The intricate design of the X5 system showcases a harmonious blend of technology and functionality, serving as a vital element in enhancing marine experiences. By exploring the various elements that comprise this innovative mechanism, users can gain valuable insights into its operational efficiency and durability.

Within this section, we aim to provide a comprehensive overview of the key components that contribute to the overall performance of the X5 system. Recognizing how each element interconnects not only aids in effective maintenance but also empowers users to optimize their equipment for maximum utility.

Delving into the specifics of these crucial components unveils the ultimate potential of the X5 system, allowing users to appreciate the engineering prowess behind its design. Understanding these intricacies can lead to improved performance and longevity, ensuring that every outing on the water is as enjoyable as possible.

Understanding the Motorguide X5

This section explores the essential components and functionalities of a popular trolling motor, providing insight into its design and operation.

Key features of this motor include:

- Durable construction for long-term use

- Advanced steering capabilities for precise navigation

- Efficient power management for extended battery life

To fully appreciate its performance, consider the following aspects:

- Build Quality: Materials used affect longevity and resilience.

- Control Mechanism: Understanding the steering system enhances user experience.

- Maintenance: Regular upkeep ensures optimal functionality.

Delving into these elements reveals the ultimate efficiency of this motor in various aquatic environments.

Key Features of Motorguide X5

The X5 model is designed to enhance the boating experience with its innovative attributes and advanced technology. It combines reliability and performance, making it an essential choice for avid anglers and boaters. This section highlights the primary characteristics that set this model apart from others in the market.

| Feature | Description |

|---|---|

| Durable Construction | Built with high-quality materials to withstand harsh marine environments. |

| Advanced Control System | Offers precise steering and speed adjustments for improved handling. |

| Powerful Thrust | Delivers strong propulsion to navigate through various water conditions. |

| Quiet Operation | Engineered for minimal noise, enhancing the fishing experience. |

| Easy Installation | Simplified setup process, allowing users to get on the water quickly. |

| Ergonomic Design | Provides comfort and ease of use during extended periods on the water. |

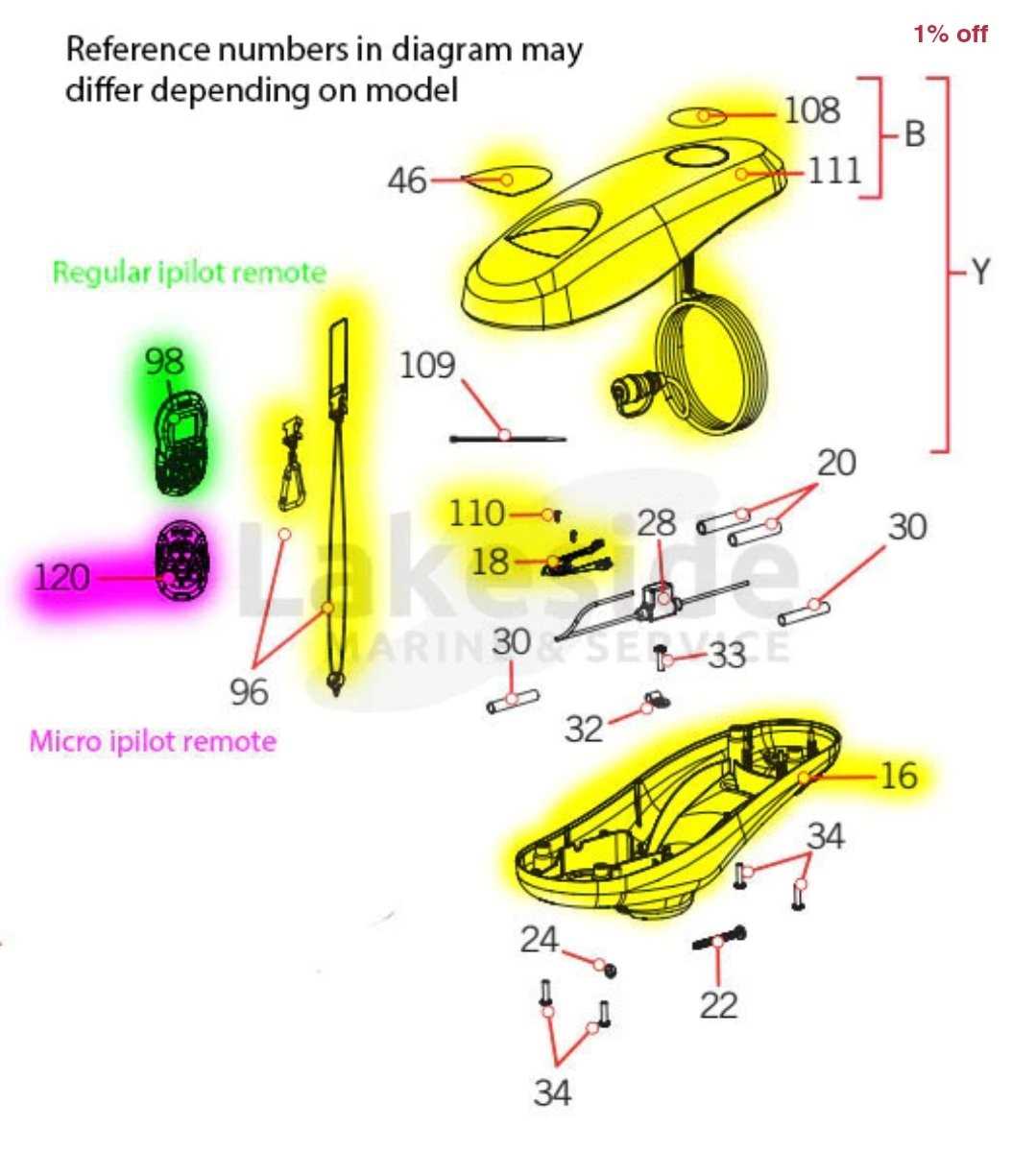

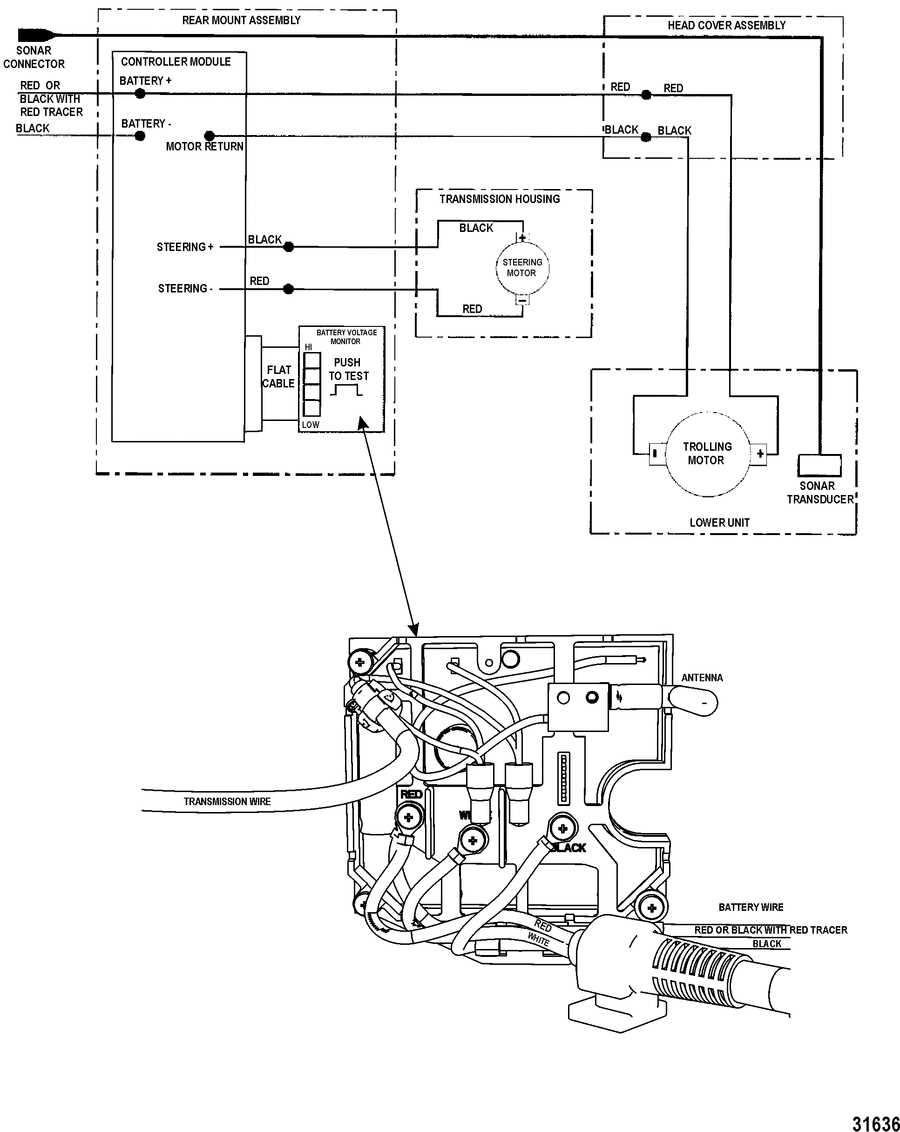

Importance of Parts Diagrams

Understanding the structure and components of a mechanical system is crucial for effective maintenance and repair. Visual representations that detail each element’s placement and function serve as invaluable resources, aiding both technicians and enthusiasts in their endeavors. These illustrations not only simplify complex assemblies but also enhance troubleshooting capabilities.

Having access to these visual aids allows users to identify specific components quickly, ensuring that replacements and repairs are executed with precision. This clarity minimizes the risk of errors during disassembly and reassembly, ultimately extending the lifespan of the equipment. Furthermore, such resources contribute to a deeper comprehension of the overall system, fostering confidence in handling mechanical issues.

In addition, these visuals facilitate communication between users and service professionals. When discussing repairs or modifications, referring to a detailed representation helps convey ideas more effectively, reducing misunderstandings. Overall, these graphical tools are essential for anyone engaged in maintaining or improving mechanical devices.

Common Issues with Motorguide X5

Understanding typical problems encountered with certain trolling motors can enhance the experience of anglers. Addressing these challenges promptly can prevent further complications and ensure optimal performance on the water.

Power and Connectivity Problems

One of the most frequent issues involves inconsistent power supply, which can lead to intermittent functionality. Ensuring secure connections and checking the battery status are crucial steps. Corroded terminals and worn wires may also contribute to these difficulties.

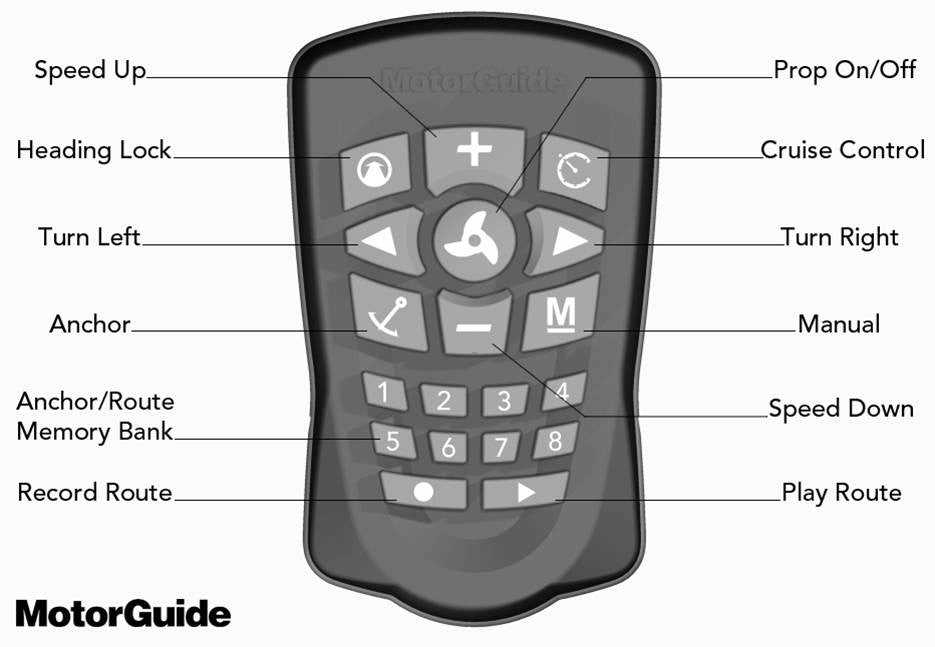

Steering and Control Malfunctions

Users often report challenges with steering responsiveness. This can stem from mechanical wear or misalignment in the control components. Regular maintenance and inspections can help identify and resolve these issues before they become severe.

Where to Find Parts Diagrams

Finding detailed illustrations and schematics for your equipment can be essential for effective maintenance and repairs. Numerous resources are available that cater to different needs, making it easier to access the necessary information. From manufacturer websites to specialized forums, the options are plentiful.

Official Manufacturer Websites: Start by visiting the official site of the equipment’s manufacturer. They often provide comprehensive resources, including detailed schematics and service manuals.

Online Retailers: Many online stores that sell components also include visual references to assist customers in identifying what they need. These platforms can be particularly useful for comparing items.

Community Forums: Engaging with enthusiasts in online forums can lead to valuable insights. Members often share links to resources, images, and personal experiences that can help others.

Social Media Groups: Platforms like Facebook have groups dedicated to specific brands or models where users frequently share technical information, including helpful illustrations.

YouTube Tutorials: Video content can be incredibly useful. Many creators post detailed walkthroughs that include visuals of the components and assembly processes, offering a practical perspective.

By exploring these avenues, you can effectively locate the visual resources necessary for your repair projects.

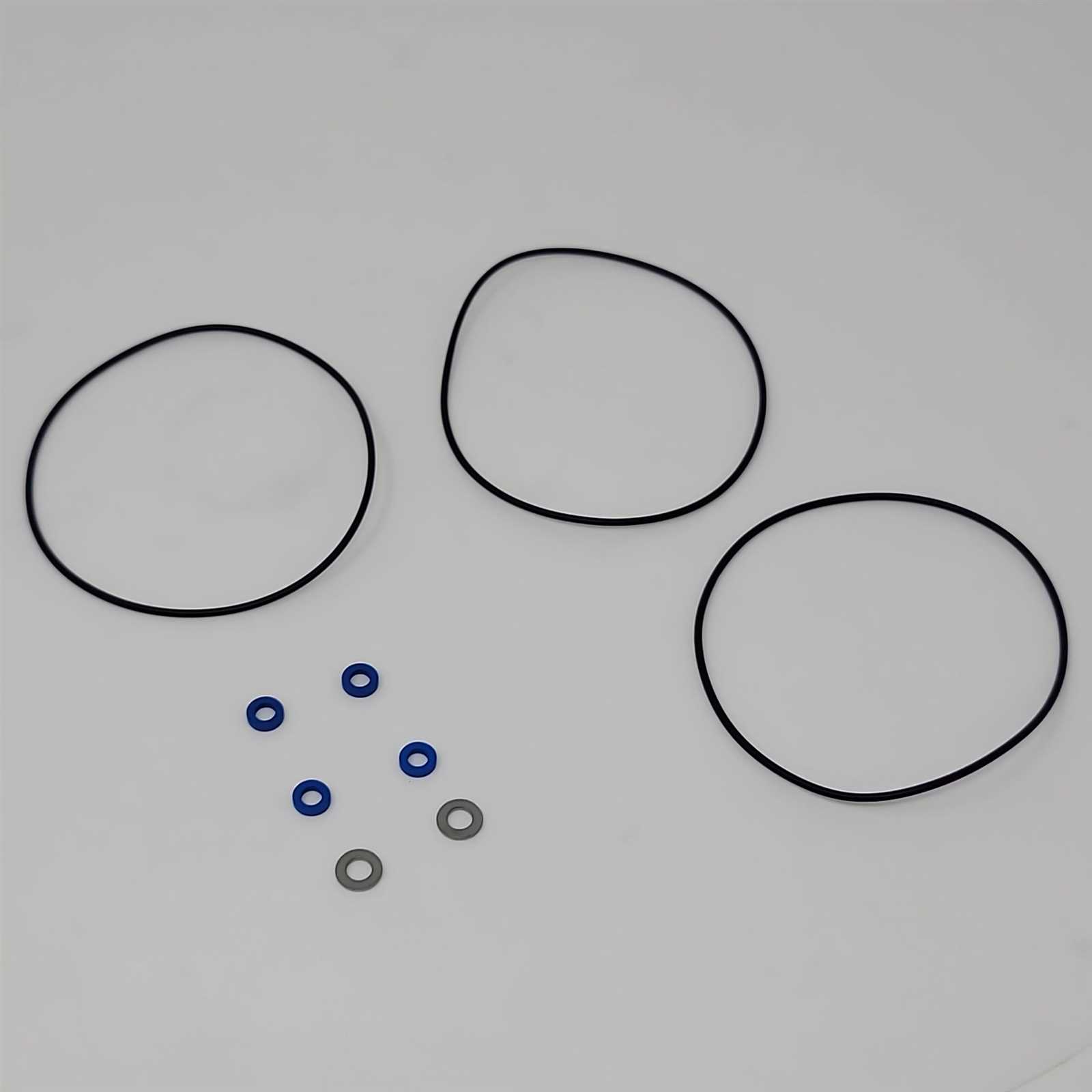

Benefits of Using Original Parts

Choosing components designed specifically for your equipment can greatly enhance performance and longevity. Utilizing authentic pieces ensures compatibility, reliability, and adherence to quality standards, ultimately leading to a smoother operation and reduced maintenance issues.

One of the primary advantages of using genuine components is the assurance of superior quality. These items are crafted to meet strict specifications, resulting in enhanced durability and reduced risk of failure.

| Advantage | Description |

|---|---|

| Compatibility | Original components are tailored to fit seamlessly, preventing operational disruptions. |

| Reliability | Authentic items undergo rigorous testing, ensuring consistent performance. |

| Warranty Protection | Using original products often keeps warranties intact, safeguarding your investment. |

| Enhanced Performance | Quality materials contribute to improved efficiency and effectiveness of your equipment. |

In summary, opting for original components not only guarantees superior quality but also contributes to the overall efficiency and reliability of your machinery, making it a wise choice for any operator.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires consistent care and attention. By implementing a few key practices, you can significantly extend its lifespan and enhance performance over time.

Regular Inspection

- Check for wear and tear on all components.

- Look for signs of rust or corrosion.

- Ensure all connections are secure and free of debris.

Cleaning and Lubrication

- Clean the exterior regularly to prevent buildup.

- Apply appropriate lubricants to moving parts to reduce friction.

- Use fresh water to rinse off salt or contaminants after use.

How to Read Parts Diagrams

Understanding visual schematics is essential for effective maintenance and repair. These illustrations provide a clear representation of various components and their relationships, enabling users to identify each piece’s function and location. Familiarity with these visuals can significantly enhance troubleshooting efficiency and facilitate successful reassembly.

Identifying Components

Begin by familiarizing yourself with the symbols and notations used in the illustration. Each element typically corresponds to a specific part, often labeled with a number or letter. Cross-referencing these identifiers with accompanying documentation will clarify the role of each section, allowing for a more informed approach to repairs.

Understanding Relationships

Pay attention to how the components interact within the system. Lines or arrows may indicate connections or flow, guiding your understanding of assembly order and functionality. Recognizing these relationships is crucial for ensuring that everything fits together properly during reassembly, leading to optimal performance.

DIY Repairs for Motorguide X5

Maintaining and fixing your motor can be a rewarding experience, allowing you to save money and gain valuable skills. Whether you’re addressing minor malfunctions or undertaking significant overhauls, understanding the basics of repair can enhance performance and longevity. This guide will help you navigate common issues and provide effective solutions.

Common Issues and Solutions

One prevalent problem is a lack of power. Check the battery connections first; corrosion or loose terminals can impede functionality. Additionally, inspect the wiring for any damage or wear. If the motor operates intermittently, consider testing the switch and circuit board for faults.

Routine Maintenance Tips

Regular upkeep is essential for optimal operation. Lubricate moving parts to reduce friction and prevent wear. Cleaning the exterior helps prevent rust and corrosion, while inspecting the propeller for damage ensures efficient performance. Keep your equipment in top shape, and you’ll enjoy a seamless experience on the water.

Recommended Tools for Repairs

Having the right tools at your disposal can significantly ease the repair process, ensuring efficiency and precision. Whether you’re addressing mechanical issues or performing routine maintenance, a well-equipped toolkit is essential for achieving optimal results.

Essential Tools

- Wrenches: A variety of sizes to handle different fasteners.

- Screwdrivers: Both flat-head and Phillips types for versatile use.

- Pliers: Useful for gripping, twisting, and cutting wires.

- Socket Set: Provides ease in loosening and tightening bolts.

- Multimeter: Essential for checking electrical components.

Additional Useful Equipment

- Torque Wrench: Ensures proper tightness of bolts.

- Cleaning Supplies: Keep components free from debris and buildup.

- Work Gloves: Protects hands during repairs.

- Safety Goggles: Shields eyes from dust and particles.

- Flashlight: Provides illumination in dark areas during work.

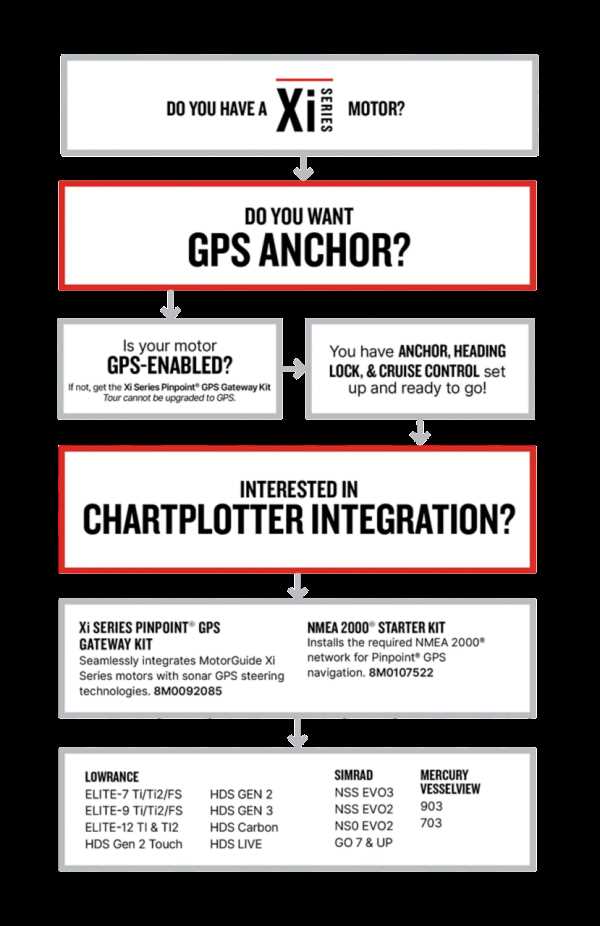

Upgrading Components for Better Performance

Enhancing your vessel’s efficiency often involves upgrading various elements to achieve superior functionality. By selecting high-quality components, you can significantly boost performance, reliability, and overall satisfaction during your outings on the water.

Choosing the Right Upgrades

When considering enhancements, focus on elements that directly impact performance, such as propulsion systems and control mechanisms. Upgrading to advanced technologies can lead to improved speed and maneuverability, giving you the ultimate advantage on the water.

Installation and Maintenance

Proper installation and regular maintenance of upgraded components are crucial for maximizing their benefits. Regular checks and adjustments ensure that everything operates smoothly, allowing you to delve into your adventures with confidence.

Compatibility with Other Models

Understanding the interrelation between different models is crucial for optimizing performance and ensuring seamless integration. Many components are designed to work across various platforms, enhancing functionality and user experience. This compatibility opens up possibilities for upgrades and replacements without the need for a complete overhaul.

Shared Features

Several models share key characteristics, making it easier to interchange elements. Identifying these common traits can save time and resources, allowing users to find suitable replacements without extensive research.

Considerations for Integration

When integrating components from different models, it is essential to evaluate specific requirements such as voltage, size, and mounting options. Ensuring these factors align will ultimately lead to enhanced performance and reliability.

Expert Advice on Troubleshooting

Tackling issues with your equipment can often feel overwhelming, but understanding the common challenges can simplify the process. This section provides valuable insights and practical steps to identify and resolve problems efficiently.

Common Issues to Look For

- Power failures

- Unusual noises

- Inconsistent performance

- Connection problems

Troubleshooting Steps

- Check all power sources and connections.

- Inspect components for wear or damage.

- Test settings and adjustments to ensure accuracy.

- Consult the manual for specific troubleshooting tips.

By following these guidelines, users can delve deeper into the issues at hand and work towards achieving optimal functionality.