The world of marine engines is intricate, with a multitude of elements working in harmony to ensure optimal performance. For enthusiasts and professionals alike, grasping the layout and functionality of each component is crucial. A comprehensive overview of these essential parts can significantly enhance maintenance practices and troubleshooting techniques.

In the following sections, we will delve into the specific segments that make up these engines, emphasizing their roles and interconnections. By familiarizing yourself with these various elements, you can better appreciate the engineering behind your watercraft’s power system.

Whether you are a seasoned sailor or a newcomer to boating, understanding the intricacies of these mechanisms can empower you to make informed decisions regarding repairs and upgrades. This knowledge not only fosters a deeper connection with your vessel but also enhances your overall boating experience.

Understanding Mercury 115 Four-Stroke Engines

Four-stroke outboard motors are renowned for their efficiency and reliability. This section explores the essential components and operational principles that define these engines, providing insights into their performance and maintenance.

Key Features

- Enhanced fuel efficiency

- Reduced emissions

- Quiet operation

- Improved torque

Maintenance Tips

- Regular oil changes to ensure optimal performance.

- Inspect the cooling system to prevent overheating.

- Check and replace the spark plugs as needed.

- Keep the fuel system clean to avoid clogging.

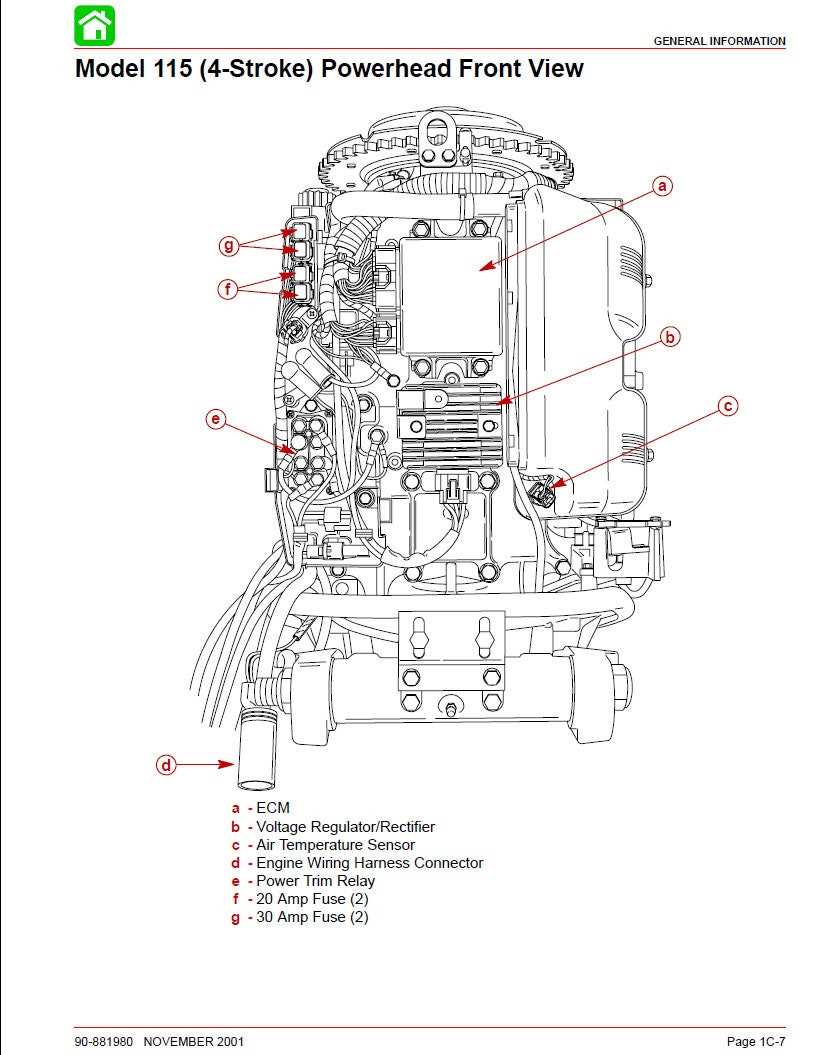

Key Components of Mercury 115

This section explores the essential elements that contribute to the performance and functionality of an outboard engine. Understanding these crucial components allows for better maintenance and enhances overall reliability.

Powerhead: The heart of the engine, housing critical mechanisms that generate power through combustion.

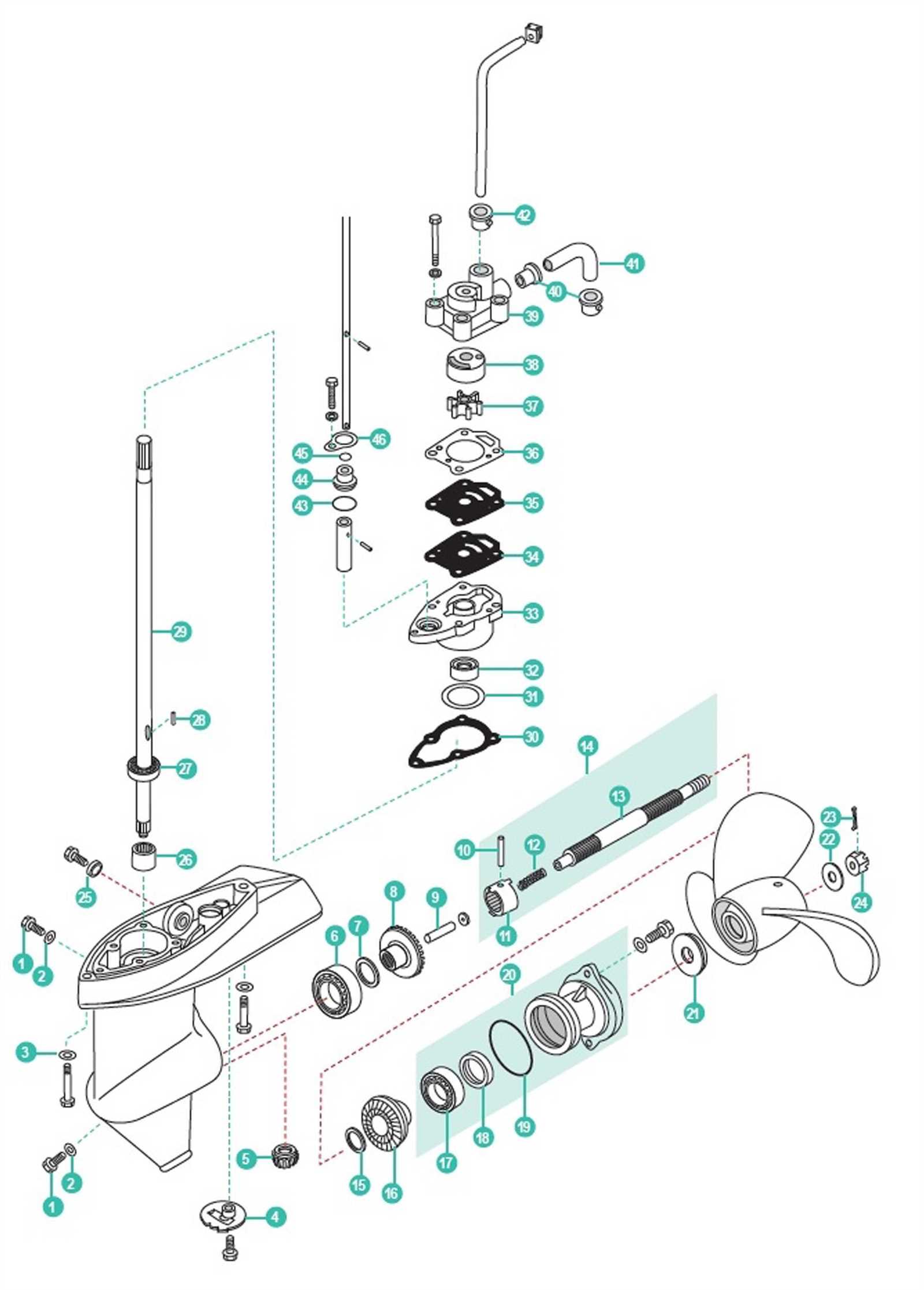

Lower Unit: This section contains the gear system, facilitating propulsion by transferring power to the propeller.

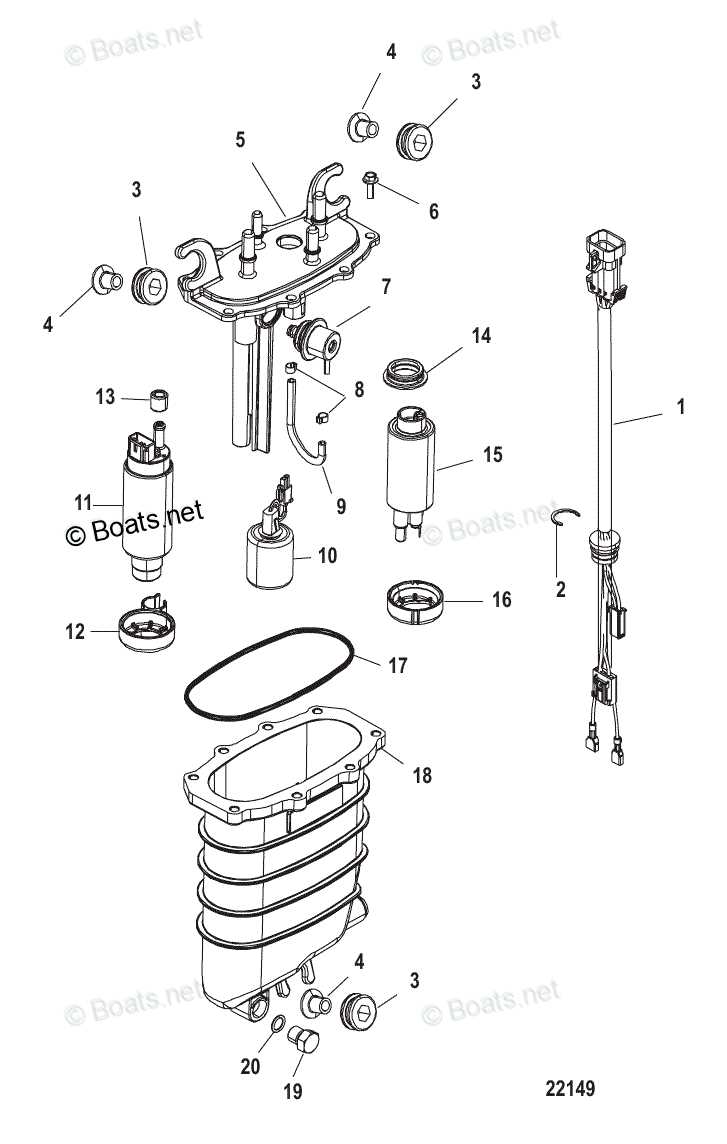

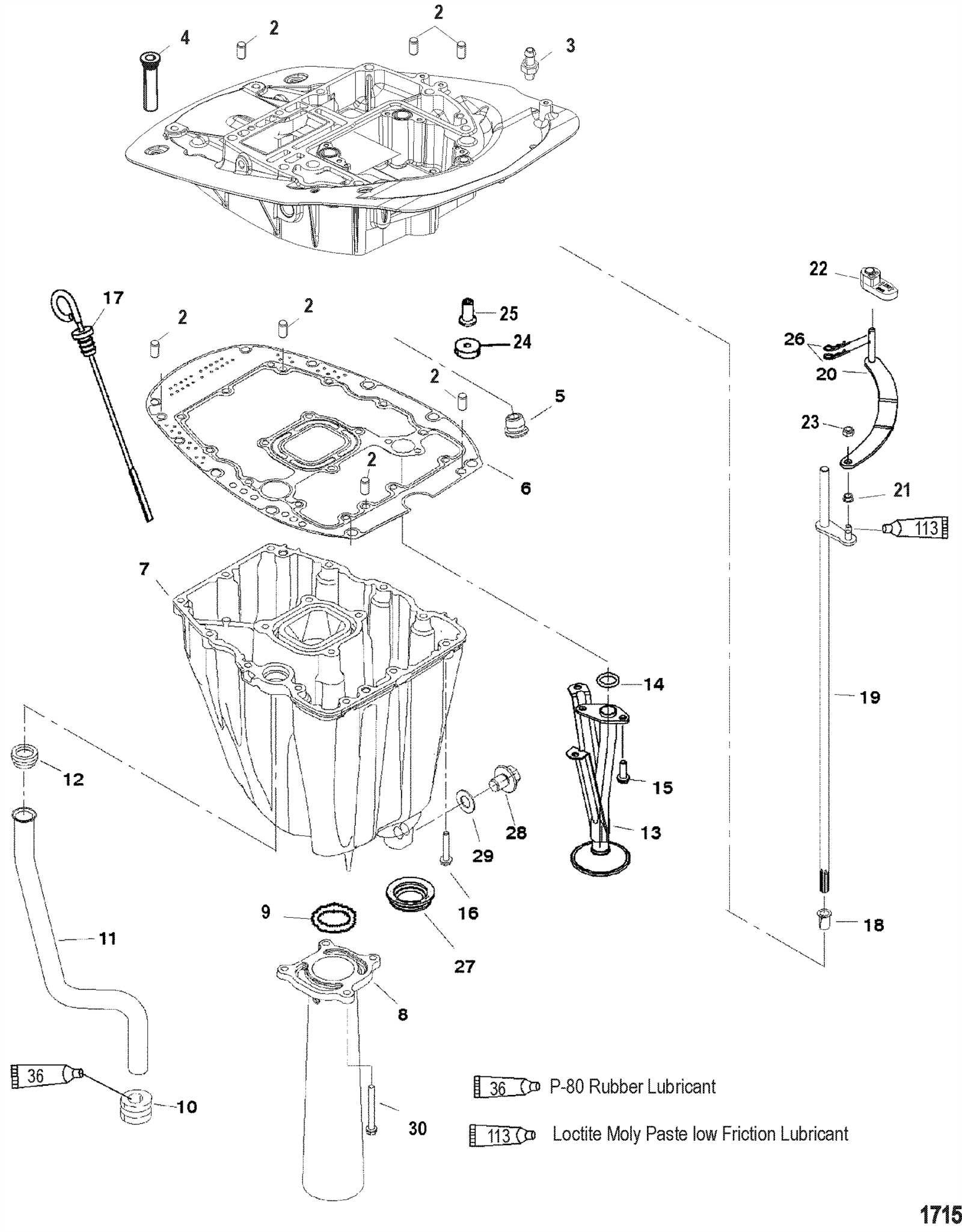

Fuel System: Comprising the fuel tank, lines, and injectors, this system ensures a steady flow of fuel to optimize performance.

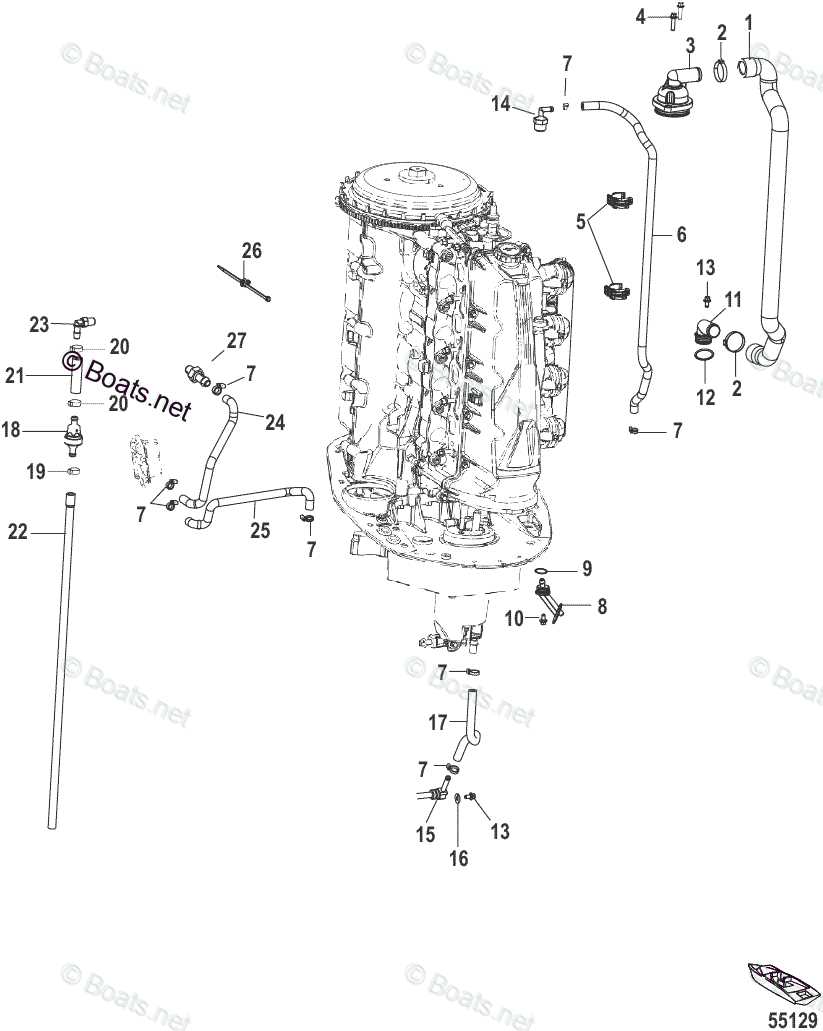

Cooling System: Essential for regulating engine temperature, it prevents overheating and ensures efficient operation.

Ignition System: This includes the spark plugs and coils, responsible for igniting the air-fuel mixture, leading to the engine’s operation.

Exhaust System: Responsible for directing exhaust gases away from the engine, this system helps maintain performance and reduce noise.

Benefits of Four-Stroke Technology

Four-stroke engines have gained popularity in various applications due to their efficiency and performance. This technology offers numerous advantages that enhance the overall experience for users, making it a preferred choice for many enthusiasts and professionals alike.

Enhanced Fuel Efficiency

One of the most significant benefits of this engine type is its improved fuel efficiency. By optimizing the combustion process, these engines consume less fuel while providing better power output. Key points include:

- Reduced fuel consumption leads to lower operating costs.

- Longer intervals between refueling enhance convenience.

- Environmentally friendly with fewer emissions compared to alternatives.

Improved Reliability and Longevity

Another advantage is the increased reliability and durability of four-stroke engines. They tend to have a longer lifespan, making them a wise investment. Notable factors include:

- Fewer moving parts reduce wear and tear.

- Consistent performance over extended periods.

- Easier maintenance due to simpler design principles.

Importance of Proper Maintenance

Ensuring the longevity and optimal performance of any engine relies heavily on consistent upkeep and care. Regular maintenance not only prevents unexpected failures but also enhances efficiency, allowing for a smoother operation over time. Neglecting this vital aspect can lead to costly repairs and reduced reliability, ultimately affecting overall enjoyment and safety.

A well-maintained engine operates at peak efficiency, which translates into better fuel economy and lower emissions. By adhering to a structured maintenance schedule, one can identify potential issues before they escalate, thus saving both time and resources. Furthermore, proper care can significantly extend the lifespan of components, providing a better return on investment in the long run.

In addition to practical benefits, maintaining an engine fosters a sense of responsibility and awareness. It encourages users to familiarize themselves with their equipment, leading to more informed decisions regarding operation and troubleshooting. This proactive approach not only enhances the user’s experience but also contributes to a safer environment on the water or road.

Common Issues with Mercury 115 Parts

In the realm of outboard engines, certain components are prone to recurring challenges that can affect overall performance and reliability. Understanding these common problems can help boat owners effectively address issues before they escalate, ensuring smoother operation on the water.

Fuel System Complications

One frequent concern involves the fuel system, where clogs and leaks may arise due to contaminants or wear. Fuel filters can become obstructed, leading to reduced efficiency and power loss. Regular maintenance, including timely replacements, can mitigate these risks. Additionally, fuel lines may deteriorate over time, increasing the likelihood of leaks, which can pose both safety and performance hazards.

Cooling System Failures

The cooling system is vital for preventing overheating, yet it can encounter issues like blockages or pump failures. A malfunctioning water pump can hinder proper circulation, resulting in elevated engine temperatures. Routine inspections and flushing of the cooling system are essential to prevent such problems. Neglecting these aspects can lead to severe damage, underscoring the importance of proactive maintenance.

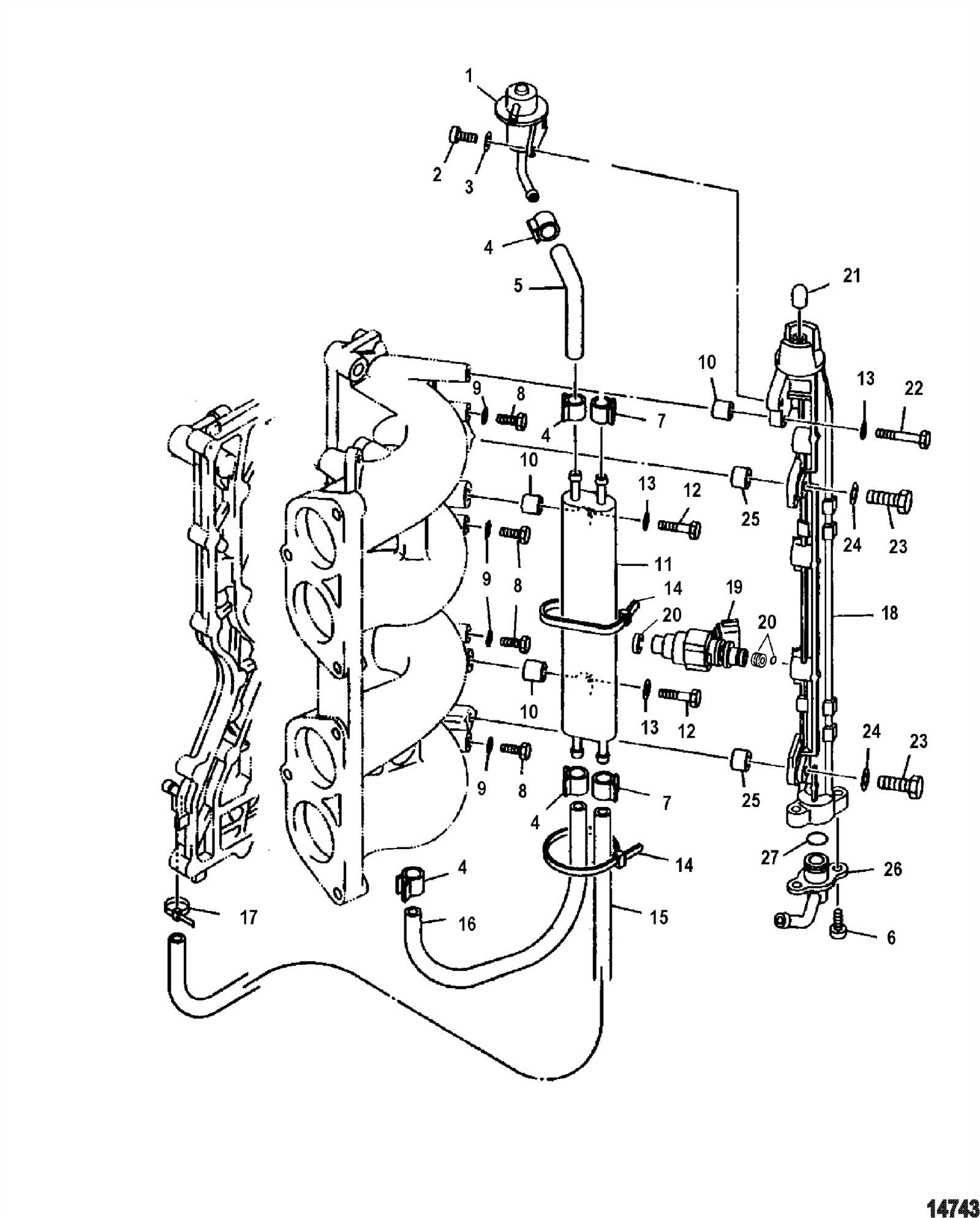

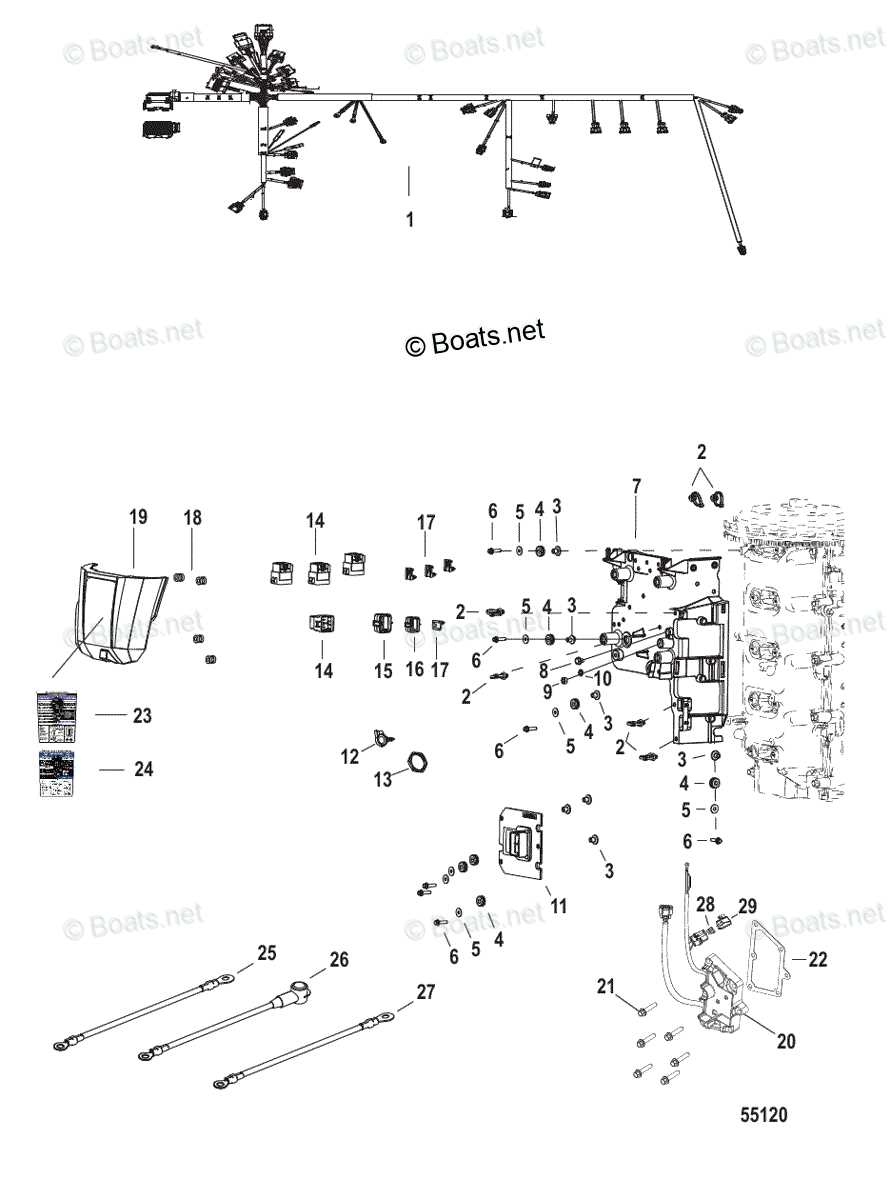

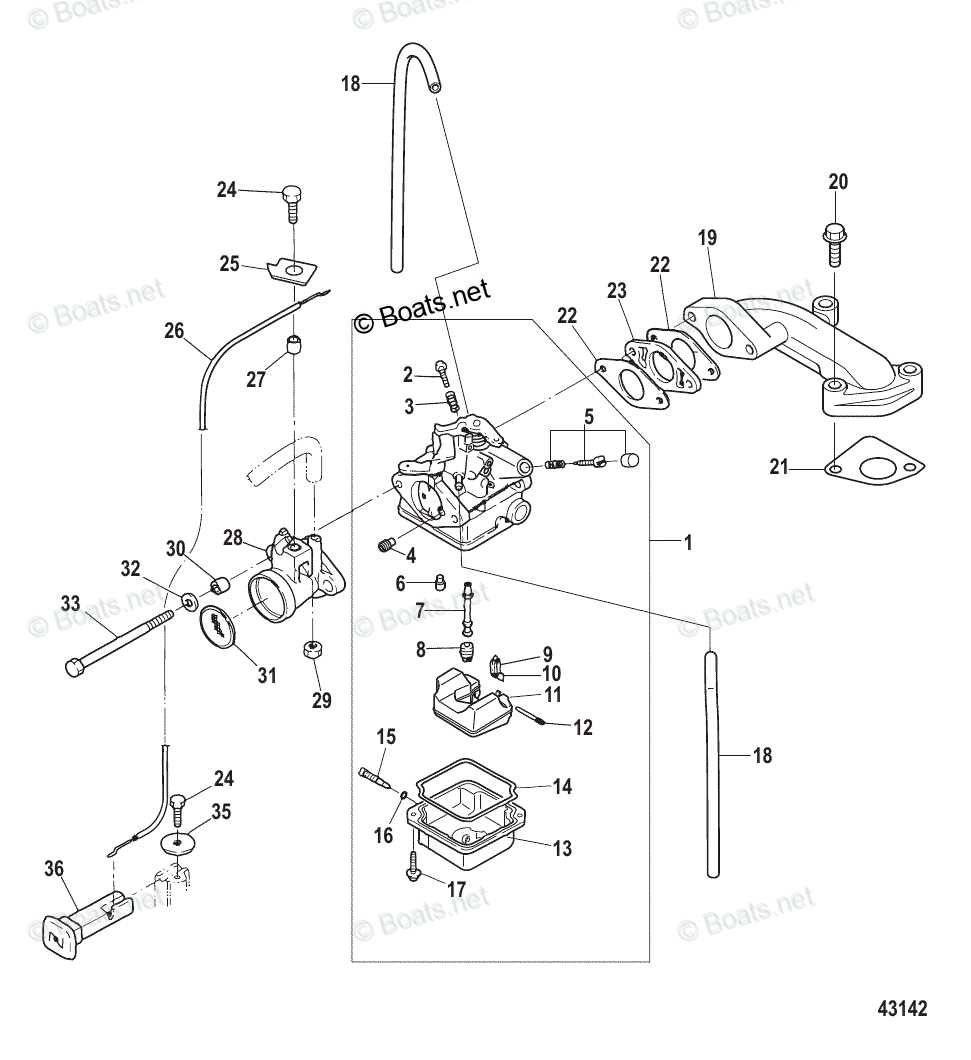

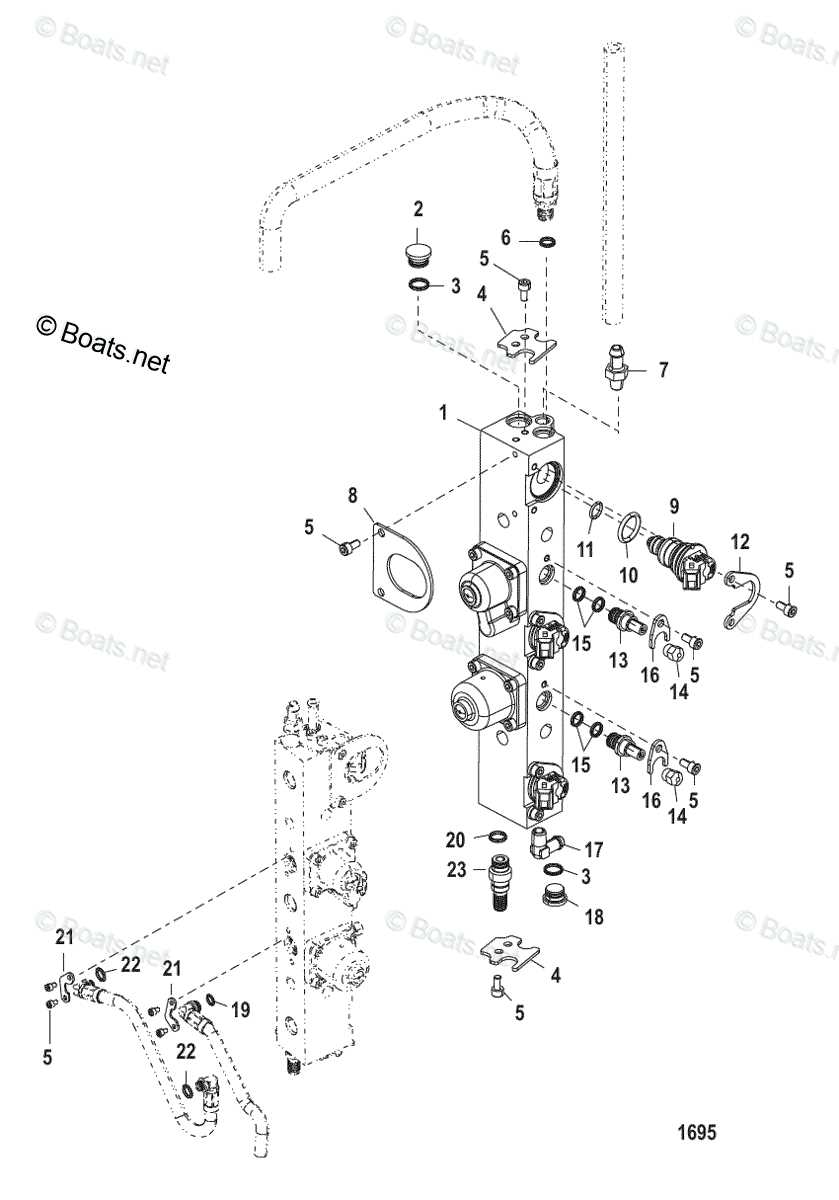

How to Read Parts Diagrams

Understanding visual representations of components can greatly enhance your ability to assemble or repair machinery. These illustrations serve as a valuable guide, providing a clear overview of various elements and their relationships within a system. Here’s a breakdown of how to effectively interpret these visuals.

Key aspects to focus on include:

- Legend or Key: This section usually explains the symbols and abbreviations used throughout the illustration. Familiarizing yourself with these will simplify the process of identification.

- Numbering System: Components are often labeled with specific numbers that correspond to a list of parts. Make sure to reference this list for accurate identification.

- Groupings: Elements may be grouped based on their functions or assembly order. Recognizing these clusters can provide insight into how the components interact.

When analyzing the visual:

- Start from the top or a designated reference point and work your way down.

- Follow the connections between elements to understand how they fit together.

- Take note of any directional arrows or lines that indicate movement or flow.

By mastering these techniques, you’ll be well-equipped to navigate through any representation of mechanical components, making repairs or assembly tasks more straightforward and efficient.

Identifying Replacement Parts Easily

Finding the right components for your engine can often feel overwhelming, especially when faced with a multitude of options. Understanding how to effectively locate and identify necessary items is essential for maintaining optimal performance. This section will guide you through practical steps to streamline the process of sourcing the right replacements.

Understanding Component Codes

One of the most efficient ways to identify what you need is by familiarizing yourself with component identification codes. These codes can provide specific information about each part, making it easier to find suitable substitutes. Here are some tips:

- Locate the serial number on your engine.

- Check the manufacturer’s catalog for corresponding codes.

- Take note of the dimensions and specifications of the components you require.

Utilizing Online Resources

The internet is a treasure trove of information for finding the right items. Here are several ways to leverage online platforms:

- Visit official manufacturer websites for detailed catalogs.

- Join online forums and communities for shared experiences and recommendations.

- Use e-commerce sites that specialize in engine components for comparative shopping.

By combining these strategies, you can simplify the process of finding the necessary replacements and ensure your equipment runs smoothly.

Tools Needed for Engine Repairs

When undertaking repairs on an internal combustion unit, having the right instruments is crucial for ensuring efficiency and accuracy. Each tool serves a specific purpose, allowing the technician to diagnose issues and execute repairs with precision. This section outlines the essential instruments required for successful maintenance and repair tasks.

Essential Hand Tools

Hand tools are fundamental for most repair jobs. They provide the flexibility to reach various components and apply the necessary force without damaging sensitive parts.

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | To drive screws into or out of components. |

| Plier Set | For gripping and manipulating small parts. |

| Torque Wrench | To apply precise torque settings for critical fasteners. |

Specialized Instruments

In addition to standard tools, specialized instruments are often necessary for more complex repairs. These tools are designed for specific tasks and help ensure that repairs are conducted safely and effectively.

| Tool | Purpose |

|---|---|

| Compression Tester | To measure the compression of engine cylinders. |

| Oil Pressure Gauge | To monitor oil pressure levels during operation. |

| Digital Multimeter | For checking electrical systems and diagnosing faults. |

| Vacuum Gauge | To assess intake manifold vacuum and diagnose leaks. |

Tips for Ordering Parts Online

When seeking components online, it’s essential to ensure accuracy and efficiency in your purchases. By following some key strategies, you can enhance your experience and reduce the risk of errors. Start by gathering all necessary specifications and compatibility information for the items you need.

Verify the credibility of the supplier by checking reviews and ratings. Reliable vendors often provide detailed product descriptions and images, which can help you make informed choices. Additionally, compare prices across multiple platforms to secure the best deal without compromising quality.

Always pay attention to shipping policies and estimated delivery times to avoid delays. Keep track of your orders and maintain communication with the seller for any inquiries or issues. This proactive approach will ultimately lead to a smoother transaction process.

Assembly Techniques for Mercury Engines

Effective assembly methods are crucial for ensuring optimal performance and longevity of marine propulsion systems. These practices involve meticulous attention to detail and adherence to specified procedures, enhancing both reliability and efficiency in operation.

One fundamental aspect of assembling marine engines is the importance of cleanliness. Contaminants such as dust and grease can severely impact performance and lead to premature wear. Therefore, maintaining a clean workspace and using appropriate cleaning agents is essential throughout the assembly process.

| Technique | Description |

|---|---|

| Torque Specifications | Always adhere to the manufacturer’s torque specifications for bolts and screws to ensure proper sealing and prevent damage. |

| Sealing Practices | Utilize high-quality gaskets and sealants to prevent leaks and maintain the integrity of the engine components. |

| Alignment Checks | Ensure that all components are aligned correctly to avoid undue stress and misoperation. |

| Lubrication | Apply suitable lubricants during assembly to reduce friction and enhance the performance of moving parts. |

| Final Inspections | Conduct thorough inspections after assembly to identify any potential issues before the engine is put into operation. |

Incorporating these techniques into the assembly process not only ensures the functionality of the engine but also promotes safety and efficiency, allowing for a smoother boating experience.

Cost Factors in Engine Repairs

Understanding the financial elements involved in engine maintenance and restoration is essential for making informed decisions. Various aspects can influence overall expenses, from labor rates to the quality of components used.

| Factor | Description |

|---|---|

| Labor Costs | The hourly wage of technicians and the complexity of the repair process. |

| Parts Quality | The choice between original manufacturer parts and aftermarket alternatives, impacting reliability and longevity. |

| Diagnosis Fees | Initial costs for identifying issues, which can vary based on the shop’s expertise. |

| Availability | How easily parts can be sourced, affecting wait times and potential markups. |

| Type of Repair | The extent of damage and whether it requires minor adjustments or a complete overhaul. |

Upgrades for Enhanced Performance

Improving the efficiency and power of your marine engine can significantly enhance your overall boating experience. A few strategic enhancements can lead to better acceleration, increased fuel economy, and a smoother ride. Exploring various modifications allows boaters to tailor their engines to meet specific needs and preferences, unlocking their full potential on the water.

Engine Tuning and Calibration

One of the most effective ways to boost performance is through precise tuning and calibration of the engine’s systems. Adjusting the fuel-air mixture and ignition timing can optimize combustion, resulting in improved horsepower and torque. Consulting with a professional can ensure that these modifications are performed safely and effectively, maximizing benefits while maintaining reliability.

Propeller Selection

The right propeller can make a significant difference in how your vessel performs. Upgrading to a high-performance propeller designed for your specific use can enhance thrust and reduce drag. Consider factors like pitch, diameter, and material when selecting a propeller to achieve the desired speed and handling characteristics, allowing for a more responsive and enjoyable ride.

Resources for Mercury Engine Owners

Owning an outboard motor involves understanding various aspects of maintenance, repair, and upgrades. Having access to quality resources can significantly enhance your experience and ensure optimal performance of your vessel.

- Official Manuals: Acquire user manuals specific to your model for detailed guidance.

- Online Forums: Join community discussions to exchange tips and solutions with fellow enthusiasts.

- Video Tutorials: Explore platforms like YouTube for step-by-step repair and maintenance videos.

- Local Dealers: Consult authorized retailers for genuine parts and expert advice.

- Maintenance Guides: Refer to comprehensive guides for seasonal upkeep and troubleshooting.

Utilizing these resources can empower you to delve deeper into the world of outboard motor ownership and achieve the ultimate performance from your engine.