Proper upkeep of agricultural and landscaping tools is crucial for ensuring smooth operation and longevity. Each element of the machine plays a significant role in its performance, and knowing how to identify and maintain these elements is a key aspect of routine maintenance. This understanding can prevent costly repairs and improve overall efficiency.

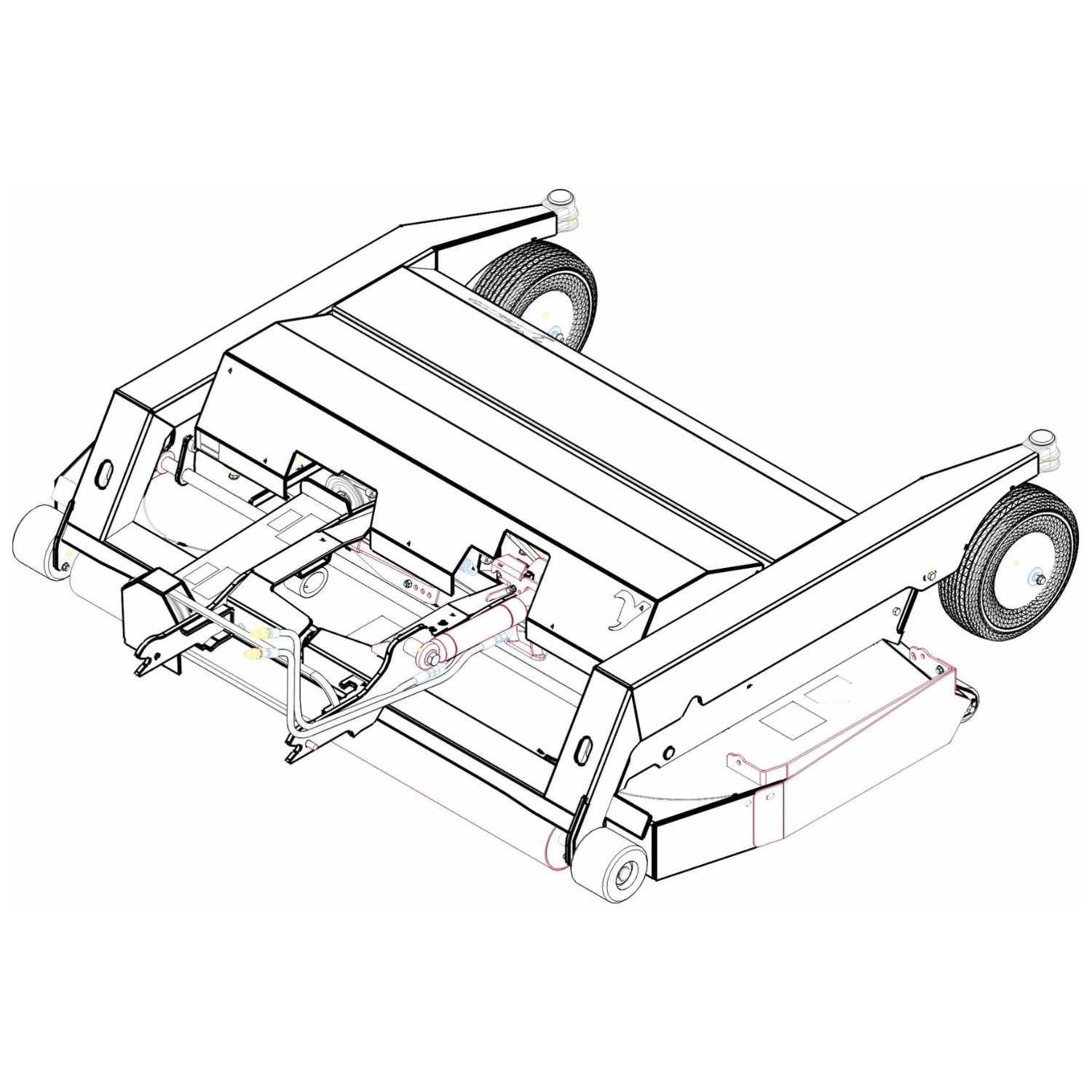

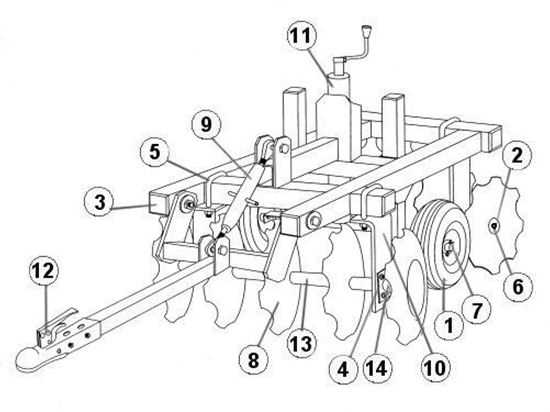

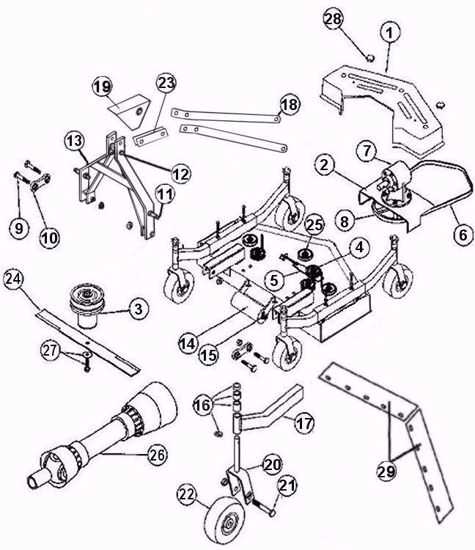

When it comes to maintaining field equipment, having access to clear and detailed technical representations of the internal and external mechanisms is invaluable. These illustrations help users understand how various sections of the machine interact and support each other, guiding repairs and adjustments when necessary. Thorough knowledge of these systems ensures that everything functions as it should, reducing downtime and enhancing productivity.

Understanding the King Kutter Finish Mower

When it comes to maintaining large areas of land efficiently, there is a specialized tool designed for delivering a clean, precise cut. This piece of equipment is highly valued for its ability to handle various terrains while ensuring an even trim. Its construction is designed to minimize effort while maximizing results, making it an essential choice for land maintenance.

Main Features

The machine comes equipped with several key components that contribute to its performance. These features not only improve the cutting experience but also extend the lifespan of the tool, providing reliable service for years.

- Durable blades designed for optimal sharpness and endurance

- Adjustable height settings to accommodate different grass lengths

- Sturdy wheels that ensure smooth movement over uneven ground

- Powerful belt system to drive the blades effectively

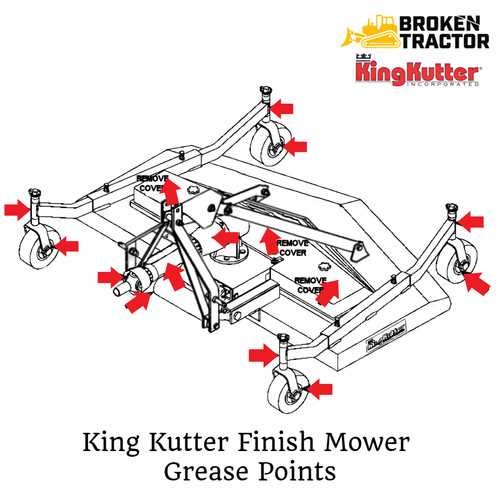

Usage and Maintenance

Regular upkeep of this equipment ensur

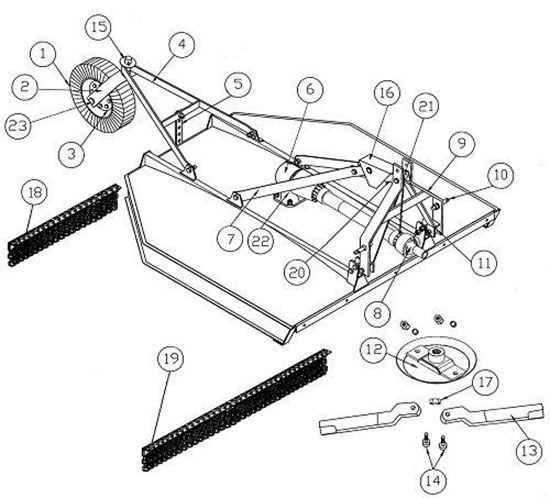

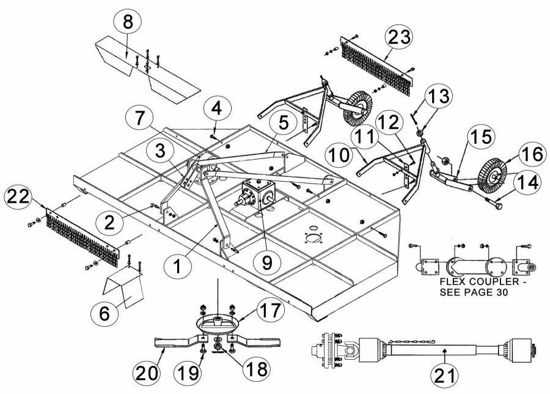

Key Components of a Finish Mower

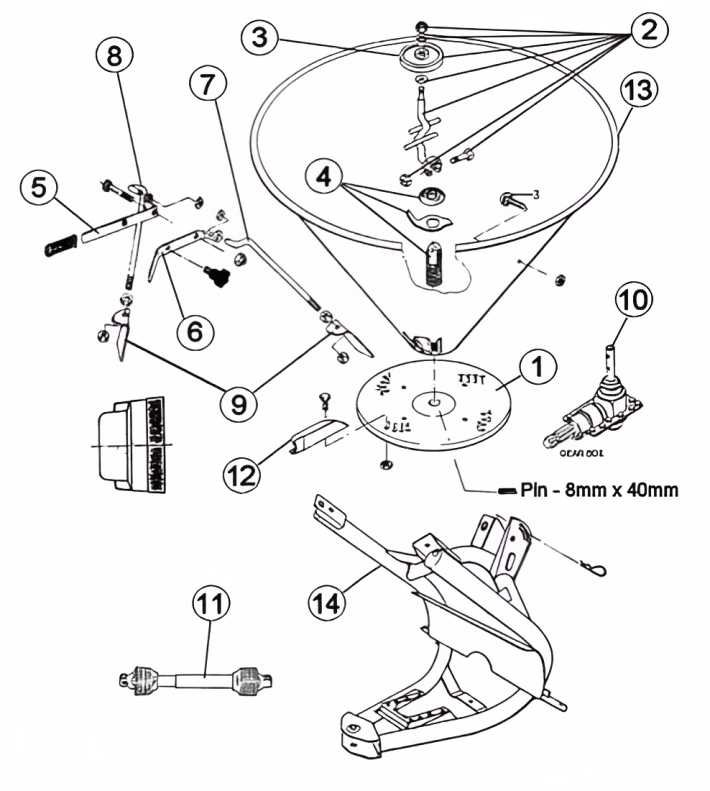

Understanding the primary elements of this equipment is crucial for ensuring its proper operation and maintenance. Each component plays a vital role in achieving a smooth and efficient cut, contributing to the overall performance of the machine.

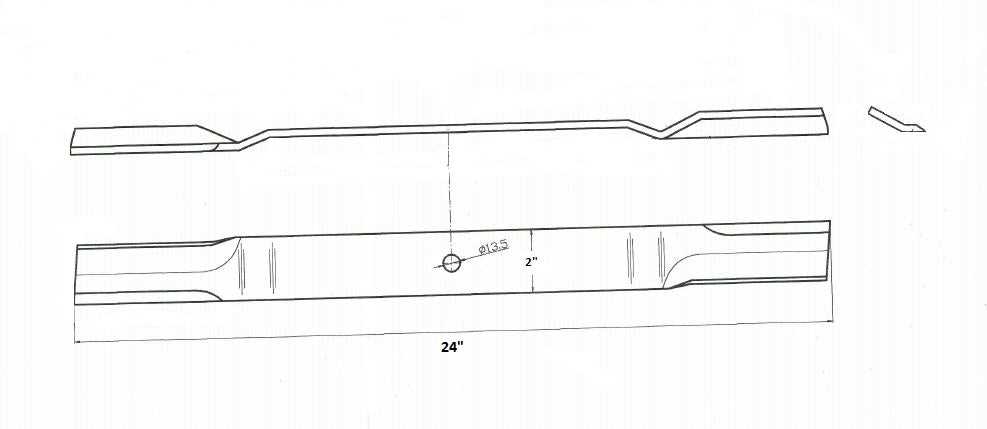

Blades

The cutting tools are at the core of the system. They are designed to rotate at high speeds, slicing through the grass to provide a clean cut. Their sharpness and balance are key to maintaining efficiency and avoiding damage to the lawn.

Deck

The deck acts as a protective housing for the cutting tools, ensuring safety and directing the flow of grass clippings. It also helps in maintaining an even cut by keeping the blades at a consistent height above the ground.

- Spindles: These connect the blades to the machine and enable their rotation. They must be lubricated and well-maintained to ensure smooth operation.

- W

Blade Assembly and Maintenance Tips

The proper upkeep and configuration of cutting blades is essential for achieving optimal performance and longevity of your equipment. Understanding how to correctly assemble the blades and perform regular maintenance ensures smooth operation and extends the life of your machine.

When installing the cutting tools, it’s important to ensure that each blade is securely fastened and positioned correctly. Misalignment or loose fittings can lead to uneven cuts or potential damage to the mechanism. Always check the manufacturer’s guidelines for torque specifications to avoid over-tightening or under-tightening the fasteners.

Maintenance of the blades includes regular inspection for wear and sharpening them when necessary. Dull edges can cause strain on the engine and result in a rougher cut. Keeping the blades sharp not only improves cutting efficiency but also reduces fuel consumption and wear on other components. After sharpening, balance each blade to avoid vibration, which can lead to furth

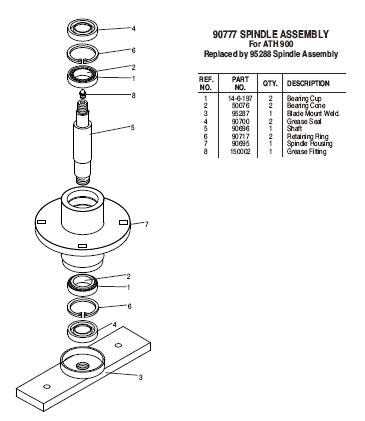

Spindle Mechanism and Its Role

The spindle mechanism is a crucial component in ensuring the effective operation of rotary cutting equipment. It is responsible for translating rotational force into the necessary motion to drive the blades, which perform the cutting action. This part plays a significant role in maintaining the balance and precision of the equipment during use, ensuring smooth and efficient performance.

Typically, the spindle assembly consists of multiple elements, including bearings, shafts, and housings. These components work in unison to provide stability and reduce friction during operation. Proper maintenance of the spindle mechanism is essential for ensuring long-lasting and optimal functionality.

Component Function Bearings Importance of Proper Belt Installation

Ensuring the correct placement and alignment of the belt in any machine is critical for maintaining smooth operation. A misaligned or improperly fitted belt can cause unnecessary wear, reduce efficiency, and lead to potential mechanical failures. The belt plays a vital role in transferring power between different components, and its correct installation is essential for optimal performance and longevity.

Consequences of Incorrect Installation

Improperly installed belts can lead to various issues such as slipping, excessive friction, or even total failure of the system. These problems can result in breakdowns, increased maintenance costs, and downtime. In addition, incorrect tension or misalignment can cause the belt to deteriorate prematurely, shortening its service life and affecting overall productivity.

Steps to Ensure Proper Installation

To ensure the belt is

Wheel and Tire Setup for Mowers

Establishing the correct configuration of wheels and tires is crucial for optimal performance and stability of lawn care equipment. The right combination enhances traction, supports the weight of the machine, and ensures even cutting across various terrains. A well-planned setup minimizes wear and tear on components while maximizing efficiency in operation.

Choosing the Right Tires is essential for achieving the desired performance. Tires designed for specific ground conditions can significantly impact how well the equipment maneuvers. For instance, wider tires offer better flotation on soft ground, while narrower options provide improved stability on hard surfaces.

Wheel Alignment plays a vital role in maintaining consistent contact with the ground. Properly aligned wheels prevent uneven wear and enhance handling. Regularly checking and adjusting wheel alignment ensures the equipment operates smoothly, reducing the risk of damage and extending the lifespan of tires.

Air Pressure Maintenance is another critical aspect of tire management. Keeping the air pressure within the manufacturer’s recommended range not only optimizes traction but also prevents overheating and blowouts. Regular inspections should be conducted to ensure tires are inflated correctly and free of damage.

In conclusion, a thoughtful approach to wheel and tire configuration is fundamental for achieving superior performance and longevity in lawn care machinery. By focusing on the right tire selection, maintaining proper alignment, and ensuring adequate air pressure, operators can enhance the efficiency and reliability of their equipment.

Pulley System Functionality Explained

The pulley system is an essential component that enhances mechanical efficiency in various applications. It operates by transferring rotational motion and force between different elements, enabling smoother operation and improved performance. Understanding how this system functions can provide insights into its importance in machinery.

Components of the Pulley System

A typical pulley assembly consists of several key components that work together to facilitate motion. These elements include the pulleys themselves, belts, and supporting structures. Each component plays a crucial role in ensuring the system operates seamlessly.

Component Function Pulley Guides the belt and helps in changing the direction of force. Belt Transfers motion and power between pulleys. Support Frame Provides stability and alignment for the entire assembly. Working Principles

The operation of the pulley system relies on the principles of leverage and mechanical advantage. By utilizing different pulley arrangements, one can achieve desired speeds and torque outputs. This adaptability makes pulley systems versatile in various settings, from industrial applications to home use.

Deck Frame Construction and Durability

The construction of the frame that supports cutting equipment plays a vital role in its overall performance and longevity. A robust and well-designed framework not only enhances stability but also contributes to efficient operation and maintenance. Understanding the materials and design features used in these structures can provide insights into their durability and functionality.

Materials Used

Durable materials are essential for creating a strong deck framework. Commonly utilized substances include:

- Steel: Renowned for its strength and resilience, steel frames can withstand significant stress and wear.

- Aluminum: Lightweight yet sturdy, aluminum provides corrosion resistance and ease of handling.

- Composite materials: These offer a blend of strength and reduced weight, contributing to overall efficiency.

Design Considerations

Effective design is crucial for maximizing the durability of the frame. Key aspects include:

- Reinforcement: Strategically placed reinforcements enhance structural integrity, particularly in high-stress areas.

- Sealing and Coating: Protective coatings prevent rust and degradation, extending the lifespan of the frame.

- Ergonomic Design: A well-thought-out configuration aids in balanced weight distribution, reducing the risk of damage during operation.

In summary, the combination of high-quality materials and thoughtful design is fundamental in ensuring the longevity and performance of the framework that supports cutting tools. Understanding these elements can lead to more informed choices when selecting and maintaining such equipment.

Common Causes of Mower Part

Understanding the frequent issues that can arise with lawn equipment is crucial for maintaining its functionality and longevity. Various factors can contribute to malfunctions, leading to decreased efficiency or complete operational failure. Recognizing these common problems allows users to take proactive measures, ensuring their machinery remains in optimal condition.

Wear and Tear: Regular use inevitably leads to natural degradation of components. Parts can become worn out over time, resulting in diminished performance. Routine inspections can help identify these issues before they escalate.

Improper Maintenance: Neglecting scheduled upkeep is a primary cause of malfunctions. Failing to clean, lubricate, or replace essential elements can lead to premature breakdowns. Adhering to maintenance schedules is vital for preventing such problems.

Environmental Factors: External conditions, such as exposure to extreme temperatures or moisture, can adversely affect the machinery. These elements can accelerate wear and compromise the integrity of different components. Protecting equipment from harsh environments is essential.

Incorrect Usage: Operating machinery outside of its intended design can lead to significant issues. Understanding the correct usage protocols and adhering to them helps in avoiding unnecessary strain on various components.

Faulty Components: Occasionally, a defective part may be the root of the problem. Manufacturing flaws can lead to early failures, necessitating prompt replacement to restore proper functionality.