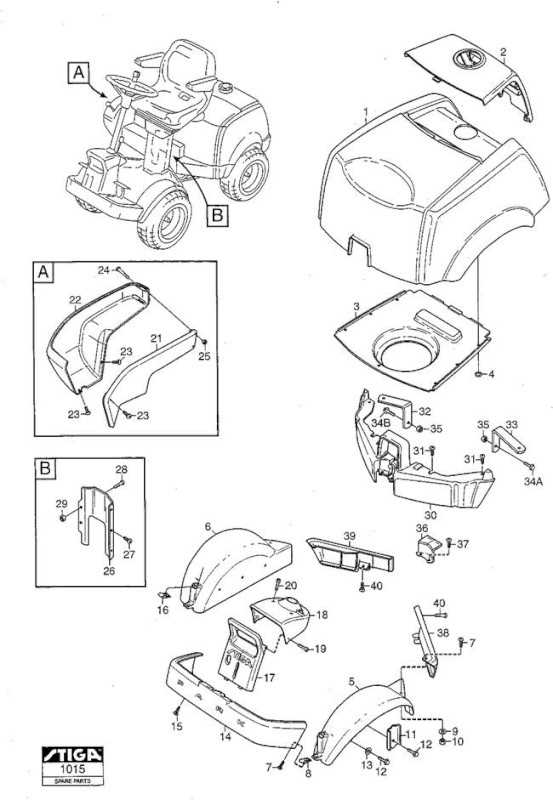

When it comes to maintaining outdoor equipment, having a clear view of its internal structure is essential. Knowing the individual elements and how they interact can make all the difference in ensuring efficient operation and extending the lifespan of the device.

Breaking down the structure into its various sections can provide a more detailed insight into its overall functionality. Identifying each element’s role within the system helps in diagnosing issues and performing routine maintenance with greater accuracy.

Whether you’re replacing worn-out sections or simply familiarizing yourself with the inner workings, a thorough understanding of each segment is invaluable. This approach enables users to keep their equipment in peak condition, ready to tackle any task efficiently.

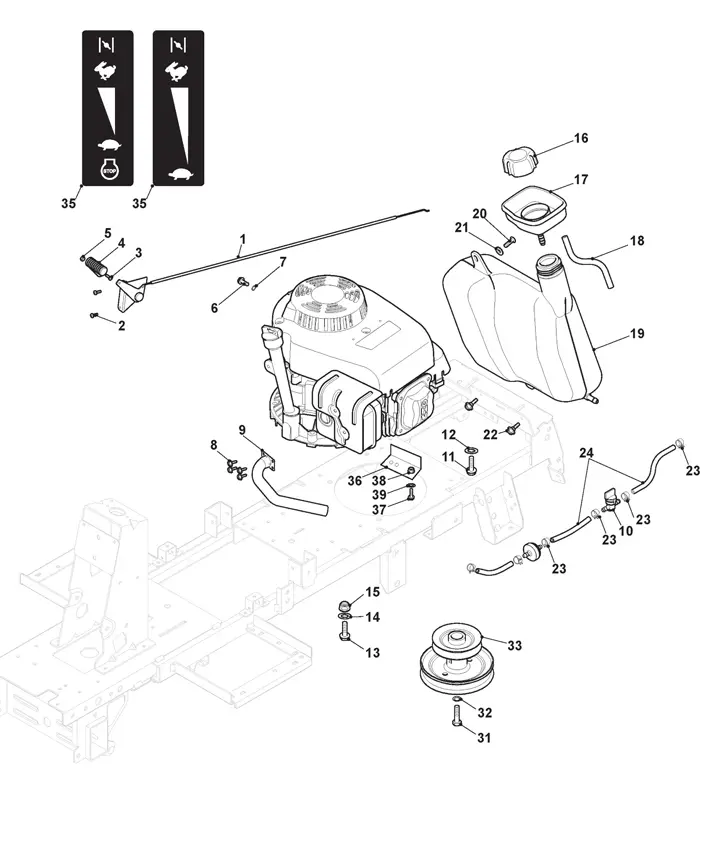

Understanding the Engine Assembly

The central mechanical unit plays a crucial role in ensuring efficient operation and consistent performance. This section focuses on examining the arrangement of various components that work together to generate power and deliver reliable functionality.

Within this assembly, each element has a precise location and a specific function. From the ignition system to the fuel mechanism, understanding how these parts interact is essential for maintenance and troubleshooting. Proper alignment and calibration are key to optimizing overall efficiency and preventing potential issues.

Key elements of this system include the combustion chamber, crankshaft, and valves, each of which contributes to the smooth operation of the machine. Regular inspections and adjustments can significantly extend the lifespan of these components and enhance their performance.

By thoroughly understanding the inner workings of this assembly, users can ensure that the unit operates at its peak potential, reducing the likelihood of mechanical failures and ensuring long-term reliability.

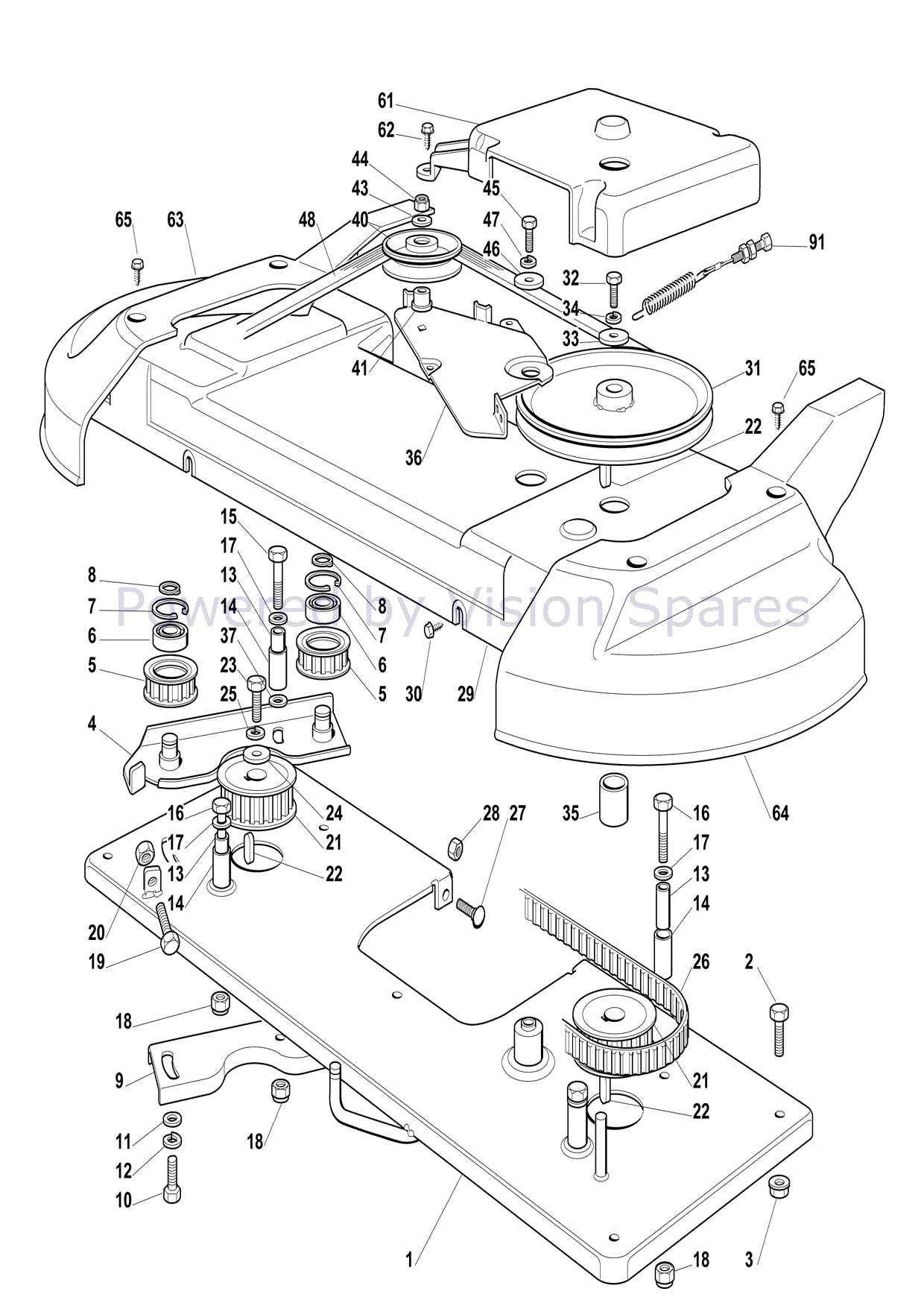

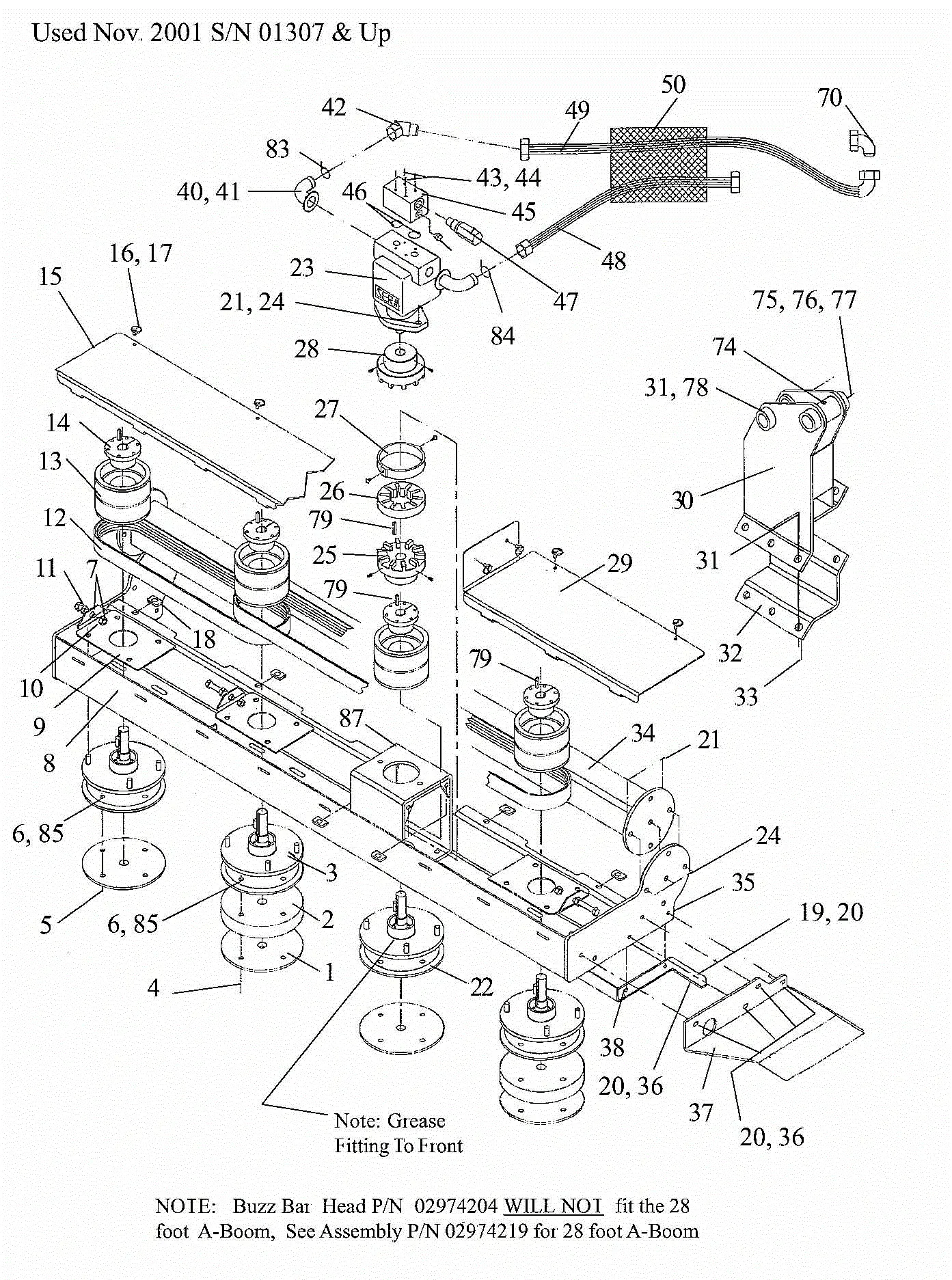

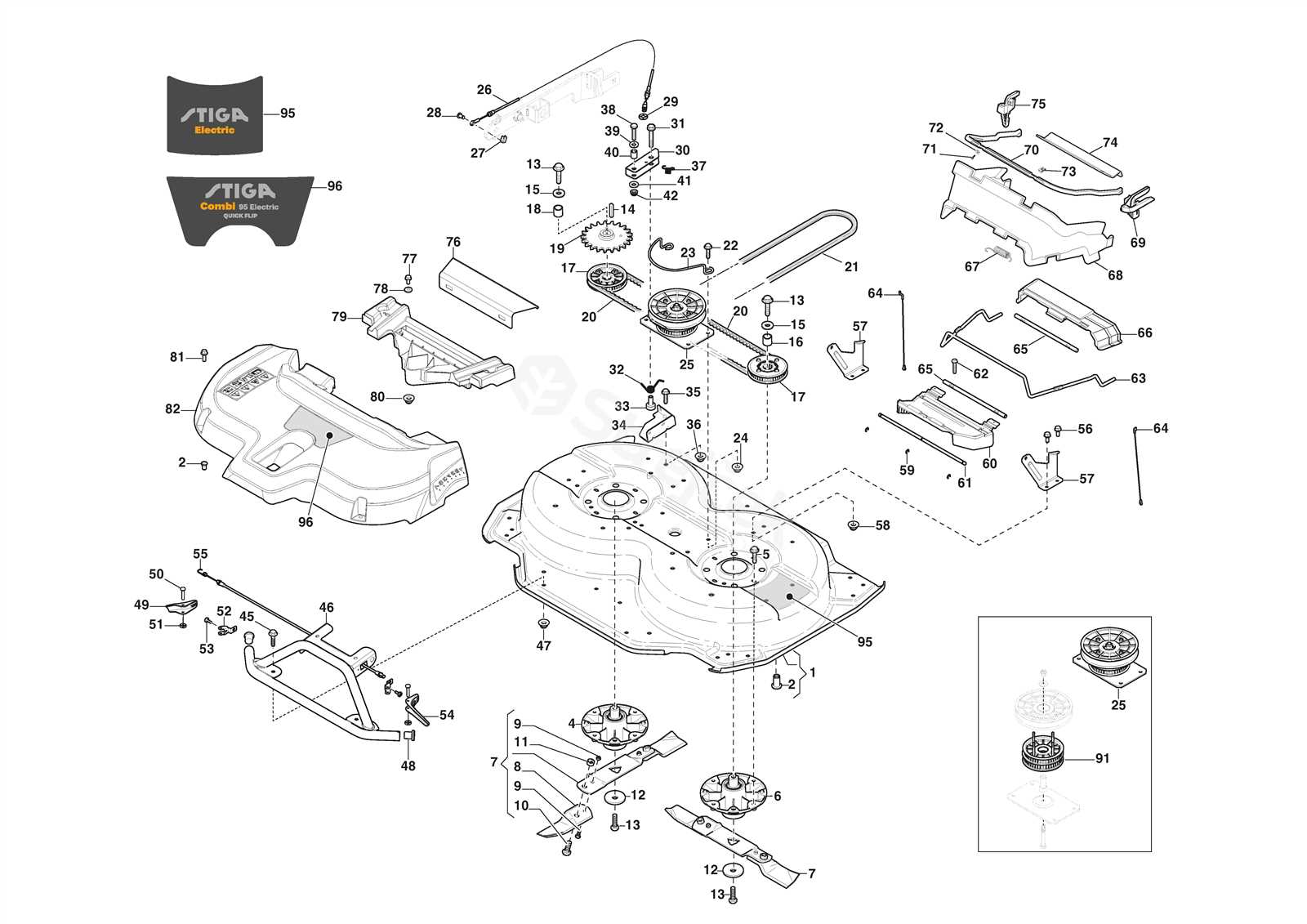

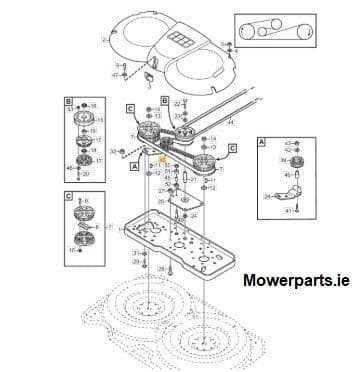

Deck Design and Configuration Explained

The structural layout and arrangement of cutting units play a crucial role in determining the overall efficiency of the equipment. A well-engineered setup ensures uniform grass trimming and enhances the smooth operation of the machinery on various terrains.

Understanding the Structure is key to optimizing performance. The assembly typically includes multiple layers and components, each contributing to the precise control of grass height and discharge. Paying attention to these details can significantly impact the quality of the cut and the equipment’s lifespan.

The component arrangement is designed to support different blade sizes and shapes, allowing for customization based on specific needs. This flexibility enables users to adapt the setup for varying lawn conditions, ensuring a seamless and effective operation.

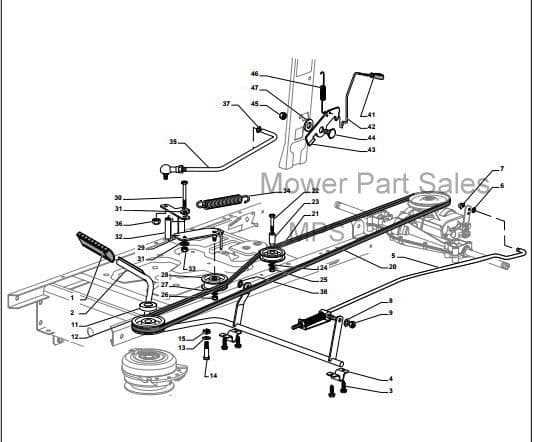

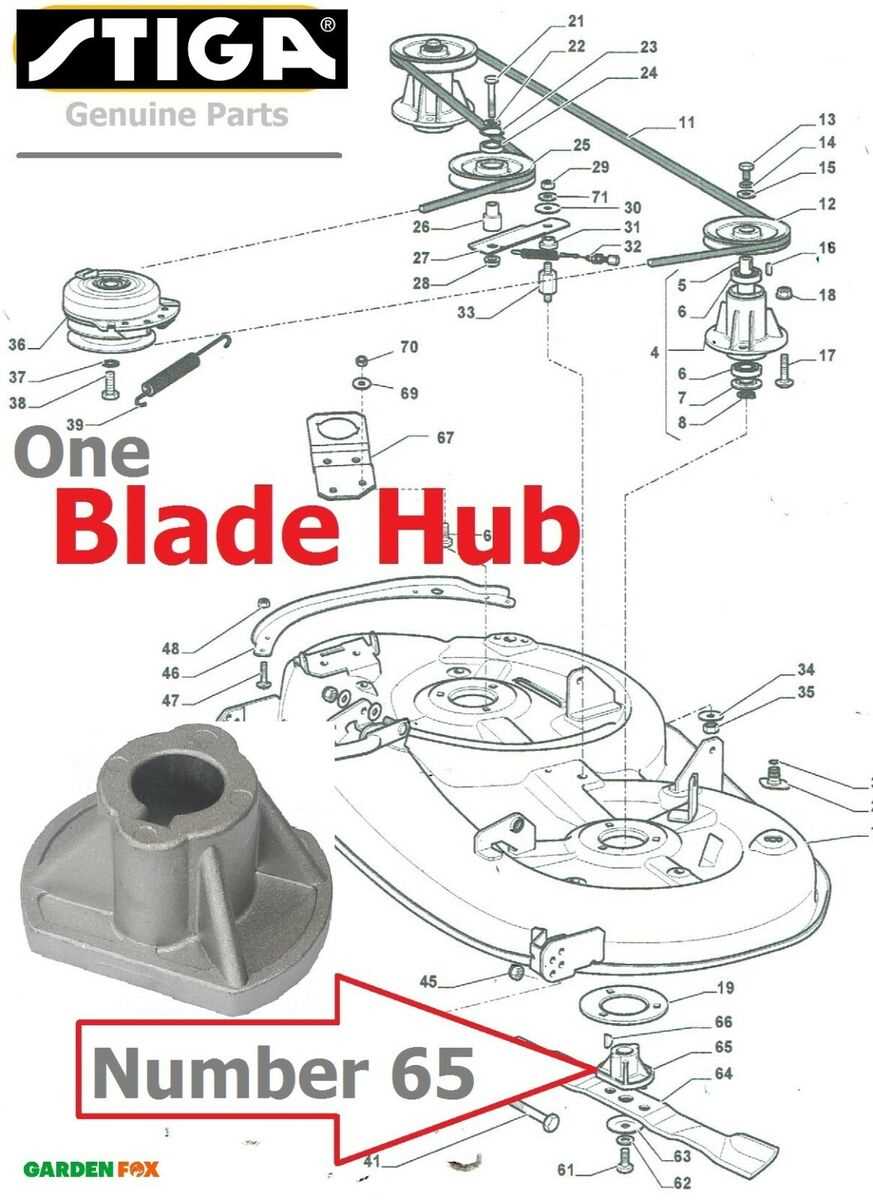

Analyzing the Cutting Blade Setup

Understanding the arrangement of the cutting components is essential for achieving optimal performance. This section delves into the configuration, focusing on its structure and positioning to enhance efficiency during operation.

- Component Alignment: Proper alignment of the elements ensures uniform trimming and reduces the risk of uneven surfaces.

- Blade Positioning: The angle at which each cutting edge is set plays a crucial role in delivering a smooth and precise cut.

- Maintenance Considerations: Regular checks for wear and damage are vital to maintaining consistent performance and longevity of the setup.

Adhering to these principles will not only improve the effectiveness of the equipment but also extend its overall lifespan.

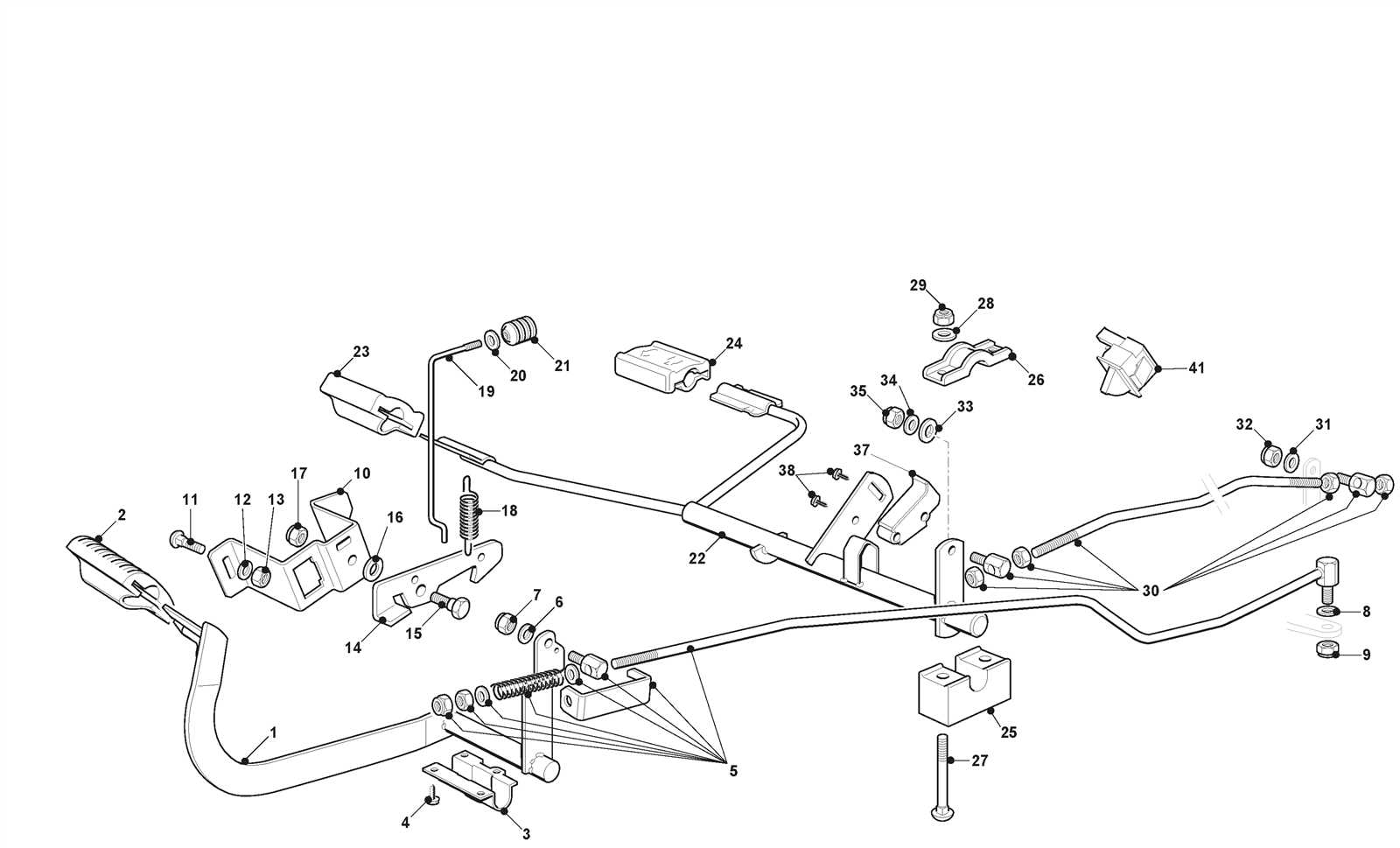

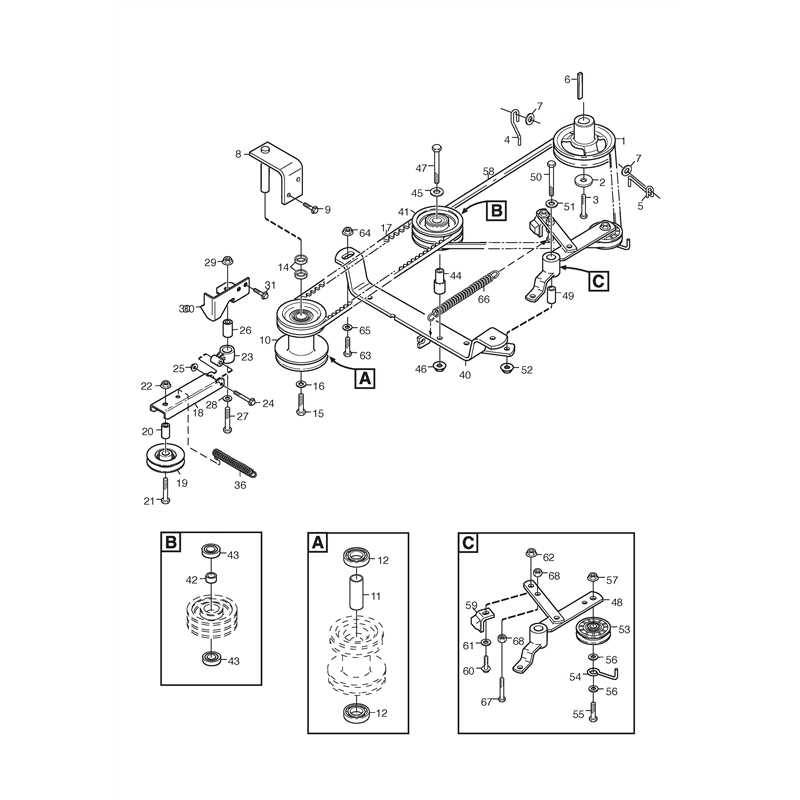

Exploring the Drive System Mechanics

The drive mechanism in outdoor equipment plays a crucial role in ensuring efficient movement and performance. Understanding the inner workings of this system helps in identifying how energy transfer occurs from the power source to the wheels or blades, allowing for smooth operation across various terrains.

Key Components and Their Functions

At the heart of the drive setup lies a combination of gears, belts, and pulleys that work together to control the machine’s speed and direction. These elements must interact seamlessly to convert the motor’s energy into motion. Proper alignment of these components is essential to prevent wear and tear, ensuring longevity and reliable operation.

Common Issues and Troubleshooting Tips

Regular maintenance of the drive elements is vital to avoid potential issues like slippage or uneven movement. Inspecting the tension of the belts and checking for any signs of damage can help in diagnosing problems early. Timely adjustments or replacements can significantly enhance the efficiency and lifespan of the drive system.

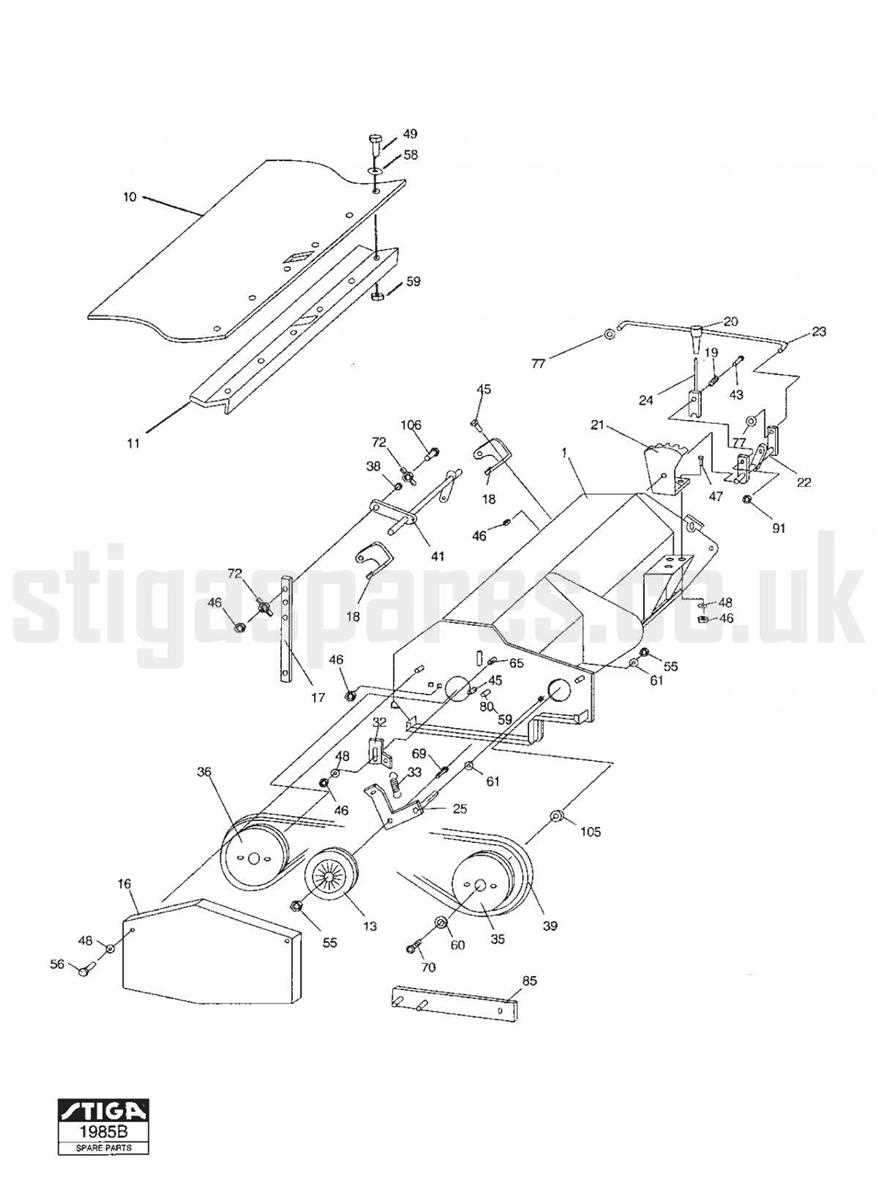

Transmission and Belt Arrangement

The organization of the power transfer system plays a crucial role in ensuring smooth operation and optimal performance. Understanding the alignment and connection of various components within this mechanism is essential for maintaining efficiency and extending the lifespan of the equipment.

The power transfer setup typically involves a series of belts and pulleys that work in unison to transmit force from one section to another. Proper alignment of these elements reduces friction and wear, which are key factors in preventing mechanical issues. Ensuring that each belt maintains the correct tension is vital for consistent functionality.

Regular inspection and adjustment of this system can help identify potential issues early, allowing for timely corrections. A well-maintained arrangement not only improves performance but also contributes to safer and more reliable operation over time.

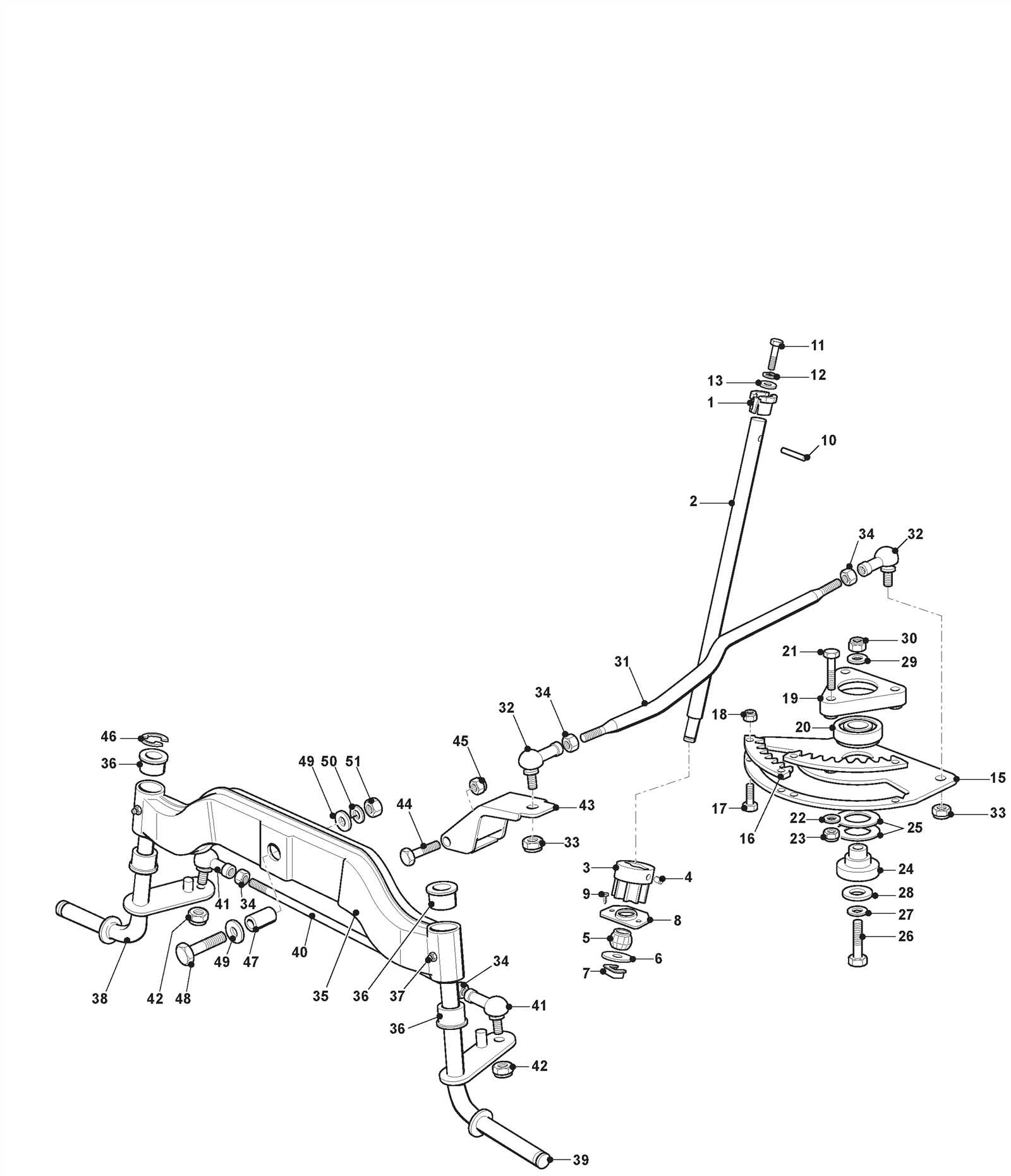

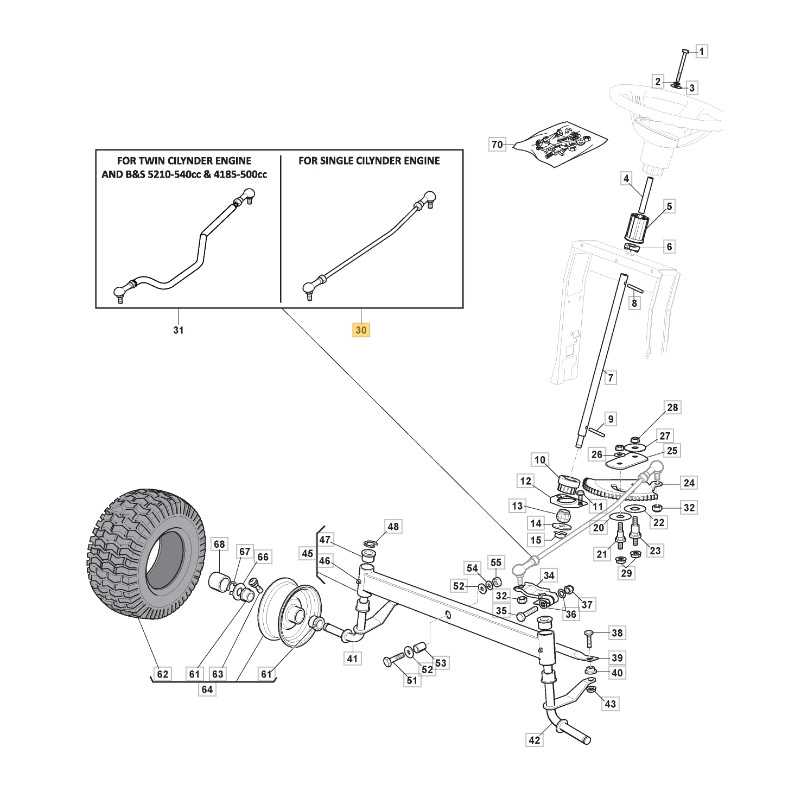

Wheels and Axle Functionality Overview

The functionality of wheels and axles is crucial in ensuring efficient movement and operation of various equipment. These components work in harmony to provide stability and support, allowing for smooth navigation across different terrains.

Wheels are designed to facilitate motion by reducing friction between the equipment and the ground. They are typically mounted on axles, which serve as the central shafts that connect and rotate the wheels. The interplay between these elements directly affects the overall performance of the machine.

- Wheel Design: Wheels come in various sizes and tread patterns to suit different surfaces, enhancing traction and control.

- Axle Role: The axle supports the weight of the machine and its operator, ensuring a balanced distribution of load.

- Materials Used: Both wheels and axles are constructed from durable materials to withstand wear and tear during operation.

- Maintenance Needs: Regular inspection and maintenance of these components are essential to prevent mechanical failures and ensure longevity.

Understanding the functionality of wheels and axles can greatly enhance the efficiency and effectiveness of the machinery in various applications.

Guidance on Front and Rear Tires

The proper selection and maintenance of wheels are crucial for optimal performance and stability. Understanding the specifications and requirements for both the front and rear wheels will enhance maneuverability and ensure a smooth operation. This section outlines essential information and recommendations for maintaining these components.

Front Tires Considerations

Front wheels play a vital role in steering and stability. Here are some key aspects to keep in mind:

- Check tire pressure regularly to maintain optimal performance.

- Ensure that the tread pattern is suitable for the terrain where the equipment will be used.

- Inspect for wear and tear, replacing tires as needed to prevent slippage.

Rear Tires Considerations

The rear wheels are crucial for traction and power transmission. Consider the following:

- Select tires with appropriate grip based on the operating environment.

- Monitor the wear on rear tires to ensure effective traction.

- Consider upgrading to wider tires if increased stability and support are necessary.

Regular maintenance and timely replacements will significantly enhance the longevity and functionality of your equipment.

Electrical System and Wiring Layout

The efficiency of any outdoor equipment relies significantly on its electrical framework and wiring arrangement. A well-structured electrical network ensures smooth operation and reliability during use. Understanding the arrangement and components involved is crucial for effective maintenance and troubleshooting.

Key Components of the Electrical Network

- Battery: Provides the necessary power to start the engine and operate electrical systems.

- Ignition System: Responsible for initiating the combustion process in the engine.

- Fuses: Protect electrical circuits from overloads by breaking the circuit when current exceeds safe levels.

- Wiring Harness: A collection of wires that transmits electrical signals between components.

- Switches: Allow the operator to control various functions such as starting the engine and activating lights.

Wiring Layout Considerations

Proper wiring configuration is essential for the seamless functioning of the electrical system. Key aspects to consider include:

- Wire Gauge: Selecting the appropriate wire gauge to handle the current load without overheating.

- Color Coding: Utilizing standardized color codes for wires to avoid confusion during installation and repairs.

- Connector Types: Choosing suitable connectors that provide reliable connections and ease of maintenance.

- Routing: Ensuring that wires are routed safely to prevent wear and accidental damage.

By comprehensively understanding the electrical system and its layout, users can enhance performance and extend the longevity of the equipment.

Battery and Ignition Components

The functionality of outdoor power equipment relies heavily on the reliability of energy storage and ignition systems. These components work together to ensure that the engine starts efficiently and operates smoothly, providing the necessary power for various tasks. Understanding these elements is crucial for maintaining optimal performance and troubleshooting any issues that may arise.

Battery Specifications

A robust energy storage unit is essential for starting the engine and powering electrical systems. Different models may utilize various types of batteries, which are characterized by their voltage, capacity, and dimensions. Regular maintenance, such as checking for corrosion and ensuring proper connections, is vital for prolonging the battery’s lifespan and ensuring reliable operation.

Ignition Mechanism

The ignition system is responsible for generating the spark needed to ignite the fuel-air mixture within the engine. This system typically includes components like the ignition coil, spark plug, and wiring harness. Proper alignment and functionality of these elements are essential for achieving efficient combustion. Regular inspection and timely replacement of worn components can prevent starting difficulties and engine performance issues.

Fuel System Structure and Maintenance

The functionality of a small engine largely depends on the efficiency of its fuel delivery mechanism. Understanding the components of this system and ensuring its proper upkeep are crucial for optimal performance and longevity. This section outlines the essential elements involved in the fuel distribution process and provides maintenance guidelines to enhance reliability.

- Fuel Tank: The reservoir where the fuel is stored before it reaches the engine. Regularly check for leaks and ensure it is free from debris.

- Fuel Filter: A critical component that prevents impurities from entering the engine. It should be inspected periodically and replaced as needed.

- Fuel Lines: Hoses that transport fuel from the tank to the engine. Ensure they are intact and free from cracks or blockages.

- Carburetor: This part mixes air and fuel for combustion. Cleaning it regularly helps maintain performance and prevent starting issues.

- Fuel Pump: Responsible for delivering fuel to the engine. Check its operation and replace it if it shows signs of failure.

Proper maintenance of the fuel system involves several key steps:

- Regularly inspect all components for wear and tear.

- Replace filters and clean the carburetor according to the manufacturer’s recommendations.

- Use the correct fuel type to prevent damage to the system.

- Store fuel in a clean, dry container to avoid contamination.

By adhering to these guidelines, you can ensure the longevity and efficiency of the fuel delivery system, ultimately enhancing the performance of your equipment.

Insight into the Carburetor Design

The carburetor serves as a crucial component in the operation of various engines, playing a vital role in the mixing of air and fuel. This essential device ensures optimal combustion, influencing performance and efficiency. Understanding its design is key to appreciating how it affects overall engine functionality.

Key Components

- Float Chamber: Maintains a steady fuel level for consistent performance.

- Venturi Tube: Creates a vacuum that draws fuel into the airstream, aiding in atomization.

- Throttle Valve: Regulates the airflow into the engine, controlling power output.

- Idle Circuit: Ensures smooth operation at low speeds by providing a controlled fuel supply.

Importance of Design

Efficient carburetor design contributes to enhanced engine responsiveness and fuel efficiency. A well-engineered unit minimizes fuel consumption while maximizing power output. Regular maintenance and understanding its components can lead to improved performance and longevity of the engine.

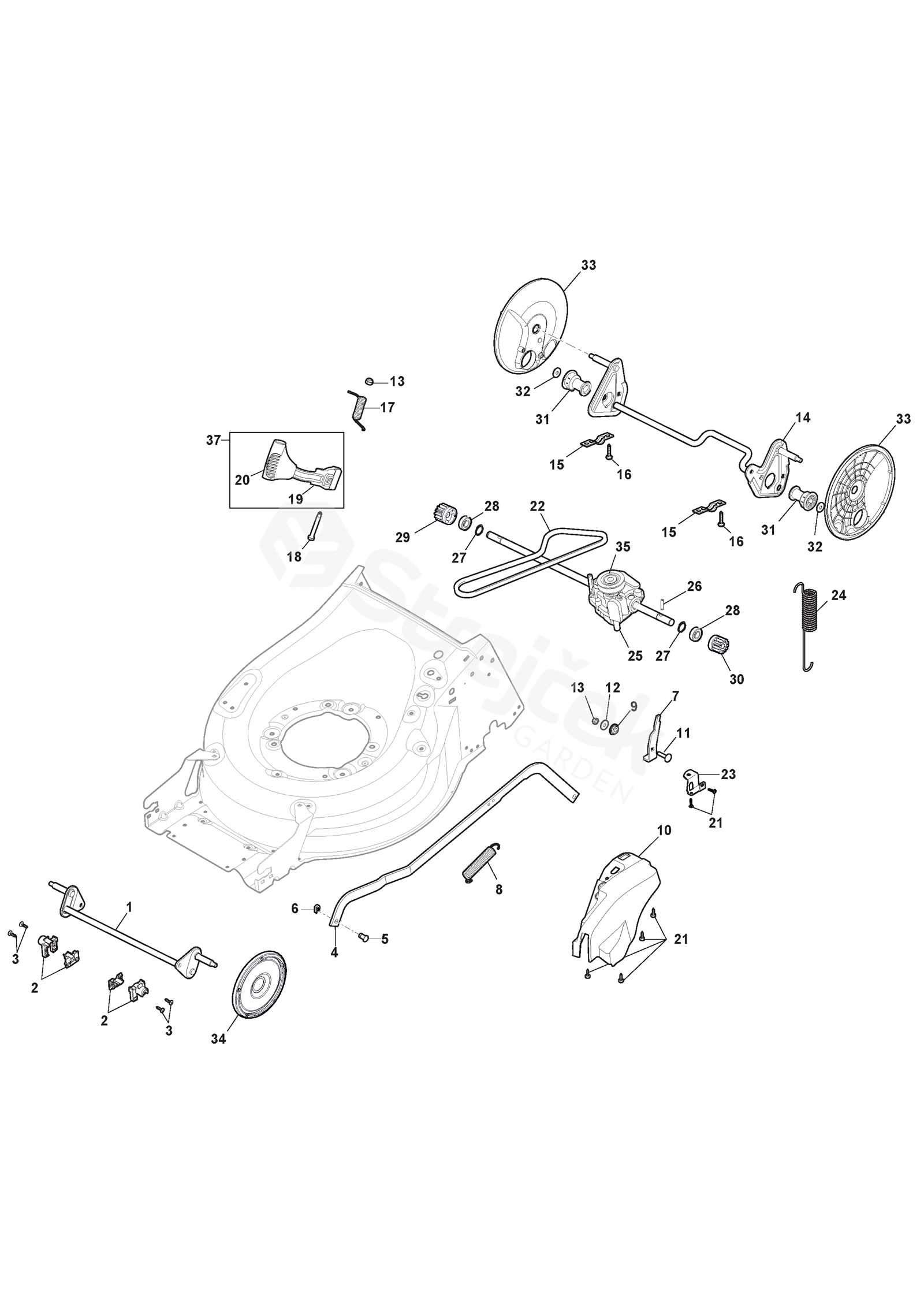

Safety Features and Control Mechanisms

When operating outdoor equipment, it is crucial to prioritize safety and effective handling. This section focuses on various protective elements and operational controls designed to enhance user safety while ensuring efficient functionality.

Key Safety Elements

- Emergency Shut-Off: An essential feature that allows the user to immediately halt the machine’s operation in case of an emergency.

- Blade Brake: This mechanism stops the cutting blades quickly, preventing accidents when the operator releases the control handle.

- Safety Guards: Protective barriers that shield users from moving parts and debris, ensuring safer operation.

- Operator Presence Control: This feature requires the operator to maintain contact with the equipment, automatically shutting it down if the user steps away.

Control Mechanisms for Enhanced Operation

- Throttle Control: Allows the user to adjust the engine speed, providing better handling based on the task at hand.

- Drive Control: A system that enables the operator to manage forward and reverse motion, ensuring precise maneuverability.

- Height Adjustment: A feature that allows the user to modify the cutting height easily, adapting to different terrain types.

Operator Presence Control Details

The operator presence control system is a vital safety feature designed to ensure the safe operation of machinery. It acts as a safeguard, preventing the equipment from functioning unless the operator is in the designated position, thus reducing the risk of accidents.

Key Components

- Switch Mechanism: This component activates the system when the operator is seated or positioned correctly.

- Safety Circuit: A critical part of the system that interrupts power to the engine if the operator leaves the seat unexpectedly.

- Indicator Light: A visual cue that informs the operator about the status of the control system.

Functionality Overview

The operator presence control system operates through a series of interconnected components that work together to enhance safety. When the operator engages with the machinery, the switch mechanism is activated, allowing the equipment to function. If the operator dismounts or moves away from the designated area, the safety circuit engages, cutting off power and stopping operation immediately. This immediate response helps to prevent potential injuries and accidents.

Regular maintenance of the operator presence control system is essential to ensure its effectiveness. Operators should routinely check the switch mechanism for any signs of wear and tear, ensure that the safety circuit is functioning correctly, and verify that the indicator light operates as intended.