When delving into the intricacies of marine propulsion systems, it becomes essential to comprehend the arrangement and function of various engine elements. This knowledge not only aids in maintenance but also enhances overall performance and longevity of the vessel.

Each component plays a vital role, working harmoniously to ensure smooth operation. By familiarizing oneself with these crucial elements, one can easily identify potential issues and undertake necessary repairs or upgrades.

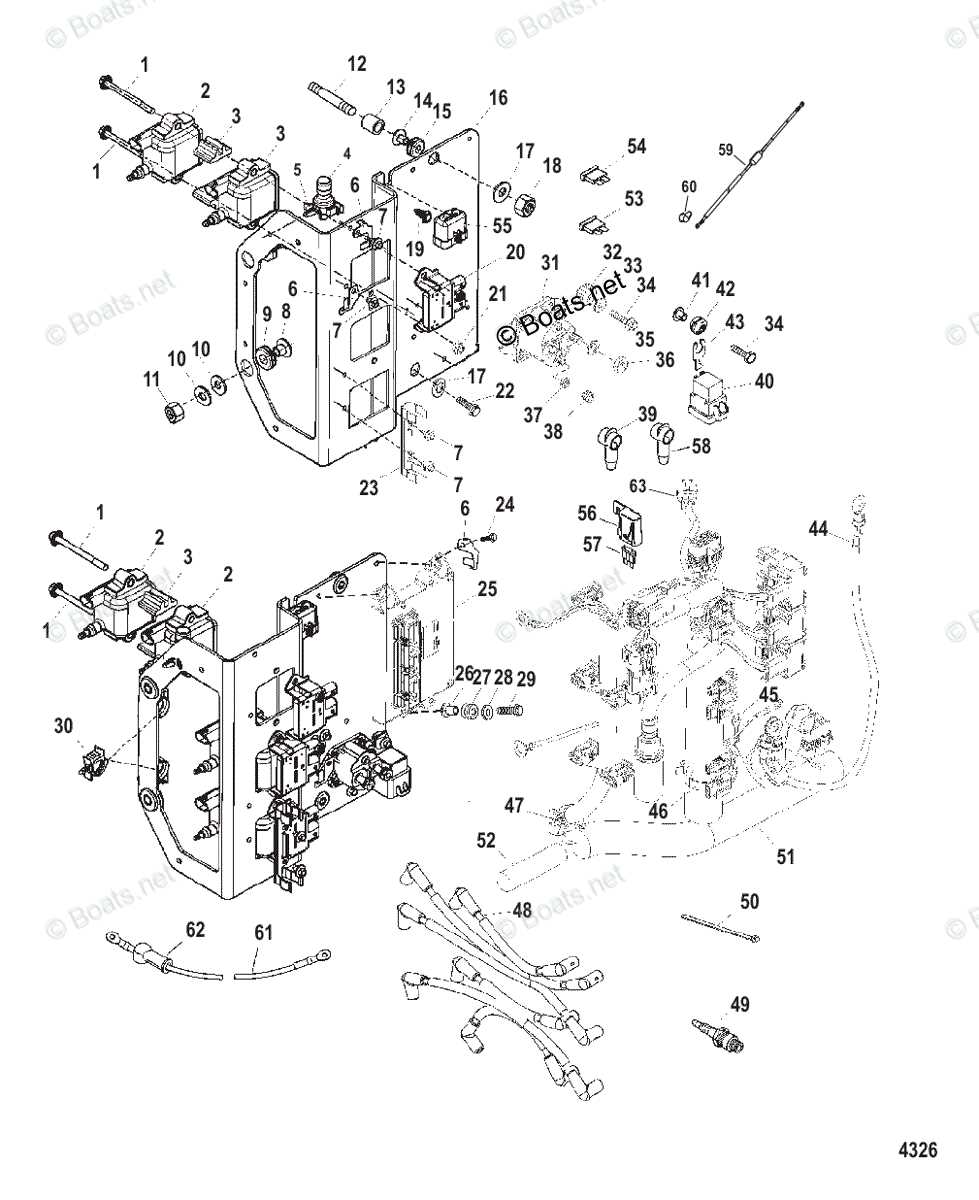

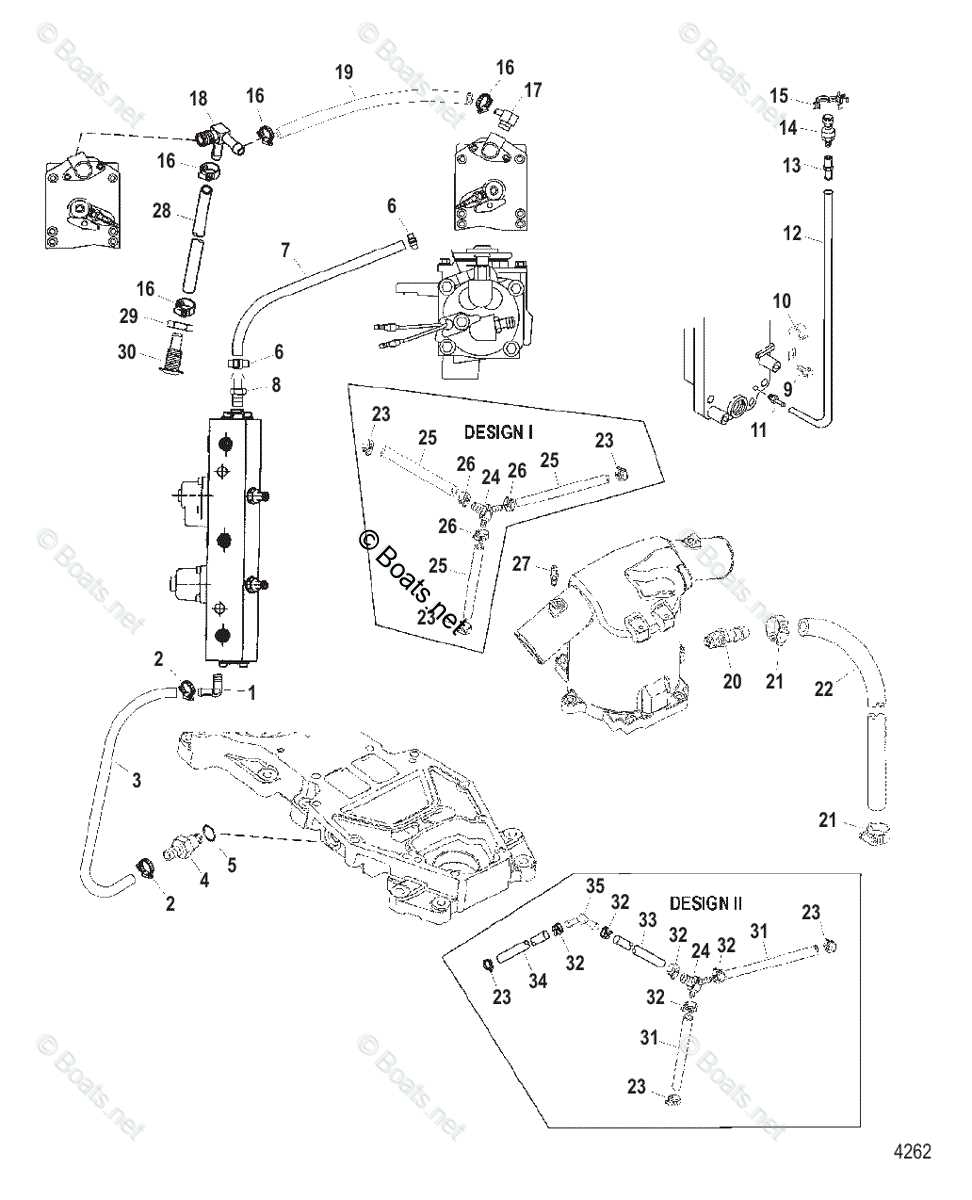

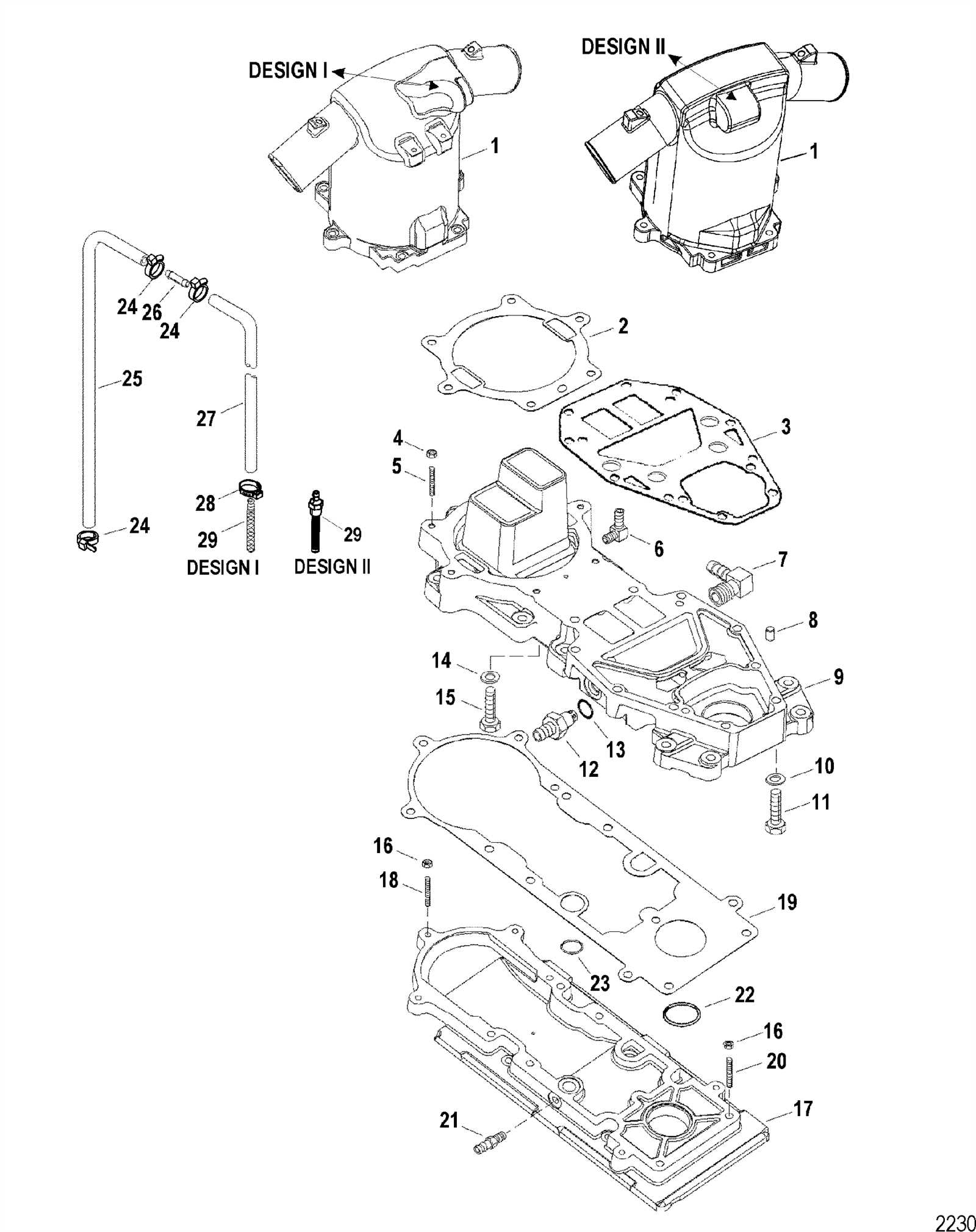

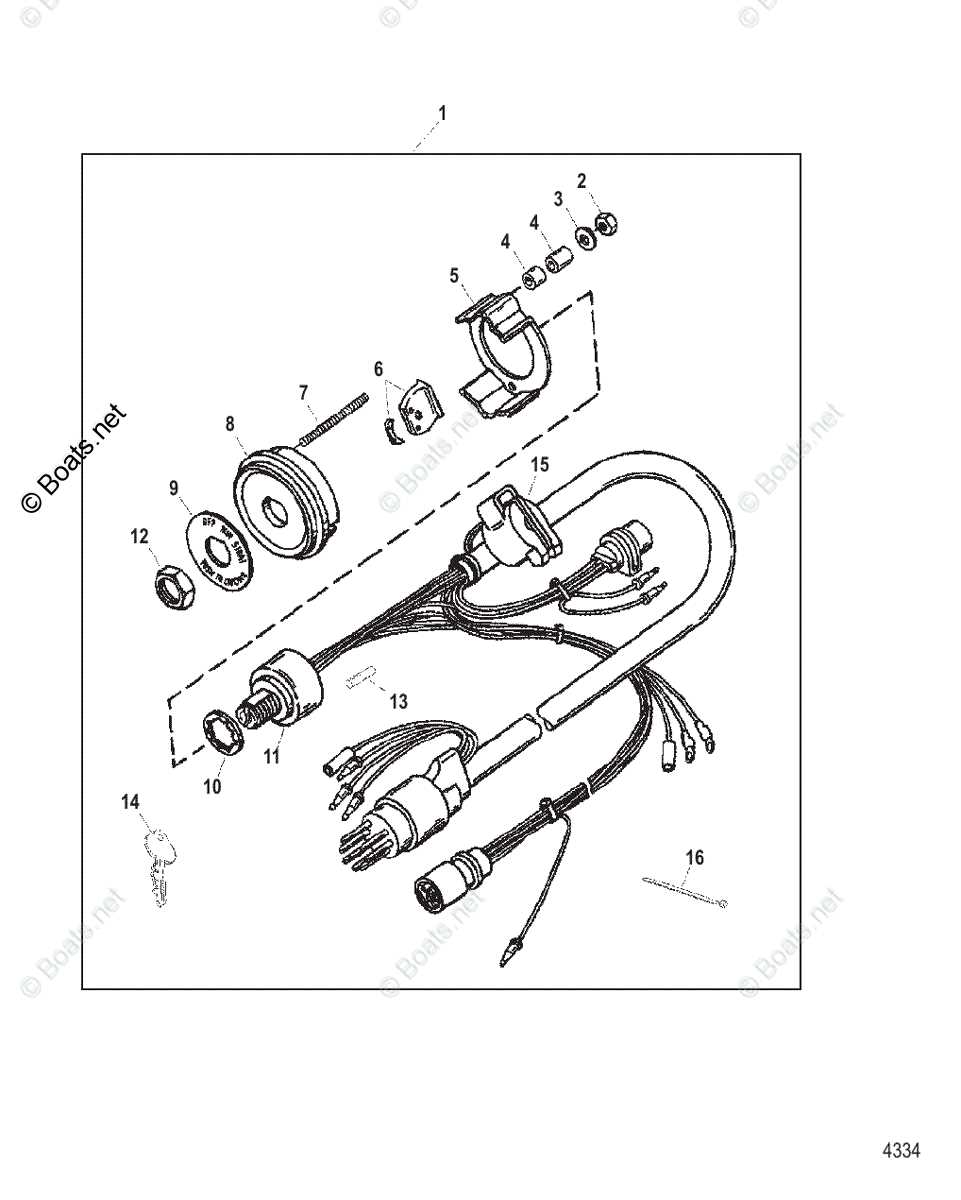

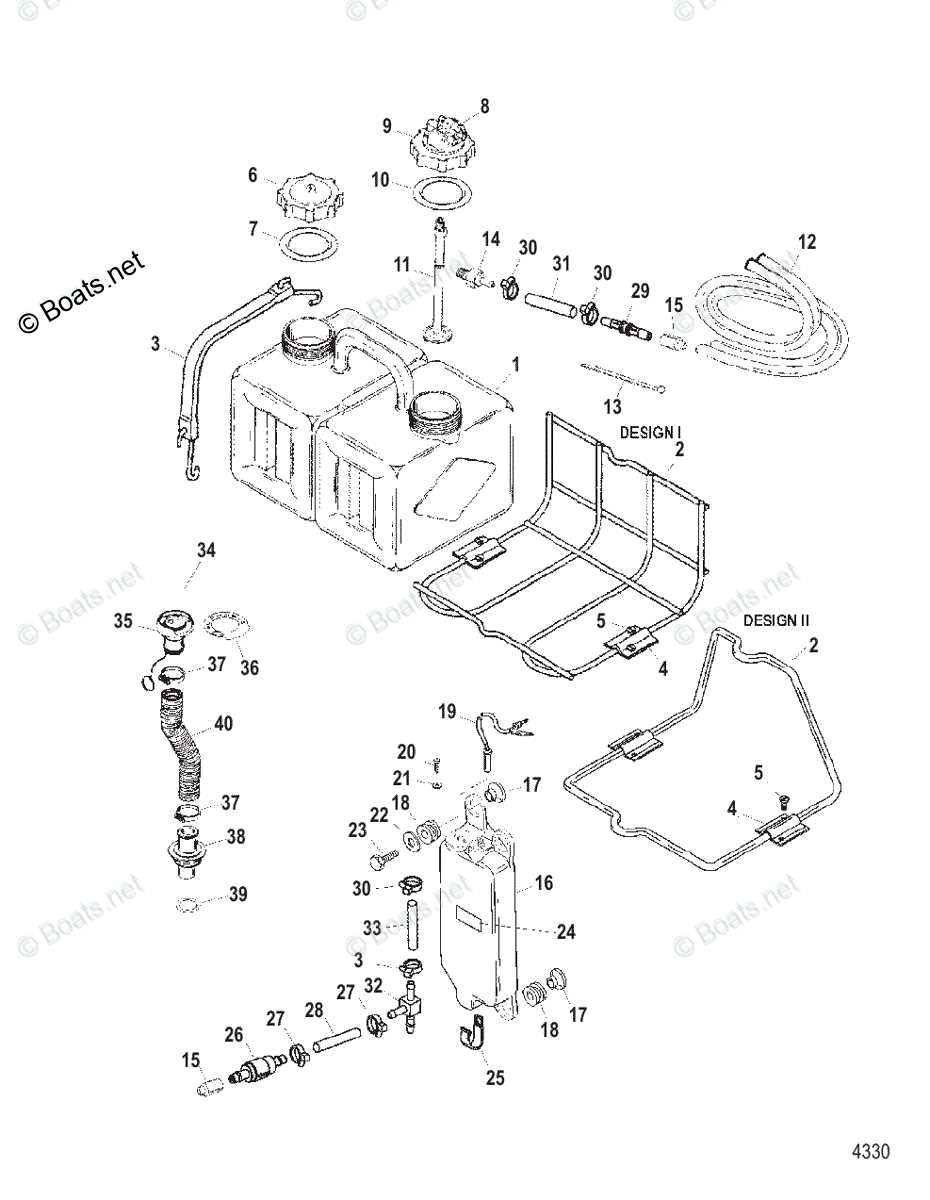

Utilizing a visual representation of these components allows for a clearer understanding of how each part interacts within the system. This approach facilitates effective troubleshooting and encourages informed decision-making when it comes to servicing the engine.

This section aims to provide an insightful overview of the components that make up a specific aquatic propulsion system. Understanding the structure and functionality of each element can greatly enhance the efficiency and performance of watercraft. The following details will explore the various parts and their roles in ensuring smooth operation.

Key Components of the System

- Engine Unit

- Propulsion Mechanism

- Cooling System

- Fuel Delivery System

- Control Mechanism

Importance of Proper Maintenance

Regular upkeep of these components is essential for optimal performance. Neglecting maintenance can lead to diminished efficiency, increased wear, and potential failures. Understanding the function of each part allows for better troubleshooting and proactive care.

Key Components of the Sport Jet

This section delves into the essential elements that constitute a high-performance watercraft engine, focusing on the mechanisms that contribute to its efficient operation. Understanding these components is crucial for anyone looking to enhance performance or perform maintenance on their vessel.

Engine Assembly

The heart of any watercraft is its engine assembly, which includes various parts designed to work harmoniously. This assembly is responsible for converting fuel into mechanical energy, ensuring smooth operation and optimal speed. Regular inspection and maintenance of this unit are vital for long-term reliability.

Fuel System

The fuel system plays a pivotal role in delivering the right amount of fuel to the engine. It encompasses the fuel tank, lines, and pump, all working together to ensure efficient fuel delivery. Proper upkeep of this system can prevent issues such as clogging and inadequate fuel flow, leading to enhanced performance.

Importance of a Parts Diagram

A schematic representation of components serves as an essential tool for understanding the assembly and functioning of complex machinery. It provides clarity by illustrating how various elements interact with one another, aiding both novices and experienced users in grasping the overall structure.

Such visual aids are crucial for maintenance and repair tasks. They allow technicians to quickly identify necessary components and facilitate efficient troubleshooting. Additionally, having a clear illustration helps in sourcing replacements and ensuring compatibility, ultimately prolonging the lifespan of the equipment.

Moreover, these representations can enhance communication among team members by providing a common reference point. This reduces the likelihood of misunderstandings and errors during repair or assembly processes, leading to improved operational efficiency.

Common Issues with Sport Jet Parts

In the realm of aquatic propulsion systems, various components may present challenges that can affect overall performance and reliability. Understanding these common difficulties is essential for maintenance and operational efficiency. By recognizing potential issues, users can take proactive measures to ensure their equipment remains in optimal condition.

| Component | Common Issue | Solution |

|---|---|---|

| Propeller | Damage from debris | Regular inspections and timely replacements |

| Fuel System | Clogs or leaks | Routine cleaning and checking connections |

| Cooling System | Overheating | Ensuring proper water intake and checking for blockages |

| Electrical Components | Corrosion or shorts | Periodic inspections and protective coatings |

Maintenance Tips for Mercury Engines

Proper upkeep of marine engines is crucial for ensuring optimal performance and longevity. Regular maintenance tasks can prevent common issues and enhance the reliability of your watercraft. Understanding the key areas that require attention will help you keep your engine running smoothly.

Routine Inspections

Conducting regular checks on various engine components is essential. This includes monitoring fluid levels, inspecting belts, and examining hoses for any signs of wear or damage. By identifying potential problems early, you can avoid costly repairs down the line.

Fluid Changes

Changing the engine oil and other fluids at recommended intervals is vital for maintaining engine health. Fresh oil helps lubricate moving parts, reducing friction and preventing overheating. Make sure to follow the manufacturer’s guidelines for fluid types and change schedules.

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 100 hours of operation |

| Inspect Fuel Lines | Every season |

| Check Spark Plugs | Every 50 hours of operation |

| Flush Cooling System | At the end of the season |

Identifying Parts Using the Diagram

The process of recognizing components through a visual representation is essential for effective maintenance and troubleshooting. Such illustrations serve as valuable references, allowing users to pinpoint various elements within the machinery accurately.

By carefully studying the illustration, one can easily correlate each labeled section with the corresponding physical element. This not only enhances understanding but also aids in ensuring that repairs or replacements are carried out with precision. Familiarity with the layout and specific labels promotes efficient assembly and disassembly, minimizing the risk of errors during servicing.

Additionally, these visual guides often include notations that provide further details about each component’s function and placement. This context can be particularly helpful when addressing specific issues or planning upgrades. Overall, utilizing these resources significantly streamlines the repair process, making it more manageable for both novices and experienced technicians alike.

Where to Find Replacement Parts

Locating suitable components for your watercraft can significantly enhance its performance and longevity. It’s essential to explore various avenues to ensure that you acquire quality replacements that meet your specific needs.

Authorized Dealers and Retailers

One of the most reliable sources for acquiring necessary components is through authorized dealers. These establishments typically offer a comprehensive selection of genuine items, ensuring compatibility and reliability. Visiting a local dealer allows you to receive expert advice and assistance in finding the right replacements for your needs.

Online Marketplaces and Forums

The internet provides a vast array of options for sourcing replacements. Numerous online platforms specialize in marine accessories, where you can browse through various offerings. Additionally, joining online forums dedicated to watercraft enthusiasts can provide valuable insights and recommendations on where to find specific components at competitive prices.

Installation Guidelines for New Parts

When integrating new components into your vessel’s system, it’s essential to follow a structured approach to ensure proper functionality and longevity. This section outlines key steps and considerations for the effective installation of these elements, providing you with a comprehensive understanding of the process.

Preparation Steps

Before commencing the installation, gather all necessary tools and components. Make sure to review any accompanying documentation for specific requirements related to the new items. Clear the workspace to prevent contamination and ensure a smooth operation.

Installation Process

Follow these steps for a successful installation:

| Step | Description |

|---|---|

| 1 | Disconnect power sources to ensure safety during the process. |

| 2 | Remove existing components that need replacement carefully. |

| 3 | Install the new items, ensuring they fit securely and are properly aligned. |

| 4 | Reconnect all necessary connections, checking for tightness and security. |

| 5 | Re-establish power and perform functionality tests to verify successful installation. |

Comparing Sport Jet Models and Parts

This section delves into the various models of watercraft engines, emphasizing the distinctions and similarities in their components. Understanding these differences is crucial for enthusiasts and technicians who seek to optimize performance and maintain efficiency in aquatic activities. Each model presents unique features that cater to diverse needs and preferences, making it essential to grasp the nuances that set them apart.

Key Differences in Engine Designs

The design of watercraft engines can significantly affect their operation and suitability for various tasks. Some models may prioritize speed and agility, while others focus on durability and fuel efficiency. By examining these design philosophies, users can make informed decisions based on their specific requirements, ensuring they select the right engine for their adventures on the water.

Common Components Across Models

Despite the variations in design and functionality, many engines share fundamental components that are integral to their operation. Elements such as ignition systems, cooling mechanisms, and fuel delivery units often display similarities, which can facilitate easier repairs and replacements. Recognizing these commonalities can simplify the maintenance process, allowing users to keep their equipment running smoothly.

Tips for Troubleshooting Problems

When faced with operational difficulties in your watercraft, a systematic approach can help identify and resolve issues effectively. Understanding the common areas to inspect and the steps to take can lead to quicker solutions and enhance your overall experience on the water.

Identify Common Issues

- Check the fuel system for clogs or leaks.

- Inspect the electrical connections for corrosion or damage.

- Examine the cooling system for blockages or improper flow.

- Assess the performance of the propulsion mechanism for signs of wear.

Steps for Effective Troubleshooting

- Begin with a visual inspection of the unit for any obvious signs of wear or damage.

- Test the electrical components using a multimeter to ensure proper functionality.

- Consult the operational manual for specific guidelines and recommendations.

- Conduct a trial run after making adjustments to confirm that issues have been resolved.

Resources for Sport Jet Owners

Owning a high-performance watercraft comes with the responsibility of maintaining it effectively. For enthusiasts looking to enhance their experience, a variety of resources can provide valuable insights and support. This section outlines essential materials and tools available to aid owners in their journey.

Essential Guides and Manuals

- Owner’s manuals for operational guidelines and maintenance schedules.

- Technical publications that offer detailed maintenance procedures.

- Online forums and communities where owners share tips and experiences.

Parts Suppliers and Service Providers

- Local dealerships that specialize in servicing performance vessels.

- Online retailers offering a wide range of accessories and replacement items.

- Certified technicians available for consultations and repairs.