In the realm of lawn maintenance, comprehending the inner workings of your machinery is essential for optimal performance and longevity. The efficiency of these powerful tools can be significantly enhanced through familiarity with their individual components. Recognizing how each element contributes to overall functionality allows for better care and maintenance.

Visual aids play a crucial role in this learning process. They provide a clear and concise way to identify and understand the various sections of your equipment. By consulting detailed representations, users can quickly locate parts and gain insight into their functions, paving the way for effective repairs and adjustments.

Moreover, having access to comprehensive illustrations can demystify the often complex structure of your device. This knowledge empowers users to tackle issues confidently, ensuring that their machinery operates at peak efficiency. Ultimately, investing time in understanding these illustrations can lead to a more rewarding and efficient lawn care experience.

Understanding Bush Hog Zero Turn Mowers

The landscape of lawn maintenance has evolved significantly, offering advanced machines designed for efficiency and precision. These innovative devices allow users to navigate complex terrains with ease, making the process of grass management more streamlined. Their unique design facilitates remarkable maneuverability, empowering operators to achieve immaculate results.

Key Features include robust engines, ergonomic controls, and durable construction that contribute to their effectiveness in various conditions. Understanding these elements is crucial for anyone looking to enhance their outdoor maintenance routine. With the right knowledge, users can maximize the performance and longevity of these remarkable machines.

Furthermore, maintenance practices play a pivotal role in ensuring optimal functionality. Regular inspections and timely replacements of essential components are vital for sustaining performance levels and avoiding unexpected breakdowns. An informed approach to upkeep can significantly impact overall satisfaction and productivity.

Key Components of Zero Turn Mowers

The efficiency and maneuverability of modern lawn care machines rely on several crucial elements. Understanding these components enhances the operation and maintenance of the equipment, ensuring optimal performance during use.

| Component | Description |

|---|---|

| Engine | Provides the necessary power to drive the machine and its features. |

| Transmission | Transfers power from the engine to the wheels, allowing for speed and direction control. |

| Deck | Houses the cutting mechanism, essential for achieving a clean cut. |

| Wheels | Enable movement and stability, crucial for navigating various terrains. |

| Steering System | Allows precise control, making it easier to navigate around obstacles. |

Benefits of Zero Turn Technology

This advanced lawn care innovation offers numerous advantages for efficient yard maintenance. With unparalleled maneuverability, it allows users to navigate around obstacles with ease, resulting in a cleaner and more precise cut.

Increased Efficiency: The unique design enables faster operation, significantly reducing the time required to complete tasks. This efficiency is especially beneficial for large properties.

Enhanced Control: Operators enjoy superior handling and responsiveness, making it easier to perform intricate landscaping tasks. The agility of these machines allows for smooth transitions and tight corners.

Comfort and Convenience: Modern models often include ergonomic features, providing a comfortable experience for users. This focus on operator comfort can lead to longer working hours without fatigue.

Overall, the integration of this technology transforms lawn care, elevating the experience to new heights.

Common Issues with Bush Hog Mowers

Understanding the frequent challenges encountered with these robust machines is essential for optimal performance and longevity. Identifying potential problems early can prevent costly repairs and enhance efficiency.

Mechanical Failures

One of the most prevalent issues involves mechanical breakdowns, often stemming from wear and tear. Regular maintenance is crucial to mitigate these occurrences.

Electrical Problems

Electrical malfunctions can disrupt operation, causing frustration. It’s important to regularly inspect wiring and components to ensure everything functions smoothly.

| Issue | Symptoms | Solution |

|---|---|---|

| Engine Trouble | Difficulty starting, stalling | Check spark plugs and fuel supply |

| Transmission Issues | Inconsistent movement, slipping | Inspect fluid levels and belts |

| Blade Problems | Uneven cutting, vibrations | Sharpen or replace blades |

Essential Maintenance Practices Explained

Regular upkeep is crucial for ensuring optimal performance and longevity of your equipment. Understanding fundamental care routines can significantly enhance its efficiency and reliability. This section delves into essential tasks that every owner should prioritize.

Inspecting Components: Frequent checks on various elements help identify wear and tear before they escalate into major issues. Make it a habit to assess belts, blades, and fluids routinely.

Cleaning: Keeping the machinery clean is vital for preventing rust and buildup. Regularly remove debris and dirt from all surfaces, particularly around moving parts.

Lubrication: Applying appropriate lubricants to moving parts minimizes friction and wear. This practice is key to maintaining smooth operation and extending the lifespan of the equipment.

Sharpening Blades: Ensuring that cutting blades are sharp allows for efficient performance and a clean cut. Dull blades can stress the engine and reduce overall effectiveness.

Following Manufacturer Guidelines: Adhering to the recommended maintenance schedule provided by the manufacturer is the ultimate way to keep your machinery in prime condition. This includes regular oil changes, filter replacements, and inspections.

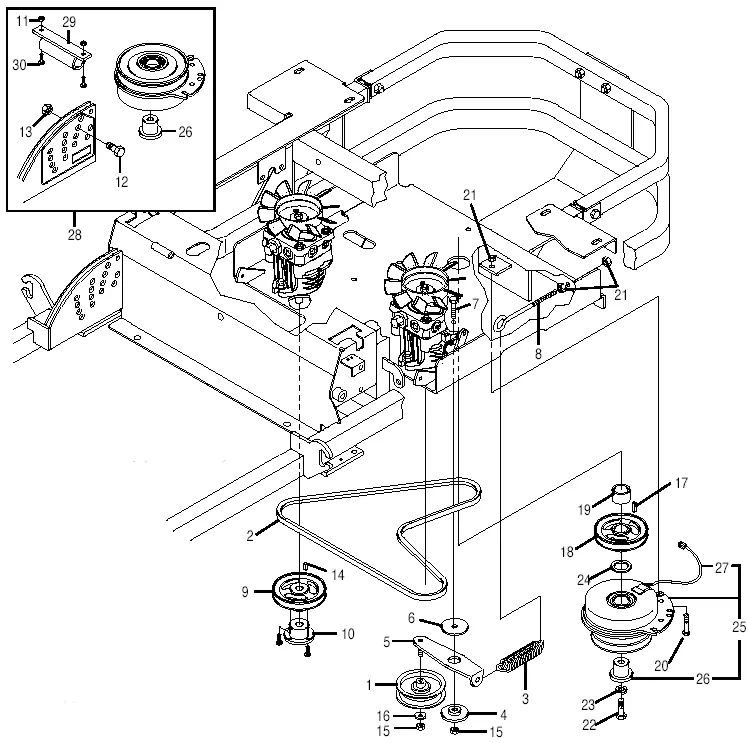

Identifying Parts from Diagrams

Understanding the components of machinery is essential for effective maintenance and repair. By examining illustrations, one can gain insights into how different elements interact and function together. This knowledge empowers users to troubleshoot issues and make informed decisions about repairs or replacements.

Understanding Symbols and Labels

Most schematics include specific symbols and labels that indicate various elements. Familiarizing oneself with these markings can significantly enhance the ability to pinpoint individual components. Recognizing these indicators aids in navigating complex systems.

Utilizing Reference Guides

Supplementing diagrams with reference guides can provide deeper context. Detailed descriptions accompany visuals, offering clarity on the function of each part. This approach ultimately enhances the user’s confidence in handling machinery.

Where to Find Replacement Parts

Finding the right components for your lawn equipment can be essential for maintaining performance and longevity. Numerous resources are available to ensure you have access to quality replacements when needed.

Online Retailers: Websites dedicated to gardening and landscaping tools often offer extensive catalogs of components. Be sure to compare prices and check for customer reviews to gauge reliability.

Local Dealers: Authorized dealers in your area can provide original components tailored for specific models. Visiting these shops also allows you to seek expert advice on installation and maintenance.

Salvage Yards: For those seeking cost-effective options, salvage yards may have functional components available. It’s a great way to find unique items while contributing to sustainability.

Manufacturer’s Website: The official site of the equipment brand can be a valuable resource. Here, you can find manuals, diagrams, and a direct link to purchase genuine components.

Online Marketplaces: Platforms like eBay or Amazon frequently have listings from various sellers, providing a wide range of options and prices. Just be cautious to check seller ratings before purchasing.

Utilizing these avenues can significantly enhance your chances of locating the necessary components, ensuring your equipment remains in optimal condition.

DIY Repairs for Common Problems

When it comes to maintaining outdoor machinery, understanding how to address frequent issues can save time and money. Tackling repairs on your own can enhance your skills and ensure your equipment runs smoothly. Here, we’ll explore some typical challenges you might encounter and how to effectively resolve them.

Identifying Common Issues

Many users face similar complications that can usually be fixed without professional help. Recognizing these problems early on can prevent more extensive damage and ensure optimal performance.

Simple Repair Solutions

Below is a table outlining common problems and their DIY solutions:

| Problem | Solution |

|---|---|

| Engine won’t start | Check the fuel level and ensure the spark plug is clean and properly connected. |

| Uneven cutting | Inspect the blade height and adjust as needed. Sharpen blades for a cleaner cut. |

| Excessive vibration | Look for loose parts or debris around the blade assembly. Tighten or clear as necessary. |

| Overheating | Ensure proper airflow and clean the air filter. Check the oil level and condition. |

By understanding these basic repairs, you can keep your outdoor equipment in great shape, allowing for a more enjoyable and efficient working experience.

Upgrading Your Mower’s Performance

Enhancing the efficiency and effectiveness of your cutting machine can significantly improve its functionality and longevity. Implementing various modifications and improvements not only boosts performance but also ensures a smoother operation during use.

Consider the following upgrades to elevate your equipment’s capabilities:

- Engine Enhancements: Upgrading to a more powerful engine can provide better torque and speed, allowing for quicker mowing sessions.

- Cutting Blades: Investing in high-quality, sharp blades ensures a cleaner cut, reducing strain on the machine and enhancing the overall appearance of your lawn.

- Tires and Suspension: Improved tires and suspension systems can enhance traction and stability, making the operation safer and more comfortable.

- Deck Modifications: Modifying the cutting deck for better airflow can improve the quality of the cut and reduce clumping.

- Fuel System Upgrades: Installing a more efficient fuel system can lead to better fuel consumption and overall performance.

By focusing on these key areas, you can ensure your equipment operates at its peak performance, making yard maintenance more enjoyable and efficient.

Safety Features of Zero Turn Models

When operating advanced landscaping machines, safety is paramount. These modern designs incorporate a variety of features that prioritize operator protection and enhance overall efficiency. Understanding these mechanisms is essential for safe and effective use.

- Emergency Brake System: Automatic engagement of brakes when the controls are released helps prevent unintended movement.

- Operator Presence Controls: These features require the operator to maintain contact with controls, ensuring the machine stops when the operator steps away.

- Rollover Protection: Structures designed to mitigate the risk of tipping over provide an extra layer of security on uneven terrain.

- Safety Shields: Covers around moving components reduce the risk of accidental contact with hazardous areas.

- Anti-Skid Technology: Enhanced grip features on wheels improve stability, especially in wet or uneven conditions.

By integrating these safety elements, manufacturers aim to reduce the risk of accidents and create a safer working environment for users. Familiarity with these features not only enhances safety but also boosts confidence while operating these machines.

Cost Comparison of Replacement Parts

When maintaining outdoor machinery, understanding the financial implications of component replacements is crucial. This analysis aims to shed light on the varying costs associated with different types of replacements, helping owners make informed decisions. Various suppliers offer a range of prices, and knowing where to look can lead to significant savings.

OEM vs. Aftermarket Options

Original equipment manufacturer (OEM) components typically come at a premium price due to their guaranteed compatibility and quality. In contrast, aftermarket alternatives often provide a more budget-friendly option. However, it’s essential to consider the longevity and performance of these substitutes, as lower initial costs may lead to higher long-term expenses if they require more frequent replacement.

Cost Variability by Supplier

Different vendors can exhibit considerable price fluctuations for similar items. Researching multiple sources, both online and local, allows consumers to compare prices effectively. Additionally, seasonal sales and promotions can further enhance savings opportunities. Emphasizing this comparison can help optimize maintenance budgets while ensuring machinery remains in excellent working condition.

Understanding Warranty and Support Options

When investing in outdoor equipment, it’s crucial to comprehend the various assurances and assistance available. These elements not only enhance your experience but also provide peace of mind regarding your purchase.

Types of Warranties

- Manufacturer Warranty: Covers defects in materials and workmanship.

- Extended Warranty: Offers additional protection beyond the standard period.

- Service Plan: May include maintenance and repairs over time.

Support Resources

- Customer Service: Direct line for inquiries and troubleshooting.

- Online Resources: Manuals, FAQs, and instructional videos.

- Authorized Dealers: Professional assistance for repairs and parts replacement.