The maintenance and repair of outdoor equipment can often seem daunting, yet having a clear visual representation of its elements simplifies the process. By breaking down the various segments of these essential machines, users can enhance their understanding and efficiency during upkeep.

Every model features a unique arrangement of components, each playing a crucial role in the overall function. Familiarizing oneself with these individual pieces not only aids in troubleshooting but also promotes effective handling and longevity of the equipment.

In this exploration, we will delve into the intricacies of a specific lawn care model, highlighting key sections and their ultimate purposes. This knowledge will empower users to tackle repairs and maintenance with confidence.

Understanding Great Dane Mowers

Exploring the mechanics and design of lawn maintenance equipment reveals the sophistication behind their operation. These machines are engineered for efficiency and durability, catering to both residential and commercial needs. Grasping their functionality can enhance user experience and ensure optimal performance.

Key Features

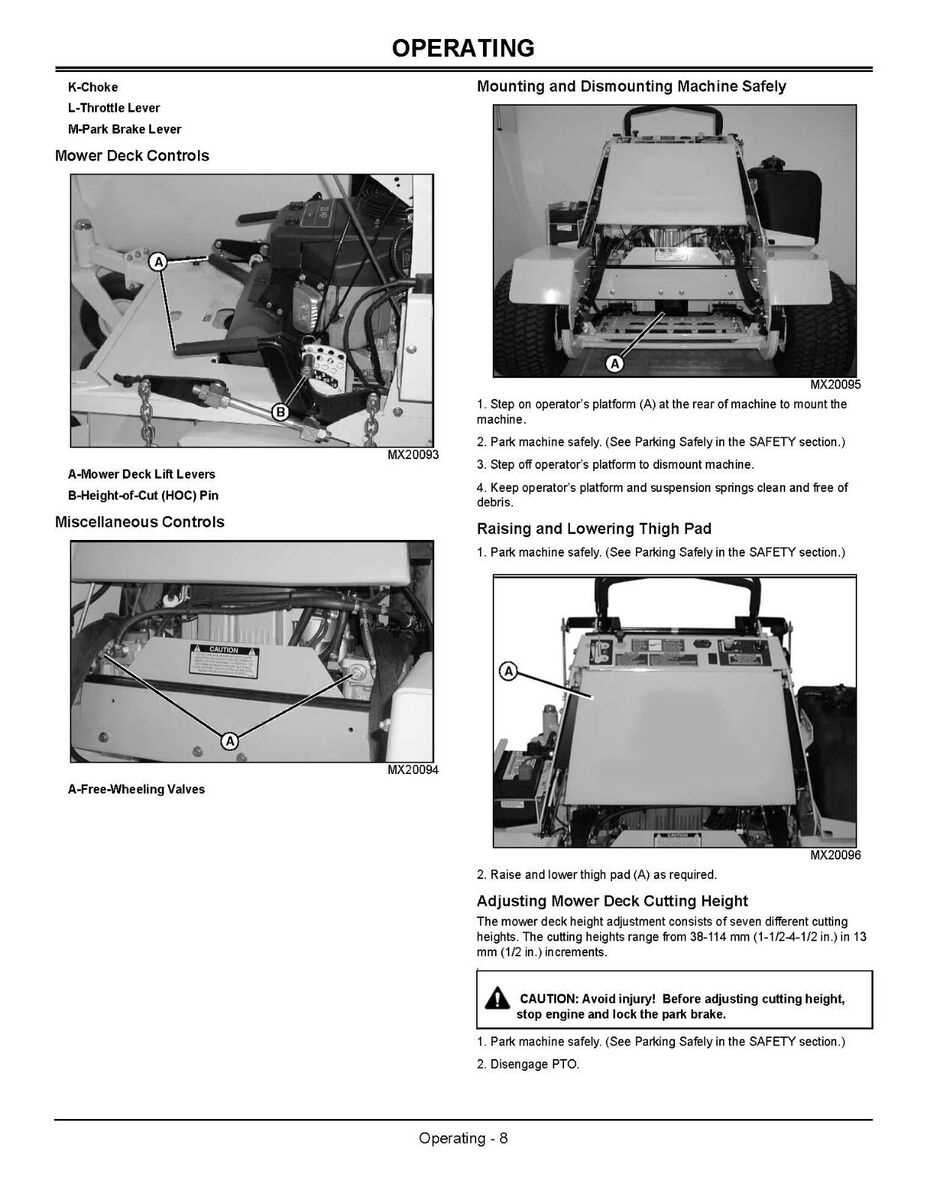

Notable attributes include ergonomic controls, robust engines, and adjustable cutting heights. Such characteristics facilitate ease of use and adaptability to various terrains, making them suitable for diverse applications.

Maintenance Tips

Regular upkeep is essential for longevity. Keeping blades sharp, checking fluid levels, and ensuring clean filters are vital practices that significantly improve efficiency and reduce wear over time.

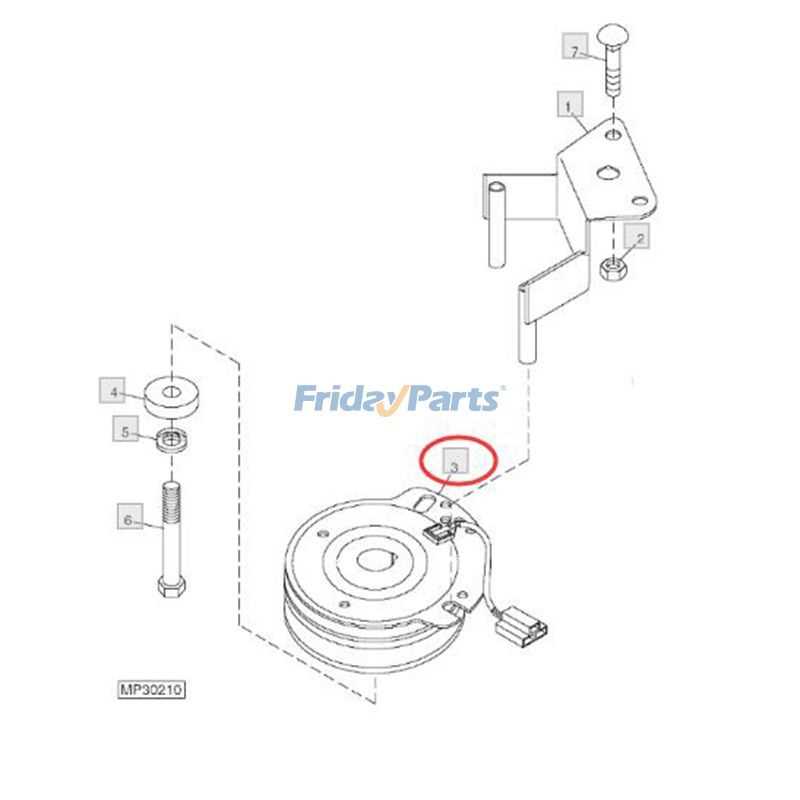

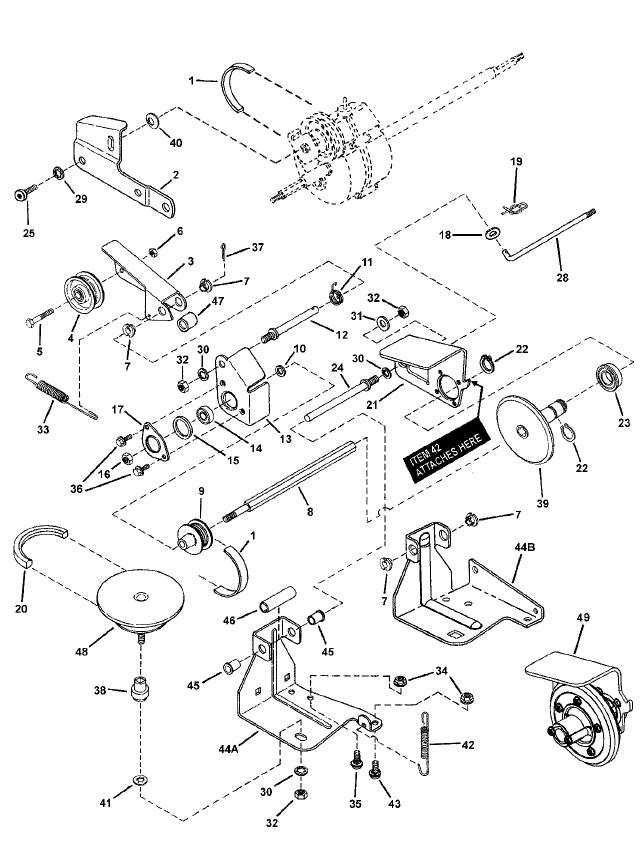

Key Components of Mower Diagrams

Understanding the essential elements within a schematic representation can significantly enhance your ability to maintain and troubleshoot your machinery. Each component plays a vital role in the overall functionality, making it crucial to recognize their positions and interconnections.

Essential Elements

- Engine: The heart of the system, providing necessary power.

- Blades: Responsible for cutting, these elements require regular inspection.

- Deck: The housing that supports and protects internal parts.

- Wheels: Facilitating movement, they affect maneuverability.

- Controls: Interfaces that allow for adjustments and operation.

Interconnections

Recognizing how these components interact is crucial for optimal performance. Key connections include:

- Power transmission: Connecting the engine to the cutting mechanism.

- Control links: Enabling user input to direct operations.

- Support structures: Ensuring stability and alignment of components.

Importance of Accurate Parts Identification

Correct identification of components is crucial for ensuring optimal performance and longevity of machinery. Without precise recognition, users may face compatibility issues, leading to unnecessary repairs and costs. Understanding each element’s specifications allows for seamless replacements and enhances overall efficiency.

Benefits of Proper Recognition

When components are accurately identified, it minimizes downtime and improves productivity. This attention to detail not only saves time but also reduces the likelihood of errors that can arise from mismatched items. Efficiency is maximized when every element is correctly matched to its intended function.

Impact on Maintenance

Routine upkeep becomes more manageable with proper component recognition. When users can easily pinpoint the right parts, maintenance schedules can be followed effectively, prolonging the life of the equipment. Preventative care relies heavily on accurate identification, making it an essential practice for any operator.

How to Read Mower Schematics

Understanding schematics is crucial for anyone looking to maintain or repair their equipment effectively. These visual representations provide detailed insights into the components and their interconnections, allowing users to troubleshoot issues and perform repairs with confidence.

Key Components of Schematics

Before diving into a schematic, familiarize yourself with common symbols and terminology. Each element represents a specific function or part, which can vary between different models. Below are some common symbols:

| Symbol | Meaning |

|---|---|

| ⬤ | Power Source |

| → | Flow Direction |

| ⚙ | Gear or Mechanical Part |

| Connection Point |

Steps to Interpret Schematics

To effectively interpret schematics, start by identifying the power source and flow direction. Trace the connections between components systematically, noting any potential points of failure. With practice, you’ll be able to quickly pinpoint issues and understand the layout of the machinery.

Common Issues with Great Dane Parts

When dealing with machinery components, various challenges can arise that may affect performance and longevity. Understanding these common problems can help users maintain efficiency and minimize downtime.

- Wear and Tear: Regular use can lead to degradation of key components, impacting functionality.

- Misalignment: Parts may become misaligned over time, causing operational issues and increased strain.

- Corrosion: Exposure to moisture and chemicals can lead to rust and deterioration, affecting reliability.

Additionally, certain parts may exhibit specific issues:

- Belts: These may fray or snap, leading to a loss of power transmission.

- Blades: Dull edges can result in poor cutting performance, requiring frequent sharpening or replacement.

- Filters: Clogged filters can restrict airflow and reduce efficiency, necessitating regular maintenance.

Addressing these issues promptly can significantly extend the lifespan of machinery and ensure optimal performance in various applications.

Finding Replacement Parts Online

In the digital age, locating specific components for your outdoor equipment has become more accessible than ever. With a plethora of online resources at your disposal, you can easily track down the necessary items to keep your machinery in optimal condition. Understanding how to navigate these platforms efficiently can save you both time and money.

Start by utilizing reputable websites that specialize in outdoor tools. Many retailers offer comprehensive catalogs and filters to help you find exactly what you need based on model numbers or descriptions. This approach minimizes the risk of purchasing incompatible items.

Don’t forget to explore forums and community groups dedicated to outdoor maintenance. Enthusiasts often share their experiences and recommendations, providing valuable insights on where to find quality replacements. Engaging with these communities can also help you troubleshoot any issues you may encounter along the way.

Additionally, consider checking manufacturer websites directly. They frequently list authorized dealers and online stores that stock genuine replacements. This ensures you receive high-quality components that meet safety and performance standards.

Lastly, remember to compare prices across different platforms. This not only helps you find the best deals but also allows you to gauge the overall market value of specific items. By taking these steps, you can confidently secure the components you require, ensuring your equipment remains reliable and efficient.

Maintaining Your Mower Effectively

Proper upkeep of your lawn care equipment is crucial for its longevity and performance. Regular attention can prevent breakdowns, enhance efficiency, and ensure optimal results. Adopting a systematic approach can make a significant difference in the lifespan of your machinery.

- Regular Cleaning: Debris buildup can hinder performance. After each use, clean the exterior and undercarriage to prevent clogs.

- Inspecting Blades: Sharp blades are essential for a clean cut. Check for wear and sharpen or replace them as needed.

- Changing Oil: Regular oil changes keep the engine running smoothly. Follow the manufacturer’s recommendations for intervals.

- Checking Filters: Air and fuel filters can get dirty over time. Clean or replace them to ensure proper airflow and fuel efficiency.

- Battery Maintenance: If applicable, check battery connections and charge levels regularly to avoid starting issues.

By implementing these practices, you can enhance the functionality and durability of your equipment, leading to a more enjoyable and efficient lawn care experience.

Tools Needed for Mower Repairs

When it comes to maintaining and fixing outdoor equipment, having the right instruments is essential for achieving efficient and safe results. Proper tools not only facilitate the repair process but also help in diagnosing issues effectively, ensuring that your machinery operates at peak performance.

Essential Instruments

To start, a good quality set of hand tools is crucial. This typically includes wrenches, screwdrivers, and pliers. These basic items will allow you to handle most tasks, from tightening loose components to replacing worn-out fixtures. Additionally, a socket set is invaluable for reaching fasteners in tight spaces, making it easier to disassemble parts without damaging them.

Specialized Equipment

In some cases, specialized instruments are necessary for more complex repairs. A torque wrench ensures that bolts are tightened to the correct specifications, preventing potential damage from over-tightening. For maintenance tasks, having a fuel line cutter or a spark plug wrench on hand can streamline the process, saving time and effort.

Comparing Different Great Dane Models

This section focuses on the various models available in a specific line of outdoor equipment, emphasizing their unique features and specifications. By examining each variant, users can make informed choices tailored to their specific needs, whether for residential or commercial applications.

Model Features

Each variant showcases distinct attributes, from engine power to cutting width. Some models prioritize efficiency and ease of use, while others excel in durability and performance under heavy conditions. Understanding these differences is crucial for selecting the right machine.

Performance Analysis

When evaluating these outdoor machines, consider how each model performs in different environments. Factors such as speed, maneuverability, and maintenance requirements can significantly influence overall effectiveness. An informed decision ultimately leads to enhanced productivity and satisfaction.

Tips for Long-lasting Mower Performance

Ensuring optimal operation of your outdoor equipment requires regular attention and care. By implementing a few essential practices, you can enhance longevity and efficiency, minimizing the need for repairs and replacements. These guidelines will help maintain peak performance throughout the seasons.

Regular Maintenance

Consistent upkeep is crucial. Clean the equipment after each use to prevent debris buildup and check for wear on critical components. Regularly changing the oil and filters, as well as sharpening the blades, will significantly improve functionality and extend lifespan.

Proper Storage

Storing your equipment correctly can make a substantial difference. Keep it in a dry, sheltered location to protect it from the elements. During winter months, ensure that the fuel system is properly managed and the machine is serviced to prevent issues when spring arrives.

Understanding Warranty and Parts Coverage

The significance of coverage and assurance cannot be overstated when it comes to equipment ownership. These elements provide peace of mind, ensuring that your investment is safeguarded against unforeseen issues.

Warranty typically covers defects in manufacturing and material quality, offering repair or replacement options. It is crucial to familiarize yourself with the terms and duration of such guarantees to maximize their benefits.

Coverage for components may vary, so it’s essential to review what is included and what might require separate consideration. Understanding these aspects will ultimately help you maintain optimal functionality and extend the lifespan of your equipment.

Resources for Mower Troubleshooting Help

When facing challenges with outdoor equipment, accessing the right resources can make all the difference. A variety of guides, forums, and videos are available to assist in diagnosing issues and providing solutions. Utilizing these materials can empower users to effectively resolve mechanical problems and maintain their machinery efficiently.

Online forums are invaluable for connecting with fellow enthusiasts who share their experiences and tips. Websites dedicated to equipment maintenance often feature comprehensive guides that cover common issues and their fixes. Additionally, instructional videos on platforms like YouTube can offer step-by-step demonstrations, making troubleshooting more approachable.

Moreover, manufacturer websites typically provide manuals and troubleshooting sections that are tailored to specific models. These documents often include diagrams and parts lists, helping users identify components and their functions. Engaging with these resources enhances the overall understanding of equipment operation and care.

Finally, local repair shops can be a great source of expertise. Many technicians are willing to share advice or recommend best practices for upkeep. Tapping into these networks can ultimately lead to more successful maintenance and repair experiences.