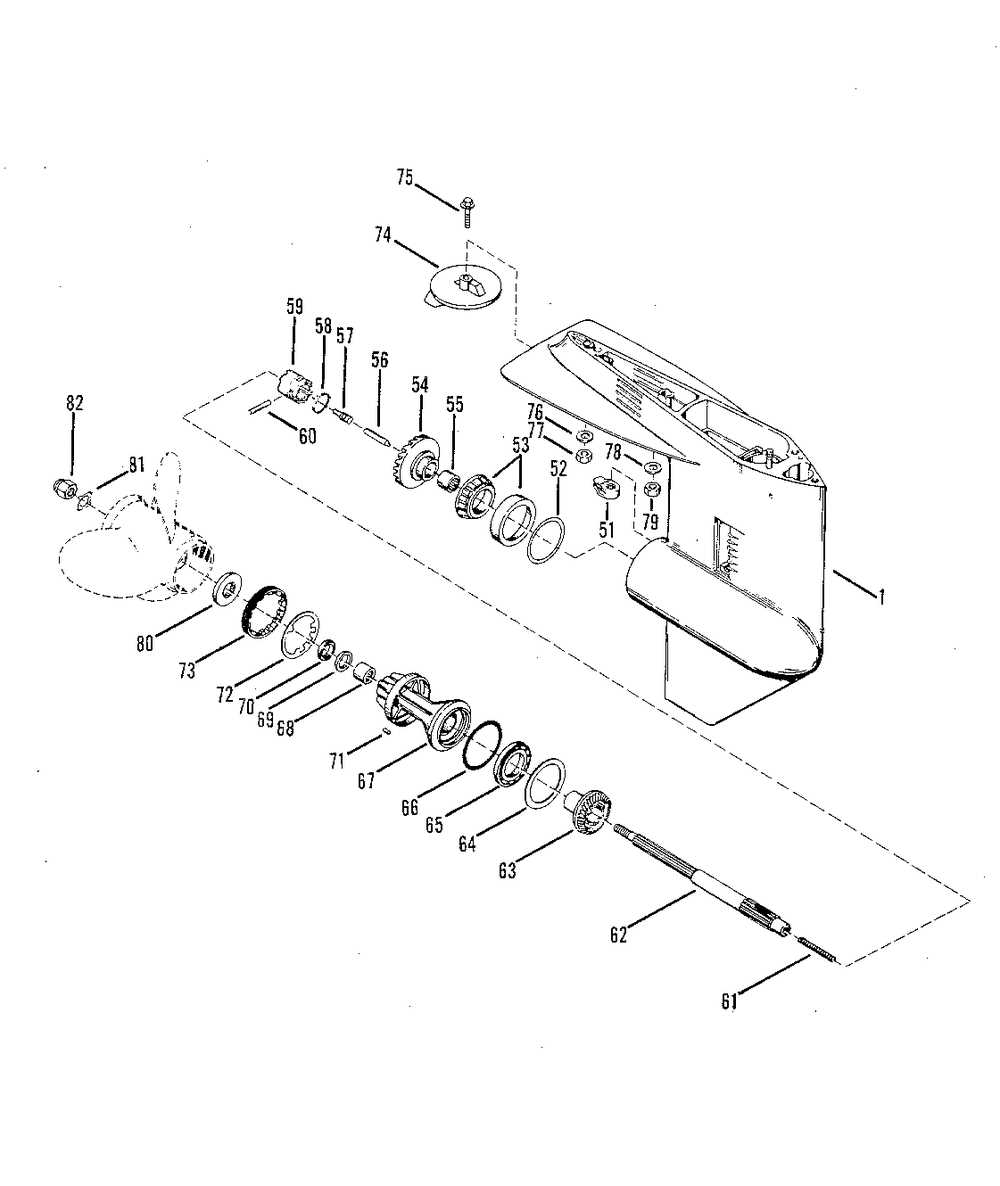

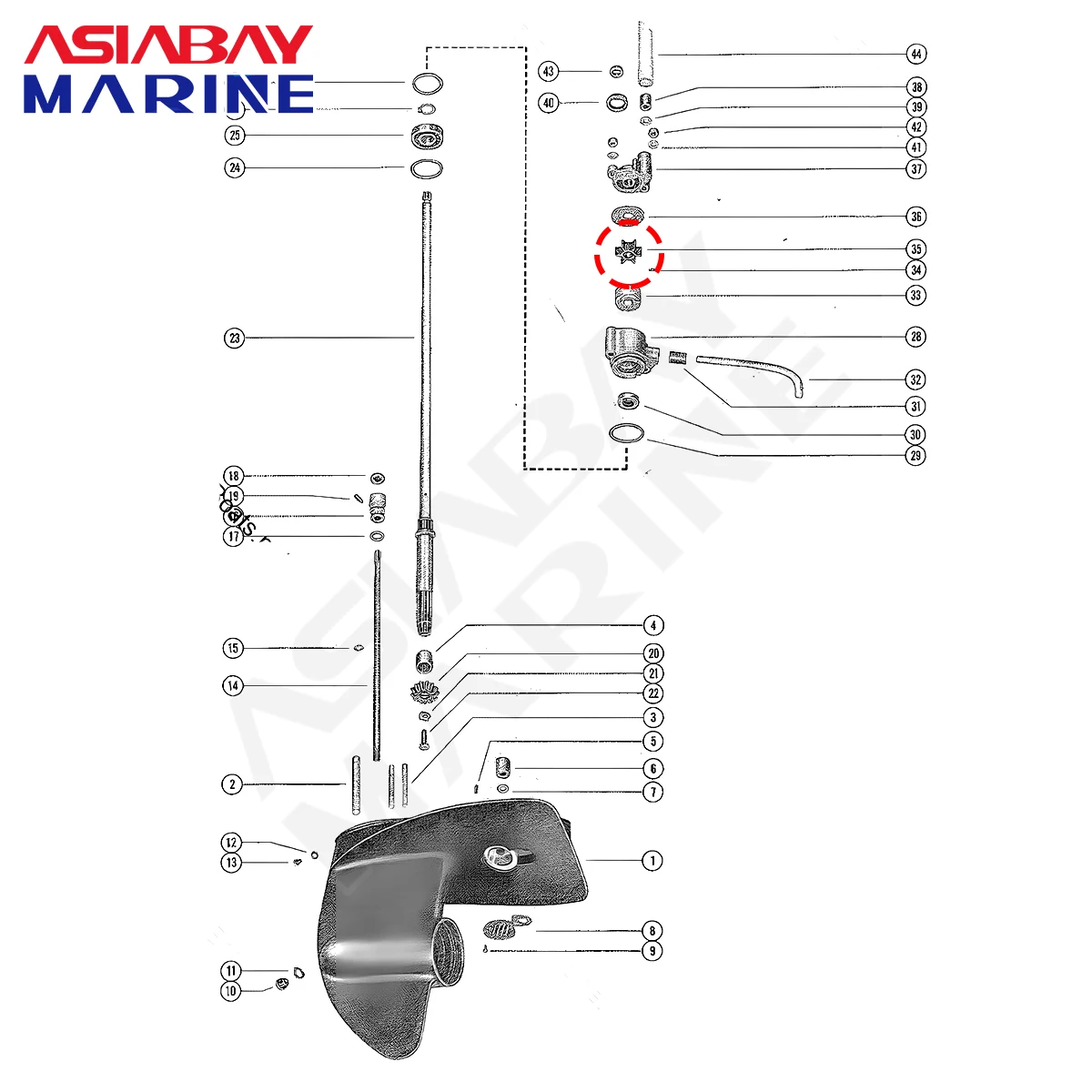

Propeller and Drive System Explained

The mechanism that enables a vessel to move through water is a critical aspect of its design. This section explores the components involved in propelling watercraft, focusing on the functionality and interaction of the propeller and its associated drive system. Understanding these elements can enhance performance and efficiency, ensuring smooth navigation.

Components of the Drive System

- Propeller: The primary element that converts rotational energy into thrust. Its design influences speed and maneuverability.

- Drive Shaft: Connects the engine to the propeller, transmitting power while allowing for movement flexibility.

- Gearcase: Houses the gears that adjust the propeller speed and torque, affecting the overall propulsion efficiency.

- Engine: The source of power that drives the entire system, working in conjunction with the propeller to create motion.

Functionality of the Propeller

The propeller’s design and pitch play vital roles in determining how effectively it can move water and, consequently, the vessel. The shape and angle of the blades influence the amount of water displaced, impacting acceleration and top speed.

- Forward Thrust: Generated by the rotation of the blades, propelling the vessel ahead.

- Reverse Thrust: Achieved by altering the blade pitch, allowing for backward movement and maneuvering.

In conclusion, the interplay between the propeller and drive mechanism is fundamental to a vessel’s performance. Proper maintenance and understanding of these components can lead to improved navigation experiences.

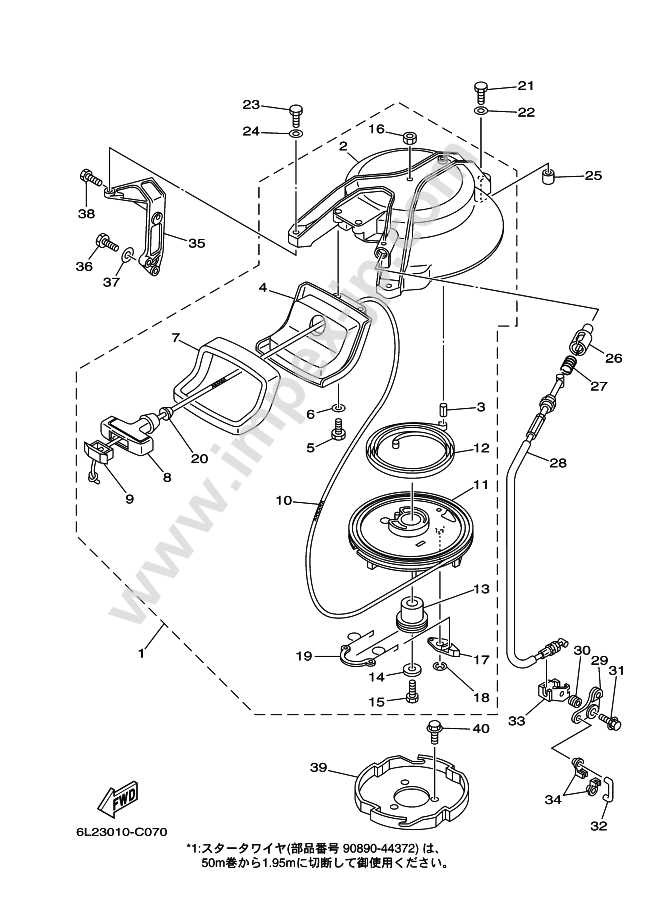

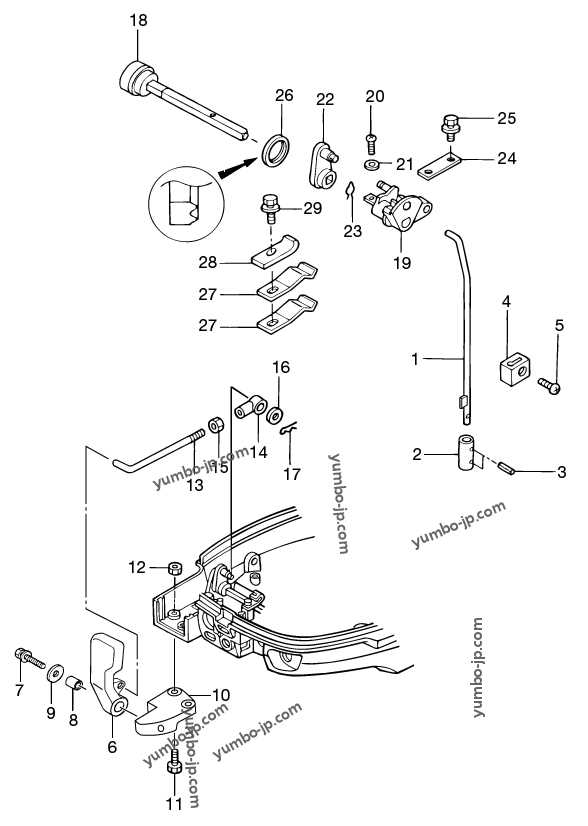

Throttle and Control Mechanism Details

The throttle and control mechanism serves as a vital component in the operation of marine propulsion systems. Its primary function is to regulate the engine’s power output, allowing for precise maneuvering and speed adjustments. This intricate assembly plays a crucial role in ensuring smooth transitions and responsiveness during navigation.

Key Components

Several essential elements comprise the control mechanism. These include the throttle lever, cables, and linkage systems. The throttle lever is the operator’s interface, providing direct control over the engine’s performance. The cables connect the lever to the engine, facilitating the transfer of commands. Linkage systems enhance the precision of these controls, ensuring that every adjustment is accurately reflected in the engine’s response.

Operational Mechanism

When the throttle lever is engaged, it manipulates the opening of the engine’s intake, allowing more or less air and fuel to enter. This regulation directly influences the engine’s output, enabling the vessel to accelerate or decelerate as required. Understanding the functionality of this mechanism is essential for effective operation and maintenance, ensuring that navigators can handle their crafts with confidence and control.

Maintenance Tips for Mercury 9.8 Outboard

Regular upkeep of your marine engine is essential for optimal performance and longevity. By adhering to a few key practices, you can ensure that your equipment remains in excellent condition and ready for every adventure on the water.

Routine Inspections

Conducting periodic examinations is vital. Check the fuel system for leaks, inspect the cooling components for blockages, and assess the electrical connections for corrosion. This proactive approach helps identify potential issues before they escalate.

Fluid Changes

Regularly replacing the lubricants is crucial for maintaining efficiency. Ensure to change the oil as recommended in the manufacturer’s guidelines. Additionally, inspect and refresh the coolant to prevent overheating and ensure smooth operation.

Remember that proper care not only enhances performance but also extends the lifespan of your equipment. Taking these steps will allow you to enjoy your time on the water worry-free.

Identifying Genuine Mercury 9.8 Replacement Parts

When it comes to ensuring optimal performance and longevity of your marine engine, selecting authentic components is crucial. Counterfeit or substandard items can lead to inefficiencies and costly repairs. This section delves into the essential aspects of distinguishing original components from imitation ones, enabling you to make informed decisions.

Examine Packaging: Authentic components typically come in well-branded packaging that includes product details and safety information. Look for high-quality printing and labels that display the manufacturer’s logo clearly.

Check Serial Numbers: Genuine items often have unique identification numbers. Verify these with the manufacturer’s database or website to confirm authenticity. This step can prevent the installation of subpar alternatives.

Research Authorized Dealers: Purchasing from certified retailers ensures that you are receiving quality items. Authorized dealers are less likely to stock counterfeit goods and can provide valuable advice on installation and maintenance.

Inspect Material Quality: Authentic components are made from high-grade materials, which contribute to their durability and reliability. When examining a replacement, consider its weight, texture, and overall craftsmanship.

Seek Professional Advice: If in doubt, consult with experienced technicians or marine specialists. Their expertise can guide you in recognizing genuine items and understanding their significance in maintaining your engine’s performance.