![]()

In this article, we will explore the essential elements and structure of a widely used agricultural tool designed for cutting and managing crops. Understanding the layout of its primary elements is crucial for efficient maintenance and repair, ensuring longevity and optimal performance.

The mechanical system consists of various interconnected components that work in harmony to provide clean and efficient cuts across large areas. Each element serves a specific function, contributing to the smooth operation of the equipment in different field conditions.

We will delve into the configuration of these elements, their interaction, and how regular upkeep of these parts ensures smooth operation. By gaining a deeper understanding of the assembly and its crucial sections, you can ensure that the equipment remains in top condition, providing reliable service throughout the harvesting season.

Overview of Vicon Mower Components

This section provides an in-depth look at the various elements that contribute to the efficiency and performance of agricultural cutting equipment. Understanding the essential mechanisms and their roles is key to ensuring reliable operation and ease of maintenance. Below, we explore the primary features and how they function within the system.

Key Mechanical Structures

Among the central components are the cutting units, which are responsible for handling the primary task of the machine. These units are carefully engineered to provide precision and durability in various field conditions. In addition, the driving mechanisms that connect the cutting elements to the power source ensure smooth and consistent motion during operation.

Support and Control Systems

Another crucial aspect includes the support systems that maintain stability and control during use. From suspension elements to protective shields, these parts help reduce wear and prolong the life of the equipment. The hydraulic and manual control systems allow operators to adjust settings as needed for different terrains and vegetation types.

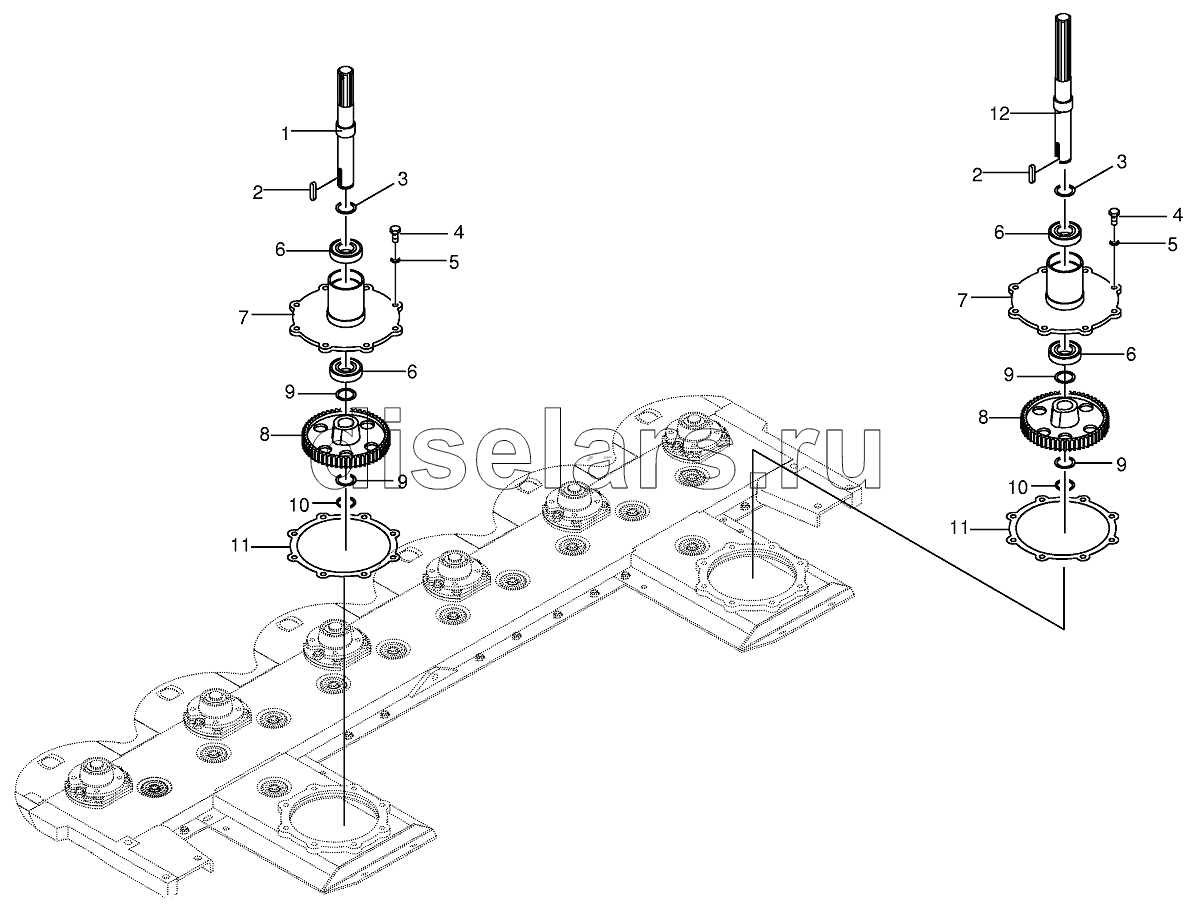

Key Elements of a Disc Mower

![]()

The machinery designed for cutting grass or crops relies on several crucial components that work together to ensure smooth and efficient operation. These mechanisms must handle a variety of conditions while providing precision in the field. Understanding these core aspects helps in maintaining performance and achieving optimal results.

Cutting Mechanism

![]()

The main feature responsible for the actual trimming process is a set of rotating blades, which move at high speeds to slice through vegetation. These blades are mounted on a robust system that ensures stability and consistent performance, even in tough conditions. The quality and sharpness of the blades play a vital role in the overall efficiency.

Drive System

![]()

The powertrain that drives the cutting mechanism is another essential component. This system transfers energy from the engine to the blades, ensuring they spin with enough force to cut through dense materials. A well-maintained transmission is critical for smooth and uninterrupted operation, enhancing the durability of the machine.

Proper care and regular maintenance of these key elements are essential for ensuring long-term reliability and high-quality performance in demanding agricultural tasks.

Understanding the Cutting System

The cutting system plays a crucial role in ensuring effective operation and precise results. It involves a series of components working together to deliver a clean and uniform cut across various conditions. This section explores the fundamental elements of the mechanism that are responsible for achieving optimal cutting performance.

Key Components and Their Function

The system is comprised of several key elements, each with a specific function. Blades, arranged in a precise pattern, are responsible for cutting vegetation efficiently. Their sharpness and alignment contribute directly to the quality of the cut. Additionally, the supporting structure ensures stability and reduces vibrations during operation, which is essential for maintaining consistent performance over time.

Maintenance for Longevity

![]()

Regular maintenance of the cutting mechanism is essential to prolong its lifespan. Proper lubrication, blade sharpening, and part inspection prevent wear and tear, ensuring that the machine continues to perform at its best. By following these simple steps, users can avoid unexpected breakdowns and ensure smooth operation throughout the season.

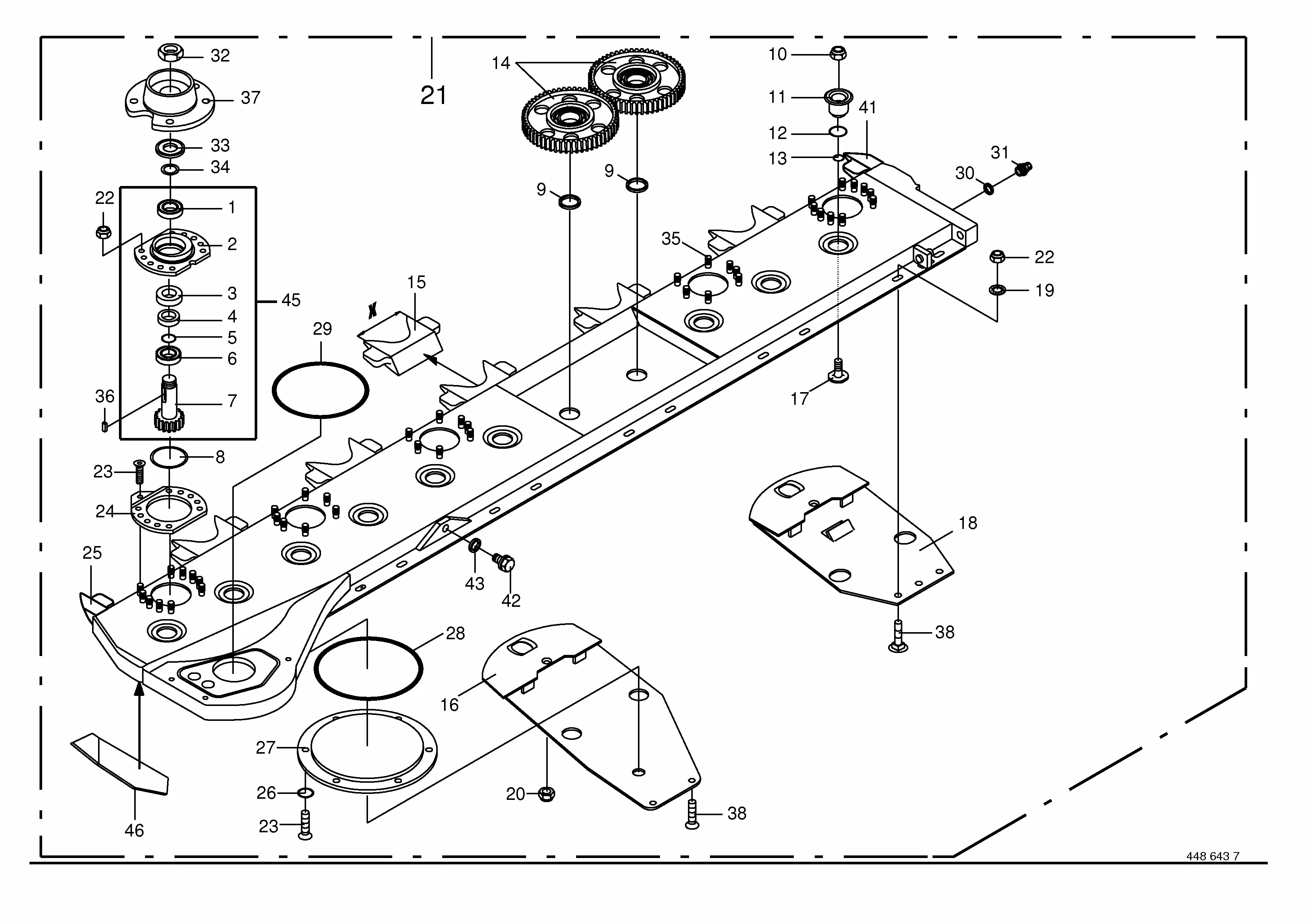

Exploring the Gearbox Mechanism

![]()

The gearbox is a crucial component that ensures the proper transmission of power within the cutting equipment. It plays a key role in converting engine energy into mechanical motion, driving the cutting mechanism with precision and efficiency. Understanding how this system works can provide valuable insights into maintaining optimal performance.

The internal structure of the gearbox consists of various interconnected elements, each contributing to the overall function. These components need to be well-coordinated to ensure smooth operation, reduce wear and tear, and prevent mechanical failures.

- Input Shaft: This element is responsible for transferring the rotational energy from the engine into the gearbox.

- Gears: A series of gears of different sizes and ratios that modulate the speed and torque, adjusting it for the desired performance.

- Bearings: Bearings help to reduce friction between moving parts, ensuring smooth and reliable operation of the gear system.

- Seals: Essential for preventing the leakage of lubricant, seals ensure that the internal components remain properly lubricated and protected from dirt and debris.

Each of these components works in harmony, allowing the machine to operate under va

Blades and Their Functions

In agricultural machinery, cutting tools play a crucial role in ensuring efficient plant management. These sharp components are designed to slice through vegetation with precision and durability. The effectiveness of the cutting process is directly influenced by the type and condition of these tools, impacting both performance and longevity.

Types of Cutting Edges

- Standard Blades: Commonly used for general purposes, providing a balance between cutting precision and endurance. Suitable for most types of crops.

- Serrated Blades: Ideal for tougher vegetation, offering additional grip and enhanced cutting ability due to their toothed design.

- Curved Blades: These are designed to improve slicing motion and reduce resistance during operation, which increases efficiency

How the Drive Shaft Works

The drive shaft plays a crucial role in transmitting power from the engine to various components of agricultural equipment. This essential element ensures that the rotational force generated by the engine is efficiently delivered to the working mechanisms, enabling smooth operation and optimal performance.

Constructed to endure high torque and stress, the drive shaft typically consists of a robust metal tube that connects different parts of the machinery. As the engine operates, it spins the shaft, which, in turn, engages the attached implements. This connection is vital for the implementation of various agricultural tasks, providing the necessary energy for effective functioning.

Moreover, the design of the drive shaft allows for flexibility and movement, accommodating the diverse terrains and conditions encountered during operation. By maintaining alignment and reducing vibration, the drive shaft contributes to the longevity of the equipment, minimizing wear and tear on both the shaft and other interconnected components.

Overall, understanding the functionality of the drive shaft is essential for anyone involved in the maintenance or operation of farming machinery. Proper care and knowledge of this component can lead to enhanced efficiency and reliability, ensuring that agricultural tasks are completed effectively.

Importance of the Cutter Bar

The cutter bar serves as a critical component in agricultural machinery, playing a vital role in the effectiveness and efficiency of grass and crop harvesting. Its design and functionality significantly influence the overall performance of the equipment, impacting both the quality of the cut and the speed of operation.

Key reasons why the cutter bar is essential include:

- Precision Cutting: A well-designed cutter bar ensures a clean and precise cut, promoting healthier regrowth of the plants.

- Durability: The construction materials used for the cutter bar must withstand harsh conditions and heavy use, ensuring longevity and reliability.

- Maintenance: Regular checks and maintenance of the cutter bar can prevent operational issues, leading to smoother performance during harvesting seasons.

- Adjustability: The ability to adjust the height and angle of the cutter bar allows operators to adapt to various field conditions, maximizing efficiency.

Overall, understanding the importance of the cutter bar and its maintenance can lead to improved productivity and reduced downtime in agricultural operations.

Maintenance of Mower Bearings

Regular upkeep of rotary equipment components is essential for optimal performance and longevity. Bearings play a crucial role in the smooth operation of these systems, and neglecting their maintenance can lead to significant issues.

To ensure the effective functioning of these vital elements, consider the following maintenance practices:

- Regular Inspections: Conduct routine checks to identify any signs of wear, damage, or misalignment. Early detection can prevent more severe problems.

- Lubrication: Ensure that bearings are adequately lubricated with the appropriate grease or oil. This reduces friction and helps in heat dissipation.

- Cleaning: Keep the surroundings clean to avoid contamination. Dirt and debris can compromise the functionality of the bearings.

- Alignment Checks: Regularly verify that the components are aligned correctly. Misalignment can cause premature wear and tear.

- Replacement: If any bearing shows significant damage or excessive wear, replace it immediately to maintain efficiency.

By adhering to these maintenance guidelines, you can enhance the reliability and lifespan of the equipment, ensuring it operates at peak performance.

Role of the PTO in Mowing

The Power Take-Off (PTO) is a vital component in the operation of agricultural machinery. It serves as a mechanical interface that transfers energy from the tractor’s engine to various implements, allowing them to function efficiently. By engaging the PTO, operators can activate the attached devices, ensuring that they perform their tasks effectively and in a timely manner.

Functionality and Importance

The PTO’s primary role lies in providing the necessary power for cutting mechanisms. It enables the blades or other cutting tools to rotate at optimal speeds, which is crucial for achieving a clean and precise cut. Without the PTO, the efficiency of these implements would be significantly reduced, impacting overall productivity on the farm.

Operational Considerations

Hydraulic System Overview

The hydraulic system is a crucial component in agricultural machinery, facilitating efficient operation through the use of pressurized fluid. This system allows for the seamless movement and control of various implements, ensuring optimal performance during fieldwork. Understanding the hydraulic system’s design and functionality is essential for maintenance and troubleshooting.

At its core, the hydraulic mechanism consists of several key components working in unison. Each element plays a vital role in generating, directing, and utilizing hydraulic pressure to perform specific tasks. The following table outlines these essential components along with their functions:

Component Function Hydraulic Pump Generates hydraulic pressure by converting mechanical energy into fluid power. Hydraulic Reservoir Stores hydraulic fluid and ensures a continuous supply to the system. Control Valve Regulates the flow and direction of hydraulic fluid to various components. Actuator Converts hydraulic energy into mechanical movement, enabling the operation of implements. Hydraulic Lines Transport hydraulic fluid between the pump, reservoir, valves, and actuators. A thorough understanding of these components and their interactions is essential for ensuring the reliability and efficiency of hydraulic systems in agricultural equipment.

Adjusting the Tensioner for Optimal Performance

Properly setting the tensioning mechanism is crucial for ensuring the effectiveness and longevity of your equipment. A well-adjusted tensioner helps maintain the correct alignment and contact between components, ultimately enhancing operational efficiency and reducing wear. Regular attention to this aspect can prevent unnecessary breakdowns and promote consistent performance.

Importance of Proper Tension

Maintaining the right level of tension allows for smooth operation, preventing slippage that can lead to inefficiencies. Insufficient tension may result in loose components, causing vibrations and additional strain. Conversely, excessive tension can lead to premature wear and potential damage. Therefore, finding the perfect balance is essential for optimal functionality.

Adjustment Process

To adjust the tensioning device, start by locating the adjustment mechanism, which typically involves a bolt or lever. Gradually tighten or loosen this mechanism while monitoring the tightness. Check the manufacturer’s specifications to determine the ideal tension level for your specific model. After adjustments, it’s advisable to run the equipment briefly and reassess the tension to ensure stability and performance.

Troubleshooting Common Issues with Vicon Mowers

Maintaining optimal performance of your agricultural machinery is crucial for efficiency and productivity. Understanding common challenges and their solutions can significantly enhance your experience. Below are typical problems encountered with these implements, along with practical troubleshooting tips to ensure smooth operation.

1. Uneven Cutting Height

If you notice inconsistent cutting heights, the first step is to check the adjustment of the cutting components. Ensure that all settings are aligned properly and that wear on the components is minimal. Regular maintenance can help prevent this issue from arising.

2. Poor Cutting Performance

When the implement fails to deliver a clean cut, inspect the sharpness of the blades. Dull blades can cause tearing instead of cutting, affecting the quality of the output. Regularly sharpen and replace blades as needed to maintain cutting efficiency.

3. Excessive Vibration

Vibration during operation can indicate an imbalance in the cutting assembly. Check for loose or damaged components, and ensure that everything is securely fastened. Regular inspections can help identify potential issues before they escalate.

4. Hydraulic Issues

Hydraulic systems are vital for the functionality of these implements. If you experience sluggish or unresponsive operation, inspect hydraulic fluid levels and look for leaks in hoses or connections. Regularly changing the hydraulic fluid can also help maintain system efficiency.

5. Blockages

Accumulation of debris can lead to blockages, hindering performance. Regularly clean the cutting area and ensure that no foreign materials are obstructing movement. A thorough cleaning after each use can prevent future complications.

By addressing these common concerns, operators can enhance the longevity and performance of their equipment, ensuring reliable results season after season.