For anyone engaged in lawn care, understanding the intricate elements of equipment is crucial for maintaining its efficiency and longevity. Each mechanical tool is made up of various essential elements that work together to ensure smooth operation. Without proper knowledge of these elements, it’s difficult to keep the machine running at its best.

In this guide, we will take a closer look at the internal structure of a commonly used lawn care tool. You’ll learn about the individual mechanical units, their roles, and how they interact with each other to deliver optimal performance. This knowledge is key to troubleshooting issues and conducting effective maintenance.

By familiarizing yourself with these details, you can better care for your lawn equipment, ensuring it continues to operate reliably for years to come. Stay tuned as we delve deeper into the various components and their specific functions.

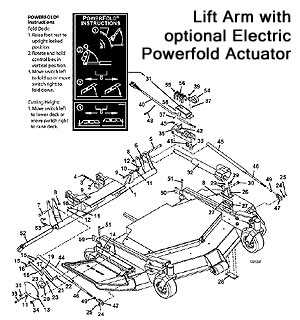

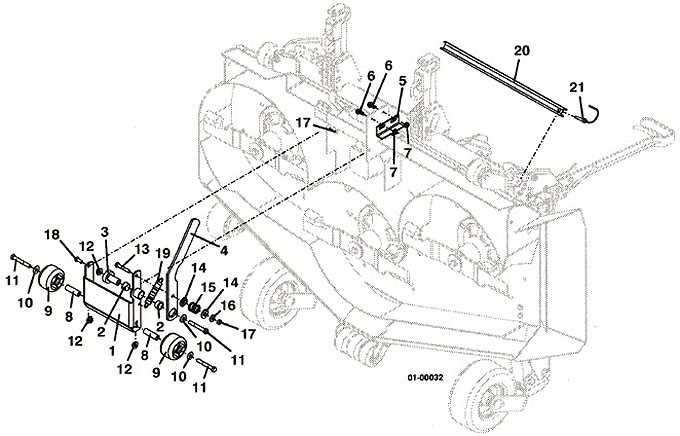

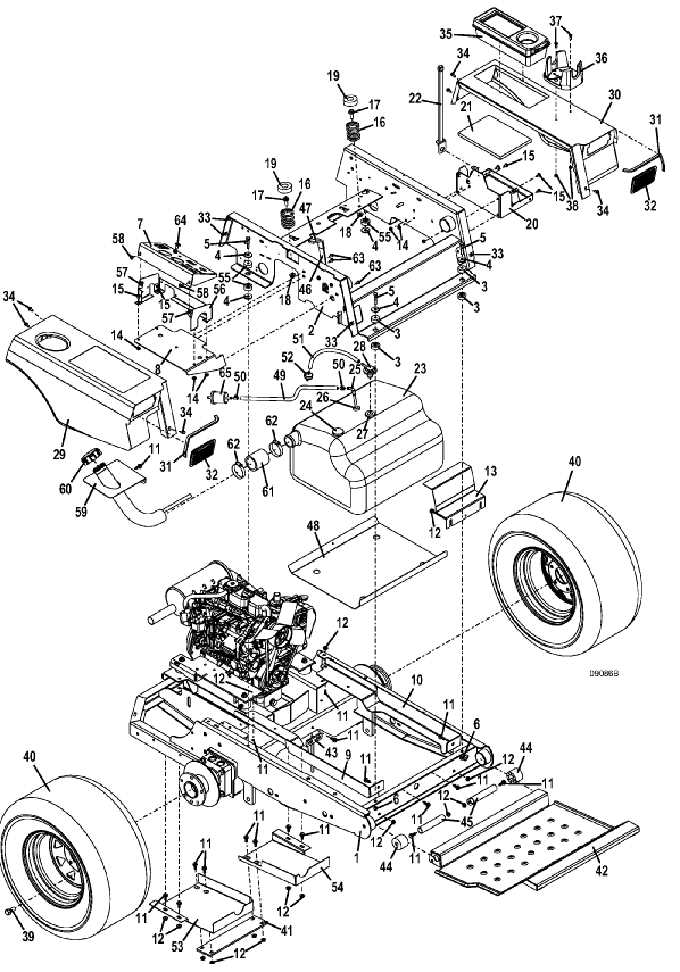

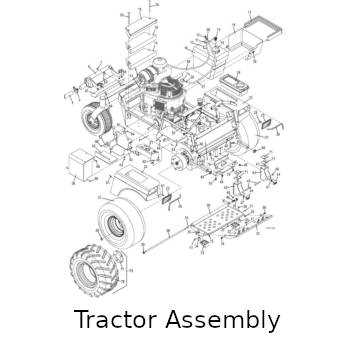

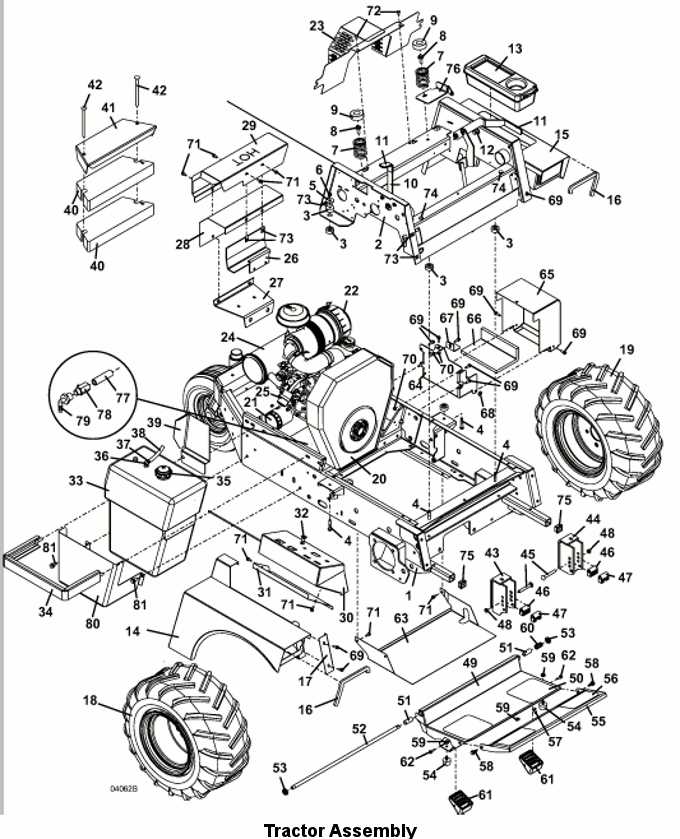

Overview of Mower Component Layout

Understanding the arrangement of essential elements in a lawn care machine is crucial for effective maintenance and troubleshooting. This section will cover the primary structural and mechanical components, providing insight into their organization and interaction within the system. By familiarizing yourself with the layout, you can easily identify individual sections for repairs or upgrades.

Key Structural Elements

- Chassis: The framework that supports all other components, ensuring stability and strength.

- Drive System: Responsible for the movement and operation, linking the power source to the wheels.

- Cutting Mechanism: The system designed to efficiently handle grass and vegetation management.

Mechanical and Control Systems

- Engine Placement: The power unit’s location is critical for balanced performance and easy access during servicing.

- Control Levers and Pedals: These parts are arranged for intuitive operation, ensuring smooth adjustment of speed, direction, and cutting settings.

- Fuel and Electrical Connections: Positioned to provide consistent energy flow while being protected from external elements.

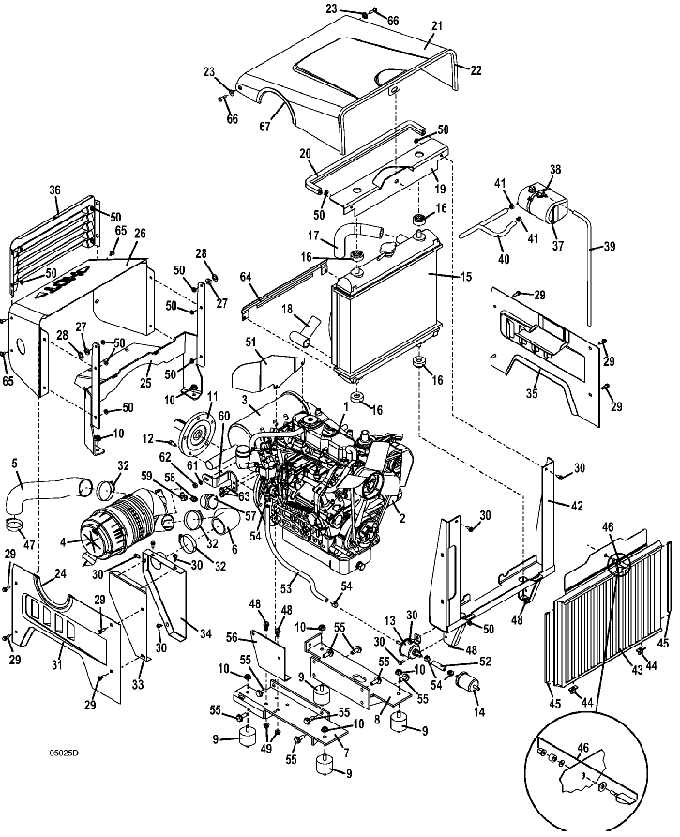

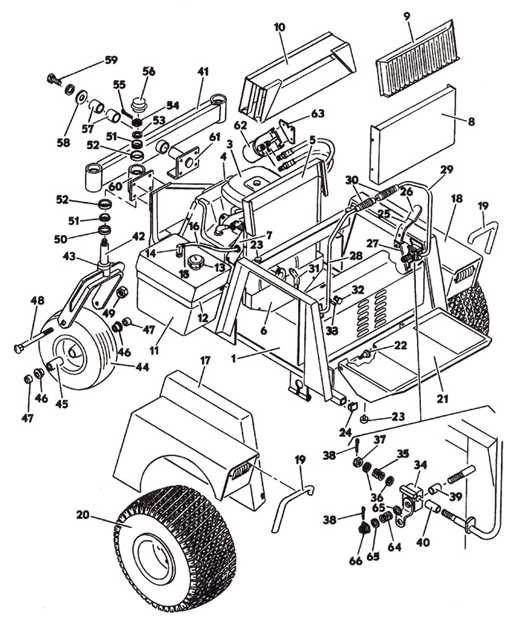

Engine and Power System Components

The engine and power system serve as the core of any outdoor machinery, ensuring consistent operation and optimal performance. Understanding the structure of these elements allows for better maintenance and troubleshooting, making it easier to address potential issues.

- Power Source: The central unit generates the necessary energy to drive various mechanisms, providing the essential force to operate efficiently.

- Fuel Delivery System: This component manages the supply of fuel, ensuring a balanced and uninterrupted flow to the energy source for smooth functioning.

- Cooling Mechanism: Prevents overheating by circulating air or liquid, helping to maintain ideal operating temperatures for all internal systems.

- Transmission Setup: Transfers the generated force to the necessary parts, allowing precise control over speed and direction.

- Exhaust Pathway: Redirects emissions away, minimizing heat and noise, and maintaining a clean operation environment.

By keeping these elements in good condition, one can ensure prolonged operational efficiency and reduce the likelihood of breakdowns. A clear understanding of how each part interacts can simplify both repairs and routine upkeep.

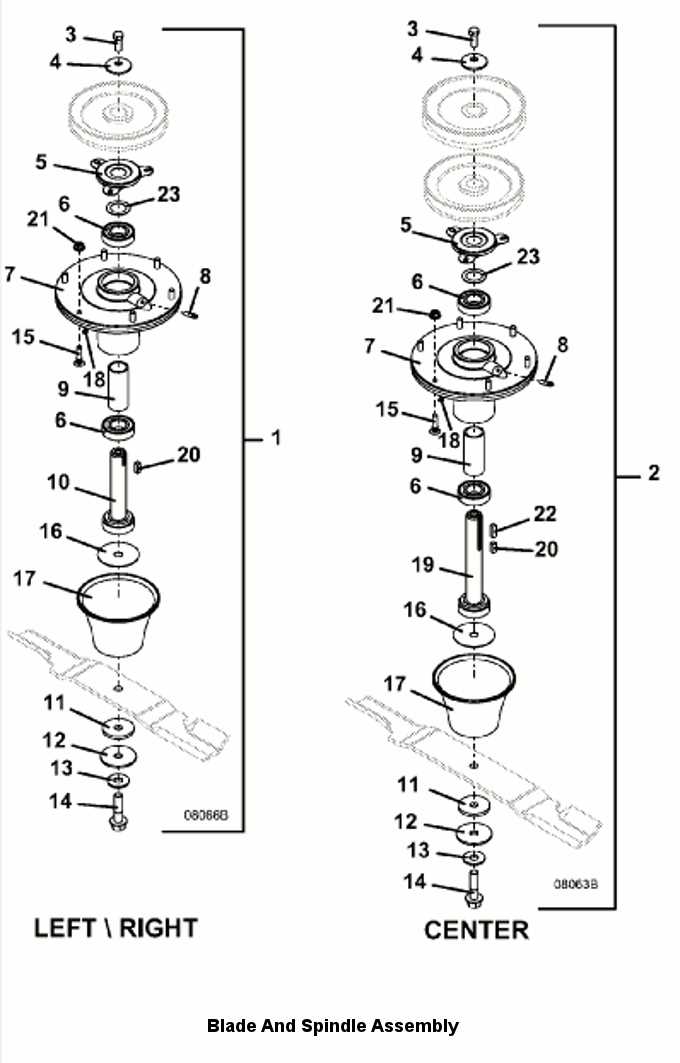

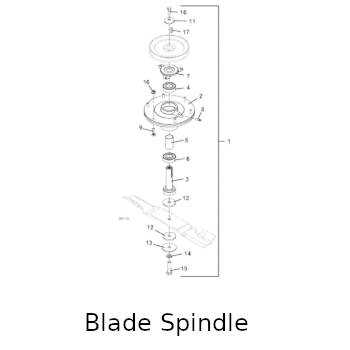

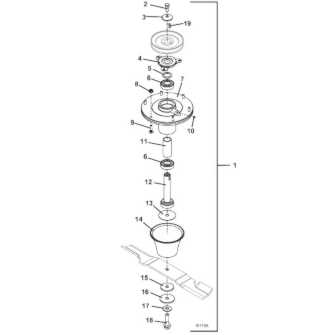

Blades and Cutting Mechanism Structure

The design of the cutting elements and their arrangement plays a crucial role in achieving efficient trimming and uniform results. The structure focuses on ensuring smooth operation, durability, and consistent performance across various conditions, allowing for precise adjustments as needed.

Cutting Elements Overview

The cutting components are typically designed to provide a sharp and effective edge. The shape and material of these elements are selected for their ability to handle various vegetation types. Their durability helps maintain efficiency over extended use, minimizing wear and tear.

Support and Adjustment Mechanisms

Alongside the cutting components, there are support structures that ensure stability during operation. These include mechanisms that allow users to adjust the height and angle of the cutting elements, adapting to different terrains and achieving the desired results with ease.

| Component | Function | Material |

|---|---|---|

| Blade Edge | Provides a sharp surface for trimming | High-carbon steel |

| Height Adjuster | Alters cutting level | Reinforced alloy |

| Support Frame | Stabilizes the cutting assembly | Heavy-duty composite |

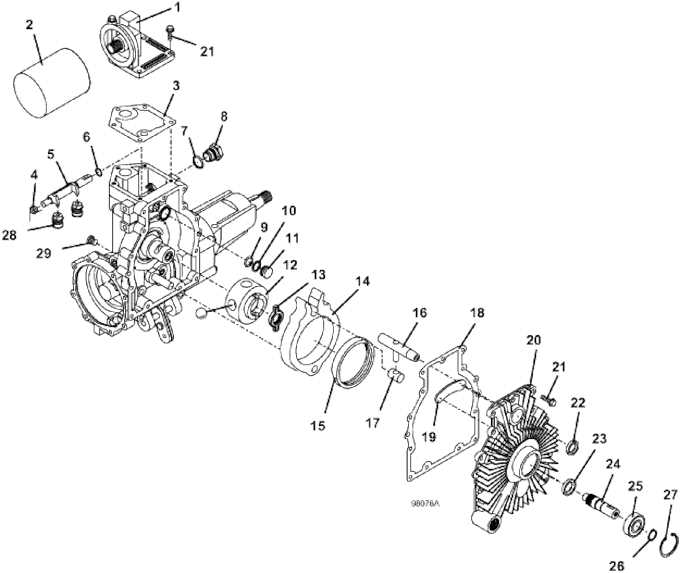

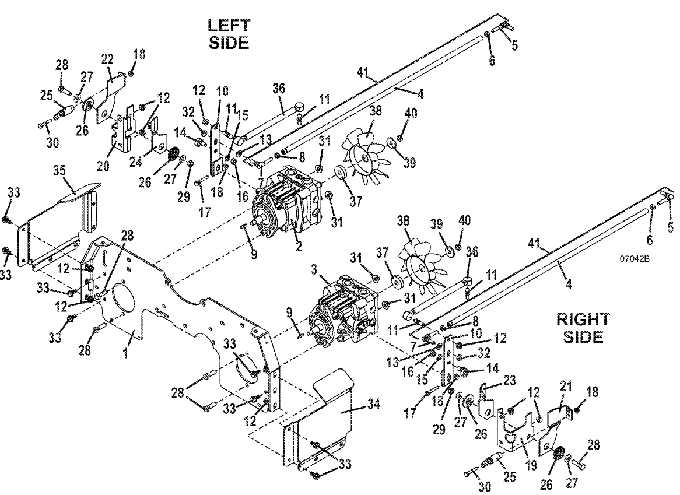

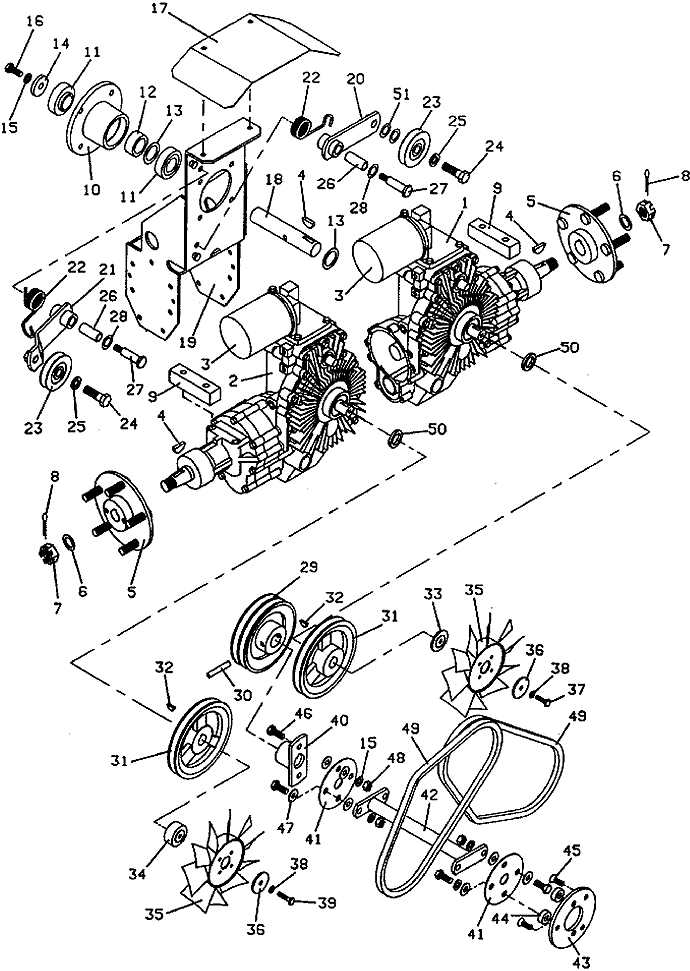

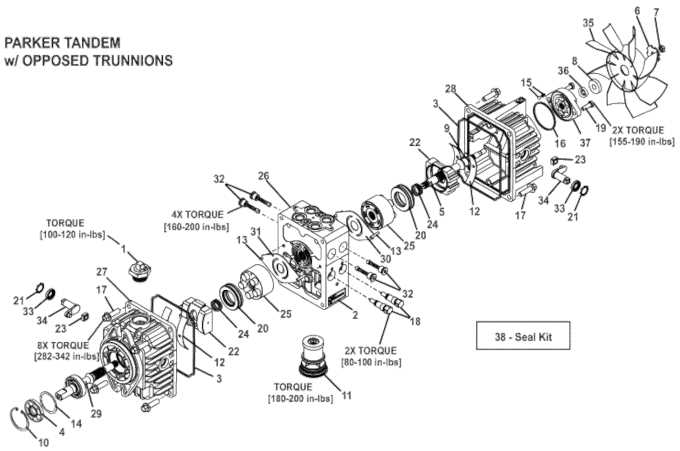

Transmission and Drive Assembly Details

The transmission system plays a crucial role in ensuring smooth movement and power transfer. It connects key components, allowing efficient operation by distributing force throughout the system. Understanding the arrangement and function of these elements helps maintain consistent performance over time.

Key Components and Their Function

At the heart of the drive setup is the power converter, which adjusts the energy flow to maintain optimal speed and torque. Alongside, the linkage mechanisms ensure proper synchronization between the engine and movement elements. These parts work in harmony to deliver consistent propulsion.

Maintenance and Adjustment Tips

Regular inspection of the power distribution pathways helps in identifying wear and potential issues. Adjusting the tension in specific sections and checking fluid levels can extend the operational lifespan. Adopting a routine maintenance schedule ensures that the entire assembly remains efficient and responsive.

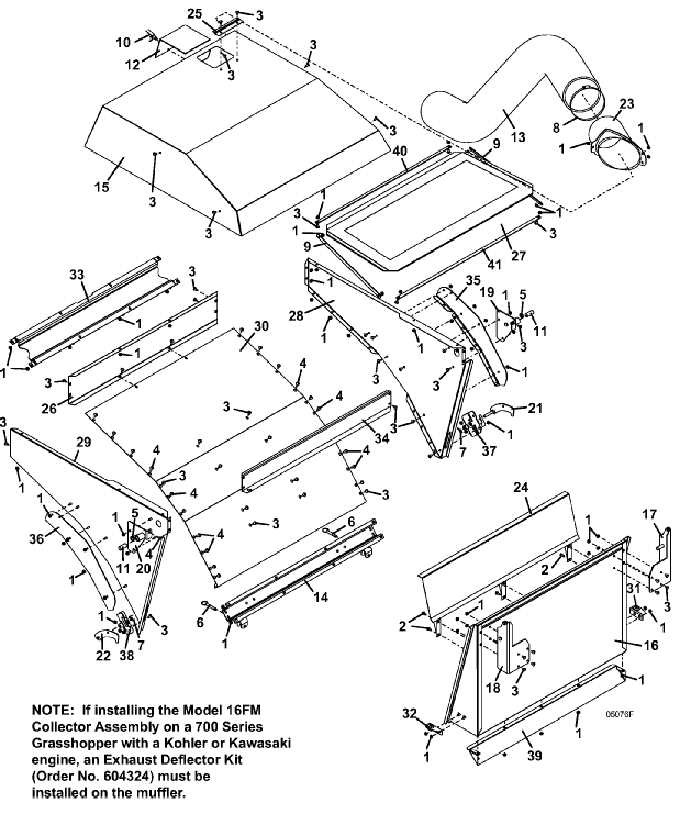

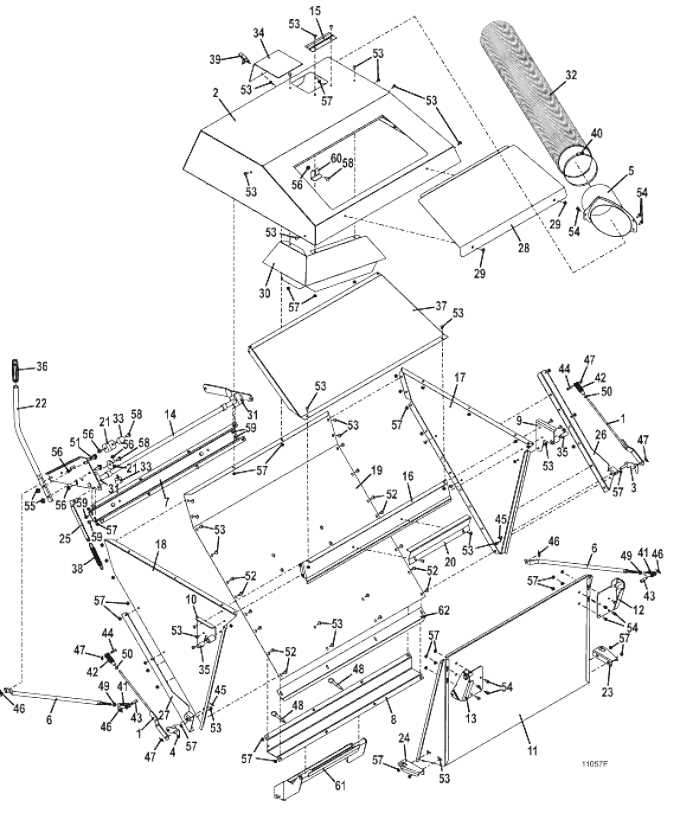

Deck Construction and Material Specifications

The design of the cutting platform emphasizes durability and precision, ensuring effective operation across various terrains. Attention to detail in the build process enhances overall performance, making the structure both sturdy and efficient. This section explores the materials and construction methods used to optimize longevity and functionality.

Structure and Build Quality

The platform’s framework is crafted with robust materials that resist wear, providing a solid foundation for extended use. Reinforced joints and carefully selected components contribute to a seamless structure that supports smooth and consistent operation. The focus on structural integrity ensures reliability during demanding tasks.

Material Selection for Longevity

High-quality alloys and composite materials are chosen to withstand exposure to different environmental conditions. The combination of corrosion-resistant elements and impact-resistant surfaces ensures the deck remains durable throughout its lifespan. This thoughtful material selection reduces maintenance needs and extends the usability of the platform.

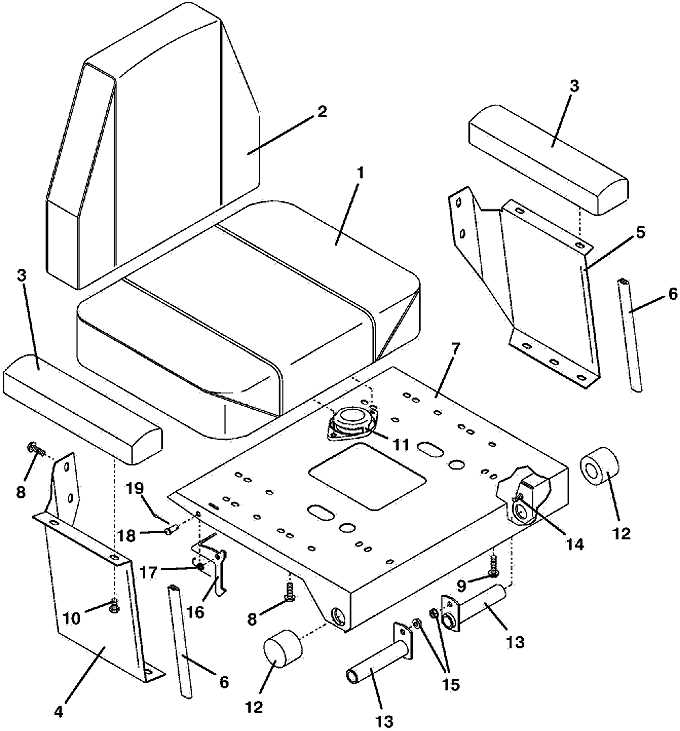

Steering and Control System Breakdown

The steering and control mechanism is essential for managing the direction and stability of the equipment during operation. This section explores the key components and their roles in ensuring smooth and precise maneuverability. Understanding how these elements work together provides a better grasp of their overall function.

Main Control Elements

The core of the system includes various levers, linkages, and hydraulic connections. These elements work in unison to adjust the direction and speed. The precise interaction between these components allows for seamless turns and responsive handling, enhancing user control over the equipment.

Adjustments and Fine-Tuning

Regular adjustments to the control mechanism ensure optimal performance. Fine-tuning of the linkages and ensuring proper alignment of hydraulic components can significantly improve steering responsiveness. Maintenance of these aspects is crucial for long-term operational efficiency and reliability.

Fuel and Oil Systems Explained

The fuel and lubrication mechanisms play a crucial role in the operation of various types of machines, ensuring that energy is delivered efficiently and components stay in optimal condition. These systems are designed to provide a smooth flow of fluids, supporting the machine’s internal processes while maintaining its performance.

Understanding the Fuel Delivery Process

The fuel delivery mechanism ensures that the energy source reaches the engine in the correct proportion for combustion. This involves several components working together to maintain a steady supply:

- Fuel Tank: Stores the energy source and ensures a consistent supply for long-term operation.

- Filters: Remove impurities, preventing blockages and extending the lifespan of the system.

- Pumps: Create pressure that helps transport the fuel through pipes and hoses to the combustion area.

The Role of the Lubrication System

The lubrication process minimizes friction between moving parts, reducing wear and preventing overheating. It is crucial for maintaining the longevity of mechanical components. The system includes:

- Oil Reservoir: Holds the lubricating liquid, ensuring a steady flow to essential parts.

- Pumps and Valves: Control the distribution of oil, directing it to areas that require consistent lubrication.

- Coolers: Help regulate the temperature of the lubricant, preventing it from breaking down under high heat.

By ensuring both fuel and oil systems function properly, these mechanisms contribute to the smooth operation and durability of machinery, providing a balanced flow of energy and maintaining vital parts in peak condition.

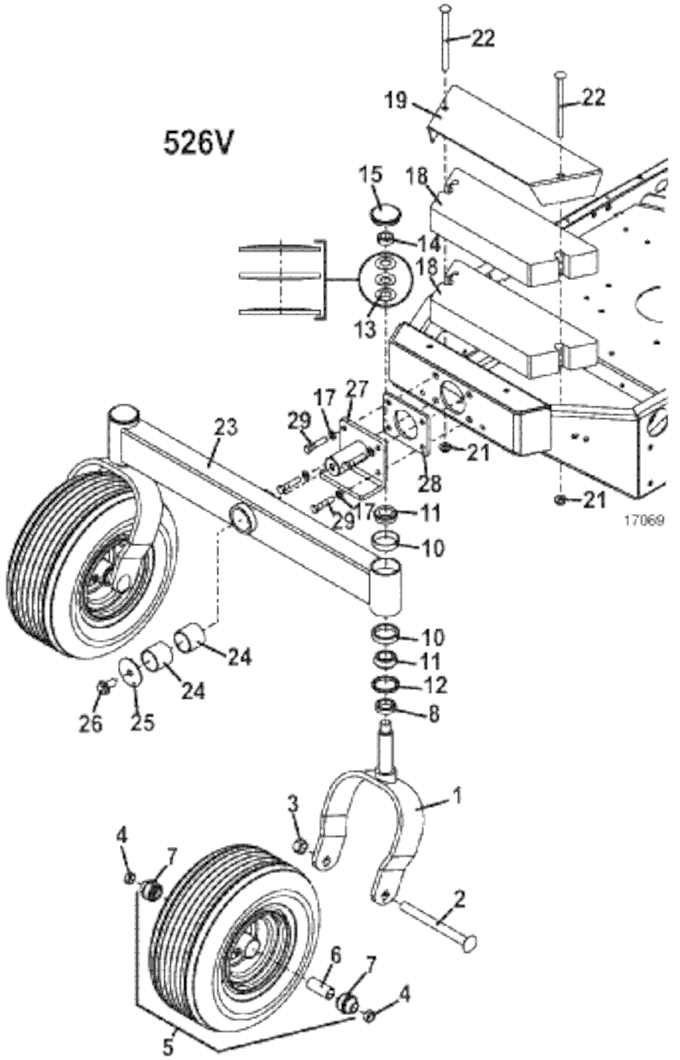

Wheels and Axle Placement Information

Proper alignment of wheels and axles is crucial for ensuring smooth movement and stability during operation. Understanding the positioning and assembly of these components helps maintain balance and efficient performance over varied surfaces.

Key Aspects of Wheel Alignment

- Symmetrical Arrangement: The wheels should be placed evenly on both sides to maintain balance, preventing tilting or uneven wear.

- Distance Consideration: The spacing between the front and rear wheels affects maneuverability and stability, allowing smoother turns and controlled navigation.

Axle Positioning Tips

- Centralized Axle Location: Placing the axle centrally distributes weight evenly, which aids in better traction and minimizes strain on the structure.

- Height Adjustments: Adjusting the height of the axles can change the ground clearance, which is useful for handling various terrains and obstacles.

Maintaining the proper arrangement of these components ensures a reliable setup that contributes to longevity and enhanced functionality. Regular inspection is advised to ensure all elements remain securely in place.

Electrical Wiring and Ignition Setup

Understanding the proper configuration of the electrical system is crucial for reliable performance. A well-organized setup ensures efficient energy flow, providing seamless operation and smooth starting mechanisms. This section explores the key components and their arrangement to maintain optimal functionality.

Key Wiring Elements

The system comprises various essential elements that work together to control the flow of electricity. Each of these components plays a role in ensuring stability and avoiding disruptions. Key elements include:

- Power Source: Provides the necessary energy to start the engine and power other components.

- Switches and Relays: Regulate the current, allowing the flow of electricity to be managed efficiently.

- Connectors: Link the different parts, ensuring secure connections throughout the setup.

Ignition Process Overview

The ignition process is central to initiating operation. It involves a sequence where electrical pulses trigger the starting mechanism, leading to smooth activation. Understanding this sequence helps to ensure that all components function together effectively.

- Initial Activation: A signal is sent from the starter, prompting the current to flow.

- Spark Generation: The current reaches the ignition coil, creating the spark required for activation.

- Engine Start: The spark ignites the air-fuel mixture, setting the internal components into motion.

A proper configuration of the wiring and ignition sequence is essential for maintaining efficient energy use and ensuring dependable operation.

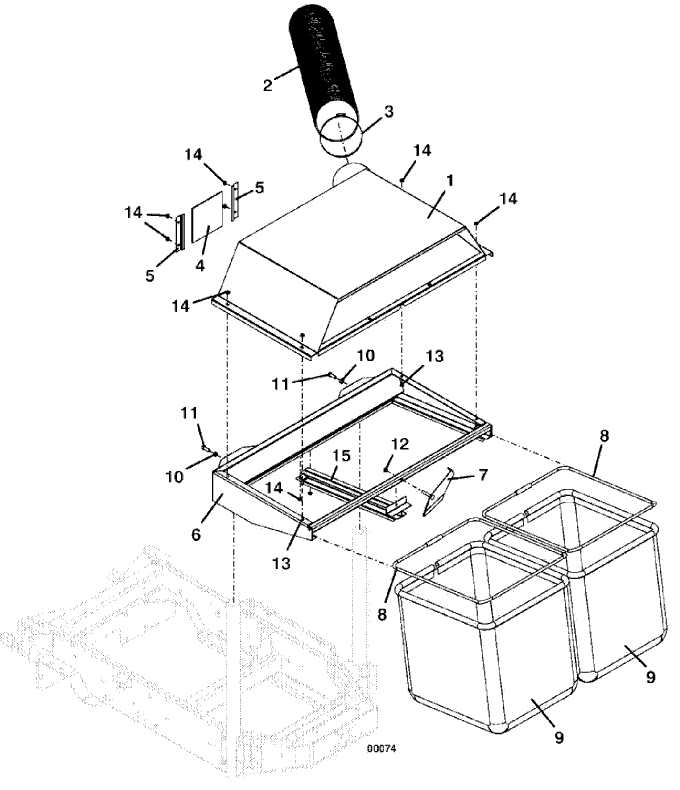

Grass Collection and Discharge Parts

The mechanism for gathering and releasing clippings plays a crucial role in maintaining a tidy and efficient lawn. It ensures that cuttings are properly managed, whether they are gathered into a storage container or directed back to the ground. This setup is designed to handle various conditions and offer a smooth flow during operation.

Collection System Components include specialized channels and receptacles that efficiently transport clippings away from the cutting area. These elements ensure minimal clogging and maintain consistent airflow, allowing the system to perform under different grass lengths and moisture levels.

Discharge Mechanisms direct the flow of cuttings, offering different options for users depending on their needs. From side-releasing options to attachments that mulch and spread clippings evenly, the choice of release method can significantly impact the final appearance of the trimmed area. Proper alignment and regular checks of these components are essential for smooth functioning.

Maintenance Tips for Common Parts

Proper care and attention can extend the lifespan and functionality of essential components in your equipment. Regular upkeep ensures smooth operation, minimizes unexpected breakdowns, and keeps everything working efficiently.

- Blades: Sharpen them periodically to maintain cutting efficiency. Inspect for any nicks or bends and replace if needed.

- Filters: Clean or swap out air and fuel filters regularly to prevent debris buildup that could hinder performance.

- Belt System: Check for tension and wear. Adjust or replace belts that show signs of cracking or slack to ensure optimal power transfer.

- Bearings and Joints: Lubricate these areas to reduce friction and prevent rust. Regular greasing helps maintain smooth movement.

- Battery: Keep terminals clean and free of corrosion. Charge the battery during off-season periods to preserve its life.

By following these care practices, you can keep your machinery in top shape and reduce the likelihood of major repairs.

Diagram Reference for Easy Repairs

This section serves as a valuable resource for those seeking to enhance their maintenance skills. By understanding the layout and components of the equipment, users can identify issues more efficiently and execute repairs with confidence.

Key Components Overview

Familiarizing oneself with the essential elements involved in the machinery allows for quicker troubleshooting. Recognizing how these parts interact can streamline the repair process.

Essential Tools and Supplies

To facilitate effective repairs, it is important to have the right tools and materials on hand. Below is a table listing necessary equipment and their typical uses:

| Tool/Material | Use |

|---|---|

| Wrench Set | Loosening and tightening bolts |

| Screwdriver Set | Fastening and removing screws |

| Replacement Blades | Ensuring optimal cutting performance |

| Oil and Lubricants | Maintaining smooth operation |

| Safety Gear | Protecting against injuries |