Exploring the intricate details of water circulation systems reveals a complex interplay of various elements, each playing a crucial role in ensuring optimal functionality. A comprehensive grasp of these components is essential for maintenance and troubleshooting, allowing users to effectively manage their systems.

In this section, we will delve into the individual segments that constitute the overall assembly, providing clarity on their specific functions and interrelations. By visualizing the arrangement and operation of these elements, one can better appreciate how they collectively contribute to the efficient circulation of water, enhancing performance and longevity.

Whether you are a seasoned technician or a curious enthusiast, familiarizing yourself with the specific configurations and interactions among these components will empower you to address issues and make informed decisions regarding repairs and upgrades.

This section aims to provide an insightful exploration of the essential components and functionality of a specific water circulation apparatus. Understanding these elements is crucial for effective maintenance and troubleshooting, ensuring optimal performance and longevity of the system.

The following table outlines the key components, their functions, and potential issues that may arise:

| Component | Function | Common Issues |

|---|---|---|

| Housing | Encases internal elements and provides structural support. | Cracks or corrosion can lead to leaks. |

| Impeller | Facilitates water movement through the system. | Wear and tear may reduce efficiency. |

| Seal | Prevents water from leaking out of the assembly. | Deterioration can cause leakage. |

| Capacitor | Helps start and run the device efficiently. | Failure can lead to a complete stop of functionality. |

Key Components of Pool Pump Motor

Understanding the essential elements of a circulating system is crucial for effective maintenance and operation. Each component plays a significant role in ensuring the efficiency and longevity of the entire system, contributing to optimal water circulation and filtration.

Essential Elements

- Housing: This protective shell encases the internal components, safeguarding them from environmental factors and wear.

- Impeller: A vital component that facilitates the movement of water by converting rotational energy into flow, crucial for maintaining circulation.

- Seal: This element prevents leaks and protects the inner workings from contaminants, ensuring durability and reliability.

- Strainer: Positioned at the intake, this filter captures debris and prevents clogging, preserving the functionality of the system.

Operational Mechanisms

Each part must work harmoniously to create an effective flow. The interaction between these components determines the system’s efficiency, highlighting the importance of regular inspection and maintenance to ensure all elements are functioning correctly.

- Electrical System: Powers the device, providing the necessary energy for operation.

- Bearings: Reduce friction, allowing smooth rotation and contributing to the system’s overall performance.

- Drive Shaft: Connects the impeller to the motor, transmitting power and facilitating movement.

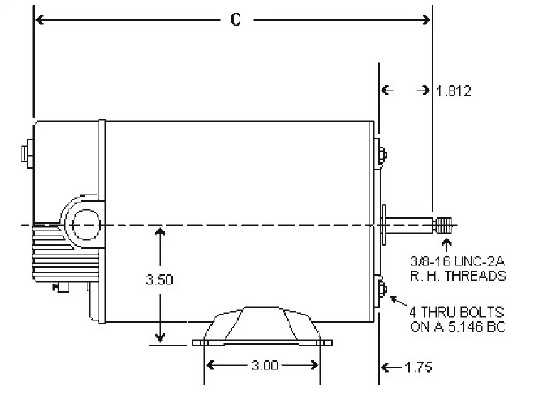

Understanding Motor Wiring Connections

When dealing with electrical equipment, comprehending the connections that link various components is crucial for efficient functionality. Each connection plays a vital role in ensuring that the entire system operates smoothly and reliably. Properly understanding these linkages can prevent malfunctions and enhance performance, making it an essential aspect for anyone involved in maintenance or installation tasks.

Typically, wiring involves several color-coded cables that serve distinct functions. Recognizing these colors and their respective purposes is fundamental for troubleshooting issues or making adjustments. Additionally, understanding how these wires connect to terminals ensures that power flows correctly through the system, thereby preventing potential hazards or damage.

Moreover, familiarity with common wiring configurations can significantly aid in diagnosing problems. For instance, knowing which connections correspond to specific operations enables quicker repairs and optimizes overall performance. By maintaining a clear understanding of these connections, individuals can ensure the longevity and efficiency of the equipment.

Types of Motors Used in Pumps

The selection of engines utilized in various types of fluid transfer systems is crucial for ensuring efficiency and performance. These devices come in different varieties, each designed to meet specific operational requirements and environmental conditions. Understanding the different engine types helps in choosing the right one for a particular application.

Induction Engines are commonly employed due to their reliability and low maintenance needs. They operate by inducing a magnetic field, which generates rotational motion. This type is favored for its robustness and ability to handle varying loads without significant performance loss.

Permanent Magnet Engines are known for their high efficiency and compact size. They utilize magnets to create a magnetic field, providing improved energy conservation. These engines are often found in applications where space is limited and energy efficiency is a priority.

DC Engines offer versatility in speed control, making them suitable for applications requiring variable speed settings. They are powered by direct current and are often utilized in systems that need precise control over the operational speed.

Brushless Motors are increasingly popular due to their durability and efficiency. They eliminate the need for brushes, reducing wear and maintenance requirements. This type is particularly advantageous in environments where longevity and reliability are essential.

Choosing the appropriate engine is vital for optimal performance and longevity of fluid transfer systems. Each type has its advantages, and the decision should be based on the specific needs of the application.

Maintenance Tips for Pump Motors

Ensuring the longevity and efficiency of any operational equipment requires regular upkeep and attention. Proper maintenance practices not only enhance performance but also help in preventing potential breakdowns and costly repairs. Below are some essential guidelines to consider for keeping your apparatus in optimal condition.

Regular Inspection

Conducting frequent examinations is crucial for identifying early signs of wear or malfunction. Focus on the following aspects:

- Check for unusual noises during operation.

- Inspect connections for signs of corrosion or loose wiring.

- Monitor vibrations to detect potential imbalances.

Cleaning and Lubrication

Keeping components clean and properly lubricated can significantly enhance efficiency. Consider these steps:

- Remove dust and debris from the exterior regularly.

- Use appropriate lubricants for moving parts, following manufacturer recommendations.

- Ensure ventilation areas are free from blockages to maintain airflow.

Common Issues with Pool Motors

Many individuals experience challenges with their aquatic circulation systems. Understanding typical problems can help owners maintain optimal performance and extend the lifespan of their equipment. Here are some frequent complications that can arise.

Electrical Problems

Electrical issues are among the most prevalent challenges faced. They can arise from various sources, leading to inadequate performance or complete failure.

- Tripped Circuit Breaker: A circuit breaker may trip due to overload or short circuits, interrupting power supply.

- Loose Connections: Frayed wires or loose terminals can prevent the system from functioning properly.

- Faulty Capacitors: Capacitors can fail, leading to difficulty starting or maintaining operation.

Mechanical Failures

Mechanical components can also experience wear and tear, resulting in inefficiencies and potential breakdowns.

- Bearings Wear: Worn bearings can cause unusual noises and hinder smooth operation.

- Impeller Issues: Debris can obstruct the impeller, reducing flow and efficiency.

- Seal Failures: Deteriorating seals can lead to leaks, causing additional damage and requiring costly repairs.

How to Replace Motor Parts

Replacing components within a mechanical assembly can significantly enhance its efficiency and longevity. This process involves several critical steps to ensure that the new elements are installed correctly, maintaining the overall functionality of the unit. Proper preparation and understanding of the procedure are essential for achieving a successful outcome.

1. Safety First: Before starting any work, ensure that the device is unplugged and the power source is disconnected. This step is crucial to prevent any accidental injuries during the replacement process. Additionally, wear appropriate safety gear, such as gloves and goggles, to protect yourself from potential hazards.

2. Disassemble the Unit: Carefully remove the outer casing to access the internal mechanisms. Take note of the arrangement of components, as this will aid in reassembly later. It may be helpful to take pictures or label parts to avoid confusion.

3. Remove the Old Components: Identify the elements that require replacement. Gently detach them from their positions, ensuring not to damage surrounding components. Keep track of any screws or fasteners, as they will be needed for the new parts.

4. Install New Components: Place the new elements into their designated spots, ensuring they fit snugly. Double-check that they are aligned properly and secure them using the original screws or fasteners. This step is vital to maintain the integrity of the assembly.

5. Reassemble and Test: Once all replacements are made, reattach the outer casing carefully. After everything is secured, reconnect the power source and conduct a test run. Observing the unit’s performance will help confirm whether the replacements were successful and if everything is functioning as intended.

By following these steps diligently, you can ensure that your unit operates smoothly and efficiently after the replacement of essential components.

Safety Precautions When Servicing

Ensuring safety during maintenance is crucial to prevent accidents and injuries. Proper precautions should be taken to protect both the technician and the equipment. Awareness of potential hazards and adherence to safety protocols can significantly reduce risks associated with servicing operations.

Always disconnect power sources before beginning any repair or maintenance tasks. This prevents accidental activation and electrical shocks. Verify that all switches are off and consider using lockout/tagout procedures for added security.

Utilize appropriate personal protective equipment (PPE) such as gloves, goggles, and masks. These items safeguard against potential injuries from chemicals, debris, or sharp objects encountered during servicing. Ensure that all protective gear is in good condition and fits properly.

Work in a well-ventilated area to minimize exposure to fumes or hazardous substances. Proper airflow helps disperse any potentially harmful vapors, making the workspace safer for handling equipment and materials.

Be cautious of moving components while performing maintenance tasks. Keep hands and tools clear of any areas where parts may shift or rotate unexpectedly. Use tools designed for the specific job to enhance safety and efficiency.

Maintain a clean workspace to reduce the risk of accidents. Remove any clutter or unnecessary items from the area to ensure safe and efficient access to the equipment. Clean up spills immediately to prevent slips and falls.

By following these guidelines, technicians can enhance their safety and ensure effective servicing of equipment.

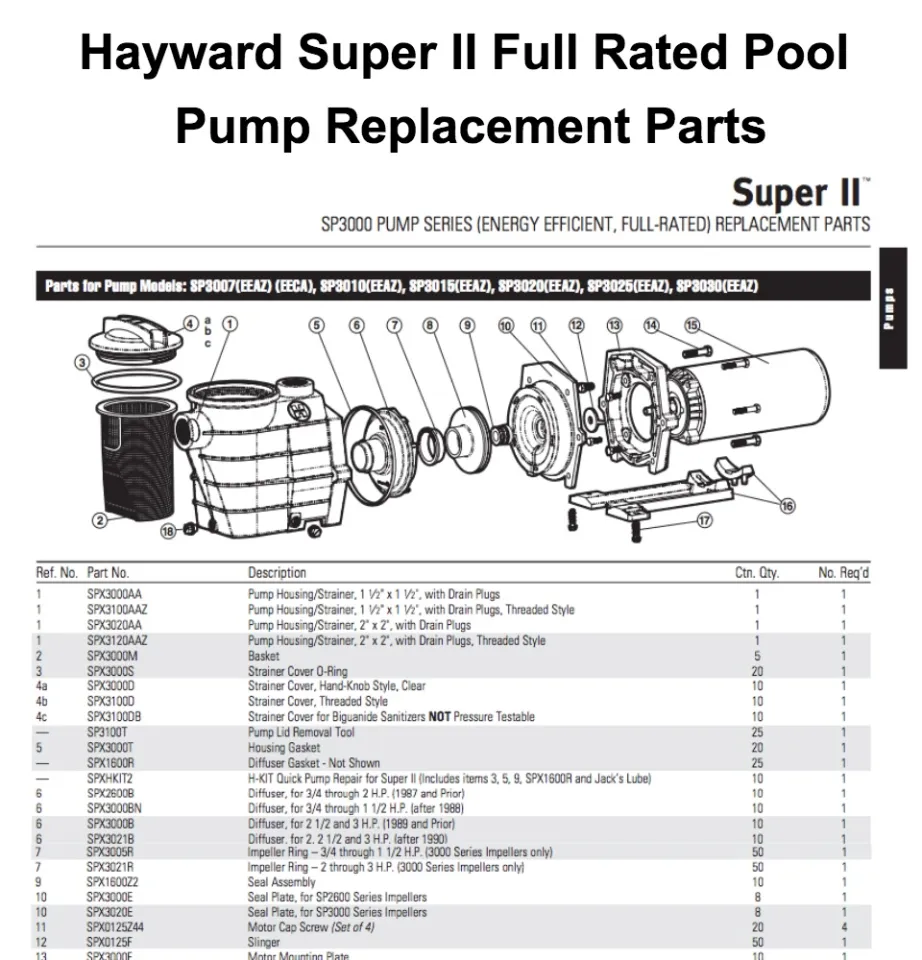

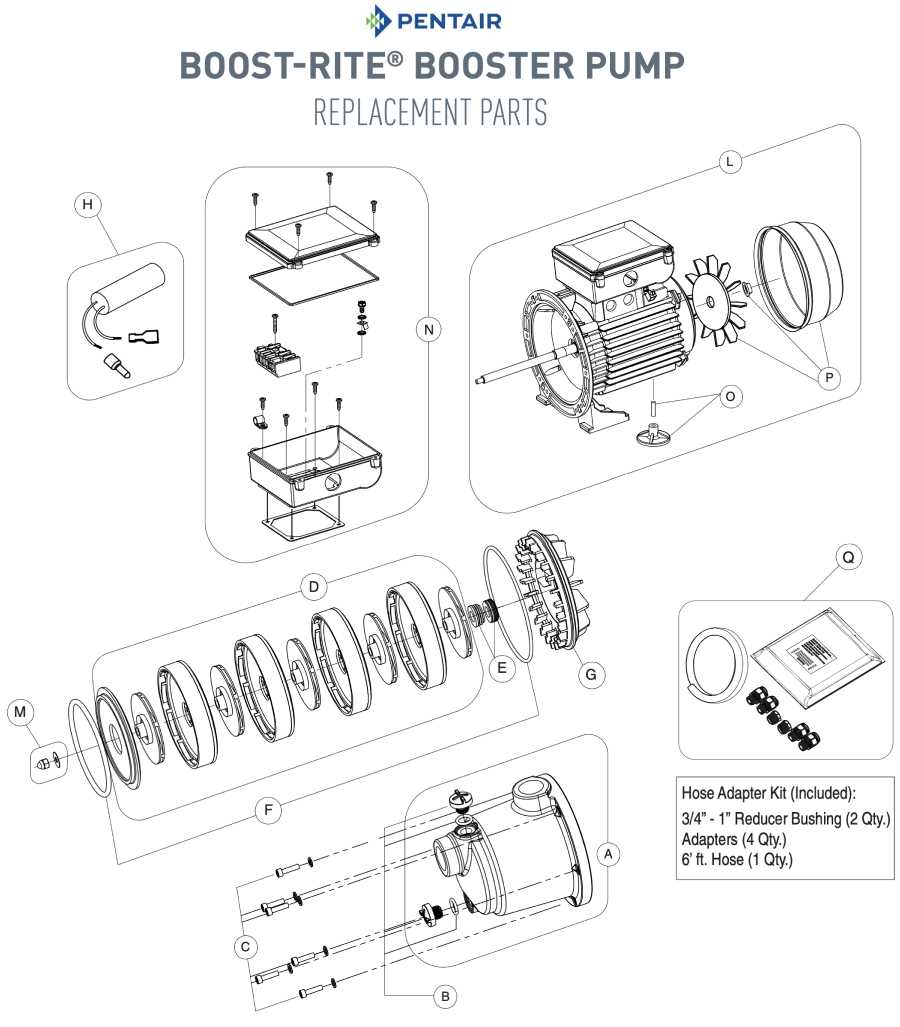

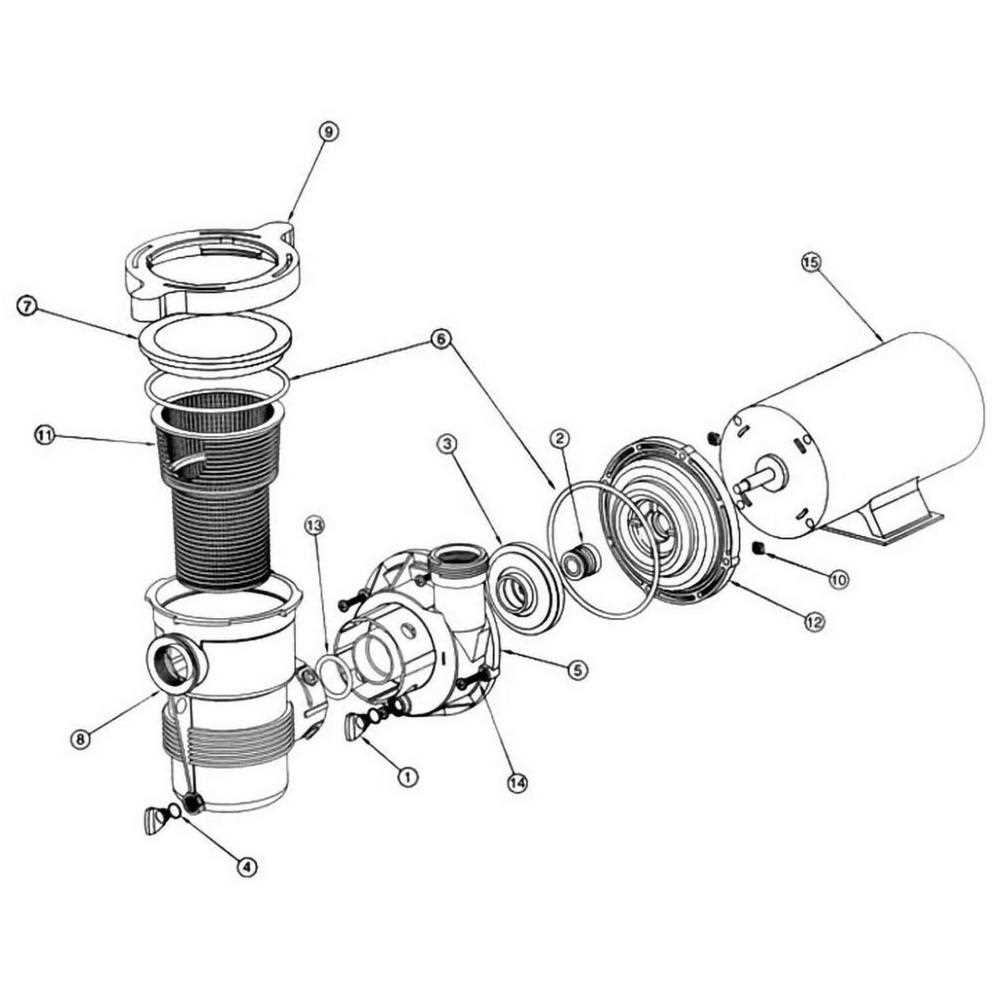

Diagram Explanation and Functionality

This section aims to clarify the components and their interrelations within the system. Understanding how each element operates is crucial for efficient maintenance and troubleshooting, enabling users to identify issues quickly and ensure optimal performance.

Key Components Overview

The primary elements consist of various assemblies working together to facilitate the overall function. Each component serves a specific purpose, contributing to the system’s effectiveness. Recognizing these roles helps in diagnosing problems and performing repairs accurately.

Operational Dynamics

Each assembly interacts in a coordinated manner, creating a seamless flow that maximizes efficiency. Observing these dynamics allows users to appreciate how the system functions as a whole, highlighting the importance of proper installation and maintenance to avoid operational disruptions.

Choosing the Right Replacement Parts

Selecting suitable components for your equipment is crucial for maintaining optimal performance and longevity. Various factors influence the decision-making process, including compatibility, quality, and cost-effectiveness. Understanding these aspects can help you make informed choices that meet your specific needs.

Compatibility with your existing setup is the first consideration. Always verify that the components match the specifications required for seamless integration. Additionally, it’s essential to consider the quality of the replacements. Investing in high-quality options can save you money in the long run by reducing the frequency of replacements and repairs.

Cost is another vital aspect to evaluate. While it may be tempting to opt for the cheapest options available, this approach can lead to more significant expenses over time if the products fail prematurely. Striking a balance between affordability and quality is key.

| Criteria | Description |

|---|---|

| Compatibility | Ensure components fit your system’s specifications. |

| Quality | Choose reliable options to enhance durability. |

| Cost | Balance price with performance to avoid future expenses. |

Benefits of Regular Maintenance

Conducting routine upkeep on your equipment is essential for ensuring longevity and optimal performance. Regular attention not only helps to identify potential issues before they escalate but also contributes to the overall efficiency of the system. By committing to a scheduled maintenance plan, users can experience enhanced reliability and reduced downtime.

Improved Efficiency

Consistent maintenance can significantly enhance the operational efficiency of your apparatus. When components are clean and functioning correctly, energy consumption decreases, leading to lower utility bills. This proactive approach mitigates the risk of overworking machinery, which can result in excessive wear and tear.

Cost Savings

Investing time and resources in regular upkeep can yield substantial financial benefits over time. By preventing major breakdowns through early detection of wear and malfunctions, users can avoid expensive repairs or replacements. Additionally, efficient operation typically results in reduced energy expenditures, further contributing to savings.

| Maintenance Activity | Frequency | Expected Outcome |

|---|---|---|

| Inspect and Clean Filters | Monthly | Optimal flow and reduced strain on components |

| Check Electrical Connections | Quarterly | Enhanced safety and functionality |

| Lubricate Moving Parts | Bi-Annually | Minimized friction and prolonged lifespan |

| Professional Inspections | Annually | Comprehensive assessment and expert advice |

FAQs About Pool Pump Motors

This section addresses common inquiries regarding the components responsible for circulating water in aquatic facilities. Understanding these devices is essential for maintaining their efficiency and ensuring a seamless experience for users.

What is the lifespan of a water circulation device?

The longevity of these systems can vary based on usage, maintenance, and environmental factors. Typically, with proper care, they can last anywhere from 5 to 15 years. Regular inspections and timely replacements of worn components can significantly extend their service life.

How can I troubleshoot common issues?

Identifying problems often starts with observing any unusual noises or performance dips. Ensure that the device is free of debris, check for proper electrical connections, and verify that the water levels are adequate. If issues persist, consulting a professional may be necessary.