When it comes to outdoor maintenance equipment, having a clear understanding of how each element works together is essential for both efficiency and durability. A well-organized visualization of key elements allows users to identify individual components and their functions within the larger assembly. This not only simplifies upkeep but also ensures better performance over time.

The proper identification and replacement of worn-out or damaged elements play a crucial role in maintaining the effectiveness of the machine. With easy access to an organized layout, users can quickly locate necessary elements for repairs or replacements, ultimately extending the lifespan of the equipment.

Exploring the technical structure of these machines provides valuable insights into how different mechanisms contribute to overall functionality. Recognizing the interdependence of each section allows for more informed maintenance decisions, ensuring that all elements work in harmony for optimal performance.

Key Component Overview

Understanding the essential mechanisms of a cutting machine is crucial for efficient maintenance and performance. This section provides an overview of the primary elements that contribute to its smooth operation and overall durability.

Main Structural Elements

- Frame: The backbone of the equipment, offering support and stability during operation.

- Cutting Mechanism: Designed to handle different terrains, ensuring clean and precise cuts.

- Wheels: Provide smooth movement and are adjustable for different cutting heights.

Engine and Power System

- Engine: A robust motor that powers the machine, available in various capacities for different tasks.

- Fuel System: Ensures a consistent fuel supply, optimizing engine performance and reducing wear.

- Transmission: Regulates speed and torque, allowing for efficient

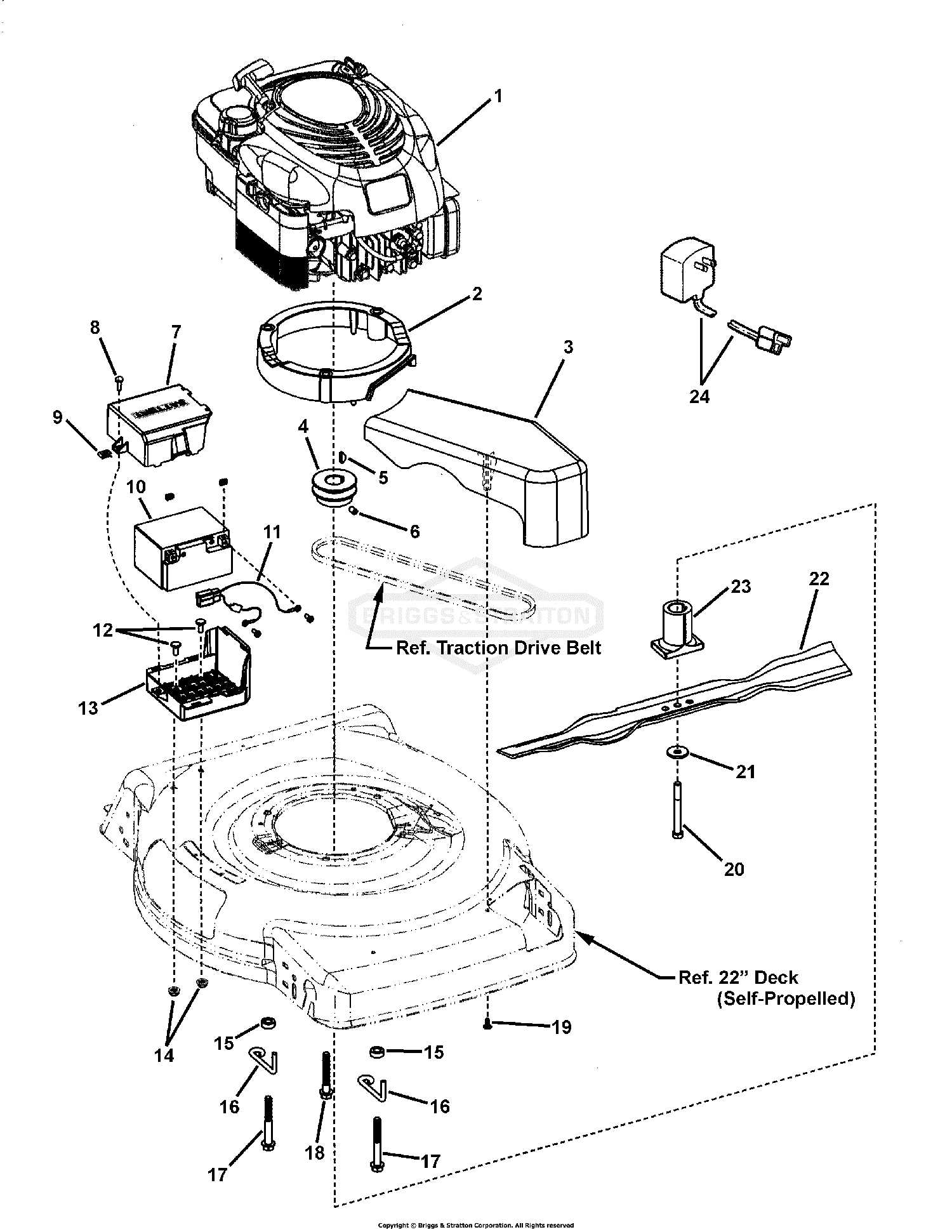

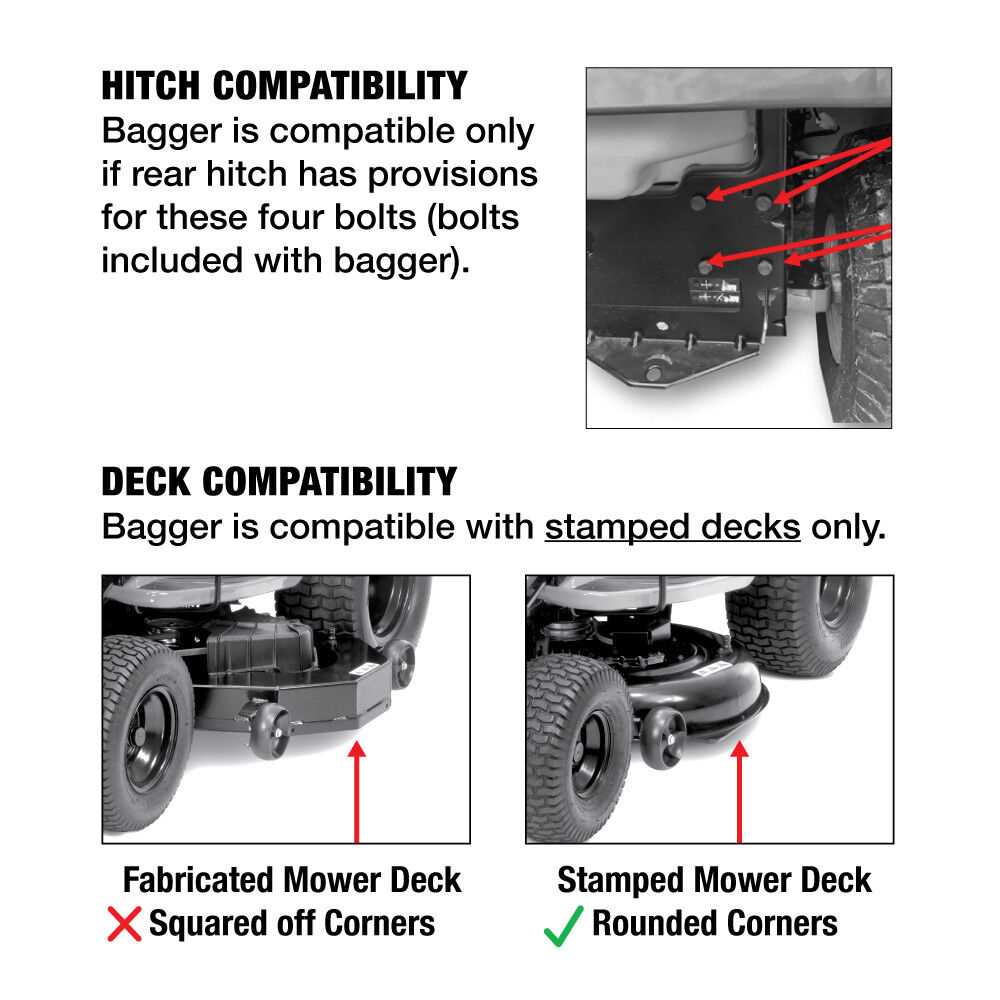

Understanding the Mower Deck Structure

The deck forms the core of the cutting system, housing and supporting the blades and other critical components. Its design impacts the overall cutting efficiency, airflow management, and durability. Understanding how this part operates is essential for ensuring optimal performance and prolonging the machine’s life.

The structure typically includes a sturdy housing that secures the cutting blades in place, while directing clippings out efficiently. Features such as discharge chutes, blade positioning, and the deck’s overall width affect how evenly and effectively the grass is trimmed. Regular maintenance of this part ensures a smooth operation and precise results.

Blade alignment and height adjustments are other key aspects. Correct positioning of these elements contributes to consistent cutting and reduces wear on the system. A well-maintained deck ensures the machinery performs effectively, even on uneven terrain.

Blade Assembly and Maintenance Tips

Proper care and setup of the cutting mechanism are essential to ensure efficient performance and prolong the lifespan of your equipment. Regular inspection and upkeep help maintain sharpness and avoid issues that may arise from wear and tear.

When working with the cutting components, follow these key steps to ensure safe and effective operation:

- Always disconnect the power source before beginning any maintenance.

- Check for any signs of damage or dullness on the cutting edges.

- If necessary, remove the blade for sharpening or replacement.

To replace or sharpen the blade, follow these instructions:

- Secure the cutting tool in place to prevent movement.

- Loosen and remove the fastening bolts holding the blade in position.

- Once removed, inspect both the blade and surrounding components for signs of wear.

- Sharpen the edges using a file or grinder, ensuring even sharpening on both sides.

- Reattach the blade, tightening the bolts securely.

Regular maintenance, such as cleaning debris and checking for alignment, can help optimize cutting

Guide to the Engine Mounting System

The engine mounting system plays a crucial role in maintaining stability and reducing vibrations during operation. It ensures that the motor remains securely attached while minimizing the impact of mechanical stress. A well-functioning setup contributes to the overall performance and longevity of the machine.

Main Components of the Mounting System

The system includes several key elements designed to securely hold the motor in place. These components include brackets, fasteners, and support structures that work together to absorb movement and provide a firm base. Proper alignment and installation are essential to avoid excessive wear and tear on the engine.

Benefits of a Properly Installed Mounting System

A correctly installed mounting system ensures smooth operation, reduces noise, and prevents damage caused by excessive vibrations. Regular checks and maintenance of the mounting components help in maintaining the equipment’s efficiency, ensuring the motor remains protected from unnecessary strain.

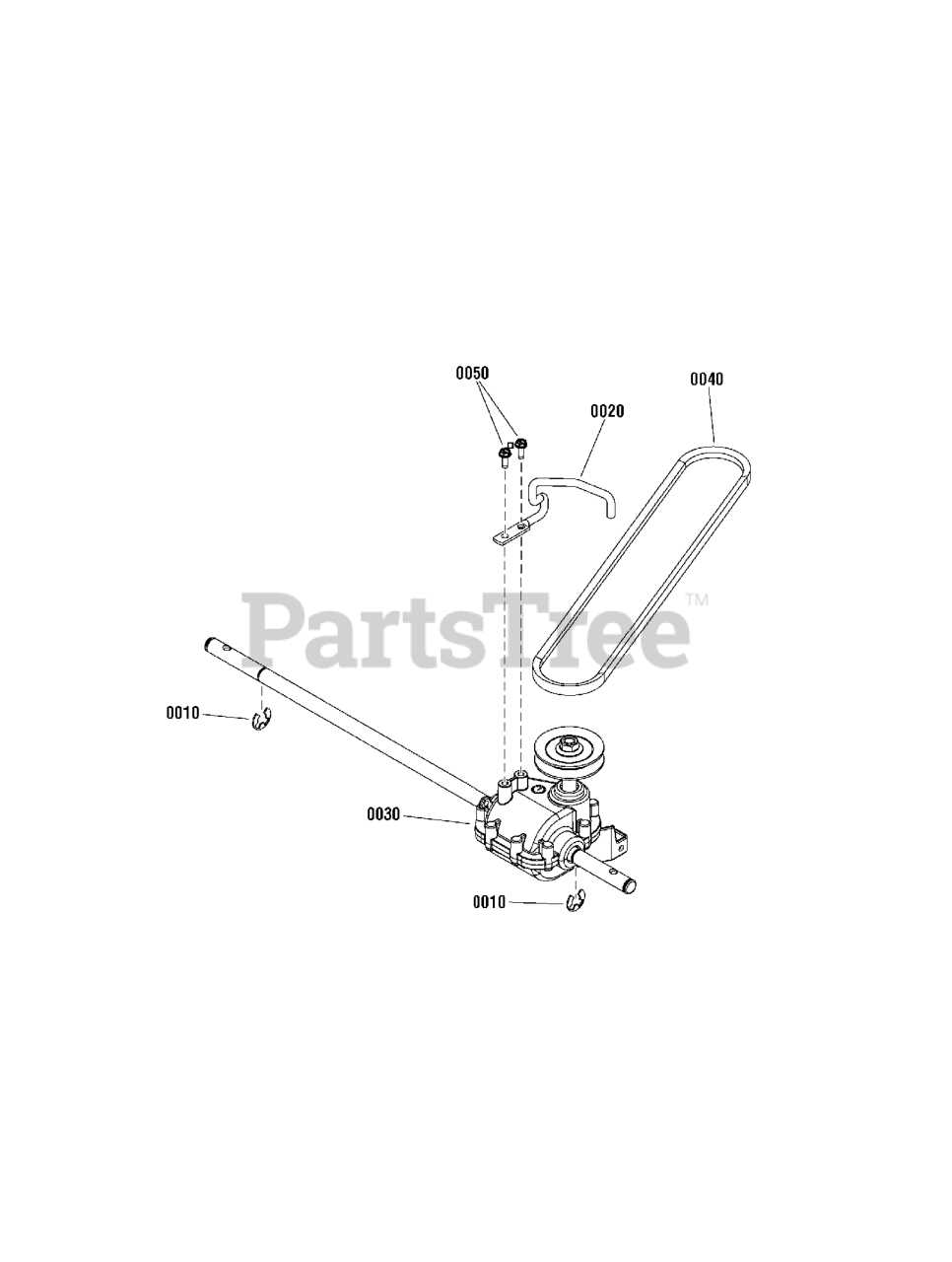

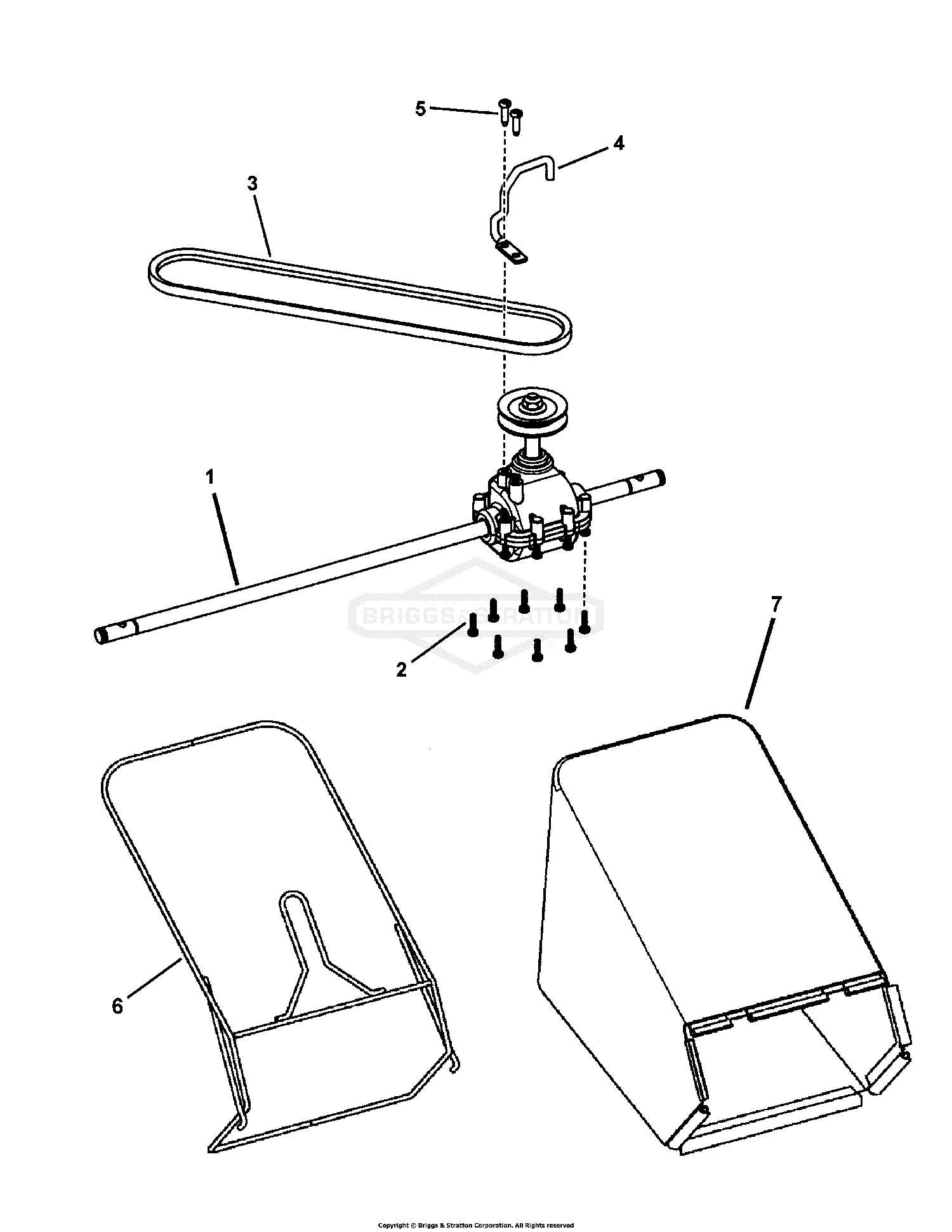

Identifying the Belt and Pulley System

The arrangement of belts and pulleys plays a crucial role in transferring power from the engine to the blades. By ensuring the proper alignment and condition of these components, the equipment operates smoothly and efficiently. This section explains how to recognize the essential elements of the belt and pulley configuration and their function within the mechanism.

Key Components of the System

The pulley system consists of circular wheels, each designed to guide and hold the belt in place. The belts are responsible for transmitting rotational energy, and they must fit securely around each pulley to maintain the right amount of tension. Understanding these core elements is essential for ensuring proper maintenance and functionality.

Checking for Wear and Alignment

Regularly inspecting the belt for signs of wear, such as cracks or fraying, helps prevent mechanical failure. Additionally, checking the alignment of the pulleys ensures that the belts remain taut and properly seated, which reduces the risk of slipping or damage. Ensuring the integrity of this system extends the life of the machine and improves overall performance.

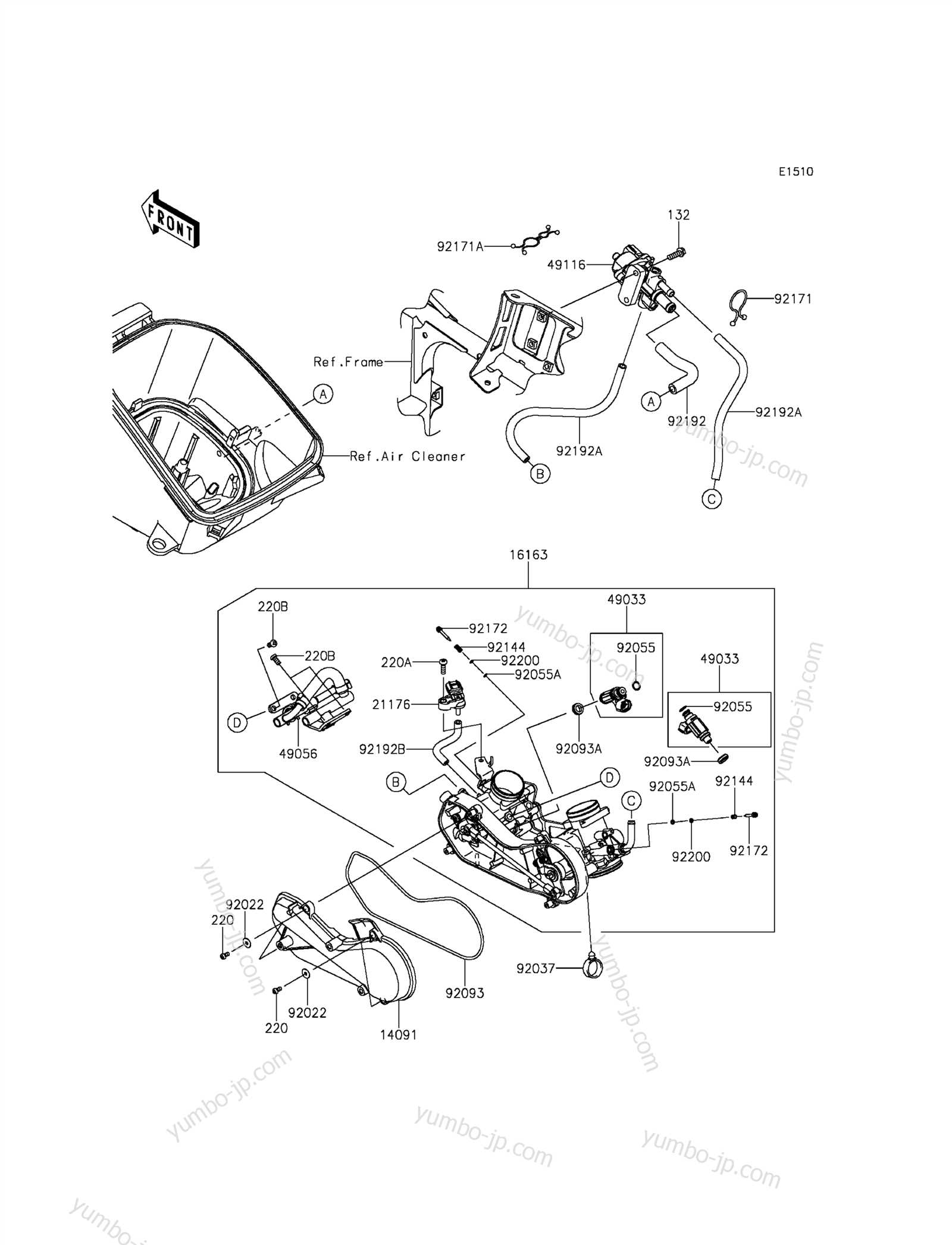

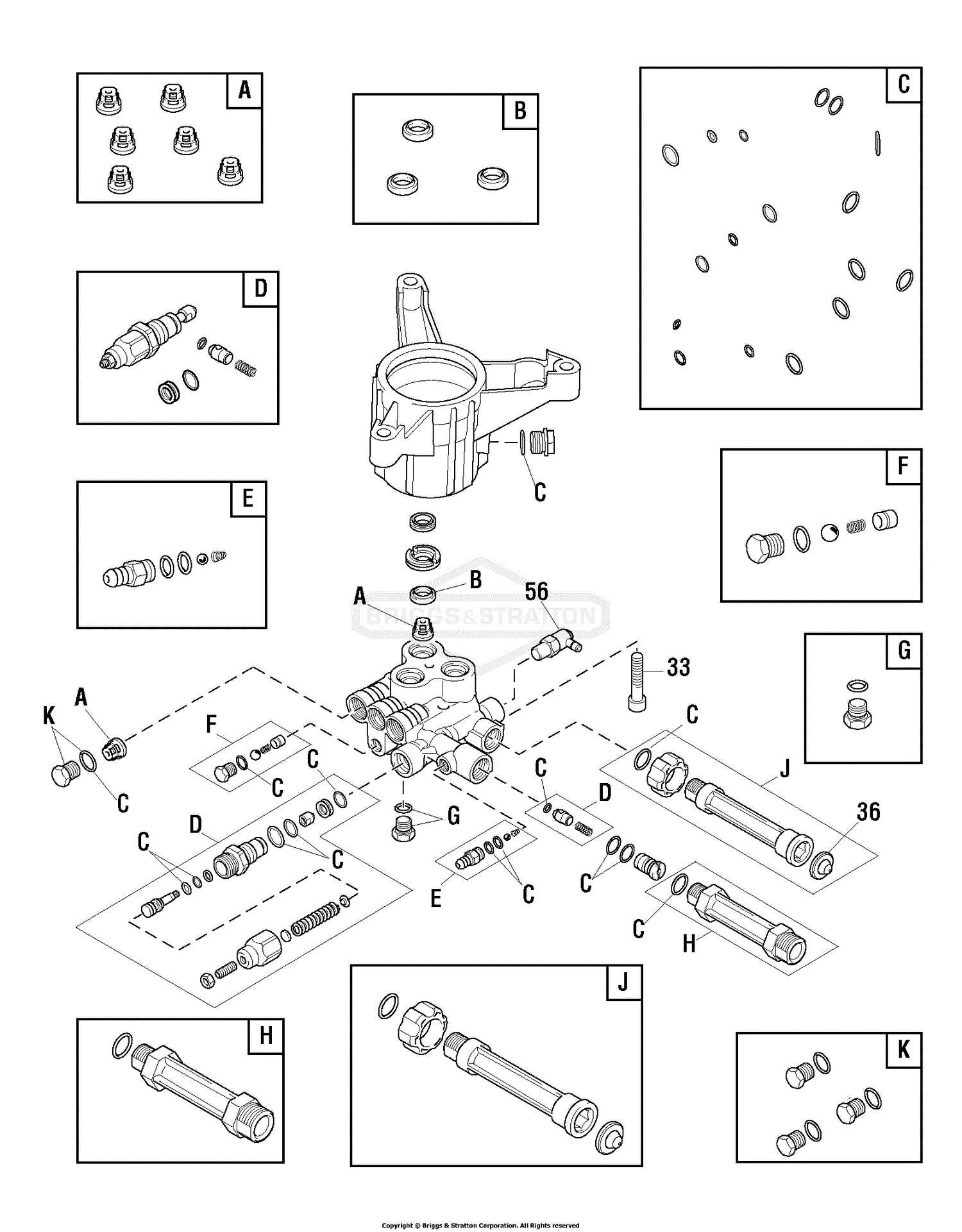

Inspecting the Fuel Delivery Mechanism

The fuel delivery system is a critical component that ensures the engine receives the necessary energy source for optimal performance. Regular examination of this system is essential for maintaining efficiency and preventing potential issues.

Start by checking the fuel lines for any signs of wear, cracks, or leaks. Damaged lines can lead to fuel loss and affect the overall functionality. Ensure that connections are secure and free from debris.

Next, inspect the fuel filter. A clogged filter can restrict fuel flow, leading to engine performance problems. Replace it if it appears dirty or blocked. Additionally, verify that the fuel pump operates correctly; listen for any unusual noises and ensure it primes effectively when starting.

Finally, assess the carburetor or fuel injection system. Clean any build-up that may hinder performance and check for proper adjustments to maintain optimal fuel delivery. Regular maintenance of these components can greatly enhance engine efficiency and longevity.

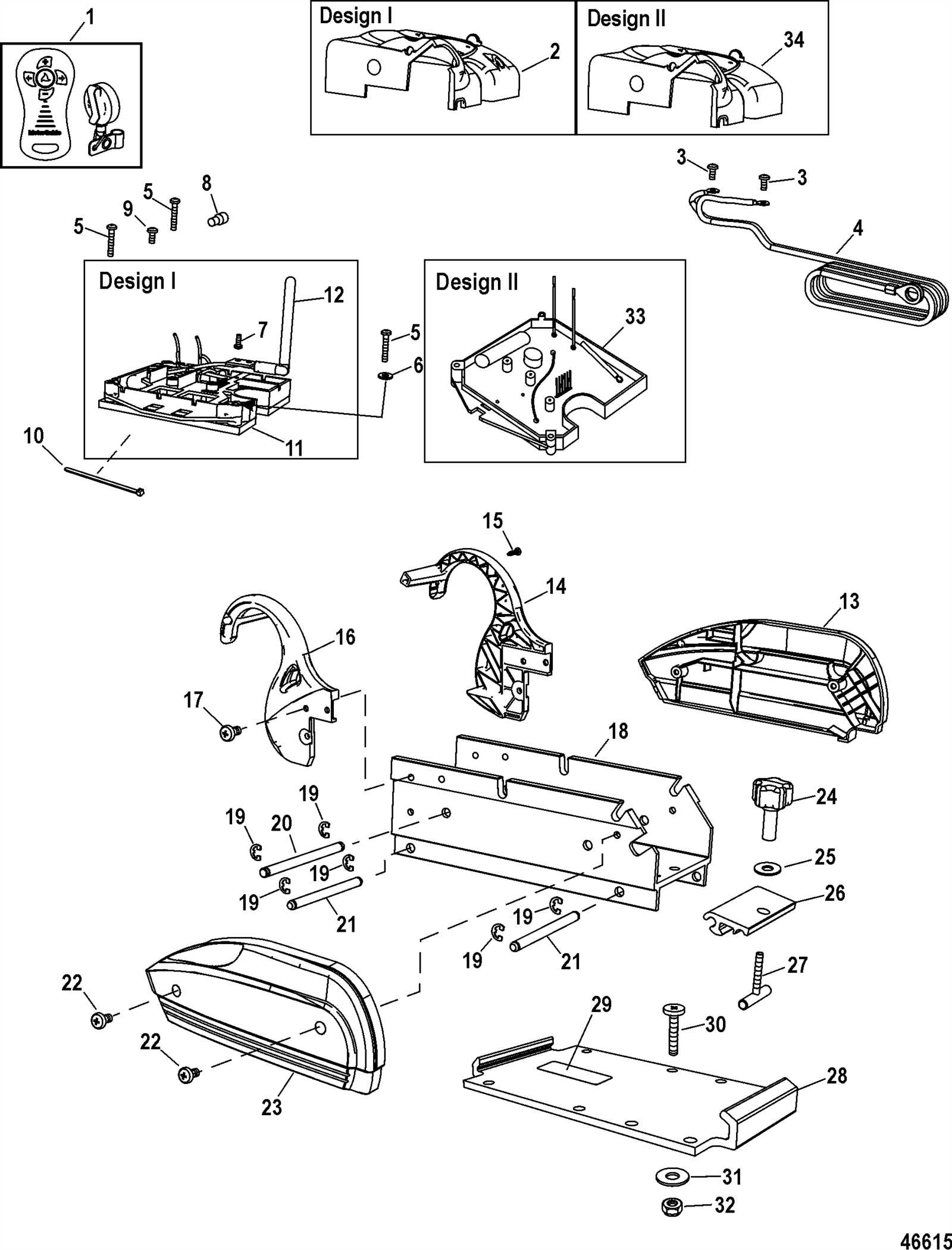

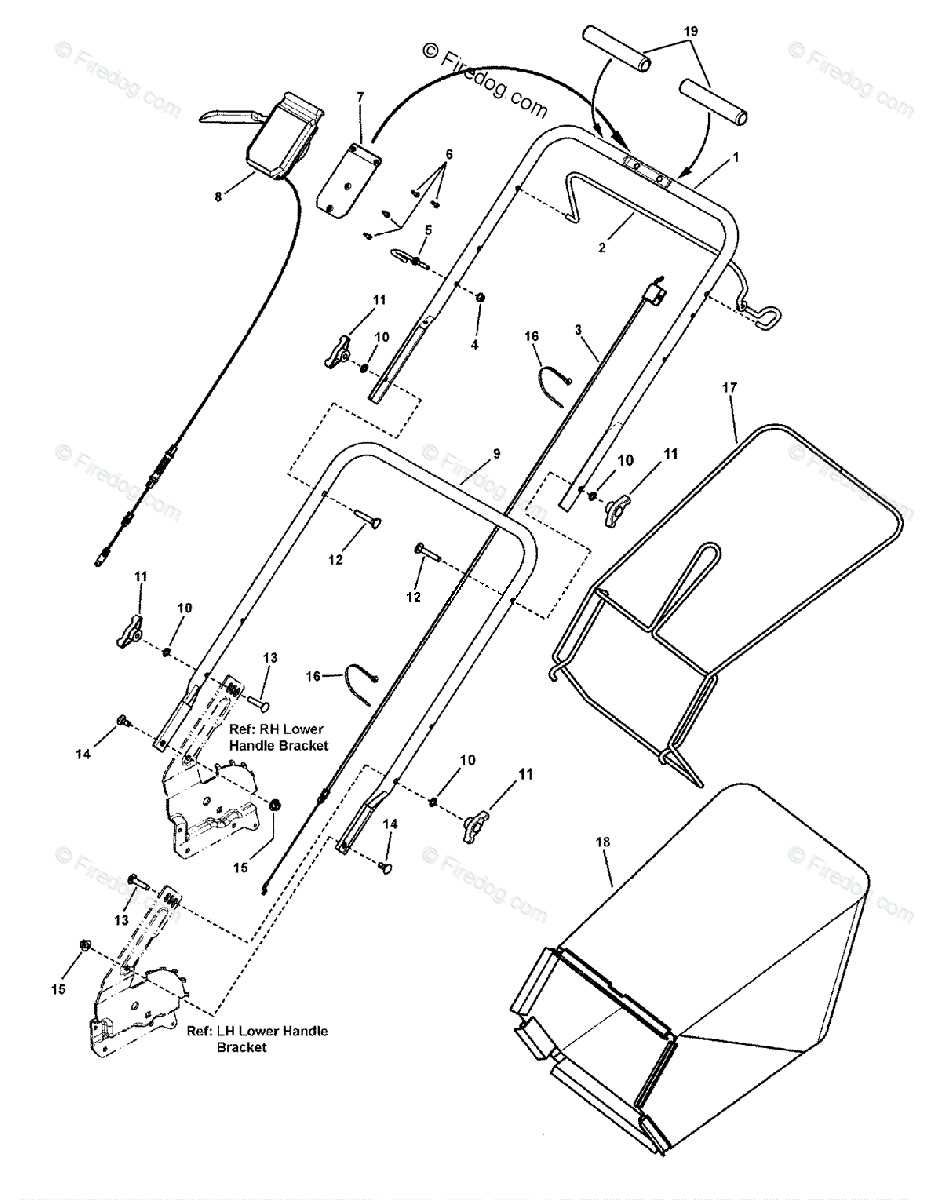

Handle and Control Panel Layout

The arrangement of the handle and control panel is crucial for the effective operation of outdoor equipment. A well-designed layout enhances user comfort, ensuring easy access to essential functions while maintaining safety during operation. Understanding the configuration of these components allows for a more intuitive experience, making tasks more efficient and enjoyable.

Ergonomic Design Considerations

Ergonomics play a significant role in the design of the handle and control panel. Features such as adjustable height, comfortable grips, and strategically placed controls contribute to minimizing user fatigue. An optimal layout ensures that the operator can maintain a natural posture while engaging with the equipment, reducing the risk of strain or discomfort during prolonged use.

Control Accessibility

Accessibility of the controls is essential for seamless operation. Controls should be positioned within easy reach, allowing the user to make adjustments without losing grip on the handle. Clearly labeled buttons and switches, as well as intuitive placements, facilitate quick responses to changing conditions. This thoughtful arrangement not only improves performance but also enhances safety by allowing the operator to focus on the task at hand.

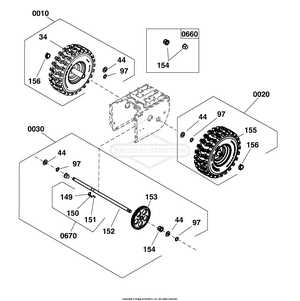

Wheels and Axle Configuration Explained

The arrangement of wheels and axles plays a crucial role in the overall performance and stability of outdoor equipment. Understanding how these components interact helps in maintaining optimal functionality and enhancing maneuverability. This section delves into the various configurations and their significance.

Key aspects of wheel and axle configuration include:

- Wheel Types: Different styles of wheels affect traction and control.

- Axle Placement: The positioning of axles influences balance and weight distribution.

- Material Composition: The choice of materials impacts durability and performance.

There are several configurations commonly used in this context:

- Single Axle: Simplifies movement and is ideal for smaller units.

- Dual Axle: Provides increased stability and is suited for larger equipment.

- Articulated Axle: Enhances maneuverability by allowing the machine to pivot more effectively.

In conclusion, grasping the intricacies of wheel and axle arrangements not only aids in better equipment operation but also in making informed decisions regarding maintenance and upgrades.

Air Filter Housing and Replacement

The air filtration system plays a crucial role in maintaining optimal engine performance. A well-functioning housing ensures that debris and contaminants do not enter the combustion chamber, thereby enhancing efficiency and longevity. Regular inspection and timely replacement of this component can prevent potential issues and keep the engine running smoothly.

Understanding the Components

The housing typically consists of a sturdy casing designed to hold the filter securely in place. It is vital to ensure that all connections are tight and that no gaps allow dirt to bypass the filtration system. Regular cleaning of the housing can also improve airflow and efficiency.

Replacement Procedure

To replace the air filtration unit, begin by removing the housing cover. Inspect the filter for dirt buildup or damage. If necessary, remove the old filter and replace it with a new one, ensuring it fits snugly within the housing. Reattach the cover securely to prevent any air leaks. Proper maintenance of this system is essential for optimal engine performance.

Spindle Assembly and Performance

The spindle assembly plays a crucial role in the overall efficiency and functionality of cutting equipment. It serves as a pivotal component that connects various elements, enabling smooth rotation and optimal cutting performance. Understanding its structure and operation is essential for maintaining peak performance and extending the lifespan of the equipment.

In a well-functioning spindle assembly, precise alignment and balance are critical. A properly assembled spindle ensures even distribution of force, minimizing wear and tear on connected parts. Regular maintenance can enhance the longevity of the assembly, allowing for consistent operation and reduced downtime. Additionally, using high-quality materials during assembly contributes to improved resilience against operational stresses.

When evaluating performance, factors such as rotational speed, bearing condition, and alignment accuracy must be taken into account. Any deviations in these areas can lead to decreased efficiency and increased operational risks. Thus, monitoring and adjusting these aspects is vital for achieving optimal results.

Throttle and Brake Cable Connections

The proper linkage of throttle and brake cables is crucial for the effective operation of the equipment. Understanding how these components interact ensures a smoother performance and enhances safety during use.

To establish reliable connections, follow these guidelines:

- Identify the cable types: Different models may have various throttle and brake cables; ensure you have the correct ones.

- Inspect the cable ends: Look for any signs of wear or damage that might affect functionality.

- Align the cables properly: Ensure they are routed in a way that allows for smooth movement without any obstructions.

Here are steps to secure the connections effectively:

- Attach the throttle cable to the designated lever, ensuring it is snug and free of twists.

- Connect the brake cable to its respective handle, making sure it engages smoothly when activated.

- Test the functionality: After securing the cables, perform a function check to confirm everything operates as intended.

Regular maintenance of these connections is essential. Periodically inspect for fraying or corrosion to maintain optimal performance.

Frame Integrity and Reinforcement Areas

The strength and durability of any outdoor equipment hinge significantly on the framework that supports its components. This section examines crucial aspects related to the structural soundness and enhancement regions within the assembly, ensuring optimal performance and longevity.

Key areas of reinforcement play a vital role in maintaining the overall stability of the construction. These zones are designed to withstand stress and prevent deformation under heavy usage. Proper evaluation and fortification of these sections contribute to the machine’s resilience against environmental challenges and mechanical wear.

Utilizing robust materials and strategic designs in these reinforcement areas ensures that the framework can endure rigorous operating conditions. Regular inspections and maintenance of these components are essential for preserving the integrity of the entire system, thereby enhancing the operational efficiency of the equipment.