The efficient operation of lawn maintenance machinery relies heavily on a comprehensive understanding of its individual elements. Each component plays a vital role in ensuring optimal performance, contributing to the overall functionality of the equipment. Familiarity with these components allows users to troubleshoot issues effectively and maintain their devices for prolonged use.

In this section, we delve into the various elements that make up lawn maintenance tools. By examining their relationships and functions, users can gain insights into how these pieces work together to achieve desired results. Recognizing the significance of each part empowers users to make informed decisions when it comes to repairs and replacements.

Furthermore, understanding these individual units facilitates better care and maintenance practices. Proper knowledge can enhance longevity and efficiency, leading to more effective and satisfying lawn care experiences. Exploring the intricacies of these elements opens the door to improved performance and reliability in everyday tasks.

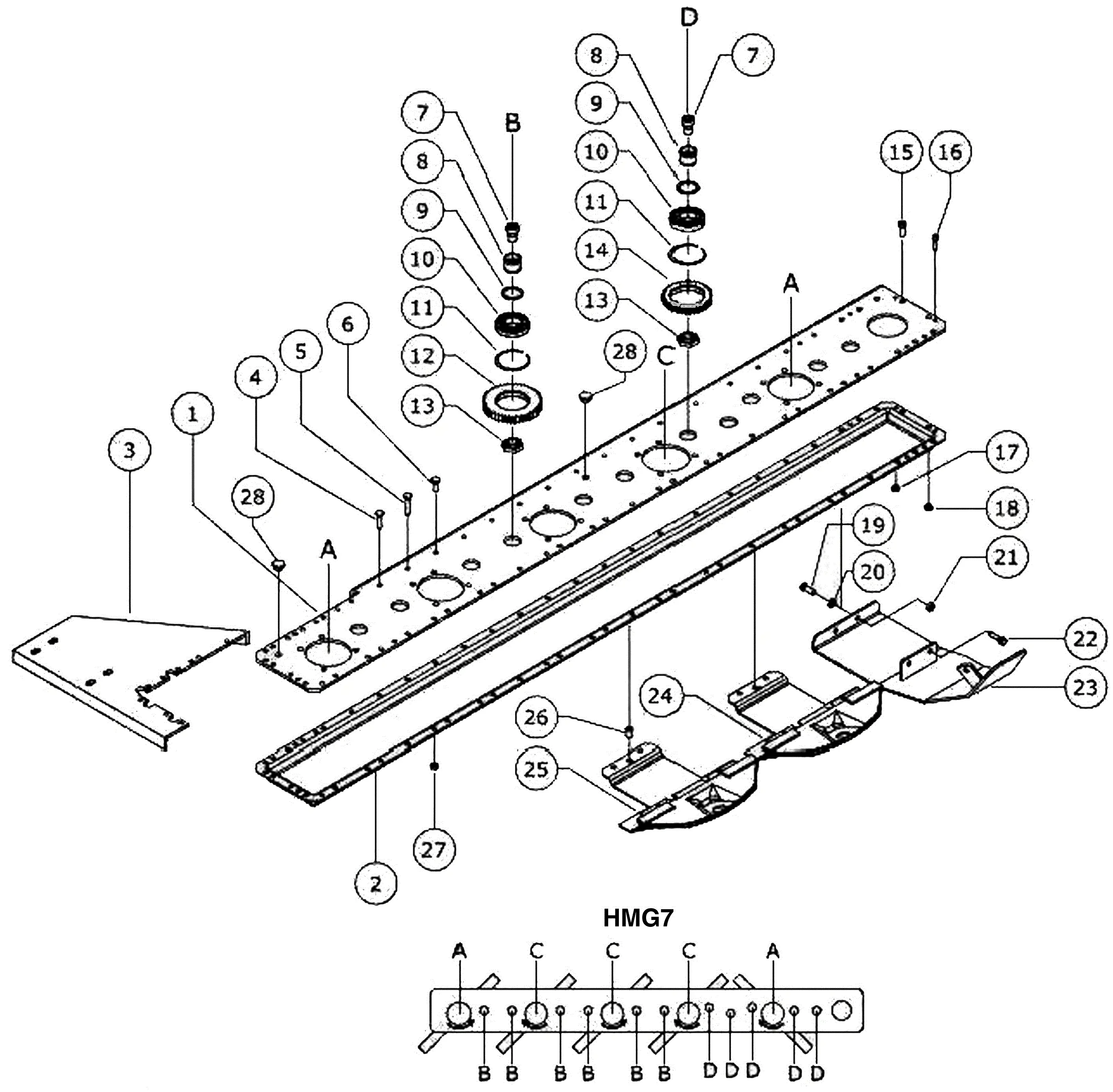

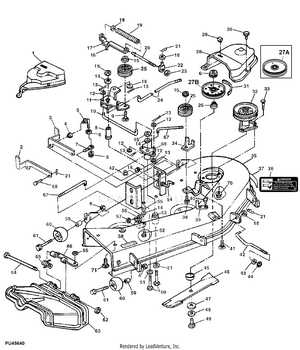

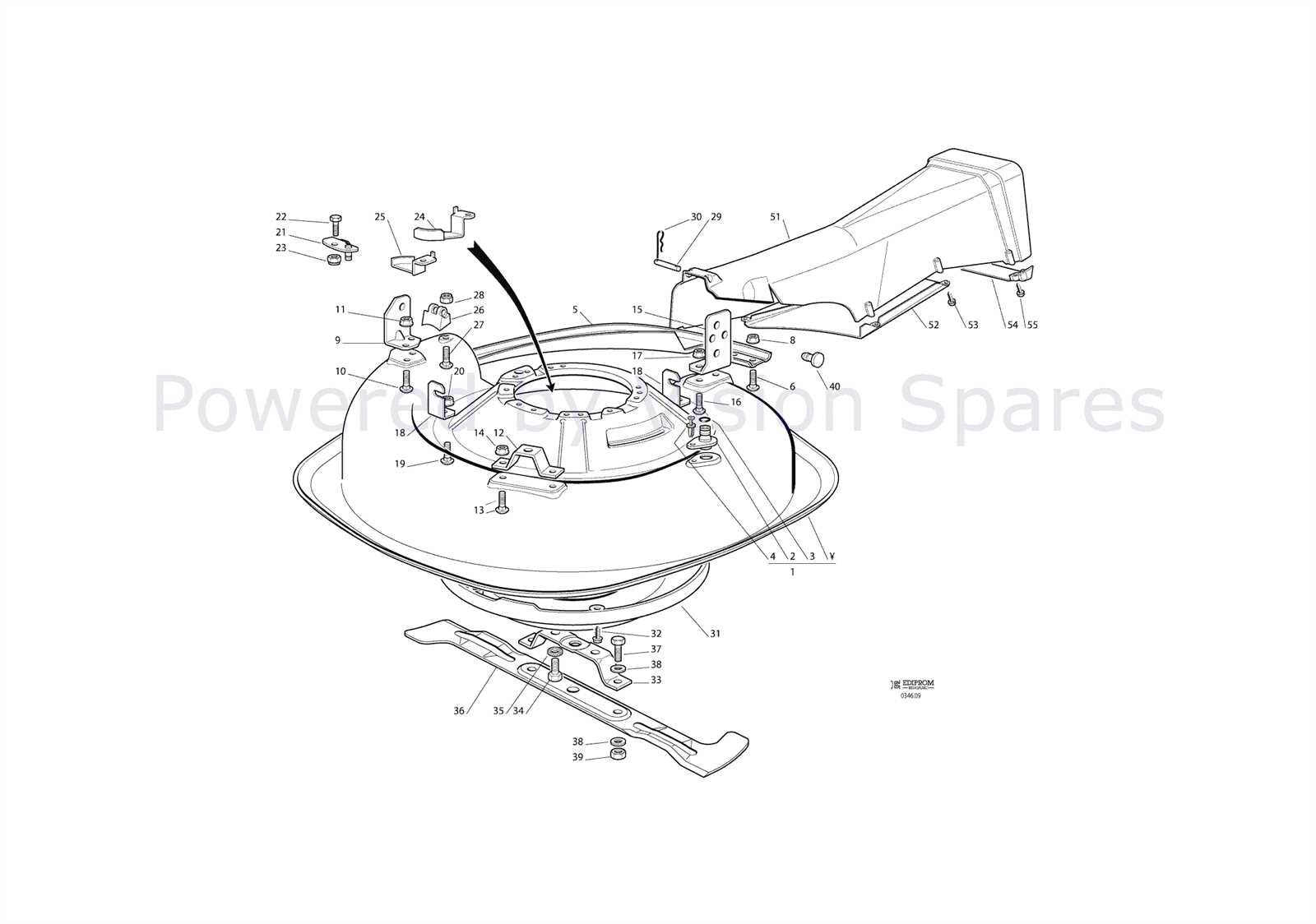

Mower Parts Diagram

This section explores the essential components of a grass cutting machine, providing insights into their arrangement and functionality. Understanding the layout of these elements is crucial for effective maintenance and repair, ensuring the equipment operates smoothly and efficiently.

Here are the key features typically represented in such illustrations:

- Engine: The heart of the equipment, responsible for providing power.

- Deck: The structure that houses the cutting mechanism, protecting the internal components.

- Blades: Sharp implements designed to cut grass at various heights.

- Wheels: Essential for mobility, allowing movement across different terrains.

- Handle: Provides control and maneuverability during operation.

- Fuel Tank: Stores the fuel required for operation, ensuring the engine runs efficiently.

Recognizing these features can enhance your understanding of how to care for the machine effectively. Familiarity with the configuration of these components helps in troubleshooting issues and performing necessary repairs.

Understanding Mower Components

Grasping the intricacies of a cutting machine is essential for effective maintenance and operation. Familiarity with its various elements enhances performance and prolongs lifespan. This section delves into the fundamental components, shedding light on their roles and significance.

Key elements include:

- Engine: The heart of the equipment, responsible for generating power.

- Deck: The housing that protects and supports the cutting mechanism.

- Blades: Essential for achieving a clean cut; different designs cater to specific needs.

- Wheels: Provide mobility, ensuring smooth operation over various terrains.

- Handle: Enables control and maneuverability, often adjustable for comfort.

Understanding the function of each component allows for better troubleshooting and repair. Regular inspections and maintenance can prevent costly issues, ensuring the machine operates efficiently and effectively throughout its lifespan.

Importance of Accurate Diagrams

Accurate visual representations play a crucial role in understanding the intricacies of mechanical systems. These illustrations provide clarity and enhance comprehension, ensuring users can effectively navigate through components and their functionalities.

Enhanced Understanding

Detailed visuals help users grasp complex mechanisms by breaking down intricate systems into manageable sections. This leads to:

- Improved troubleshooting capabilities

- Better maintenance practices

- Increased efficiency in assembly and disassembly

Effective Communication

Clear visuals facilitate communication among users, technicians, and manufacturers. This fosters:

- Standardized terminology

- Reduction in errors during repairs

- Streamlined collaboration in team environments

In summary, precise illustrations are indispensable for promoting understanding and ensuring effective communication, ultimately leading to enhanced performance and reliability in mechanical systems.

Common Parts in Lawn Mowers

Understanding the essential components of a grass cutting machine is crucial for effective maintenance and repair. Each element plays a vital role in ensuring the smooth operation of the equipment, contributing to its efficiency and longevity.

Typically, these machines consist of several key elements that work in unison. Below is a table outlining some of the most common components, along with their functions:

| Component | Function |

|---|---|

| Engine | Powers the equipment, enabling it to operate and perform cutting tasks. |

| Blades | Designed to cut grass efficiently, these rotating elements are fundamental for achieving a clean cut. |

| Deck | Houses the cutting mechanism and protects other components from debris and grass clippings. |

| Wheels | Facilitate mobility across different terrains, allowing for smooth maneuvering. |

| Handle | Provides the user with control and guidance during operation. |

Identifying Wear and Tear

Over time, regular use of any mechanical equipment leads to the natural degradation of its components. Recognizing early signs of wear is crucial for ensuring smooth operation and preventing potential malfunctions. Paying attention to subtle changes can help avoid larger issues and costly repairs down the line.

Common Symptoms of Deterioration

Physical indicators such as cracks, rust, or thinning on metallic surfaces suggest that parts have been subjected to excessive stress. Additionally, changes in performance, such as unusual noises or decreased efficiency, are often linked to internal wear.

Addressing the Issue Early

Routine inspections should focus on both

Tools for Diagram Interpretation

Understanding technical blueprints or schematics requires more than just a glance. A comprehensive approach involves familiarizing oneself with the various instruments and resources that facilitate the decoding of complex visual information. These tools enhance the ability to navigate through intricate connections and ensure proper comprehension of the presented layout.

The most essential resources include specialized software designed to zoom in on fine details, making it easier to focus on individual components. Additionally, standardized symbols play a crucial role in providing a uniform language across different types of schematics, allowing users to quickly recognize and interpret key elements without confusion. Reference guides are also indispensable, offering quick access to explanations of unfamiliar elements and their functions within the design.

In conjunction with digital tools, traditional physical instruments such as magnifiers can still prove useful for close inspection of

Repair vs. Replacement Decisions

When equipment begins to show signs of wear or malfunction, deciding whether to fix it or invest in a new one can be a difficult choice. Both options have their own set of advantages, and the right decision depends on various factors that go beyond immediate costs.

Repairing offers the benefit of extending the life of existing tools and often comes with lower upfront expenses. However, repeated repairs can become costly in the long term, especially if the underlying issues continue to resurface. Additionally, repair may not always restore the equipment to its full efficiency, leaving it prone to further breakdowns.

On the other hand, replacing old equipment can bring long-term savings by reducing future maintenance needs and in

Maintenance Tips for Longevity

Regular care and attention are essential to ensure that your equipment functions smoothly and lasts for years. Consistent upkeep helps prevent wear and tear, saving you from costly repairs and downtime. By following simple steps, you can maximize the efficiency and durability of your machine.

- Clean after each use: Make it a habit to thoroughly clean all components. Dirt and debris can accumulate and impact performance over time.

- Check fluid levels regularly: Inspect oil and fuel levels to ensure everything is properly lubricated and operating at optimal levels.

- Sharpen blades periodically: Dull edges reduce efficiency, leading to uneven results and unnecessary strain on the engine.

- Inspect

Sources for Replacement Parts

Finding reliable sources for components is essential for maintaining your equipment’s efficiency. Whether you are looking for specific items or general supplies, knowing where to look can save you time and money.

Online Retailers: Numerous e-commerce platforms specialize in various accessories. These sites often provide extensive catalogs and user reviews, which can help in making informed choices.

Local Dealerships: Many authorized dealers offer a range of essential items tailored to specific brands. This option often guarantees compatibility and quality, making it a reliable choice.

Salvage Yards: For those seeking budget-friendly options, salvage yards can be a treasure trove. These locations may have used but functional components that are still in good condition.

Manufacturer Websites: Visiting the official websites of brands can provide direct access to original equipment. This ensures authenticity and often includes useful information on installation and compatibility.

Forums and Community Groups: Engaging with online communities can lead to valuable recommendations. Members often share their experiences and can point you towards trustworthy sources.

By exploring these avenues, you can effectively locate the necessary components to keep your equipment operating at its best.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. By following specific guidelines, individuals can create a secure environment that minimizes risks while working with machinery.

Proper Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is essential. This includes safety goggles to protect the eyes from debris, gloves to safeguard hands from sharp edges, and ear protection if noise levels are high. By taking these precautions, one can significantly reduce the likelihood of injury.

Work Environment Considerations

Maintaining a clean and organized workspace is vital. Ensure that tools are easily accessible and that the area is free from clutter. Additionally, working on a stable surface will help prevent accidents. Always be mindful of surroundings, and never rush through tasks, as patience often leads to safer outcomes.

Upgrading Mower Features

Enhancing the functionalities of your lawn care equipment can significantly improve its performance and user experience. By integrating advanced technologies and additional capabilities, you can ensure more efficient operation and better results in maintaining your outdoor spaces. This section explores various upgrades that can transform your machine into a more effective tool for landscaping tasks.

Consider the following enhancements to elevate your equipment’s capabilities:

Upgrade Description Benefits Electric Start Switch from manual to electric ignition for easier starting. Convenience and reduced effort for users. Mulching Kit Install a system that finely cuts grass clippings for nutrient recycling. Improved lawn health and reduced waste disposal. Self-Propelled Mechanism Upgrade to a self-propelled system to ease maneuverability. Less physical strain and quicker coverage of larger areas. Advanced Blade Technology Replace blades with high-performance alternatives for cleaner cuts. Enhanced cutting efficiency and reduced wear. Smart Sensors Integrate sensors for automatic height adjustment based on terrain. Consistent results and reduced manual adjustments. Implementing these enhancements can lead to a more enjoyable and effective landscaping experience. Evaluate which upgrades align with your needs to optimize your outdoor maintenance routine.

Learning from Professional Resources

Gaining knowledge from expert materials is essential for anyone looking to enhance their understanding of machinery and equipment maintenance. These resources provide invaluable insights that can help individuals troubleshoot issues effectively and improve their skills. By delving into well-researched documentation, one can learn about the various components and their functionalities, leading to a more comprehensive grasp of the subject.

Benefits of Expert Guidance

Utilizing professional resources offers numerous advantages. Firstly, it ensures that the information is accurate and up-to-date, which is crucial for effective repairs and maintenance. Additionally, these materials often include detailed illustrations and step-by-step instructions, making complex processes easier to understand. Furthermore, accessing industry knowledge can inspire confidence in tackling various challenges.

Where to Find Quality Information

There are several platforms where one can locate credible resources. Online databases, manufacturer websites, and specialized forums are excellent starting points. Moreover, attending workshops or webinars led by industry professionals can further enhance learning experiences. Engaging with these resources not only broadens knowledge but also fosters a community of like-minded individuals eager to share insights and experiences.