Exploring the intricate layouts of mechanical systems reveals the essential structure that supports their functionality. A comprehensive overview of these arrangements provides insights into how various elements interact within the machinery. This knowledge is crucial for effective maintenance and repair, ensuring longevity and optimal performance.

In examining these layouts, one gains a clearer perspective on the significance of each component’s placement and connection. An organized representation allows for easier identification of parts and their specific roles in the overall operation. Understanding these relationships enhances the ability to troubleshoot and optimize mechanical systems efficiently.

Whether for educational purposes or practical applications, familiarizing oneself with the arrangement of these systems can significantly improve one’s proficiency in handling and servicing them. By delving into the structured outlines, individuals can foster a deeper appreciation for the complexity and engineering that drives such machinery.

Key Components of the Mercury 110

Understanding the essential elements of this particular model is crucial for effective maintenance and optimal performance. Each component plays a significant role in ensuring smooth operation and longevity.

Engine Assembly: The heart of the machinery, responsible for generating power. This section includes various internal parts that work in harmony to deliver reliable performance.

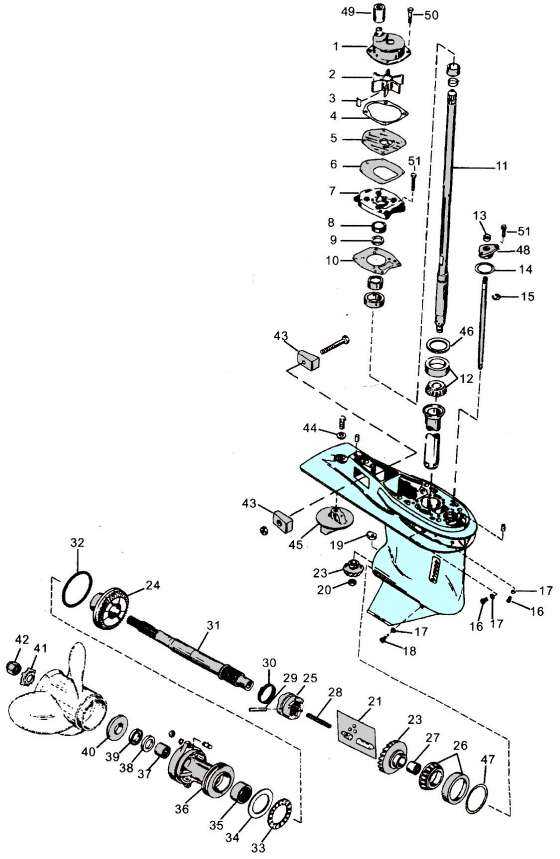

Transmission System: Vital for transferring power from the engine to the wheels, this system includes gears and other mechanisms that facilitate movement and control.

Suspension Mechanism: This part ensures stability and comfort while navigating different terrains. It consists of springs and shock absorbers that absorb impacts and enhance handling.

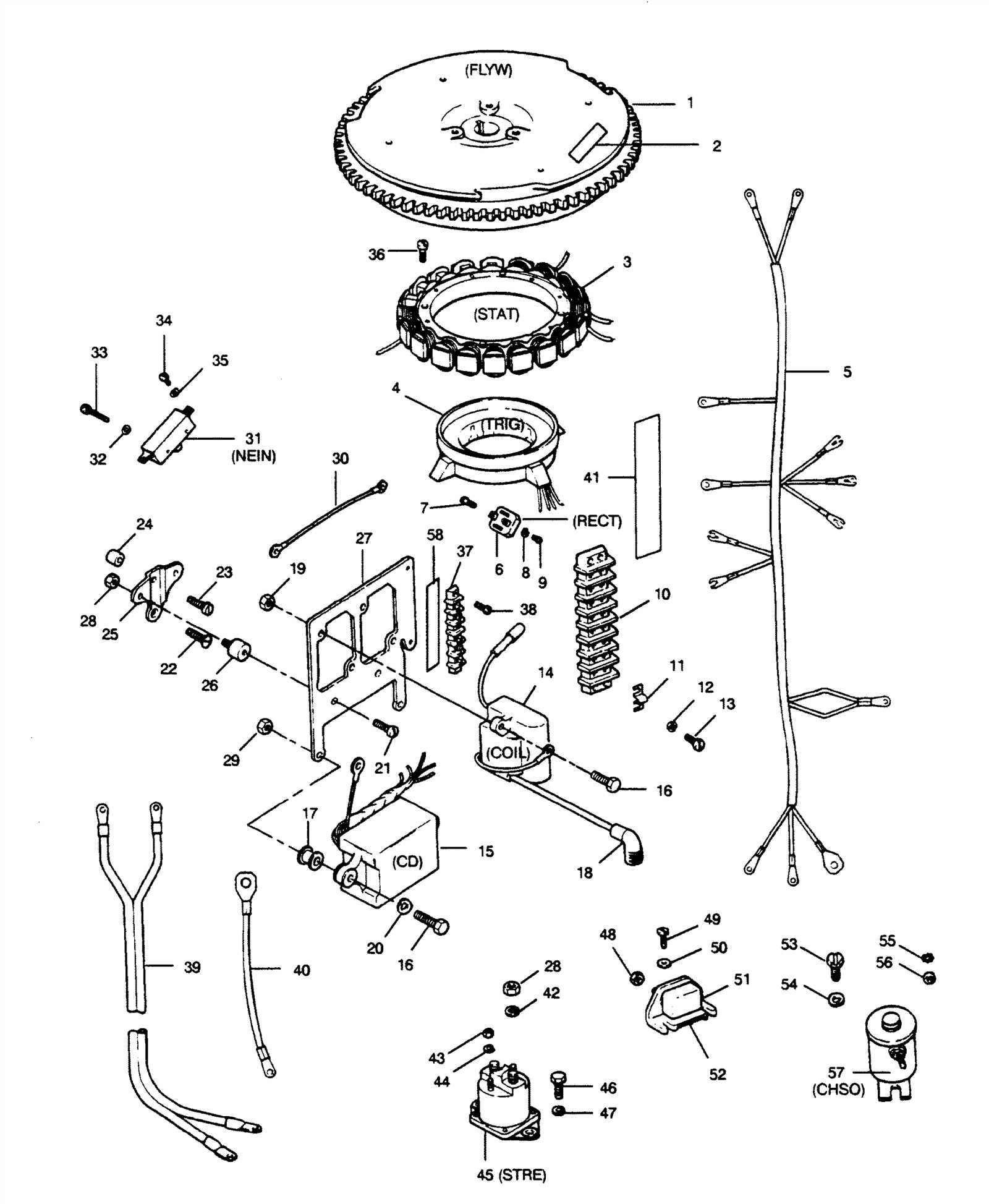

Electrical Components: Essential for starting the engine and powering various systems, these parts include batteries, wiring, and sensors that regulate functionality.

Cooling System: Prevents overheating by circulating coolant throughout the engine. This system is critical for maintaining optimal operating temperatures.

Familiarity with these fundamental aspects enhances overall understanding and management of the vehicle’s capabilities.

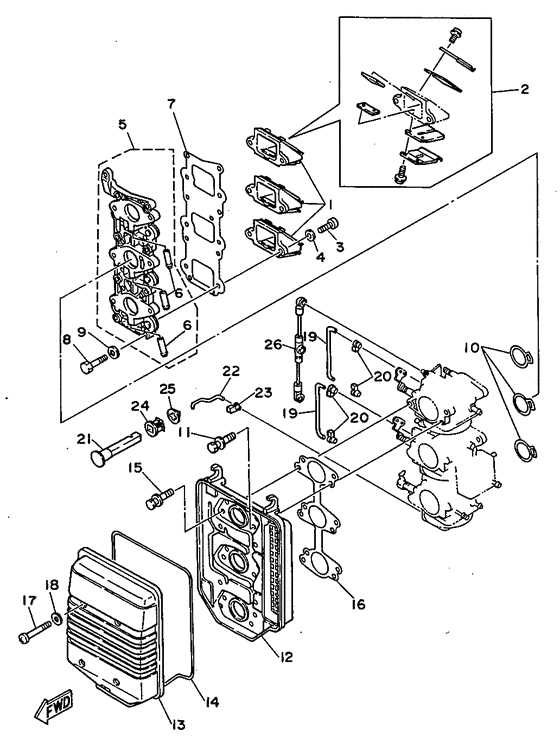

How to Understand the Component Schematic

When deciphering the illustration depicting various elements of the machine, it is crucial to grasp its visual language accurately. This graphical representation serves as a guide to identify individual parts and understand their spatial relationships within the assembly. The diagram employs symbols and labels to denote each component, facilitating clarity in identification and aiding in the navigation of repair or assembly processes.

Interpreting Symbols and Labels

The schematic utilizes a series of graphical symbols and alphanumeric labels to denote different parts and their functions. Each symbol corresponds to a specific component, while labels provide additional details such as part numbers or crucial dimensions. Understanding these symbols and labels is essential for effectively navigating the schematic and comprehending the structural composition of the machine.

Common Issues with Mercury 110 Parts

In this section, we explore common problems encountered with components of the Mercury 110 engine. These issues can affect various parts, leading to operational challenges and requiring careful inspection and maintenance.

1. Persistent Fuel System Troubles

- Recurring fuel leaks from deteriorated hoses or faulty seals.

- Carburetor clogging due to sediment buildup in the fuel tank.

- Inconsistent fuel delivery causing engine stalling.

2. Electrical System Challenges

- Frequent battery drain issues despite regular charging.

- Corrosion on electrical connectors leading to poor conductivity.

- Ignition coil failures resulting in intermittent spark.

Addressing these issues promptly with proper maintenance and replacement of worn parts can help maintain the reliability and performance of the Mercury 110 engine.

Essential Tools for Repairing Mercury 110

When tackling the maintenance and repair of various mechanical devices, having the right tools at your disposal is crucial. A well-equipped toolkit ensures that you can efficiently address any issues that may arise, allowing for a smoother repair process.

Wrenches are fundamental for loosening and tightening bolts, making them indispensable for any repair work. Consider having both adjustable and socket types to accommodate different sizes and shapes.

Screwdrivers of various types and sizes are essential for accessing different components. A set that includes flathead, Phillips, and specialized screwdrivers will enhance your ability to work on intricate parts.

Pliers are versatile tools that can assist in gripping, twisting, and cutting wires. Needle-nose pliers, in particular, are excellent for reaching tight spaces.

Torque Wrench is necessary for ensuring that bolts are tightened to the manufacturer’s specifications. This tool is vital for preventing damage due to over-tightening.

Cleaning Supplies such as brushes, rags, and solvents are important for maintaining a clean working environment, which is crucial for effective repairs. Keeping parts free from dirt and grime will improve their functionality and longevity.

Having these essential tools readily available will not only facilitate repairs but also enhance your overall efficiency and effectiveness in maintaining your mechanical equipment.

Maintenance Tips for Mercury 110

Regular upkeep of your Mercury 110 engine is essential to ensure optimal performance and longevity. Proper maintenance not only enhances reliability but also prevents costly repairs down the line. Here are some practical guidelines to keep your engine in top shape:

| 1. | Change lubricants and fluids at recommended intervals to maintain smooth operation. |

| 2. | Inspect fuel lines and filters regularly to avoid fuel system issues. |

| 3. | Check spark plugs for wear and replace them as needed to optimize ignition. |

| 4. | Examine propeller condition and alignment to prevent vibration and ensure efficiency. |

| 5. | Clean and inspect cooling system components to prevent overheating. |

By following these maintenance tips diligently, you can extend the life of your Mercury 110 engine and enjoy trouble-free boating experiences. Consistency in maintenance is key to preserving performance and reliability over the long term.

Where to Find Replacement Parts

Finding suitable components for your vehicle can be a straightforward process if you know where to look. Numerous sources offer access to high-quality replacements, ensuring that your machine remains in excellent condition.

- Authorized Dealers: Visiting an authorized dealer is often the best option for acquiring genuine components. They can provide specific recommendations based on your model and needs.

- Online Retailers: Many websites specialize in automotive replacements. These platforms allow you to compare prices and availability conveniently. Always check user reviews to ensure reliability.

- Local Auto Parts Stores: Brick-and-mortar shops in your area may have what you need. Speaking to staff can help you find the right fit and alternative suggestions.

- Salvage Yards: For those on a budget, salvage yards can be a treasure trove of usable items. It’s worth exploring these places for potentially less expensive solutions.

- Online Marketplaces: Platforms like eBay or specialized forums can connect you with sellers offering specific components. Be cautious and verify the seller’s reputation.

By exploring these options, you can effectively source the necessary items for your vehicle, ensuring its longevity and performance.

Step-by-Step Repair Process

When it comes to restoring a malfunctioning vehicle component, a systematic approach is essential. This guide outlines the fundamental stages of the repair journey, ensuring clarity and efficiency throughout the process. Each step aims to provide a thorough understanding of what is required to bring the part back to optimal condition.

Initial Assessment

Begin by examining the component for any visible signs of wear or damage. Identify potential issues that may be affecting its performance. Taking detailed notes and photographs can be beneficial for reference during the repair.

Disassembly and Cleaning

Once the assessment is complete, proceed with disassembling the part carefully. Utilize appropriate tools to avoid any further damage. Cleaning all components thoroughly is vital to ensure that any residue or debris does not interfere with the repair process.

Upgrading Your Mercury 110 Components

Enhancing the functionality and performance of your vessel can significantly improve your overall experience on the water. This section focuses on various modifications and enhancements that can be made to your outboard engine, helping you achieve better efficiency and reliability.

Key Areas for Improvement

- Fuel Efficiency

- Power Output

- Durability

- Maintenance Ease

Popular Upgrades to Consider

- Propeller Replacement: Selecting the right propeller can optimize your engine’s performance, providing better speed and fuel consumption.

- Ignition System Upgrade: A more advanced ignition system can lead to smoother starts and improved overall efficiency.

- Fuel System Enhancements: Upgrading to a high-performance fuel pump or injectors can result in better fuel delivery and increased power.

- Cooling System Improvements: Ensuring your cooling system is efficient can prevent overheating and extend the life of your engine.

Investing in these enhancements not only boosts performance but also ensures a more enjoyable and trouble-free experience on the water.

Safety Precautions During Repairs

When engaging in maintenance or restoration tasks, ensuring a safe working environment is paramount. Adhering to specific safety guidelines helps to minimize the risk of accidents and injuries, allowing for a more efficient repair process.

Before starting any work, it is essential to wear appropriate personal protective equipment, such as gloves, goggles, and masks. This gear safeguards against potential hazards, including sharp objects, chemicals, and debris that may be encountered during the procedure.

Additionally, it is crucial to organize the workspace, keeping tools and materials in designated areas. A clutter-free environment reduces the likelihood of slips and falls, promoting overall safety. Furthermore, ensuring proper lighting and ventilation contributes to a more secure atmosphere.

Before proceeding with any repairs, it is advisable to disconnect any power sources. This precaution prevents electrical shocks and other related incidents. Always refer to manufacturer guidelines and service manuals to ensure compliance with recommended practices.

In case of uncertainty regarding any repair steps, seeking assistance from a knowledgeable individual can enhance safety and effectiveness. Collaborating with others not only fosters a secure working environment but also provides valuable insights that can improve the overall repair process.

Resources for Mercury 110 Owners

For individuals looking to maintain and enhance their vehicle, various tools and sources of information are essential. Accessing the right resources can significantly improve your understanding and handling of your automobile. Here are some valuable options to consider.

Online Forums and Communities

Participating in online discussions can be incredibly beneficial. Engaging with fellow enthusiasts allows for the exchange of tips, troubleshooting advice, and personal experiences. Some popular platforms include:

- Automotive enthusiast websites

- Social media groups focused on vehicle maintenance

- Dedicated forums for automotive discussion

Instructional Manuals and Guides

Having access to reliable manuals is crucial for effective maintenance. These documents typically provide step-by-step instructions and technical details. Consider the following options:

- Factory service manuals available for purchase

- Online databases offering free manuals

- Local libraries with automotive literature