The world of aquatic propulsion is intricate and fascinating, featuring a myriad of mechanisms that work harmoniously to ensure seamless navigation on water. This section delves into the essential elements that contribute to the efficient operation of marine engines. A thorough grasp of these components can significantly enhance both performance and maintenance practices.

Exploring the intricate layouts of these systems allows enthusiasts and professionals alike to pinpoint issues and streamline repairs. Knowledge of each element’s function and relationship with others is vital for optimal performance. Understanding these intricate connections not only aids in troubleshooting but also fosters a deeper appreciation for engineering excellence in marine technology.

Whether you are a seasoned expert or a novice eager to learn, having access to detailed visual representations of these systems is invaluable. Such illustrations serve as crucial references, facilitating clearer understanding and effective problem-solving. Engaging with these resources empowers individuals to take control of their aquatic adventures, ensuring smooth sailing every time.

Understanding Mercury Outboard Parts

When it comes to marine propulsion systems, a clear grasp of their components is essential for maintenance and repairs. Each element plays a crucial role in ensuring optimal performance and reliability on the water. Familiarity with these mechanisms not only aids in troubleshooting but also enhances the overall experience for boaters and enthusiasts alike.

Key Components and Their Functions

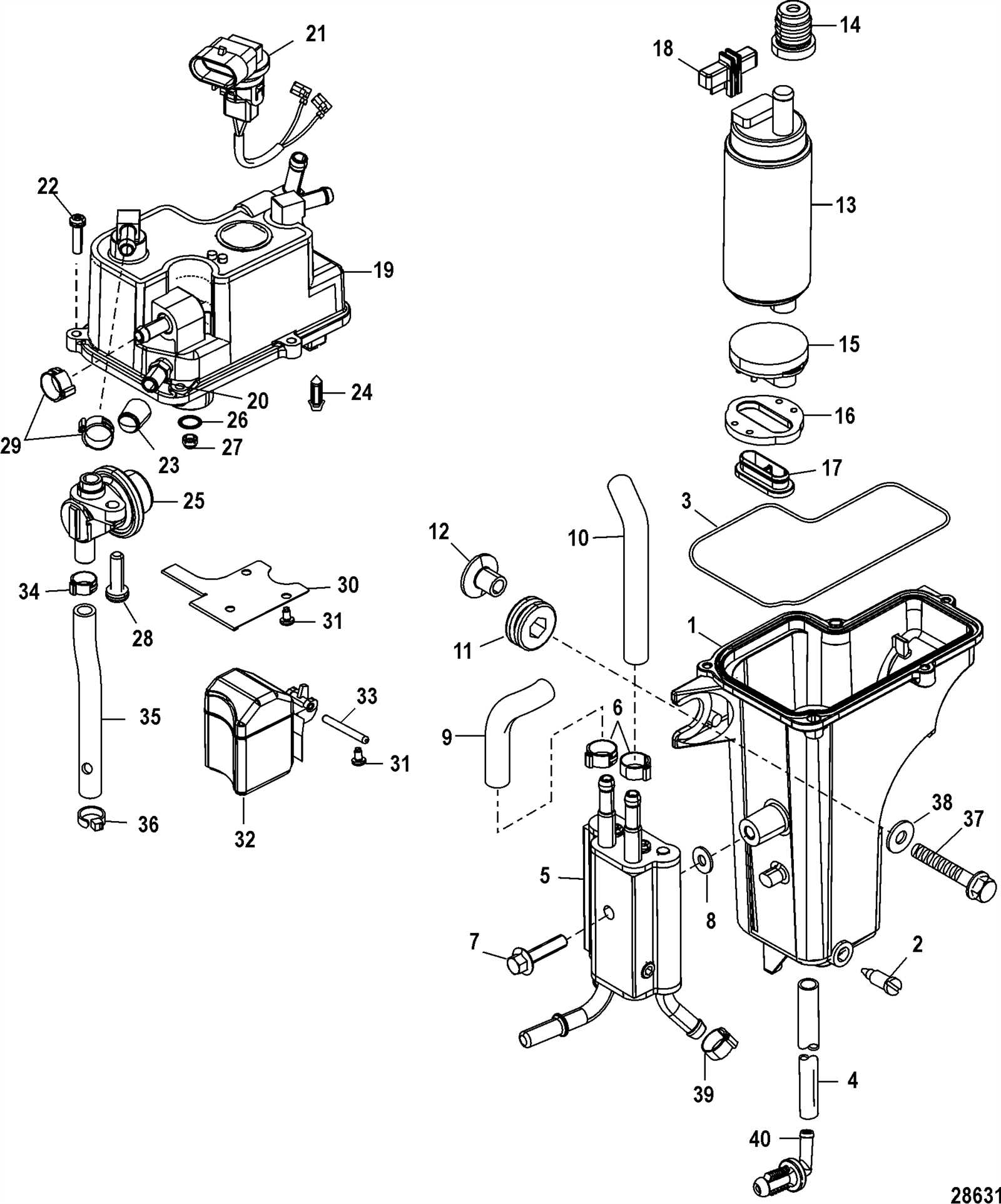

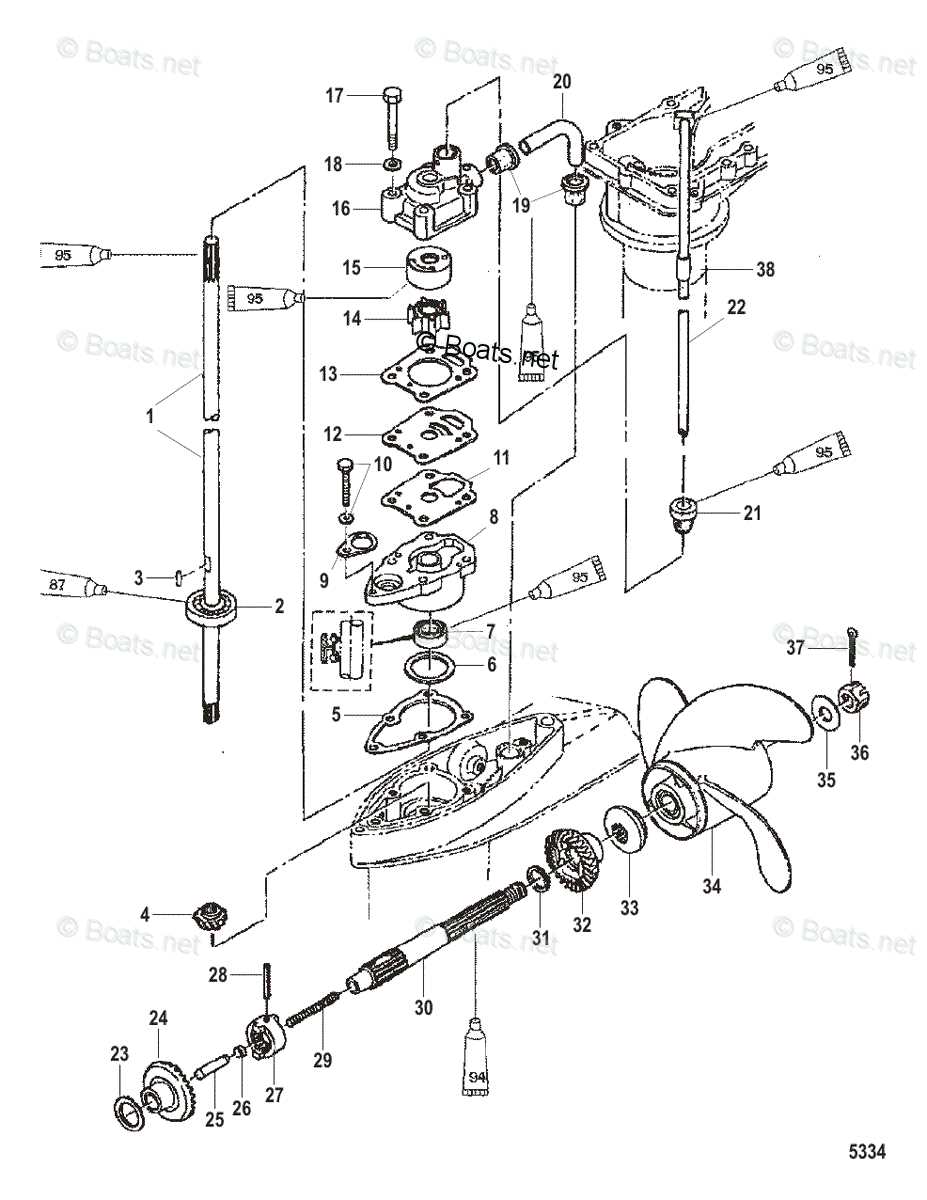

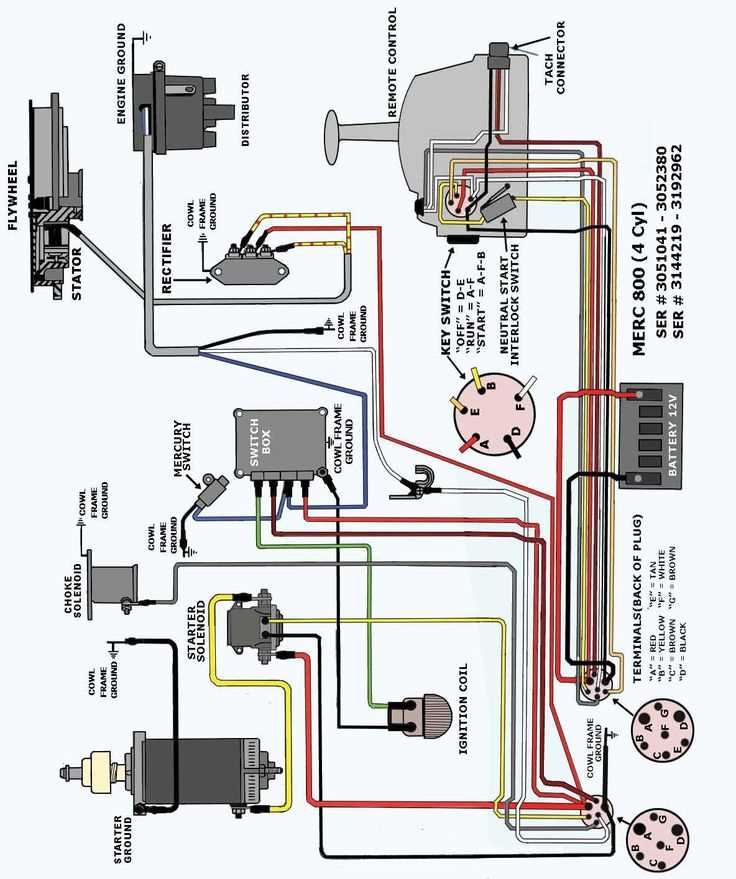

Among the most vital elements are the power unit, which generates the necessary thrust, and the fuel delivery system, ensuring that the engine receives the right amount of fuel for efficient operation. Other significant parts include the cooling system, which prevents overheating, and the ignition mechanism, responsible for starting the engine smoothly. Understanding how these components interact can lead to better care and extended longevity.

Common Maintenance Practices

Regular inspections and timely replacements are crucial for keeping these systems running smoothly. For example, changing filters, checking the propeller, and ensuring electrical connections are in good condition can significantly improve performance. Adopting a proactive maintenance routine not only saves time but also prevents costly repairs down the line.

Importance of Accurate Diagrams

Precision in technical illustrations is crucial for ensuring the effective assembly and maintenance of mechanical systems. These visuals serve as essential guides that aid users in understanding the complex interactions between various components.

Enhancing Understanding

- Clear visuals improve comprehension of intricate designs.

- Accurate representations reduce the likelihood of errors during assembly.

- Users can identify specific elements more easily, facilitating troubleshooting.

Boosting Efficiency

- Time savings in locating and installing components.

- Minimized downtime due to reduced miscommunication.

- Streamlined processes lead to overall improved performance.

Common Components in Mercury Engines

Understanding the key elements that make up marine propulsion systems is essential for effective maintenance and repair. These fundamental components work together to ensure optimal performance and reliability on the water.

| Component | Description |

|---|---|

| Powerhead | The core unit housing the combustion mechanism, responsible for generating thrust. |

| Lower Unit | This part connects to the propulsion system and includes gears and drives for power transfer. |

| Fuel System | A system comprising the tank, pump, and injectors that supply fuel for combustion. |

| Cooling System | A network of passages and components designed to manage engine temperature. |

| Ignition System | This system generates the spark needed to ignite the fuel-air mixture for engine operation. |

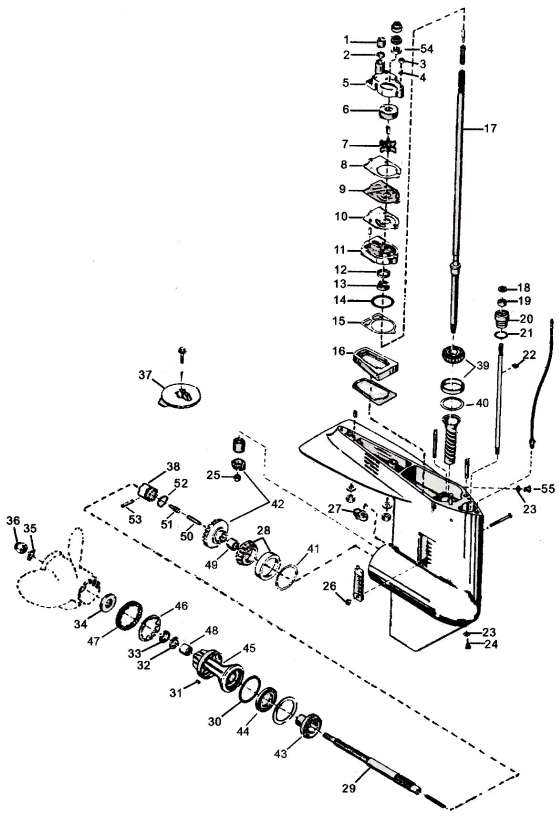

How to Read Parts Diagrams

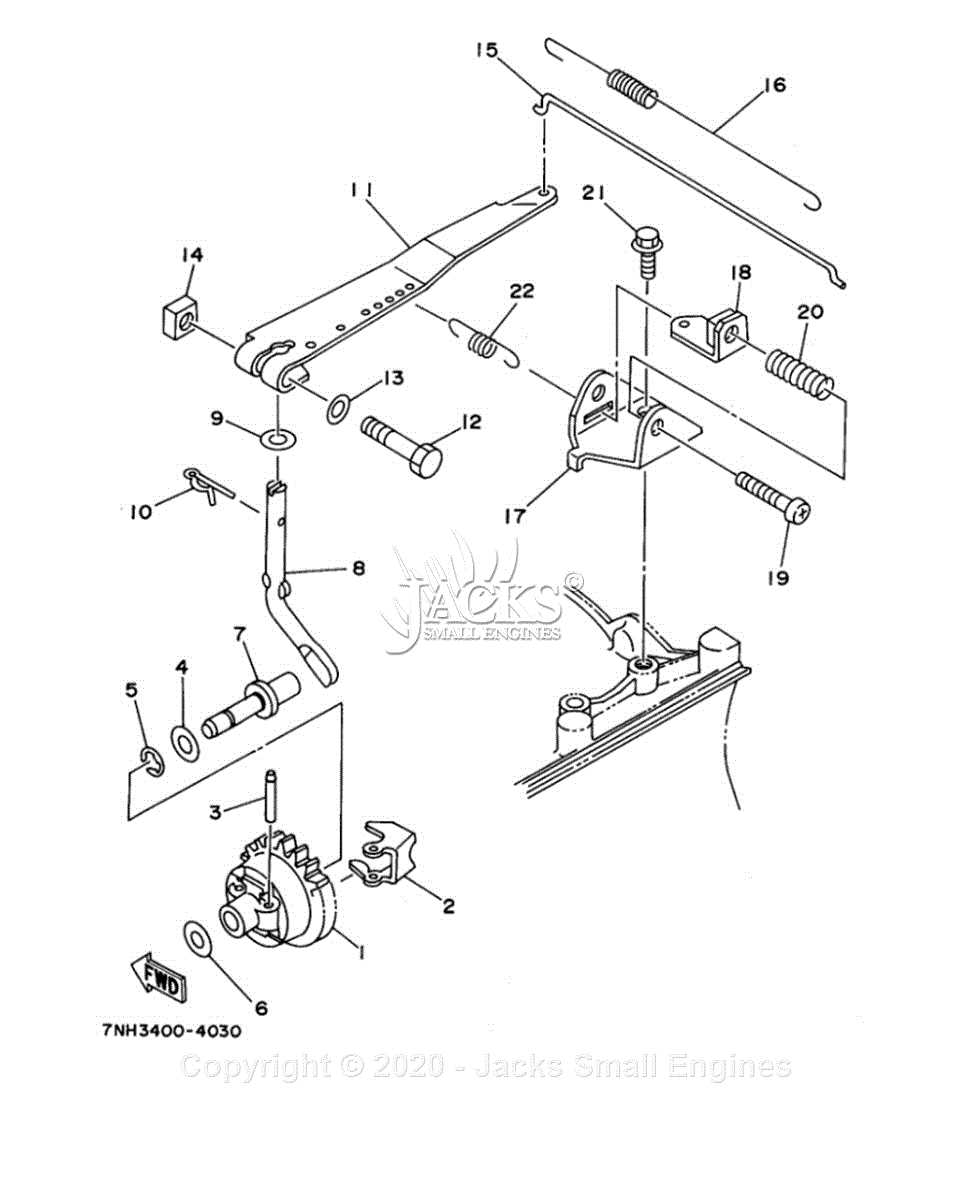

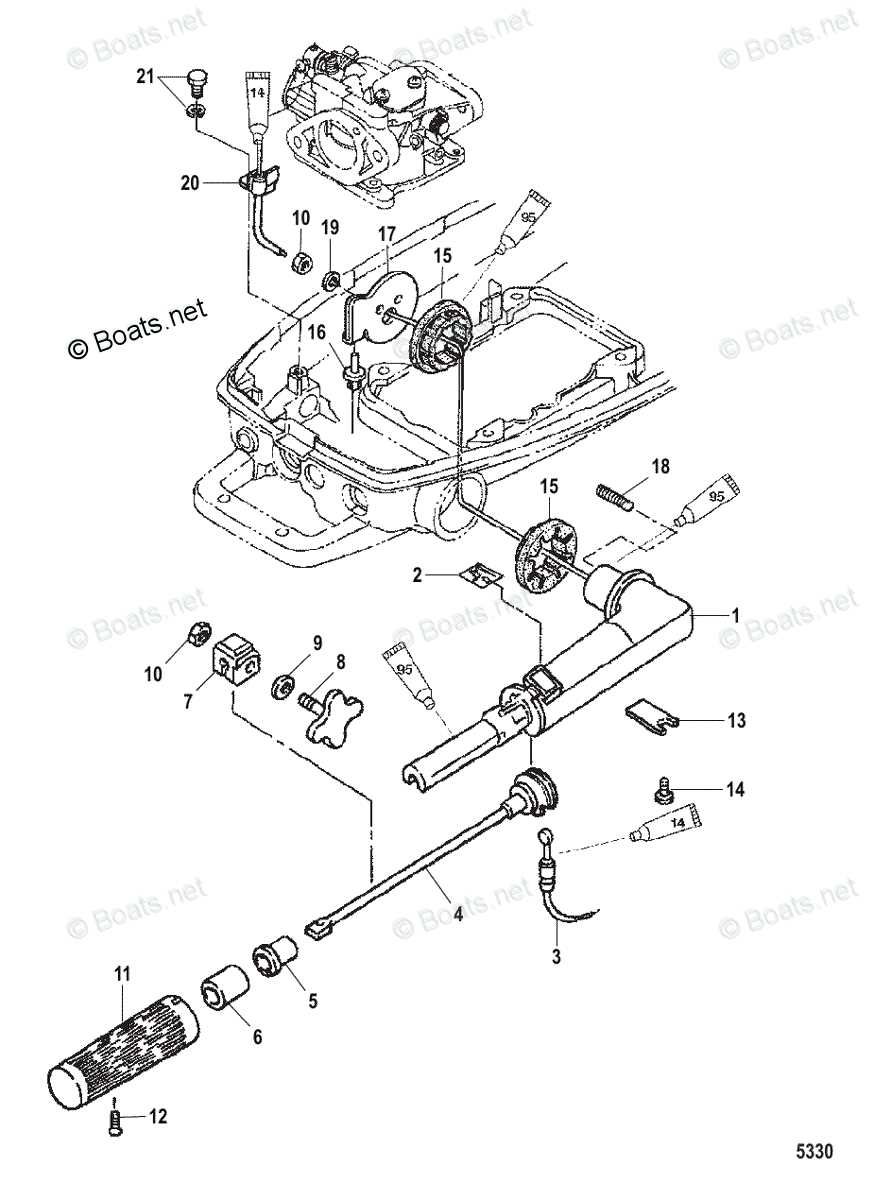

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide a comprehensive overview of the various elements, their arrangement, and interconnections. Familiarity with these visuals can greatly enhance the efficiency of troubleshooting and assembling machinery.

Identifying Key Elements

Start by familiarizing yourself with the main symbols and labels. Each element is often represented by a specific icon or notation. Look for reference numbers and part names, which usually accompany the visuals to aid in identification. This helps in understanding the function and location of each component within the overall system.

Understanding Relationships

Next, focus on the connections between different components. Arrows or lines often indicate how parts interact or fit together. Pay attention to assembly sequences and any accompanying notes that may highlight specific installation instructions or maintenance tips. This knowledge is crucial for ensuring that all elements work harmoniously.

Identifying Your Engine Model

Understanding the specific model of your marine engine is crucial for ensuring optimal performance and maintenance. Each model comes with its own set of specifications and requirements, making accurate identification essential for proper care.

Start by locating the serial number, typically found on the transom or mounting bracket. This number is a unique identifier that links your engine to its specific make and model.

Next, consult the manufacturer’s documentation or website, where you can often find detailed charts or guides that match serial numbers to specific models. This information can help you understand the nuances of your engine’s design and functionality.

Lastly, consider reaching out to a local dealer or service center, as they can provide invaluable insights and help you confirm your engine’s model, ensuring you have the ultimate information for any maintenance or repairs.

Sources for Reliable Diagrams

When seeking accurate illustrations for marine engine components, it’s essential to identify trustworthy sources. Reliable visuals play a crucial role in understanding assembly and maintenance processes, ensuring that users can make informed decisions.

One of the best places to start is the official manufacturer’s website. These platforms often provide detailed visual aids along with technical documentation that can enhance comprehension. Additionally, they may offer updates and revisions, ensuring users have access to the latest information.

Another valuable resource is specialized forums and community groups. Enthusiasts and professionals alike share insights and visuals that can aid in troubleshooting and repairs. Engaging with these communities not only provides access to diagrams but also fosters connections with experienced individuals who can offer support.

Online retailers that focus on marine equipment can also be useful. Many of these sites feature comprehensive catalogs that include illustrations of various components, often accompanied by user reviews and tips for installation. This can help users gauge the reliability of the information provided.

Finally, technical manuals and publications are indispensable. These resources are often available in print or digital format and contain exhaustive details about various engine models, including step-by-step guides and corresponding visuals. Investing in a quality manual can save time and prevent costly mistakes in maintenance tasks.

Maintenance Tips for Outboard Parts

Proper upkeep of marine equipment is crucial for ensuring longevity and optimal performance. Regular care not only enhances efficiency but also prevents costly repairs, making it essential for any boating enthusiast.

Routine Inspection

- Check for signs of wear or corrosion.

- Inspect seals and gaskets for leaks.

- Examine wiring and connections for damage.

Cleaning and Lubrication

- Rinse components with fresh water after each use.

- Apply lubricant to moving parts to reduce friction.

- Use appropriate cleaners for specific materials.

Replacement Parts: What You Need

Maintaining the performance of your marine engine requires knowledge of its essential components and their replacements. Understanding which elements may need substitution ensures the longevity and efficiency of your vessel. Being proactive about repairs can prevent larger issues down the line.

Common Components to Replace

Regular wear and tear affects several critical elements. Familiarizing yourself with the typical items that require replacement will help you prepare adequately.

| Component | Function | Replacement Frequency |

|---|---|---|

| Fuel Filter | Ensures clean fuel reaches the engine | Every 100 hours |

| Water Pump Impeller | Maintains water circulation for cooling | Annually |

| Spark Plugs | Ignites the air-fuel mixture | Every 100 hours |

| Gear Oil | Lubricates the gearbox | Every 50 hours |

Choosing Quality Replacements

Opting for high-quality substitutes is crucial for performance and durability. Research reliable manufacturers and consult with experts to ensure you select the best options for your needs. Quality components can significantly impact your vessel’s reliability and efficiency, ensuring you enjoy your time on the water without unnecessary interruptions.

DIY Repairs Using Diagrams

Undertaking repairs on your watercraft can be a rewarding experience, allowing you to save money and gain valuable knowledge. Utilizing visual guides simplifies the process, providing clear instructions and illustrations that facilitate effective troubleshooting and replacement tasks. With these resources, even novice enthusiasts can tackle maintenance with confidence.

Step-by-step guides enable you to understand the assembly and function of various components, ensuring you approach each task methodically. Visual aids can help you identify specific parts, making it easier to follow along and avoid mistakes. This approach not only enhances your skill set but also fosters a deeper connection with your vessel.

By carefully studying these resources, you can pinpoint issues, streamline repairs, and ultimately prolong the lifespan of your equipment. Embrace the challenge and enjoy the journey of learning through hands-on experience!

Professional Help vs. DIY

When it comes to maintenance and repairs, the choice between enlisting expert assistance or tackling the task independently can be daunting. Each approach carries its own set of advantages and challenges, influencing both time investment and overall cost. Understanding these factors is essential for making an informed decision.

| Aspect | Professional Help | DIY |

|---|---|---|

| Expertise | High level of skill and experience | Varies; depends on personal knowledge |

| Cost | Higher initial investment | Lower, but may incur unexpected expenses |

| Time | Typically quicker due to experience | Can be time-consuming, especially for beginners |

| Quality of Work | Usually guarantees high standards | Quality may vary based on individual skill |

| Access to Tools | Professional-grade equipment available | May require additional investment in tools |

Frequently Asked Questions

This section addresses common inquiries regarding components and their assembly, helping users navigate the intricacies of maintenance and repair. By providing clear answers to frequent concerns, we aim to enhance understanding and facilitate effective troubleshooting.

What should I do if I can’t find the right component?

If you’re struggling to locate a specific item, consider consulting online resources or reaching out to specialized retailers. Many platforms offer extensive catalogs and can assist in identifying compatible elements based on your requirements.

How can I ensure proper installation of a new component?

To guarantee a successful installation, it’s advisable to follow the manufacturer’s guidelines carefully. Utilize tools that fit correctly and ensure that all connections are secure. Additionally, referencing a detailed schematic can be immensely helpful in visualizing the assembly process.

Staying Updated on New Parts

In the world of marine engines, keeping abreast of the latest components and innovations is crucial for optimal performance and maintenance. Regularly updating your knowledge ensures that you can make informed decisions when it comes to repairs and upgrades.

Here are some effective ways to stay informed about new components:

- Follow Manufacturer News: Subscribe to newsletters and updates from manufacturers to receive the latest information on releases and technological advancements.

- Join Online Communities: Engage with forums and social media groups where enthusiasts and professionals discuss new releases and share insights.

- Attend Trade Shows: Visit industry events to discover new products and connect directly with manufacturers and suppliers.

- Read Industry Publications: Regularly check magazines and blogs dedicated to marine technology for reviews and features on new components.

- Consult Your Dealer: Establish a relationship with your local dealer who can provide firsthand information about new arrivals and recommended upgrades.

By utilizing these resources, you can ensure that your knowledge remains current, enabling you to enhance the longevity and reliability of your vessel’s performance.