Outdoor equipment designed for managing dense vegetation and uneven landscapes consists of various intricate elements. Each component plays a critical role in ensuring smooth operation and effective performance. Whether you’re tackling overgrown areas or maintaining a large field, knowing the structure of this machine can greatly improve its functionality and longevity.

Many users are unaware of how essential it is to have a clear understanding of the internal mechanisms that drive such devices. By familiarizing yourself with the layout and assembly, you can not only enhance its durability but also carry out necessary repairs or upgrades with greater ease.

In the following sections, we will delve into the primary units and their specific functions, highlighting how each piece contributes to the overall operation of this versatile tool. Gaining insight into these details can make a substantial difference in performance and efficiency.

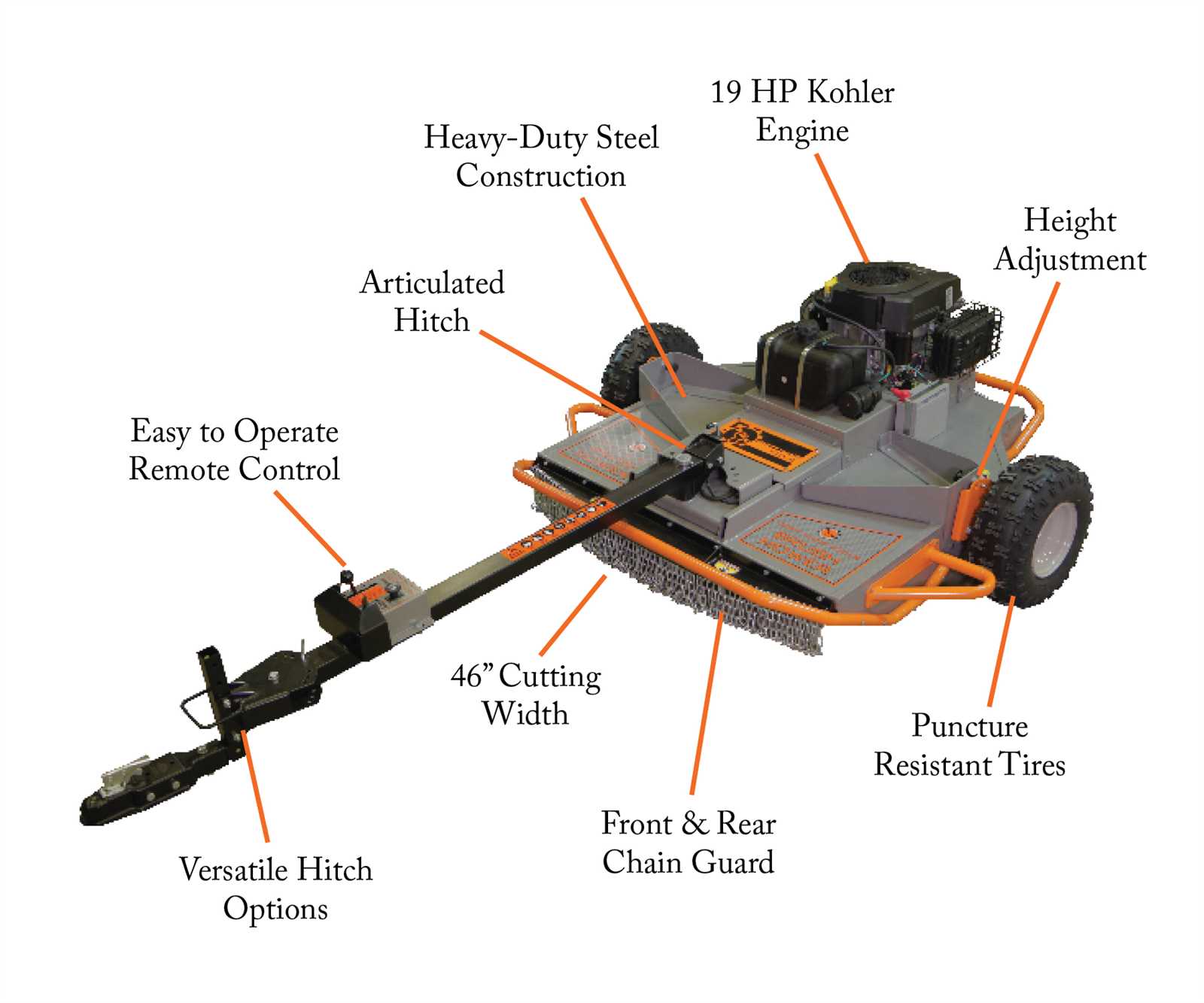

Dr All Terrain Mower Parts Overview

Understanding the components that make up the machinery is essential for maintaining its efficiency and performance. Each element plays a crucial role in ensuring the device functions smoothly across diverse conditions. By exploring the structure and key elements, you can easily identify which parts might require attention or replacement over time.

Key Mechanical Components

- Engine – The powerhouse that drives the cutting mechanism and enables the equipment to handle various surfaces.

- Blades – Essential for efficient cutting, ensuring a clean and precise trim.

- Frame – Provides durability and support to withstand regular usage and demanding environments.

Additional Functional Elements

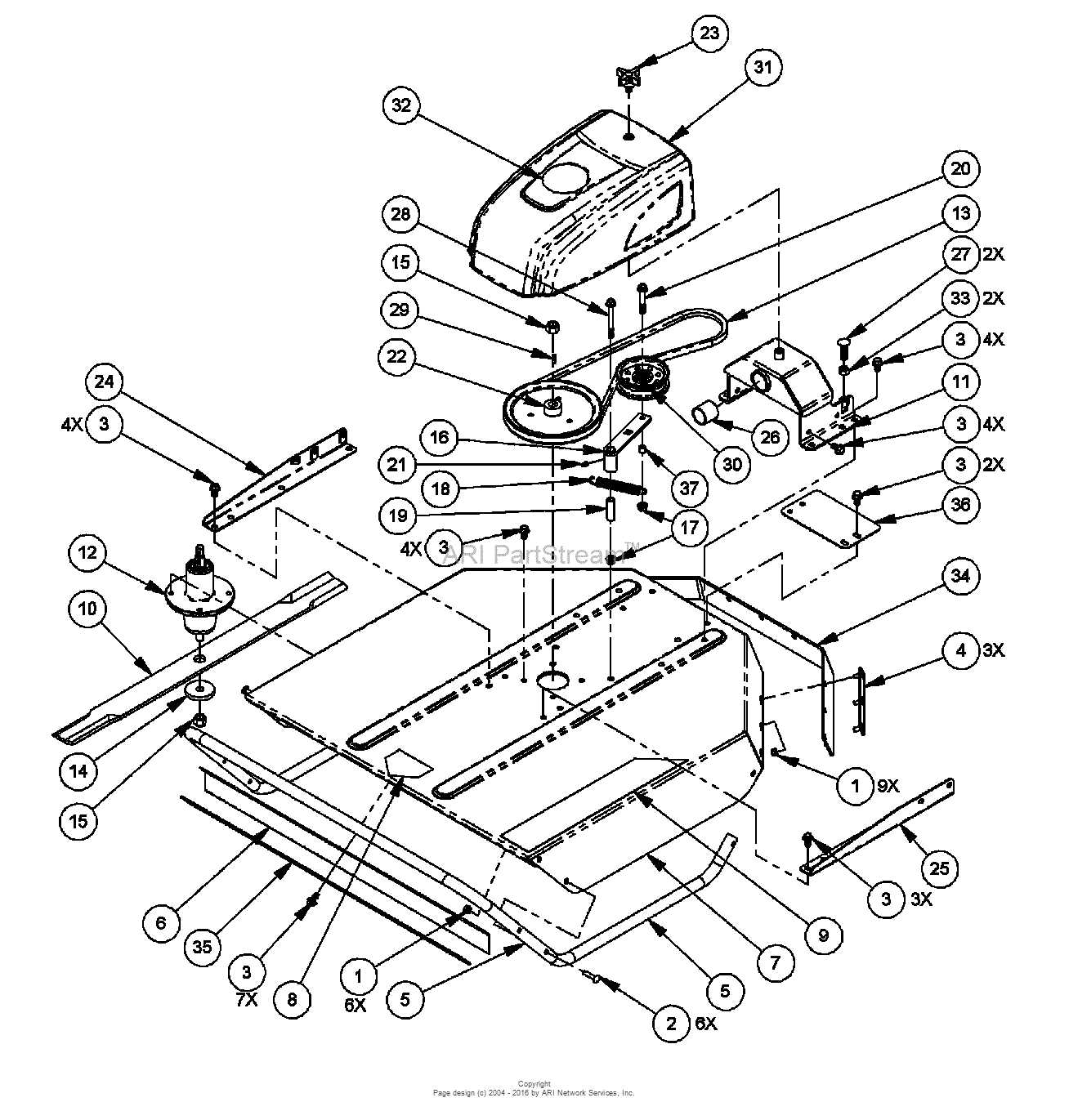

Understanding the Cutting Mechanism Components

The cutting system in modern grass-cutting equipment is a crucial aspect to consider for its efficiency and precision. This section delves into the key elements responsible for trimming vegetation, focusing on the individual parts that work together to achieve a smooth and effective result.

Blades are central to the operation, serving as the primary tools for slicing through plant material. These sharp, rotating components need to be robust and durable to handle various conditions while maintaining sharpness for a consistent cut.

Drive mechanisms ensure that the blades move at the correct speed, creating the ideal balance between power and efficiency. This process relies on a system of belts or gears that must be well-maintained to avoid any interruptions in performance.

In addition to the

Essential Blades and Their Functions

The cutting components of outdoor equipment play a critical role in ensuring optimal performance. These elements are specifically designed to handle different types of vegetation and terrains, offering various solutions for efficient trimming and cutting. Understanding the unique functions of each blade type can help enhance the machine’s overall effectiveness.

Standard Cutting Blades

These blades are designed to provide a clean, precise cut, making them ideal for everyday maintenance tasks. Their sharp edges allow for smooth slicing through grass or similar plant life, ensuring a well-manicured finish.

Heavy-Duty Blades

For tougher jobs, more robust blades are required. These are thicker and more durable

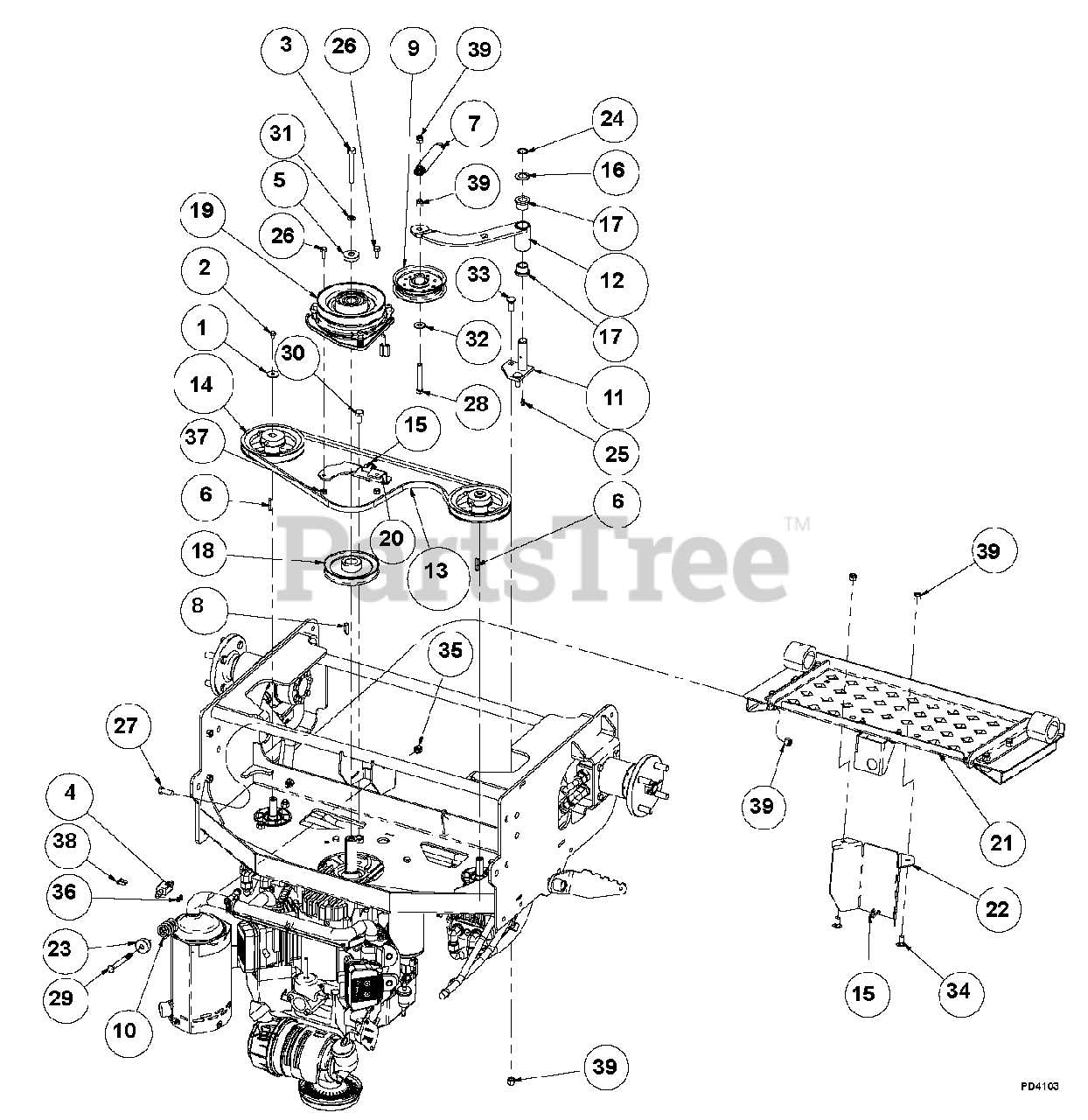

Power Transmission System Breakdown

The energy transfer mechanism plays a critical role in ensuring efficient functionality. It serves as the backbone that connects the engine’s output to various working components, allowing for seamless operation. Understanding this system is key to maintaining optimal performance and longevity of the equipment.

Main Components and Their Roles

The system consists of several key elements that work in harmony. The drive belt is responsible for transferring energy from the engine, while gears and pulleys direct that energy to the essential functions. Each component has a specific role, and their cooperation ensures smooth and reliable performance.

Common Issues and Maintenance Tips

Over time, wear and tear can affect the efficiency of the system. A stretched or damaged belt can lead to power loss, while worn gears may cause disruptions. Regular inspection and timely replacement of components can prevent these issues, ensuring continuous and efficient operation.

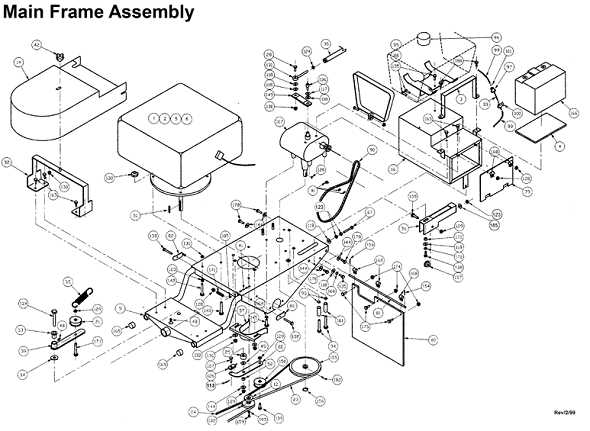

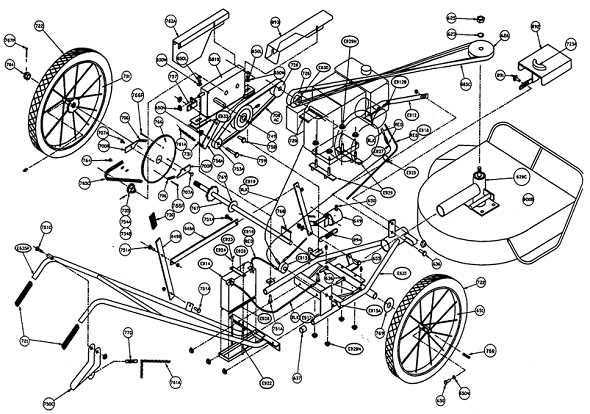

Chassis and Structural Integrity Parts

The framework of a machine is essential for ensuring its durability and long-term use. This section will explore the core components responsible for supporting the structure, maintaining balance, and safeguarding the overall functionality of the equipment.

Main Frame Components

- Support Frame: The primary structure that holds the entire device together, distributing weight evenly.

- Reinforcement Bars: These bars enhance rigidity, especially when navigating uneven surfaces, ensuring stability.

- Protective Covers: Shields that prevent damage to internal mechanisms and improve longevity.

Structural Stability Enhancers

Exploring the Engine and Fuel System

The heart of any machine lies within its power unit and energy delivery mechanism. Understanding these components is essential for efficient operation and maintenance. The engine transforms fuel into mechanical energy, while the fuel system ensures a consistent supply of energy for optimal performance.

Engine Mechanics

At the core of the power unit, various elements work together to convert energy. Key components include the cylinder, crankshaft, and camshaft. Each plays a crucial role in the combustion process, enabling the machine to function smoothly. Regular inspection and maintenance of these components can significantly enhance longevity and performance.

Fuel Delivery System

The energy delivery mechanism is vital for ensuring that the engine receives the right amount of fuel at the appropriate time. It typically consists of a fuel tank, pump, filter, and injectors. Maintaining the cleanliness of the fuel system is crucial, as contaminants can lead to performance issues. Additionally, selecting the right type of fuel will ensure that the engine operates efficiently.

Wheels, Tires, and Mobility Elements

The functionality of outdoor equipment heavily relies on its rolling components. These elements play a crucial role in ensuring smooth navigation across various surfaces, providing stability and control. Understanding their features and specifications can significantly enhance the overall performance and usability of the machine.

Types of Wheels

Different varieties of wheels are designed to meet specific requirements:

- Solid Wheels: Durable and puncture-proof, ideal for rough conditions.

- Pneumatic Wheels: Air-filled for better shock absorption and traction on uneven surfaces.

- Swivel Wheels: Provide enhanced maneuverability, making it easier to navigate tight spaces.

Tire Specifications

Selecting the right tires is vital for optimizing performance:

- Tread Patterns: Determine grip and handling; different designs cater to various environments.

- Size: Affects speed and stability; choosing the appropriate dimensions is essential for efficiency.

- Load Rating: Indicates the maximum weight a tire can safely support, crucial for heavy-duty applications.

Handlebars and Steering Mechanism Explained

The control system of a cutting machine plays a vital role in ensuring ease of operation and maneuverability. This section delves into the components responsible for steering and guiding the device, highlighting their significance in achieving optimal performance. A thorough understanding of these elements allows operators to navigate various environments with precision and confidence.

Components of the Control System

The control apparatus consists of several key components that work together to facilitate steering. Handlebars serve as the primary interface, allowing the operator to direct the movement of the equipment. Additionally, the steering mechanism includes linkages and pivots that translate the handlebars’ movements into responsive actions on the cutting device.

Importance of Proper Adjustment

Ensuring that the control system is correctly adjusted is essential for effective operation. Misalignment or wear in the components can lead to difficulty in steering, negatively impacting both safety and efficiency. Regular maintenance and checks of the handlebars and steering mechanism are crucial for optimal performance, enabling smooth navigation across varying landscapes.

Safety Features and Protective Shields

Ensuring user safety is paramount when operating any outdoor machinery. Various protective components are designed to minimize risks and enhance security during operation. These features play a crucial role in safeguarding both the operator and bystanders from potential hazards associated with powerful equipment.

Robust shielding is commonly integrated into the design, effectively preventing accidental contact with moving elements. These barriers are essential in shielding users from debris, sharp objects, and other dangers that may arise during use. Additionally, emergency shut-off mechanisms serve as a critical safety net, allowing operators to quickly halt the equipment in case of unexpected incidents.

Moreover, implementing ergonomic handles ensures a comfortable grip, reducing fatigue and improving control while operating. Regular maintenance checks are also vital for ensuring that all safety features function properly, contributing to a safer working environment.

Electrical System and Battery Layout

The electrical architecture of a multifunctional cutting machine is crucial for ensuring optimal performance and reliability. This framework encompasses various components, including wiring, switches, and the power storage unit, which work in unison to facilitate the operation of the equipment.

At the heart of the system lies the power storage unit, typically a rechargeable battery that supplies energy to all electronic elements. Understanding the arrangement of these components is essential for effective troubleshooting and maintenance. A well-organized layout minimizes the risk of electrical failures and enhances the overall efficiency of the device.

Additionally, proper connections and secure fittings between the battery and other electrical parts are vital. Regular inspections of the wiring can prevent issues caused by wear or environmental exposure, ensuring that the machinery operates smoothly under various conditions.

Maintenance Tips for Key Components

Proper upkeep of essential elements is crucial for ensuring optimal performance and longevity of your equipment. Regular inspections and timely interventions can prevent costly repairs and enhance overall functionality.

Regular Cleaning: Keep all surfaces free from debris and buildup. Dirt and grime can hinder the efficiency of various components, leading to premature wear and tear.

Inspect for Wear: Periodically check critical elements for signs of damage or excessive wear. Early detection can help avoid major issues and extend the lifespan of your equipment.

Lubrication: Ensure that moving parts are adequately lubricated. Proper lubrication minimizes friction, reducing the risk of overheating and mechanical failure.

Replacement of Worn Components: Timely replacement of damaged or worn components is vital. Using original or high-quality replacements ensures compatibility and reliability.

Check for Proper Alignment: Regularly inspect the alignment of key components. Misalignment can lead to uneven wear and inefficient operation, impacting performance.

Following these maintenance tips will help in preserving the functionality of your equipment, ensuring it remains reliable and efficient throughout its usage.

Accessories for Enhanced Performance

To optimize the efficiency and functionality of outdoor machinery, various enhancements can be employed. These additions not only improve the overall user experience but also extend the lifespan of the equipment. Selecting the right accessories can significantly elevate performance, ensuring tasks are completed with greater ease and effectiveness.

Consider the following essential enhancements that can boost productivity and performance:

Accessory Description High-Performance Blades Designed to provide a cleaner cut, improving the overall health of the grass. Heavy-Duty Tires Enhance traction and stability on various surfaces, enabling smoother operation. Additional Weight Kits Increase stability and reduce slipping, especially in challenging environments. Mulching Kits Allow for efficient grass recycling, promoting nutrient retention in the soil. Cleaning Accessories Facilitate easy maintenance and upkeep, ensuring longevity and optimal performance.