In the realm of aquatic machinery, efficient operation relies heavily on a well-coordinated network of components. This intricate assembly ensures that vessels can maneuver gracefully and perform optimally under various conditions. Grasping the layout and function of each element is essential for both maintenance and troubleshooting, making the comprehension of these systems invaluable for enthusiasts and professionals alike.

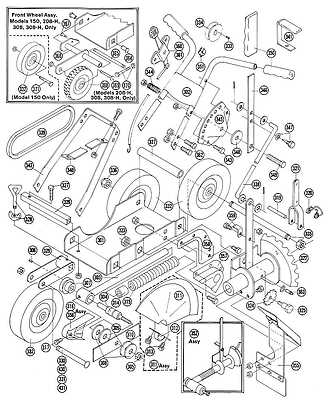

To facilitate a deeper understanding, it is beneficial to explore a visual representation of the various components involved. Such illustrations provide clarity, allowing users to identify specific sections and their interconnections. With a comprehensive overview, operators can enhance their skills in diagnosing issues and implementing effective solutions, ultimately leading to improved performance and longevity of the equipment.

Moreover, familiarizing oneself with the specific features and functions of each element can empower users to take proactive measures. Whether it’s routine maintenance or addressing unforeseen challenges, having a solid grasp of the system’s architecture equips individuals with the knowledge needed to navigate complexities confidently. By delving into these diagrams, one can cultivate a greater appreciation for the technology that drives marine operations.

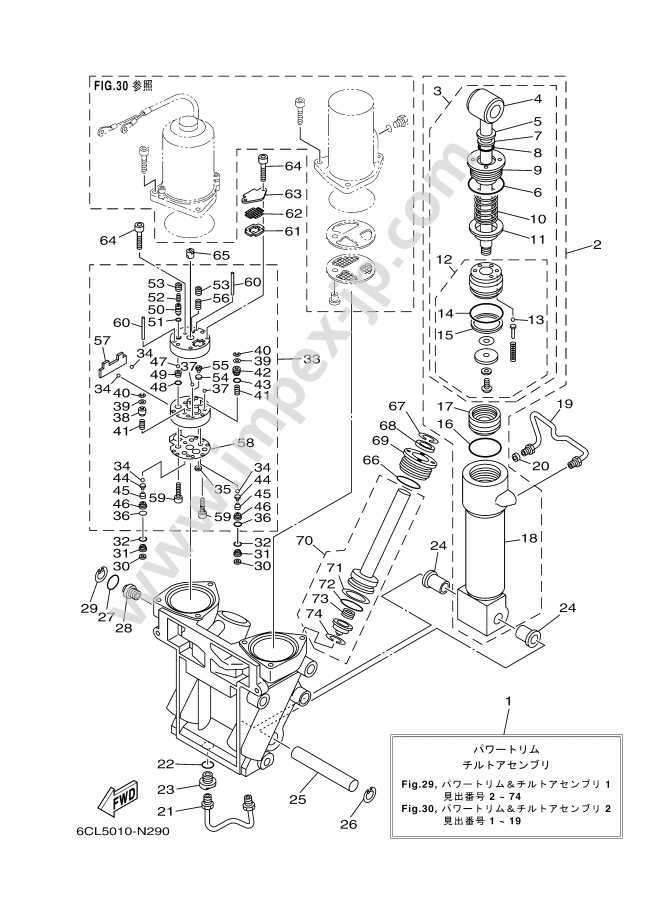

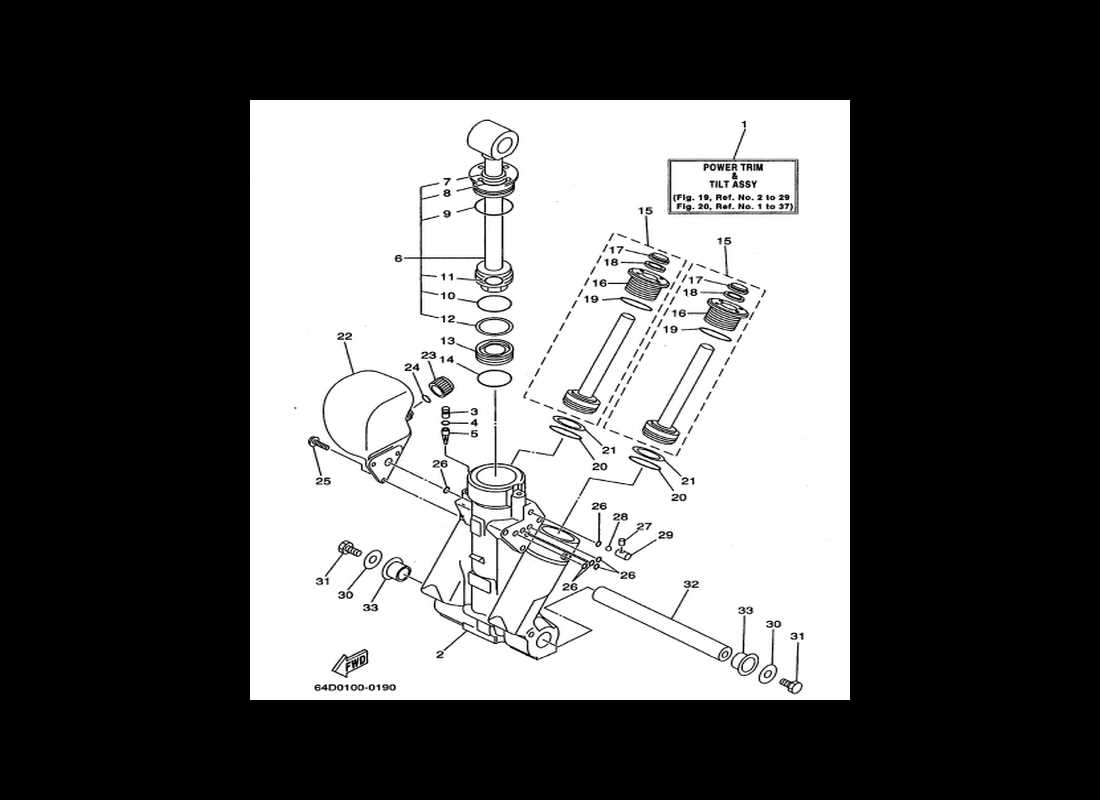

Understanding Power Trim Model 150

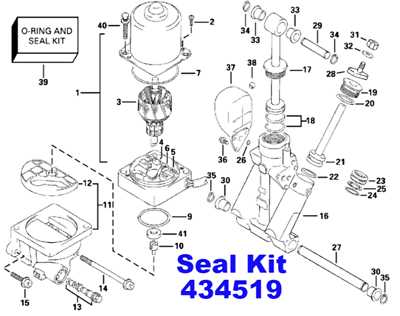

This section delves into the mechanics and functionalities of a specific elevation adjustment system utilized in marine applications. Designed to enhance the user experience, this technology allows for precise control of the vessel’s angle, improving both performance and maneuverability on the water.

At its core, this system comprises various components that work in harmony to achieve seamless elevation changes. Each part plays a crucial role, from hydraulic mechanisms to electronic controls, ensuring reliable operation under diverse conditions. By familiarizing oneself with these elements, users can optimize their craft’s performance and troubleshoot issues more effectively.

Understanding the intricacies of this system not only aids in maintenance but also empowers users to make informed decisions regarding upgrades and repairs. A comprehensive grasp of its layout and functionality will contribute to a safer and more enjoyable boating experience.

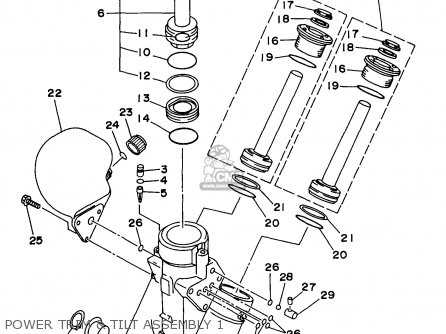

Essential Components Overview

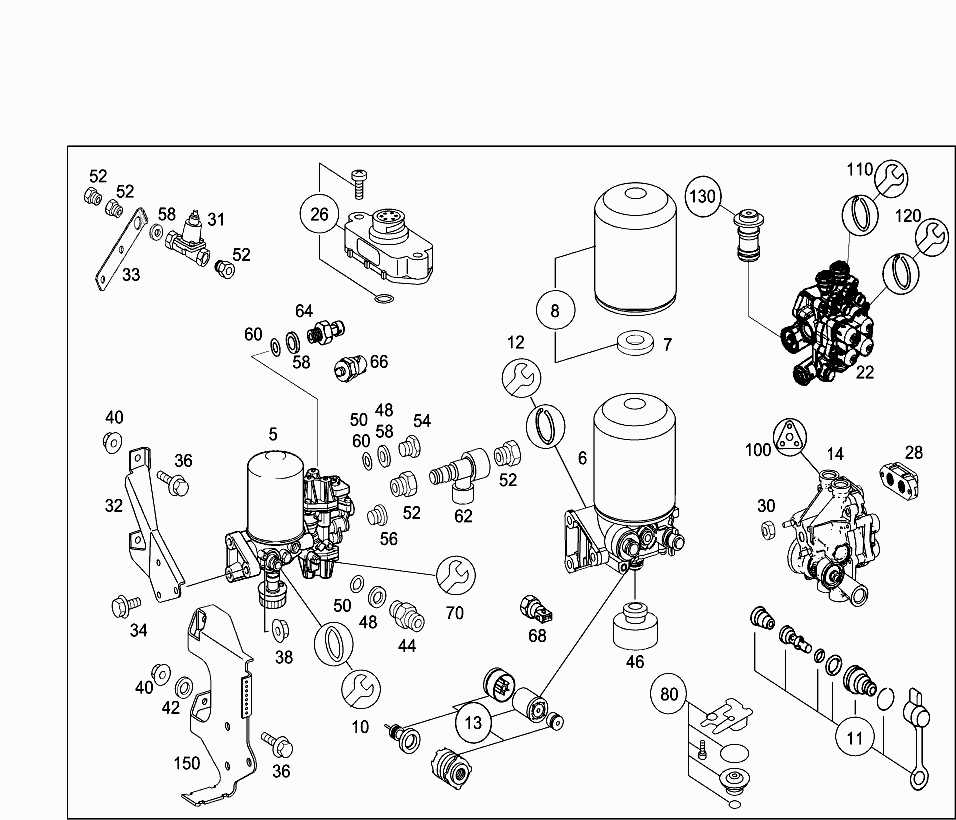

Understanding the fundamental elements of a marine propulsion system is crucial for effective maintenance and performance enhancement. Each component plays a vital role in ensuring smooth operation and reliability on the water.

- Hydraulic System: Responsible for controlling the angle and position of the outboard, ensuring optimal thrust and maneuverability.

- Mounting Bracket: Provides a sturdy connection between the engine and the vessel, supporting the entire assembly.

- Actuator: Facilitates movement and positioning, allowing for precise adjustments as needed.

- Control Unit: The brain of the system, it interprets user commands and regulates the hydraulic flow accordingly.

- Seals and Gaskets: Essential for preventing leaks and ensuring that the hydraulic fluid remains contained within the system.

Each of these components works in harmony, contributing to the overall functionality and efficiency of the marine engine setup. Regular inspection and maintenance of these elements are essential for optimal performance.

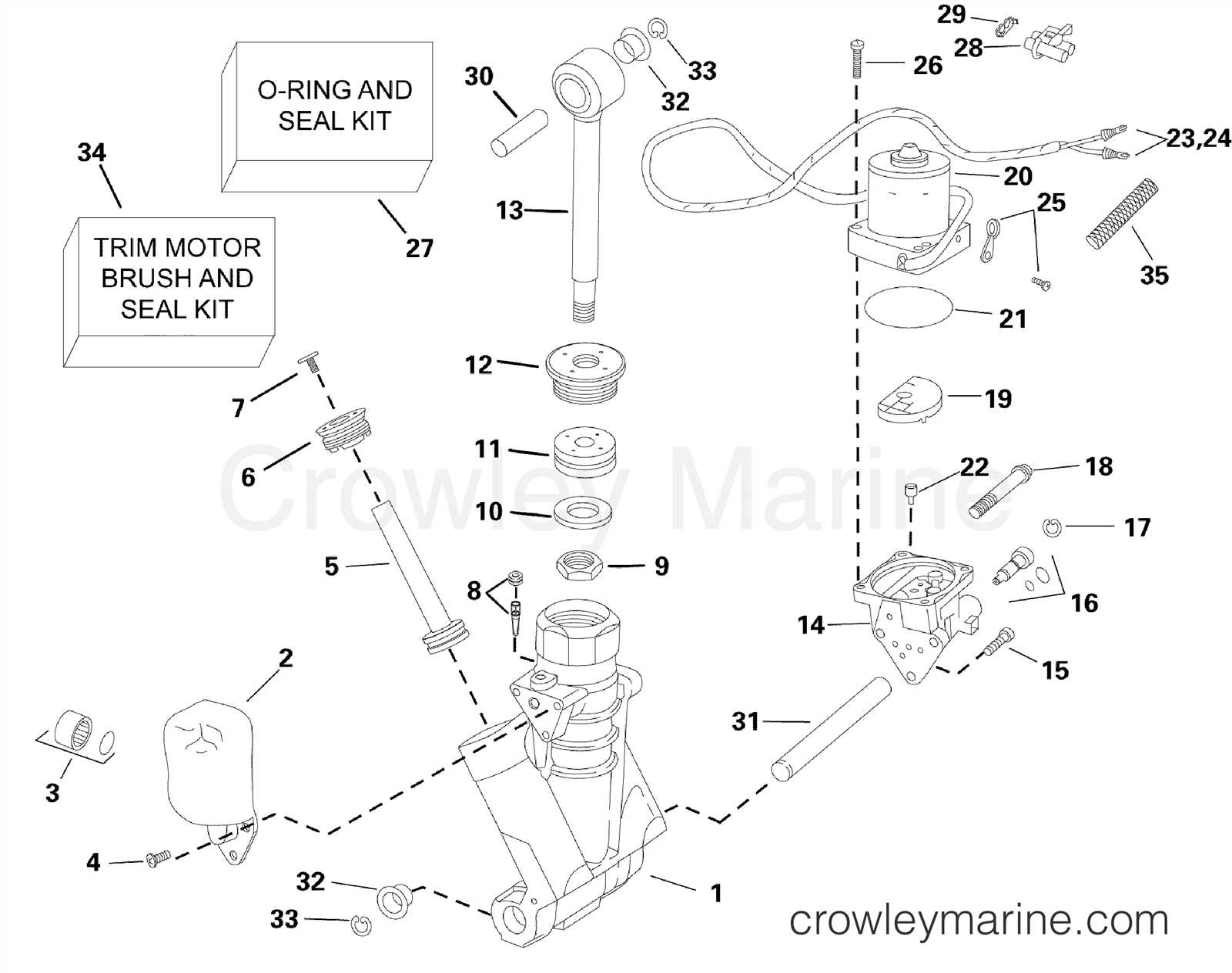

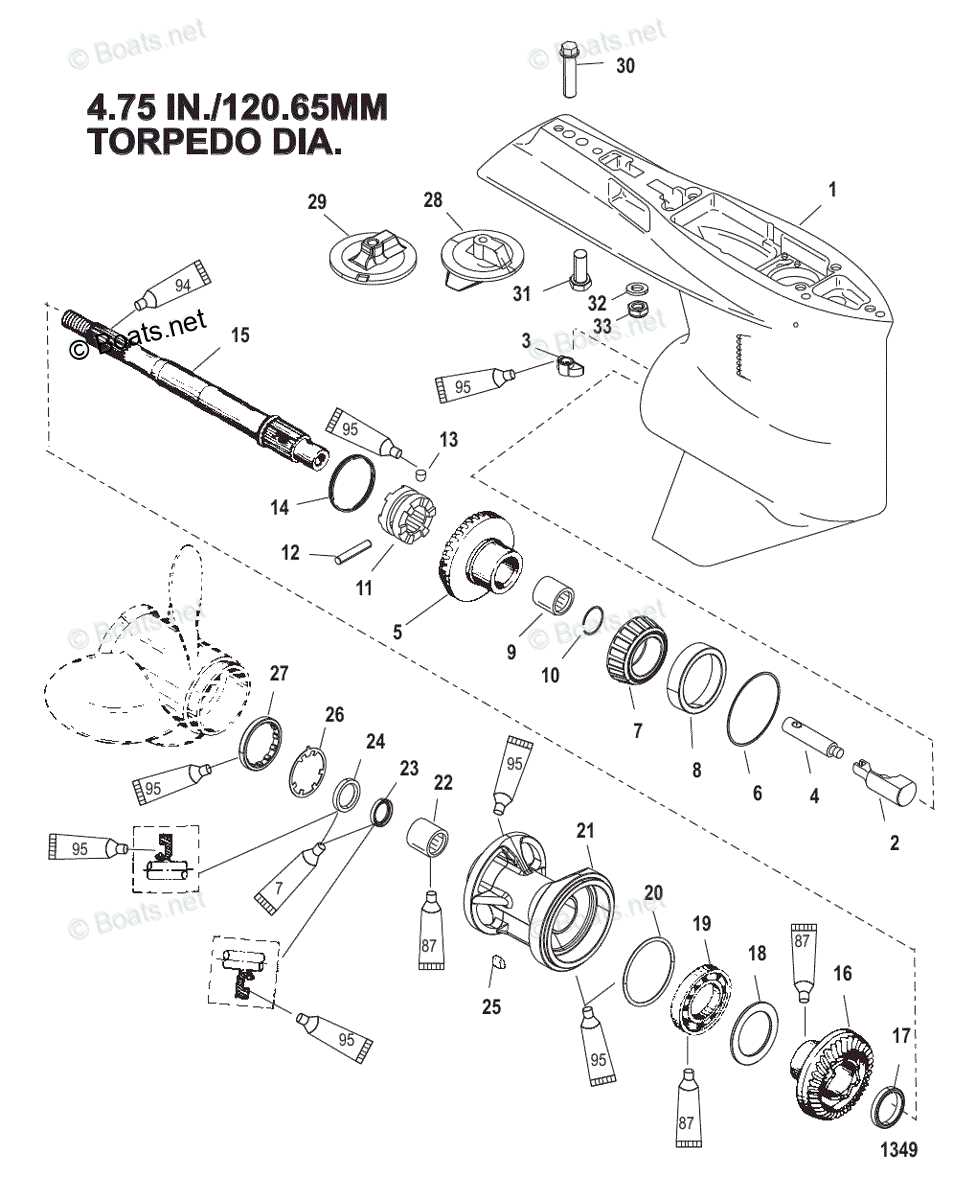

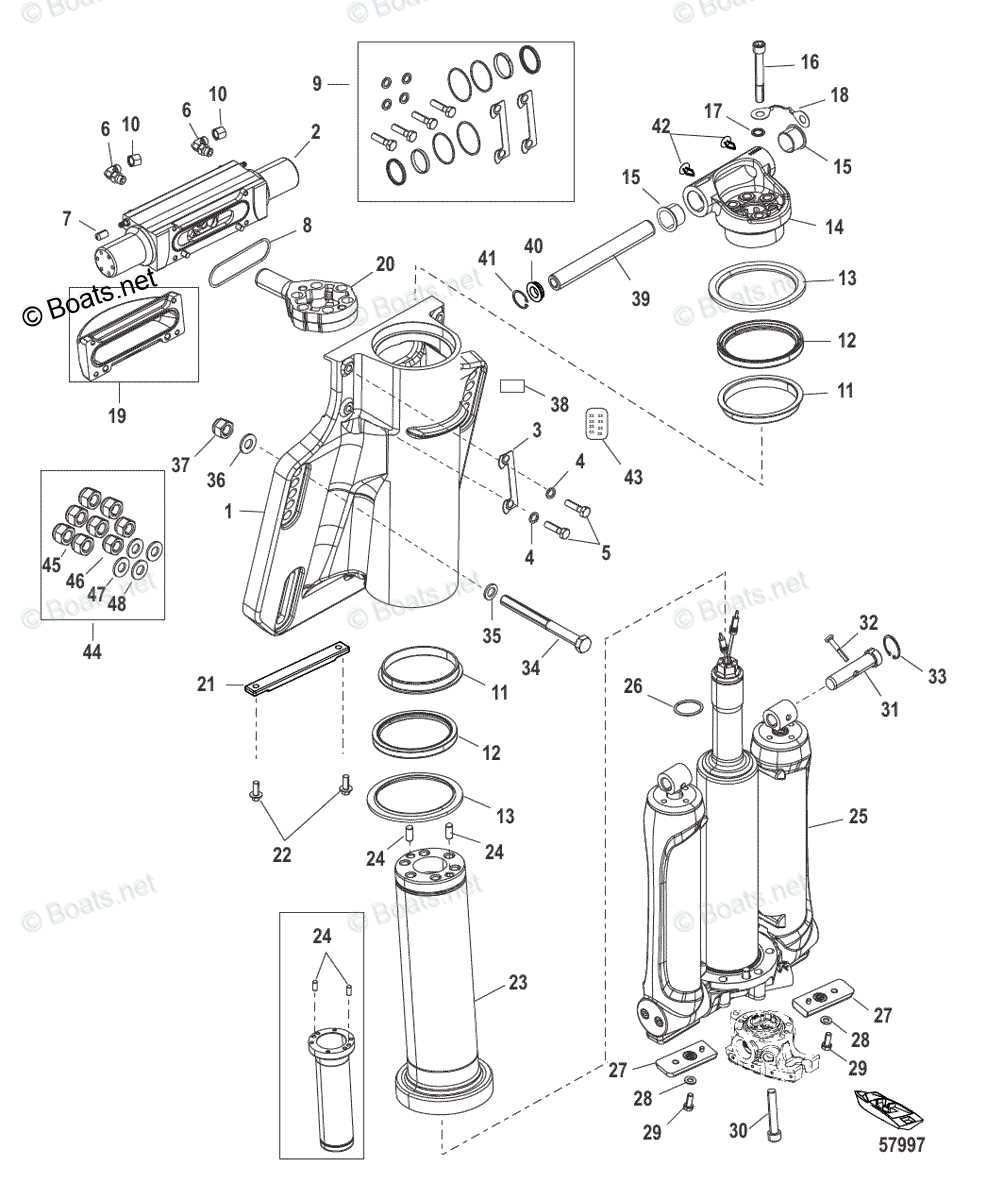

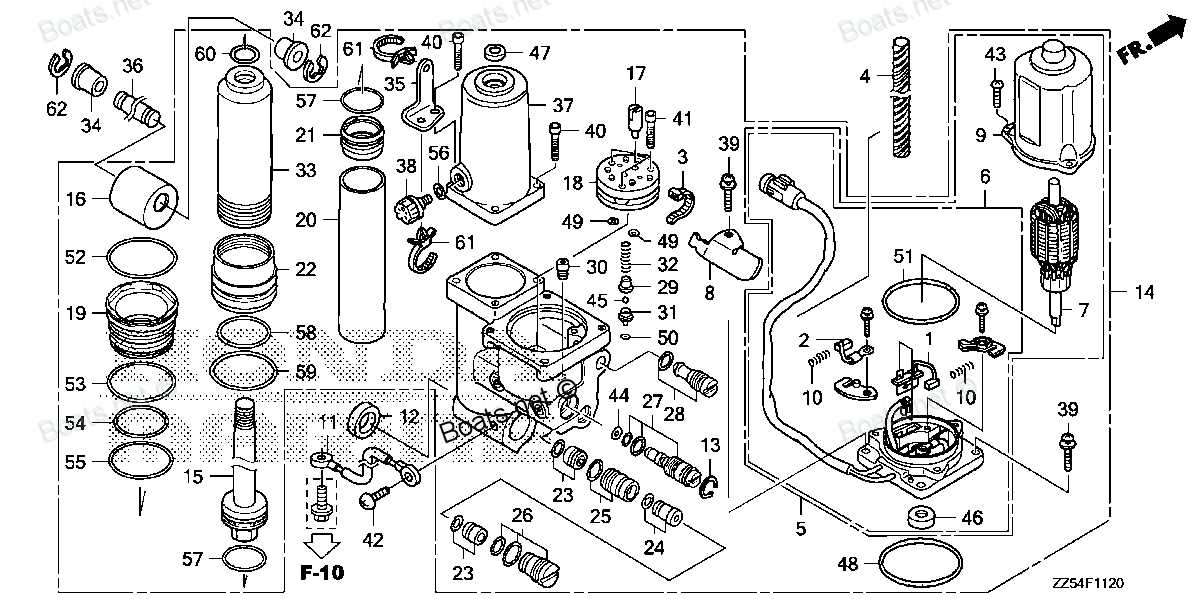

Detailed Parts Diagram Explanation

This section aims to provide a comprehensive overview of the intricate visual representation that showcases various components and their relationships within a particular system. By examining this illustration, users can gain insight into how each element functions individually and collectively, enhancing their understanding of the entire assembly.

Every segment is meticulously labeled, ensuring clarity when identifying specific pieces. The arrangement highlights connectivity, revealing how parts interact to contribute to the overall operation. This not only aids in troubleshooting but also facilitates maintenance and repair efforts.

In exploring this visual guide, one can delve into the specifics of each unit, recognizing the ultimate significance of every detail. Such knowledge empowers users to make informed decisions regarding repairs, replacements, and upgrades, ensuring optimal performance of the equipment.

Installation Guide for Key Parts

This section provides a comprehensive overview for properly installing essential components of your equipment. Following precise instructions will ensure optimal functionality and longevity of the system.

Preparation Steps

Before beginning the installation process, gather all necessary tools and components. Ensure that you have a clean workspace to avoid any contamination or damage. Read through the installation manual thoroughly to familiarize yourself with each component’s role and the overall assembly sequence.

Installation Procedure

Start by positioning the primary unit securely. Next, attach the critical components according to the specified order in the manual. Use the appropriate fasteners and ensure that each part is tightened to the recommended torque settings. Double-check connections to confirm that everything is aligned correctly, which will prevent potential malfunctions during operation.

Common Issues with Power Trim

Several challenges can arise when operating hydraulic lifting mechanisms, impacting performance and reliability. Identifying these issues early can help maintain efficiency and prevent more significant repairs.

Frequent Problems

- Fluid Leaks: A common concern that can lead to inadequate operation.

- Electrical Failures: Malfunctions in wiring can disrupt control and functionality.

- Slow Response: Delayed movements may indicate internal wear or blockages.

Troubleshooting Tips

- Check for leaks regularly and inspect seals and hoses.

- Examine electrical connections for corrosion or loose wires.

- Flush the system to clear any potential obstructions.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment requires consistent care and attention. Regular maintenance not only enhances performance but also prevents costly repairs down the line.

1. Regular Inspection: Frequently check all components for signs of wear or damage. Addressing minor issues promptly can prevent major failures.

2. Cleaning: Keep surfaces free of dirt and debris. Regular cleaning helps maintain optimal functioning and reduces corrosion risks.

3. Lubrication: Use appropriate lubricants on moving parts. Proper lubrication minimizes friction and wear, promoting smooth operation.

4. Storage: Store your equipment in a dry, cool place. Proper storage conditions can significantly extend the lifespan of various components.

5. Follow Guidelines: Adhere to manufacturer recommendations for maintenance schedules and procedures. This ensures that all aspects are properly cared for.

By incorporating these practices, you can effectively enhance the durability and efficiency of your equipment.

Upgrading Parts for Performance

Enhancing the functionality of your equipment can lead to significant improvements in efficiency and responsiveness. By selecting high-quality components and making strategic modifications, you can achieve superior performance and reliability.

Considerations for upgrades include material quality, design improvements, and compatibility with existing systems. Investing in advanced materials can reduce weight while enhancing durability, which ultimately leads to better performance.

Additionally, optimizing airflow and fluid dynamics through specialized components can maximize efficiency and output. Careful evaluation of each element allows for a tailored approach to enhancement, ensuring that every upgrade contributes to the overall capability.

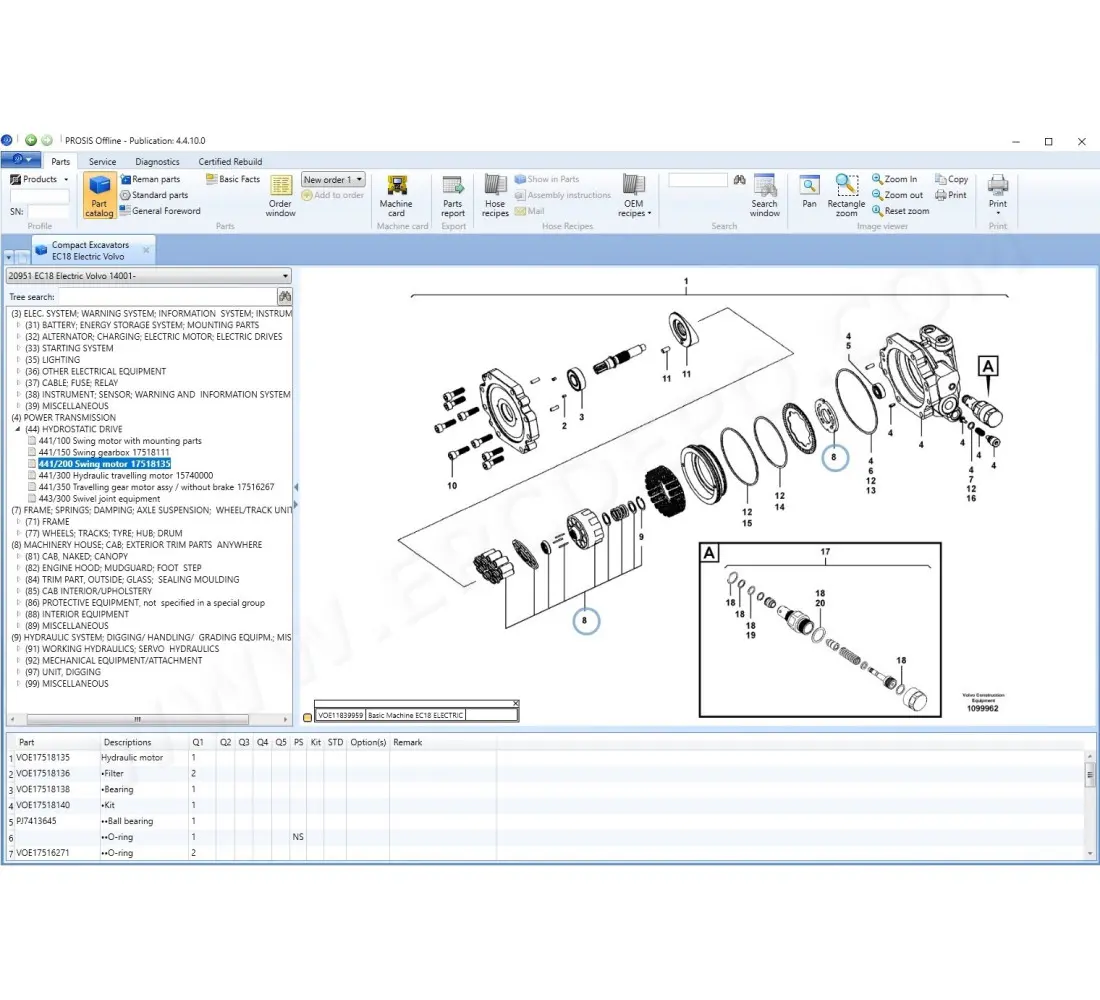

Finding Replacement Parts Online

In today’s digital age, sourcing components for marine equipment has become significantly easier thanks to the plethora of online resources available. Whether you’re in need of a specific item or just browsing for options, the internet offers various platforms to assist in locating what you require. Understanding where to look and how to navigate these resources can save time and ensure you find the right pieces for your maintenance needs.

Popular Online Platforms

Several websites specialize in marine equipment and can provide a wide range of components. Here are some well-known platforms:

| Website | Description |

|---|---|

| MarinePart.com | A comprehensive resource for various marine components, offering detailed search options. |

| BoatPartsWorld.com | This site features a vast selection of items, along with customer reviews to guide your choices. |

| eBay | A marketplace that often includes both new and used items, providing competitive pricing. |

| Amazon | With a wide array of products, Amazon is a convenient option for quick deliveries and customer service. |

Tips for Successful Searches

To enhance your experience when looking for items, consider the following tips:

- Use specific keywords related to the components you need.

- Check multiple sites to compare prices and availability.

- Read reviews and ratings to ensure the quality of the items.

- Take advantage of online forums and communities for recommendations.

Expert Recommendations for Users

For those looking to enhance their experience with their marine equipment, understanding the intricacies of its components is crucial. Having a comprehensive grasp of how each element functions can significantly improve performance and longevity.

First and foremost, regularly consult the manufacturer’s resources for updates and insights. This ensures that you are using the most current information available.

Additionally, establishing a routine maintenance schedule is essential. Regular checks and adjustments can prevent minor issues from escalating into major repairs.

Engaging with fellow enthusiasts and professionals through forums or workshops can provide invaluable hands-on advice and tips tailored to specific needs.

Finally, investing in quality replacement components rather than opting for cheaper alternatives can make a significant difference in overall functionality and safety.

Safety Precautions During Repairs

Ensuring safety while undertaking maintenance tasks is paramount to prevent accidents and injuries. By adhering to proper protocols, individuals can create a secure environment, allowing them to focus on their work without unnecessary risks. Awareness and preparation are essential components in safeguarding oneself and the workspace.

Before commencing any repair, it is vital to wear appropriate personal protective equipment such as gloves, goggles, and sturdy footwear. This gear acts as a barrier against potential hazards. Additionally, maintaining a tidy work area minimizes the risk of tripping or mishaps.

Moreover, disconnecting power sources and using tools correctly are crucial steps that should never be overlooked. Familiarizing oneself with the equipment and following manufacturer guidelines can significantly reduce the likelihood of errors. Finally, having a first aid kit readily available can provide peace of mind and prompt assistance in case of emergencies.

Frequently Asked Questions About Components

This section addresses common inquiries related to various elements of marine equipment, providing clarity and insight for users seeking to understand their functionality and maintenance requirements. Whether you’re a novice or a seasoned enthusiast, these FAQs aim to enhance your knowledge and assist in your journey.

What are the key functions of these elements?

The primary roles of these components include ensuring efficient operation, enhancing performance, and contributing to overall safety. Understanding these functions can significantly improve the longevity and effectiveness of your equipment.

How can I identify the correct replacements?

Identifying suitable replacements involves consulting manufacturer specifications, utilizing visual references, and seeking expert advice when necessary. Accurate identification is crucial for optimal performance and compatibility.