Maintaining a pristine outdoor space requires not just skill, but also a thorough understanding of the machinery that aids in this task. The efficiency and longevity of your lawn maintenance tools often depend on the proper knowledge of their individual elements and how they work together. This section delves into the intricate assembly of these machines, shedding light on the various components that contribute to their performance.

Each piece of equipment is a complex system, where every part plays a crucial role in ensuring effective operation. Whether it’s the engine, blades, or transmission, understanding how these elements interact can lead to better maintenance practices and more successful outcomes. By familiarizing oneself with these essential elements, users can enhance their equipment’s reliability and ultimately their overall lawn care experience.

In this exploration, we will present a detailed overview of the structural organization of lawn maintenance machinery, focusing on how different sections work in unison. This knowledge not only empowers users to troubleshoot issues but also assists in making informed decisions regarding repairs and upgrades, ensuring that every session of outdoor work is as productive as possible.

Poulan Pro Mower Parts Overview

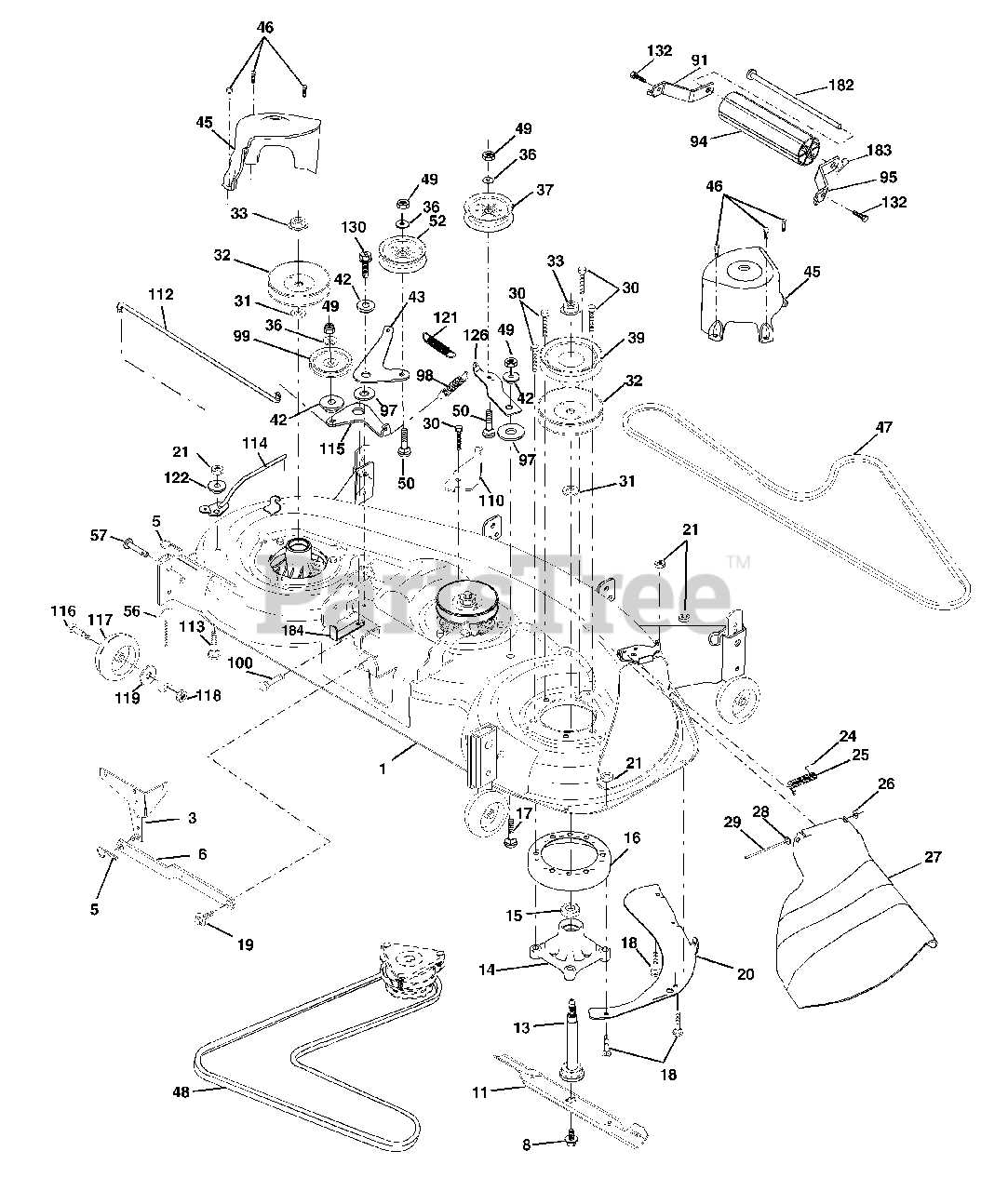

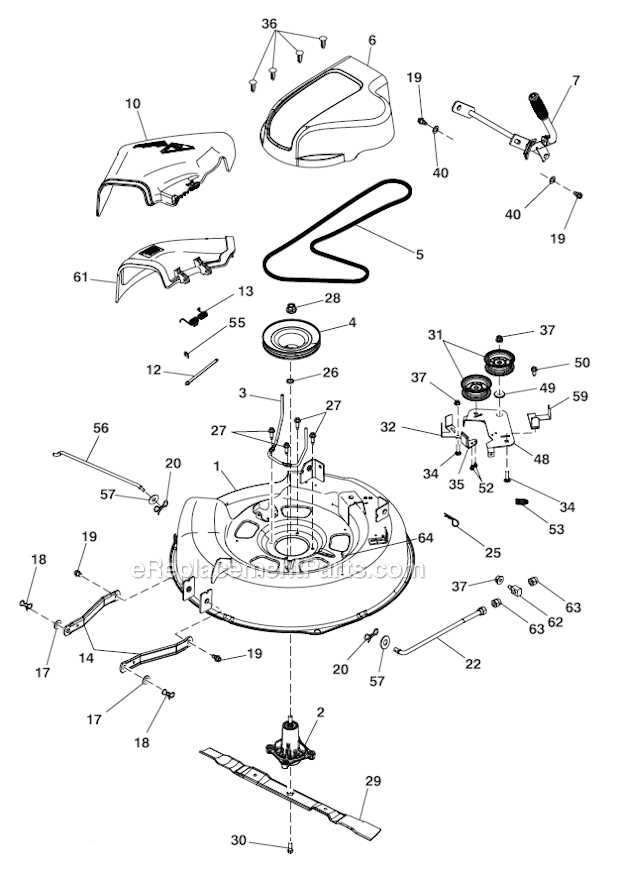

This section provides an insightful look into the essential components of a popular outdoor maintenance tool. Understanding these elements is crucial for efficient operation and maintenance. Each component plays a vital role in ensuring the equipment functions optimally.

Main Components

- Engine: The powerhouse that drives the entire unit.

- Deck: The body housing the cutting mechanism, designed for durability.

- Blades: Sharp elements responsible for achieving a clean cut.

- Wheels: Facilitate movement and maneuverability across various terrains.

- Fuel System: Supplies energy to the engine for operation.

Maintenance Tips

- Regularly check and sharpen the blades for efficiency.

- Inspect the engine and replace filters as needed.

- Keep the deck clean to prevent grass buildup.

- Monitor the fuel system for leaks or clogs.

- Examine the wheels and ensure proper inflation and alignment.

Understanding Mower Components

Gaining insight into the various elements of a lawn maintenance machine is essential for effective operation and maintenance. Each component plays a critical role in ensuring optimal performance and longevity.

| Component | Function |

|---|---|

| Engine | Drives the entire system, providing power for operation. |

| Blade | Responsible for cutting grass, varying in design for different tasks. |

| Deck | Encloses the blade, influencing cutting height and quality. |

| Wheels | Facilitate movement and maneuverability across different terrains. |

| Handle | Provides control and stability while operating the machine. |

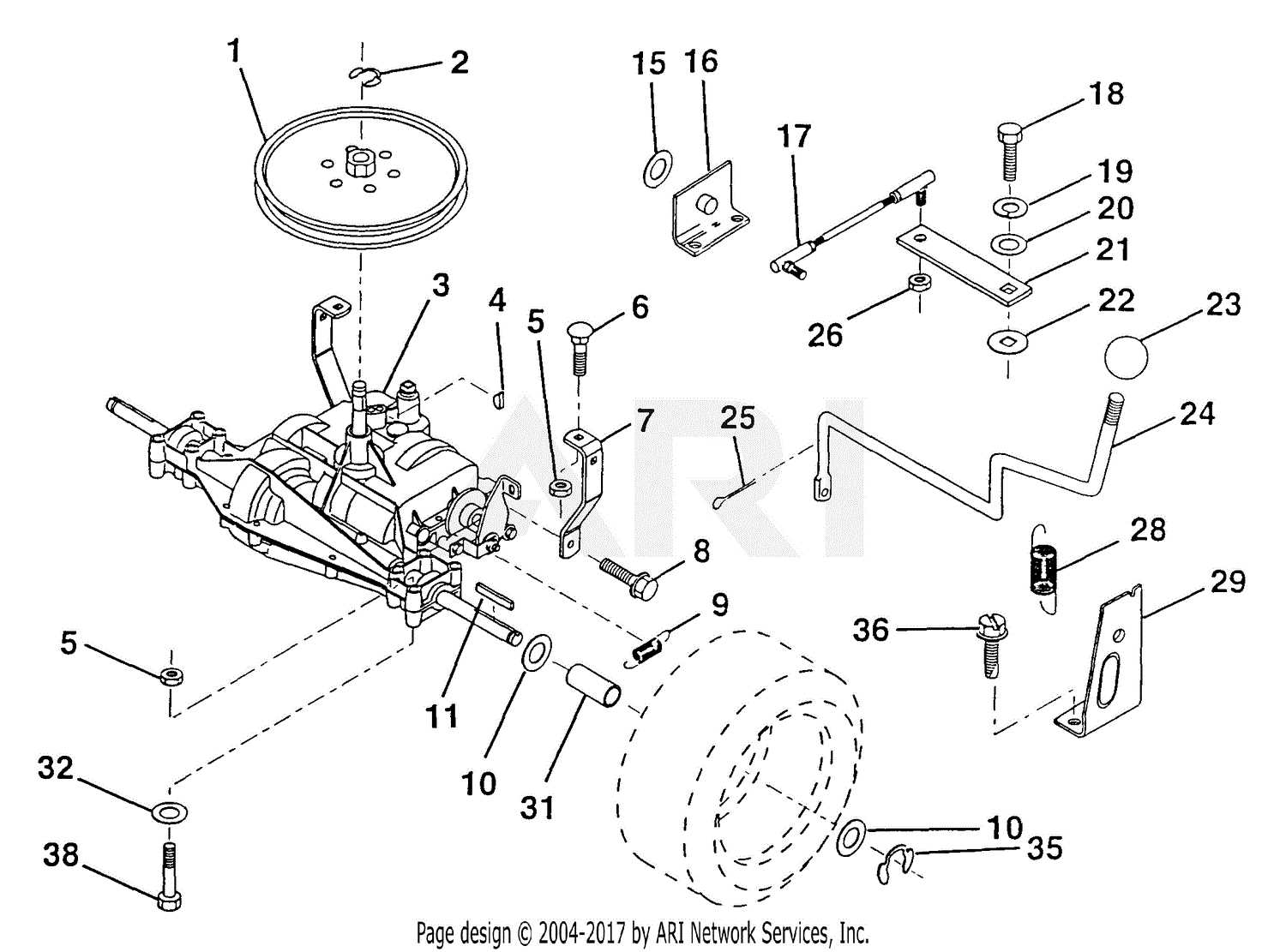

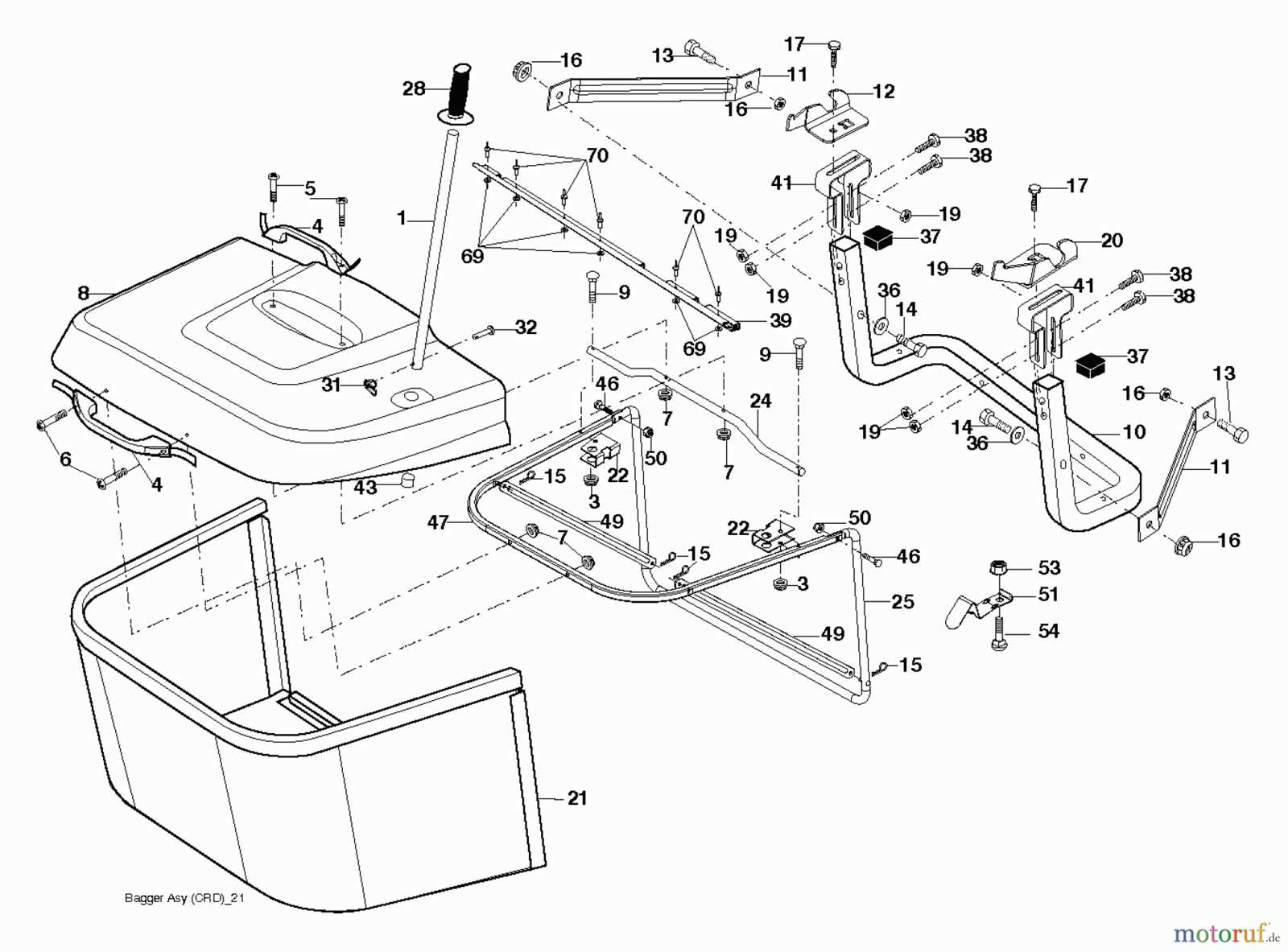

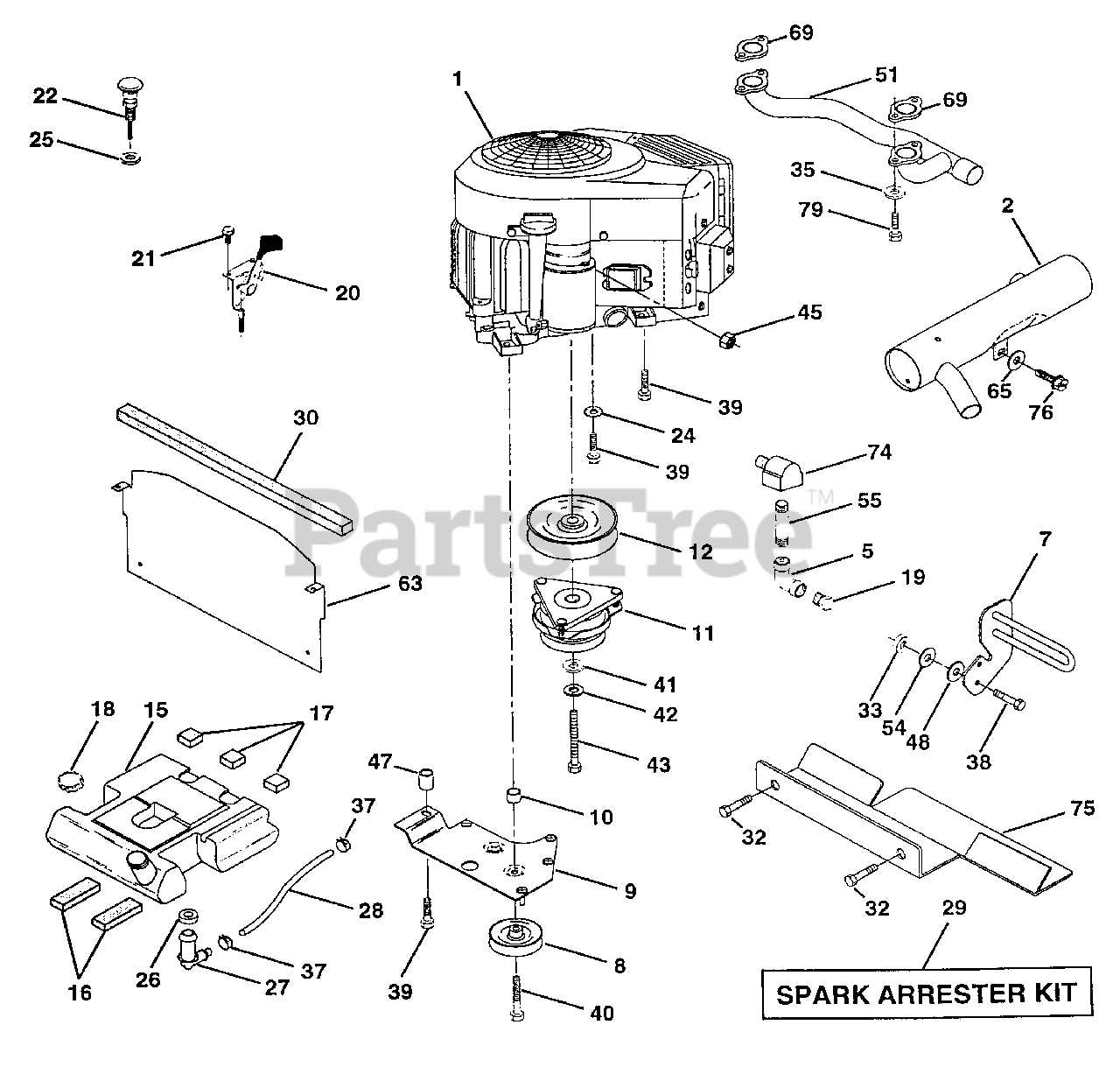

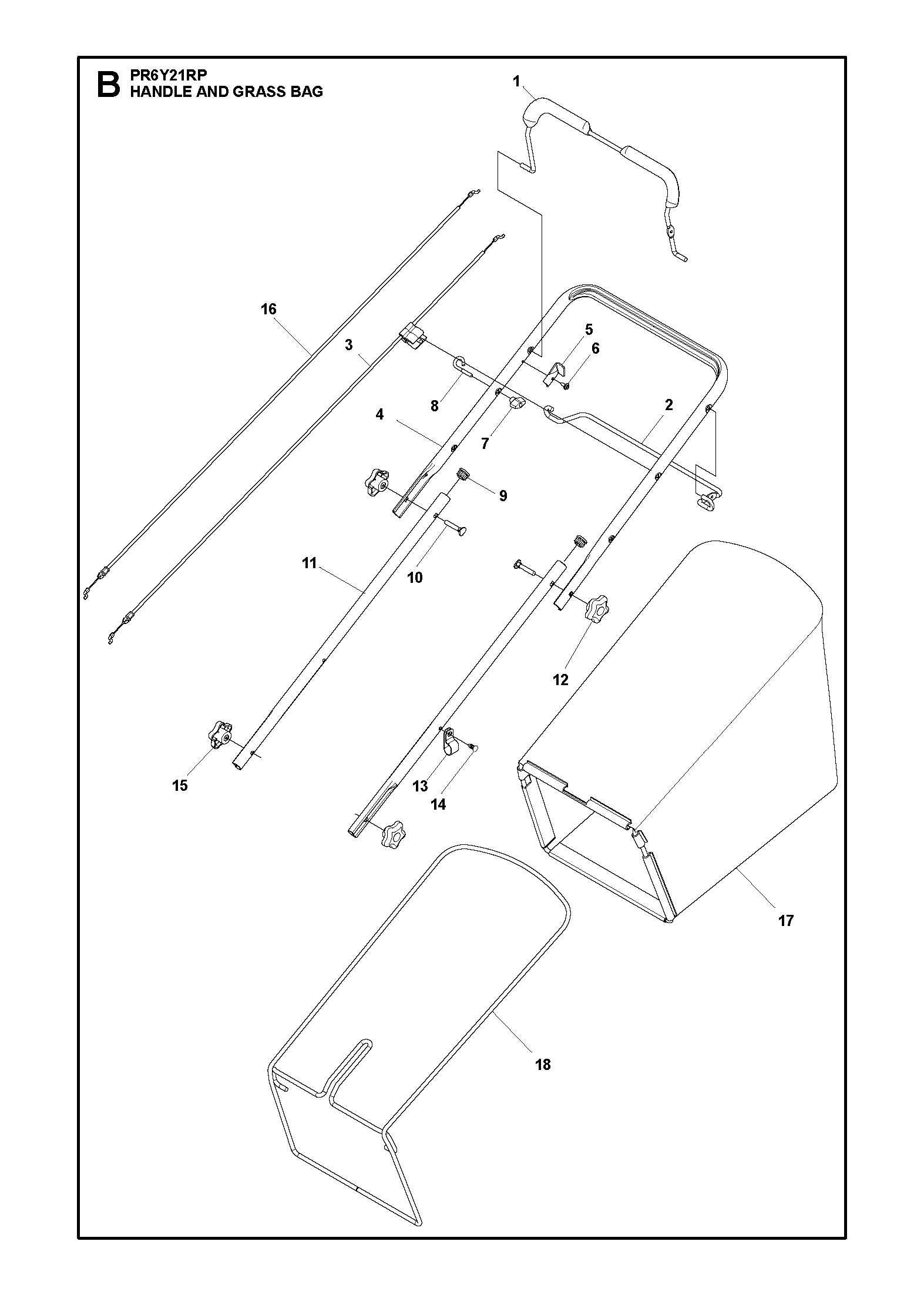

Importance of Accurate Diagrams

Precise illustrations are crucial for ensuring that equipment maintenance and repairs are carried out effectively. They provide a clear representation of components, allowing users to understand the relationships and functions of various elements within a system.

Without detailed visuals, the risk of errors during assembly or troubleshooting increases significantly. Accurate depictions can save time and resources, guiding users through complex processes with ease. Furthermore, they enhance safety by helping individuals identify potential hazards associated with specific parts.

In essence, having reliable visual aids is essential for anyone looking to delve into the mechanics of their tools. They empower users to execute tasks with confidence, ultimately leading to better performance and longevity of equipment.

Common Issues with Mower Parts

When it comes to the maintenance of grass-cutting equipment, various complications can arise that hinder performance. Understanding these typical problems can help owners diagnose issues more effectively and enhance the longevity of their machines. Regular inspections and awareness of potential failures can save time and effort in the long run.

Frequent Problems Encountered

Several common issues can disrupt the functionality of cutting equipment. Identifying these can lead to quicker resolutions and a more efficient operation.

| Issue | Description | Potential Solutions |

|---|---|---|

| Clogged Blades | Debris accumulation can impede cutting efficiency. | Regular cleaning and maintenance. |

| Worn Belts | Belts may fray or become loose over time, affecting power transfer. | Periodic checks and replacements as needed. |

| Inefficient Engine | Engines can struggle due to fuel issues or spark plug problems. | Ensure clean fuel and check spark plugs regularly. |

| Faulty Starter | Difficulty in starting can arise from electrical or mechanical faults. | Inspect wiring and connections; replace faulty components. |

Preventive Measures

Taking proactive steps can mitigate many of these issues. Regular servicing, including lubrication and component checks, can prevent minor problems from escalating into major repairs. Familiarity with common failures equips operators with the knowledge to maintain optimal performance.

Where to Find Diagrams

Locating comprehensive schematics for outdoor equipment can be essential for maintenance and repairs. Various resources are available to assist users in finding accurate representations of components and their arrangements. These visuals are invaluable for understanding assembly, troubleshooting, and ensuring proper function.

Here are some reliable sources to consider:

| Source | Description |

|---|---|

| Official Manufacturer Websites | Many brands provide downloadable manuals and schematics directly on their websites. This ensures you get the most accurate and up-to-date information. |

| Online Retailers | Several online stores that sell equipment may also have sections dedicated to manuals, allowing you to view or download needed visuals. |

| Forums and Community Groups | Joining online forums can connect you with experienced users who often share diagrams and tips for maintenance and repairs. |

| Repair Guides | Websites that specialize in repair guides may offer detailed schematics alongside step-by-step instructions for various tasks. |

| Local Dealerships | Visiting local dealerships can provide access to printed materials and the opportunity to ask for guidance from knowledgeable staff. |

Utilizing these resources can significantly enhance your understanding of equipment components and improve your ability to perform repairs effectively.

Step-by-Step Repair Guide

This section aims to provide a comprehensive approach to repairing your lawn care equipment effectively. Whether you are facing minor issues or major malfunctions, following a structured guide can simplify the process and enhance your confidence in handling repairs.

1. Identify the Issue: Begin by diagnosing the problem. Listen for unusual sounds, check for leaks, and observe performance. Document any symptoms to pinpoint the root cause.

2. Gather Necessary Tools: Collect all required tools and replacement items before starting the repair. Common tools may include wrenches, screwdrivers, and safety gear.

3. Refer to the Manual: Consulting the user manual is essential. It provides specific guidance and safety instructions tailored to your equipment model, ensuring proper procedures are followed.

4. Disassemble Components: Carefully take apart the relevant sections of the machine. Keep track of screws and small pieces by using labeled containers to avoid losing them during the process.

5. Replace or Repair: Based on your initial diagnosis, either replace the damaged components or attempt to repair them. Ensure that all replacement parts are compatible and of high quality.

6. Reassemble the Equipment: Once repairs are complete, reassemble the parts in reverse order. Double-check that all components are securely fastened to avoid any operational issues.

7. Test the Equipment: After reassembly, conduct a thorough test to ensure everything is functioning correctly. Monitor for any irregularities and address them promptly.

8. Maintain Regular Checks: To prolong the lifespan of your equipment, schedule routine maintenance checks. Keeping everything in good condition can prevent future breakdowns and save you time and effort.

Tips for Maintenance and Care

Proper upkeep is essential for ensuring the longevity and efficiency of your equipment. Regular attention can prevent issues and enhance performance, making your tasks smoother and more enjoyable.

- Check and clean filters regularly to ensure optimal airflow.

- Sharpen blades consistently to maintain cutting efficiency.

- Inspect belts and cables for wear and tear, replacing them as needed.

- Change the oil periodically to keep the engine running smoothly.

- Store your equipment in a dry place to prevent rust and damage.

By following these guidelines, you can significantly improve the reliability and effectiveness of your machine.

Upgrading Your Mower Parts

Enhancing the components of your cutting machine can significantly improve its performance and longevity. By selecting higher-quality or advanced alternatives, you not only optimize functionality but also create a more enjoyable experience while maintaining your landscape.

Benefits of Upgrading

Investing in superior elements can lead to enhanced efficiency and reliability. Upgrades can also reduce maintenance costs in the long run, making your investment worthwhile. Improved durability and performance are key advantages that come with these enhancements.

Choosing the Right Components

When considering upgrades, it’s crucial to research compatible options that align with your specific machine. Look for reputable brands and consult with experts to ensure you make informed choices. Delving into customer reviews and product specifications can guide you toward the ultimate upgrades for your needs.

Frequently Asked Questions

This section addresses common inquiries related to equipment maintenance and component identification. Whether you are troubleshooting or seeking to understand various aspects of your machine, these questions and answers aim to provide clarity and assistance.

General Inquiries

| Question | Answer |

|---|---|

| What should I do if my machine won’t start? | Check the fuel level, battery condition, and ensure all safety features are engaged. If issues persist, consult the manual for troubleshooting steps. |

| How often should I perform maintenance? | Regular maintenance should be conducted at least once a season or after every 25 hours of use, depending on your operational frequency. |

Component Specifics

| Question | Answer |

|---|---|

| Where can I find replacement components? | Replacement items can typically be found at authorized retailers, online stores, or directly through the manufacturer’s website. |

| How can I identify the correct part for my machine? | Refer to the user manual for part numbers and specifications. You can also check online resources for diagrams that match your model. |

Comparing Different Models

When exploring various outdoor equipment, it’s essential to analyze the differences among the available options. Each version brings unique features and specifications that cater to diverse needs and preferences.

Performance is a crucial factor; some variants are designed for efficiency on larger landscapes, while others excel in maneuverability for smaller areas. Durability also varies, with certain models featuring reinforced components for rugged use, which can be beneficial for frequent tasks.

Additionally, maintenance requirements can differ significantly, impacting long-term ownership costs. Understanding these distinctions allows users to make informed decisions based on their specific requirements and the ultimate utility of the equipment.

Best Practices for Safe Operation

Ensuring a safe working environment is crucial when operating outdoor equipment. Adhering to specific guidelines can significantly reduce the risk of accidents and injuries.

- Always wear appropriate safety gear, including gloves, goggles, and sturdy footwear.

- Inspect the machine before each use to check for any damages or loose components.

- Maintain a clear workspace, free from debris and obstacles.

- Follow the manufacturer’s instructions for operation and maintenance.

- Keep bystanders, especially children and pets, at a safe distance during use.

By implementing these practices, operators can maximize safety and efficiency while minimizing hazards.

Resources for Further Learning

Exploring the intricacies of lawn care equipment can greatly enhance your maintenance skills and knowledge. There are numerous avenues available for those eager to dive deeper into this subject, from online tutorials to community forums. Each resource provides unique insights that can empower you to tackle various challenges effectively.

Online Tutorials: Numerous websites offer step-by-step guides and video demonstrations that cover a wide range of topics related to maintenance and repair. These resources are invaluable for visual learners who benefit from seeing processes in action.

Community Forums: Engaging in discussions with fellow enthusiasts can provide practical advice and solutions. Many online platforms host forums where users share their experiences, troubleshoot problems, and exchange tips, fostering a collaborative learning environment.

Manufacturer Websites: Official sites often feature detailed manuals, troubleshooting guides, and FAQs that can clarify common issues. Accessing these resources can help you understand the specifics of your equipment and its optimal operation.

Books and Manuals: For those who prefer traditional learning methods, various books and maintenance manuals are available. These texts can offer comprehensive information on care techniques, equipment operation, and even safety precautions.

Workshops and Classes: Many local community centers or equipment retailers host hands-on workshops. Participating in these can provide practical experience and direct guidance from experienced instructors.

By leveraging these diverse resources, you can expand your understanding and improve your skills, ensuring your equipment remains in excellent condition for years to come.