Understanding the structure and configuration of agricultural machinery is essential for effective maintenance and repair. Each element plays a crucial role in ensuring smooth operation, minimizing downtime, and enhancing field productivity. This section focuses on providing detailed insights into the arrangement and interaction of individual mechanical components.

With numerous moving elements working in unison, identifying the correct replacements and upgrades becomes critical. Proper knowledge of assembly layouts helps operators maintain efficiency and avoid potential malfunctions during operation.

This guide emphasizes the importance of organized component layouts, enabling users to perform repairs confidently. Whether dealing with mechanical adjustments or routine upkeep, precise reference material ensures the

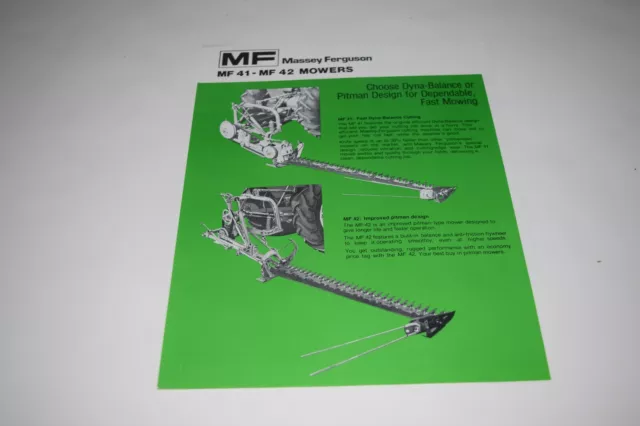

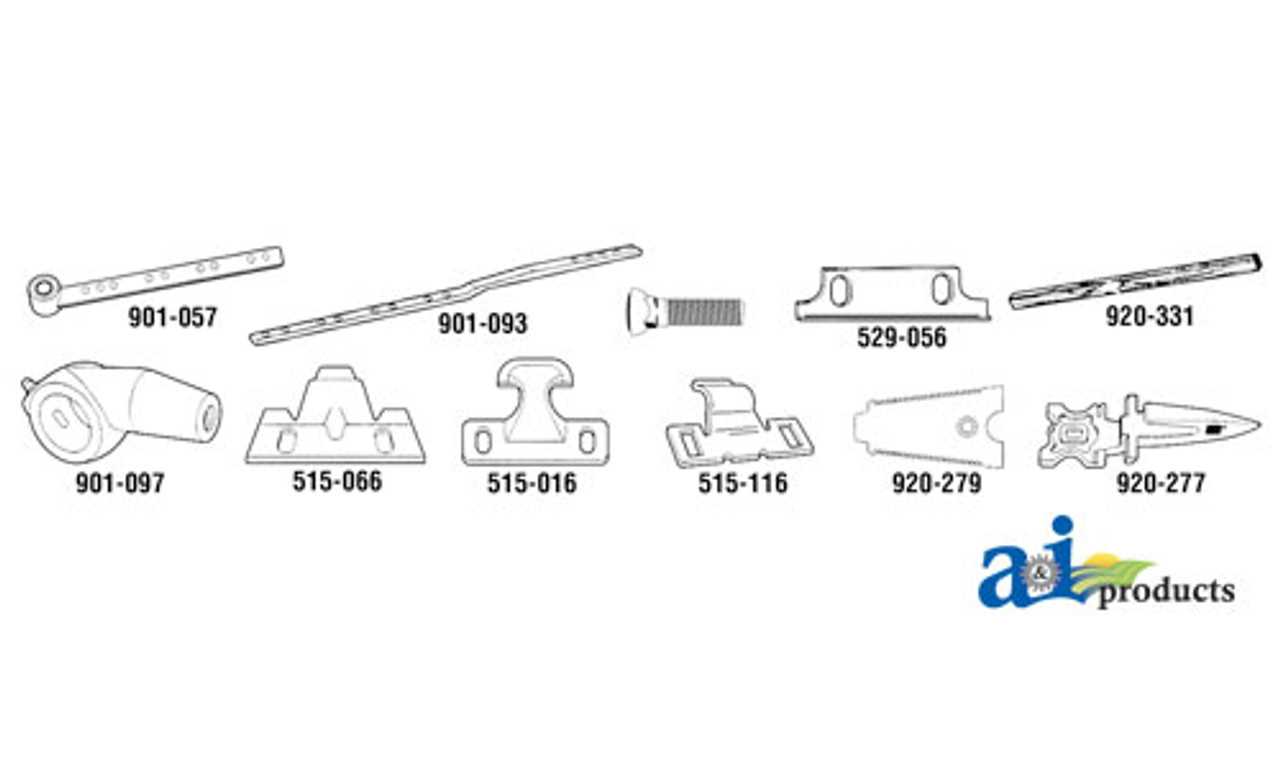

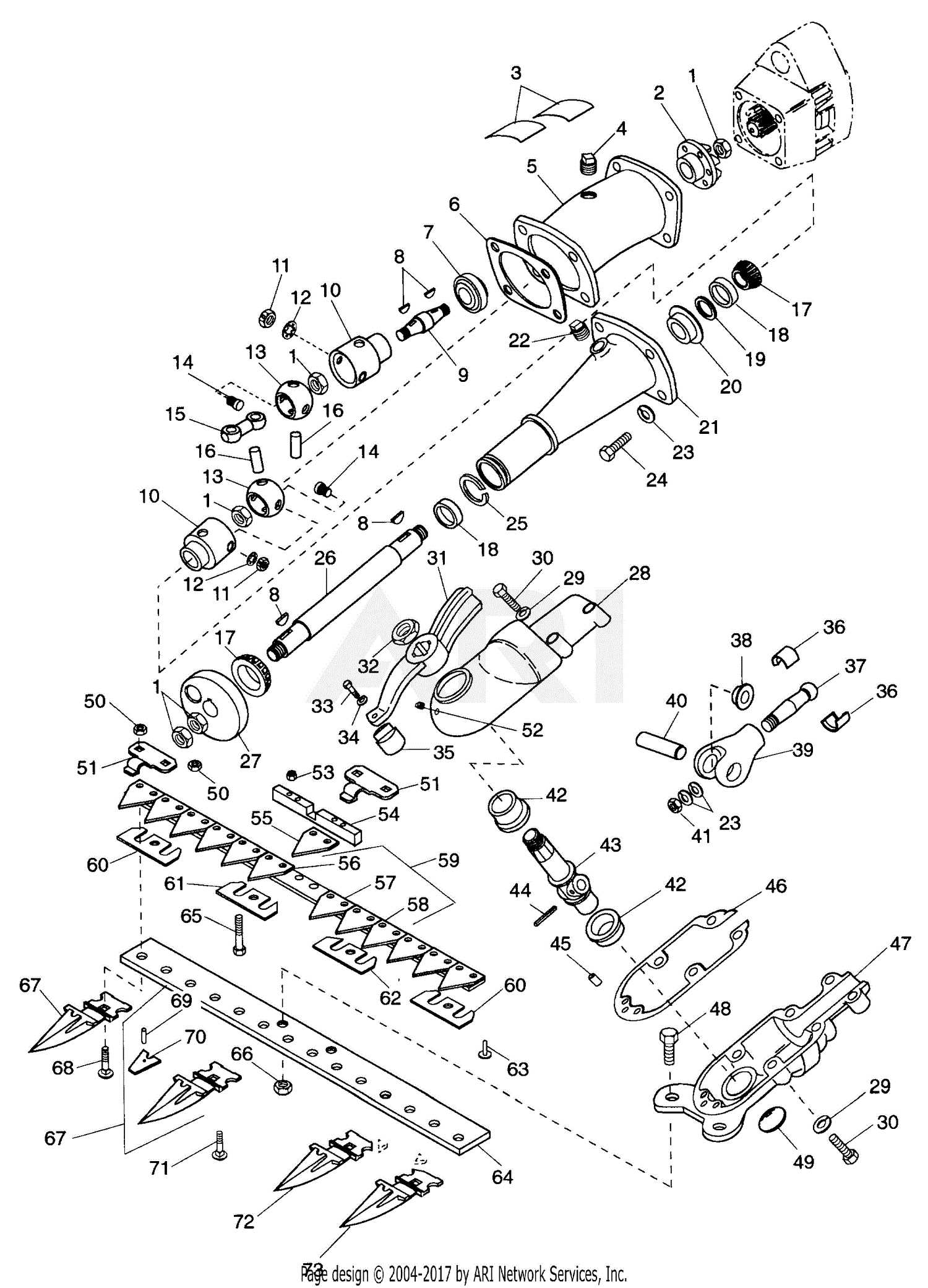

Massey Ferguson 41 Sickle Mower Parts

Efficient agricultural equipment requires the right components to maintain peak performance. Each element in such machinery plays a specific role in ensuring smooth operation and durability during use. Timely replacement of worn elements helps avoid breakdowns and prolongs the life of the equipment.

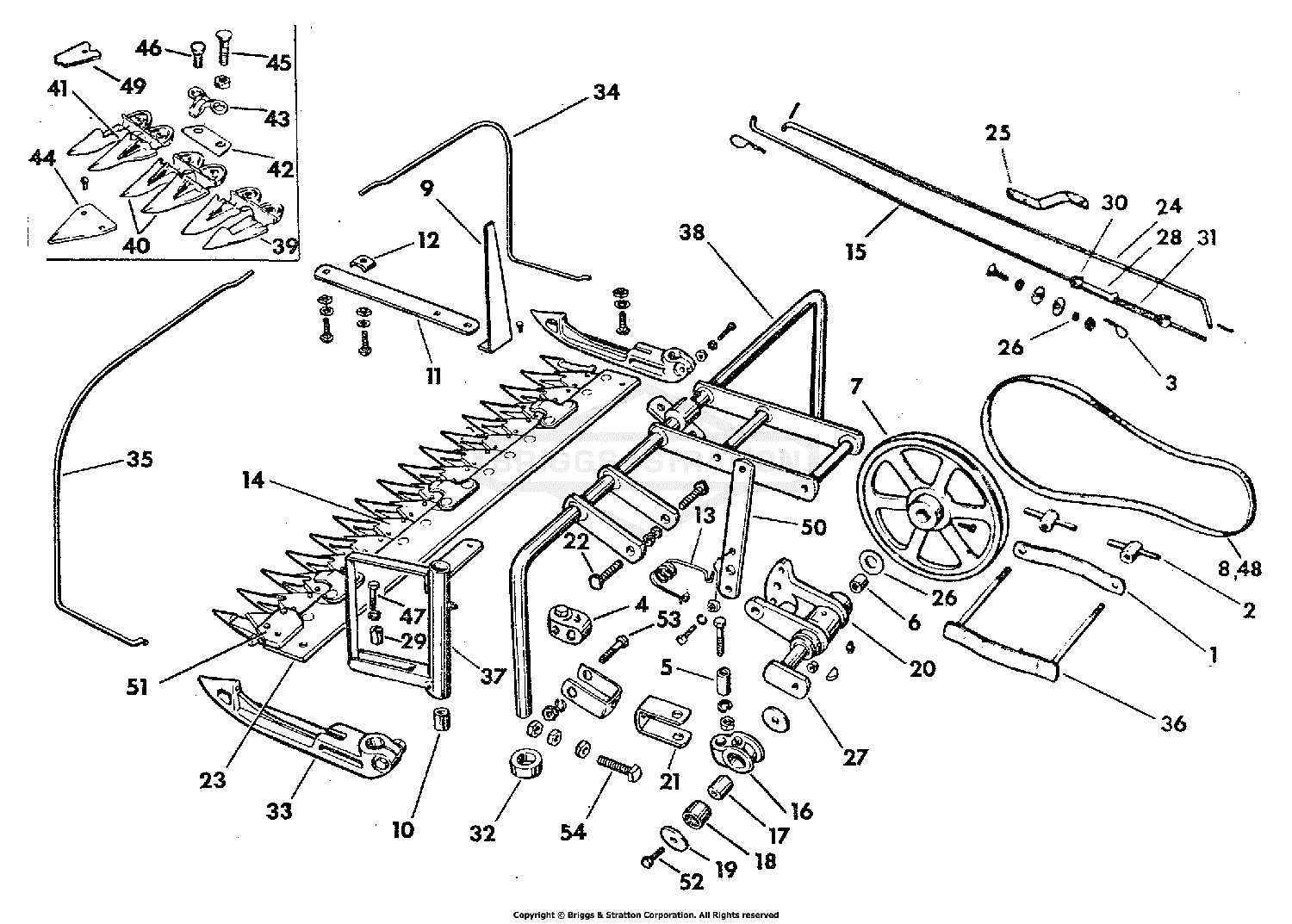

Cutting Mechanism: The core assembly consists of blades responsible for precise trimming. Regular inspection of these elements is essential to maintain sharpness and avoid disruptions in functionality.

Drive System: This section contains belts, gears, and pulleys, transferring power from the engine to other components. Ensuring that these parts remain properly tensioned and free from wear

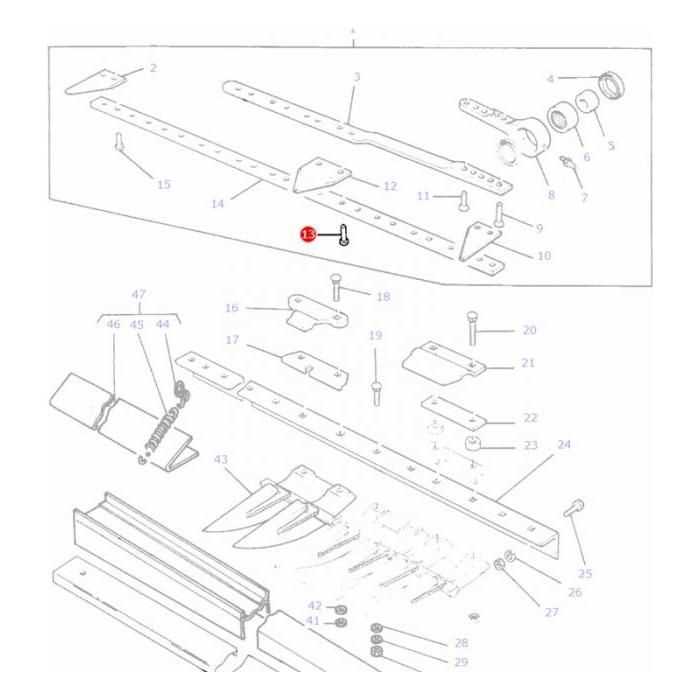

Overview of Cutter Bar Components

The cutter bar is an essential element in agricultural machinery, designed to efficiently trim vegetation. Its construction ensures precise and clean cuts, enabling smooth operations in various field conditions. This section explores the key elements that contribute to its functionality, focusing on how they work together to maintain optimal performance.

The primary cutting mechanism relies on a series of interconnected blades that move in synchronization to slice through grass or crops. These blades are supported by guards, which help align the cutting action and protect the cutting edges from impact with stones or other obstacles. The alignment of these components ensures consistent operation, minimizing interruptions during use.

Additional elements, such as the knife head and drive mechanism, play crucial roles in ensuring smooth movement along the bar

Common Issues with Knife Sections

Over time, the cutting components of agricultural machines are prone to various challenges that can impact performance and reduce efficiency. These issues often result from wear, misalignment, or environmental factors, leading to decreased productivity if not addressed promptly.

Signs of Wear and Damage

- Frayed or cracked edges on the blades can hinder the precision of the cut.

- Excessive dullness causes the cutting action to become inefficient, requiring more effort.

- Loosened fasteners may result in rattling or vibration during operation.

- Inspect belts and chains regularly to ensure they are not frayed or stretched. Replace worn-out components immediately to avoid system failures.

- Lubricate all moving parts according to the manufacturer’s recommendations to minimize friction and wear.

- Front Guards: These are positioned at the forefront of the equipment, safeguarding the operator from debris and protecting the cutting mechanisms from damage.

- Side Guards: Located on either side, these components prevent materials from escaping and direct them into the processing area, enhancing efficiency.

- Rear Guards: These elements help contain materials within the working area and protect against rearward ejection of debris, contributing to safer operation.

- Adjustable Guards: Designed for versatility, these can be modified based on operational needs, allowing for tailored protection and enhanced performance in various conditions.

Drive Mechanism Maintenance Tips

Proper upkeep of the drive system ensures smooth performance and extends the longevity of agricultural machinery. Routine inspections, lubrication, and timely repairs can prevent unexpected breakdowns and maintain operational efficiency.

Blade Replacement and Adjustment Guide

Ensuring optimal cutting performance requires regular attention to the sharpness and alignment of the blades. Timely replacement and precise adjustments play a crucial role in maintaining smooth operation and achieving efficient results.

Removing and Replacing Blades

Begin by securing the equipment to prevent any unintended movement during the process. Use appropriate tools to loosen the fasteners holding the worn-out blades. After removing them, inspect the mounting points for any signs of wear. Install the new blades, ensuring they are positioned correctly and tightened securely for stable operation.

Adjusting Blade Alignment

Proper alignment is essential to avoid uneven cutting. To

Types of Guards and Their Functions

In agricultural machinery, protective components play a crucial role in ensuring safety and operational efficiency. These elements serve to shield the operator from moving parts, prevent material loss, and enhance the overall performance of the equipment. Understanding the different types of protective elements and their specific functions is essential for maintaining optimal machinery performance.

Each type of protective element serves a distinct purpose, collectively ensuring the safe and efficient functioning of the machinery. Regular inspection and maintenance of these components are vital for optimal performance and safety.

Understanding Pitman Arm Operation

The functionality of the pitman arm is crucial in many agricultural implements, acting as a vital link between various components. This lever system transmits motion, enabling efficient operation during cutting tasks. By converting rotational movement into linear action, it plays an essential role in the overall mechanism, ensuring optimal performance.

Mechanics of the Pitman Arm

The pitman arm operates by connecting the main drive to the cutting assembly. As the drive rotates, the pitman arm swings back and forth, effectively transferring energy. This action allows for precise movement of the cutting components, ensuring a clean and effective operation. Understanding this mechanism is fundamental for maintaining the implement’s efficiency.

Importance of Regular Maintenance

Regular inspection and maintenance of the pitman arm are vital for sustained performance. Wear and tear can lead to inefficiencies and potential failures in the system. By ensuring that this component remains in good condition, operators can enhance the overall functionality of their equipment, leading to better results in the field.

Belt and Pulley Alignment Techniques

Proper alignment of belts and pulleys is crucial for the efficient functioning of various machinery. Misalignment can lead to premature wear, increased energy consumption, and even mechanical failure. Therefore, understanding the techniques for ensuring correct alignment is essential for maintaining equipment longevity and performance.

One effective method for checking alignment involves using a straightedge or laser alignment tool. By placing the tool along the length of the pulleys, operators can visually assess whether the surfaces are aligned. Adjustments can then be made to reposition the pulleys for optimal alignment.

Another technique involves the use of alignment marks. By marking reference points on both pulleys, users can monitor any changes in alignment during operation. Regularly checking these marks can help identify misalignment before it leads to more significant issues.

Additionally, tensioning the belt appropriately is vital for maintaining alignment. An overly tight or loose belt can cause the pulleys to shift, leading to misalignment. Using a tension gauge can help achieve the correct tension, ensuring that the system operates smoothly.

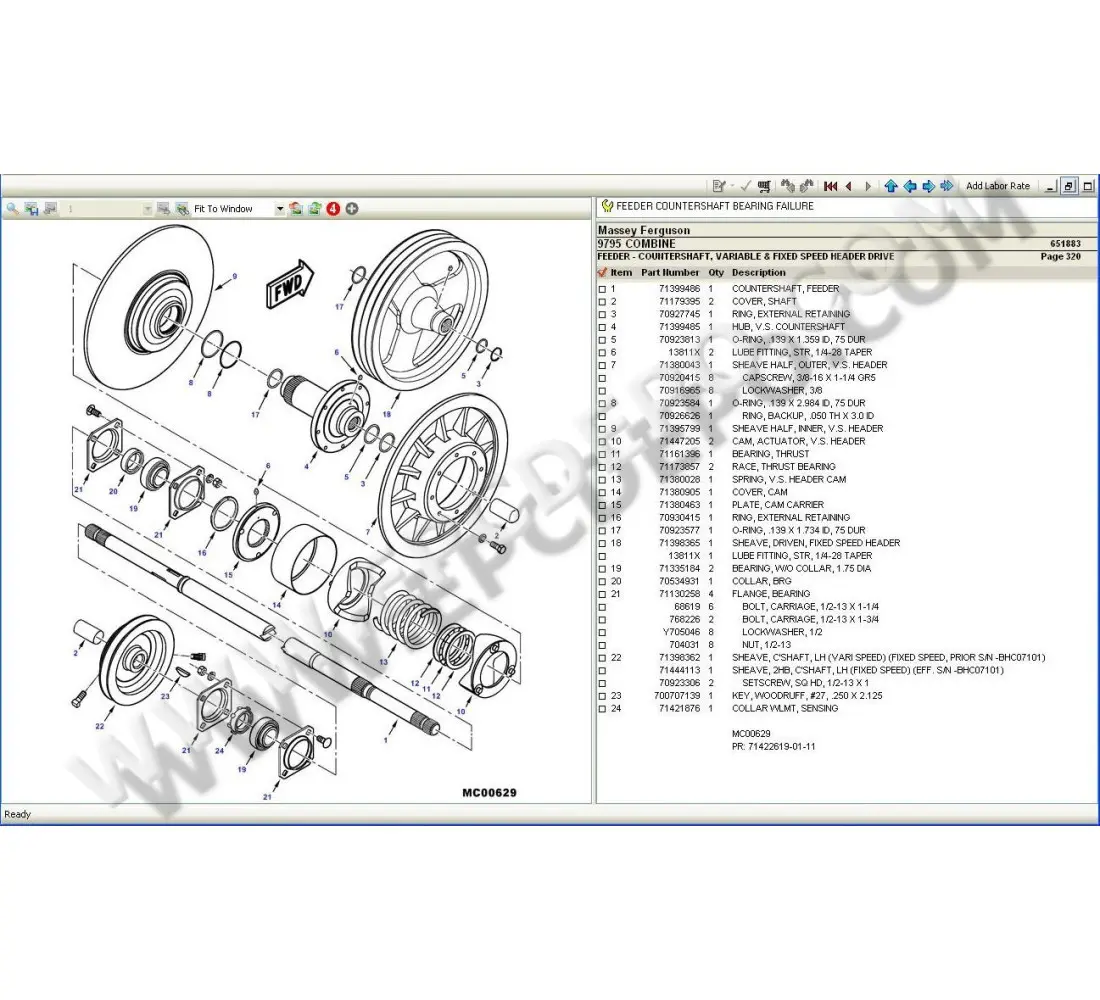

Troubleshooting Gearbox Performance

When dealing with the efficiency of a transmission system, it is essential to identify potential issues that may hinder optimal functionality. Understanding the common problems and their underlying causes can significantly enhance performance and longevity.

Common Symptoms: Various indicators suggest gearbox malfunction, such as unusual noises, overheating, or erratic movements. Recognizing these signs early can prevent further complications and costly repairs.

Diagnosis Steps: Begin by examining the fluid levels and quality, as inadequate lubrication can lead to excessive wear. Listen for abnormal sounds during operation, which may indicate worn gears or bearing issues. Additionally, inspect for any signs of leakage that could compromise the system’s integrity.

Solutions: If low fluid levels are detected, replenish with the appropriate lubricant. For unusual noises, consider disassembling the unit to assess gear condition and replace any damaged components. Regular maintenance and timely interventions are crucial for sustaining optimal gearbox functionality.

Grease Points and Lubrication Needs

Proper maintenance of machinery is essential for ensuring optimal performance and longevity. One of the critical aspects of upkeep involves addressing lubrication requirements at various points throughout the equipment. Regularly lubricating these areas not only minimizes wear and tear but also prevents potential breakdowns, contributing to the overall efficiency of the machine.

Identifying Key Lubrication Areas

To maintain smooth operation, it is crucial to identify the key areas that require grease application. Focus on joints, bearings, and pivot points, as these components are subject to significant movement and friction. Regular inspection of these locations will help to ensure that they are adequately lubricated, reducing the risk of damage over time.

Recommended Lubrication Schedule

Establishing a lubrication schedule based on the manufacturer’s recommendations can significantly enhance the performance of the equipment. Depending on usage, some areas may need more frequent greasing than others. Keep track of usage patterns and environmental conditions, adjusting the schedule as necessary to maintain optimal function.

Where to Find Spare Parts

Locating essential components for agricultural machinery can often be a challenge. However, various reliable sources are available that can assist in acquiring the necessary items. It is important to explore multiple avenues to ensure the best quality and pricing for these essential replacements.

One effective way to obtain these items is through specialized suppliers who focus on agricultural equipment. These vendors typically carry a wide range of options and can provide valuable insights into compatibility and functionality. Additionally, many manufacturers offer online catalogs that feature detailed listings of available replacements, making it easier to identify the required components.

Furthermore, online marketplaces have become a popular option for sourcing these essentials. Websites that specialize in farming equipment often host a variety of listings from different sellers, allowing for easy price comparisons. Utilizing forums and community groups related to agriculture can also yield helpful recommendations for trusted suppliers.

In conclusion, whether seeking components from local dealers or exploring online options, a proactive approach can lead to successful procurement of necessary replacements for your machinery.