Maintaining and operating outdoor machinery requires a thorough understanding of their inner workings. For enthusiasts and professionals alike, familiarity with the various components is essential for efficient upkeep and repair. This knowledge not only extends the lifespan of the equipment but also enhances its performance during use.

Visual representations play a crucial role in grasping the structure and organization of these machines. By studying comprehensive illustrations, users can easily identify the arrangement of individual elements, making troubleshooting and replacement much simpler. Such guides serve as valuable resources for both novice users and seasoned operators, streamlining the maintenance process.

Delving into the specifics of each component empowers users to tackle issues proactively. Whether it’s replacing a worn-out element or simply performing routine checks, having access to accurate visual references significantly reduces the likelihood of mistakes. This understanding ultimately leads to smoother operation and improved efficiency, ensuring that the equipment remains in optimal condition for years to come.

Understanding Woods Mower Parts

Comprehending the components of lawn equipment is essential for effective maintenance and optimal performance. Each element plays a crucial role, contributing to the overall functionality and durability of the machinery. A thorough grasp of these components empowers users to troubleshoot issues and make informed decisions regarding repairs and replacements.

| Component | Function |

|---|---|

| Blade | Responsible for cutting grass and vegetation. |

| Deck | Houses the cutting mechanism and protects other components. |

| Drive Belt | Transmits power from the engine to the cutting blade. |

| Engine | Powers the entire machine, providing necessary energy. |

| Wheels | Facilitate movement and maneuverability across various terrains. |

Importance of Diagrams for Maintenance

Visual representations play a crucial role in the upkeep of machinery, ensuring that components are easily identifiable and accessible. They provide a clear roadmap, helping users to understand the relationships between various elements and how they function together.

By utilizing these illustrations, technicians can effectively troubleshoot issues, streamline repairs, and perform routine checks with confidence. This ultimately leads to increased efficiency, reduced downtime, and enhanced longevity of equipment.

Moreover, having access to detailed visuals fosters a better understanding of the mechanical structure, allowing both experienced and novice users to navigate maintenance tasks with greater ease. In essence, these tools are invaluable for anyone aiming to achieve optimal performance from their machinery.

Common Woods Mower Models Explained

This section explores various popular models known for their efficiency and durability in maintaining landscapes. Understanding the differences between these machines can aid users in selecting the right model for their specific needs.

| Model | Engine Power | Cutting Width | Features |

|---|---|---|---|

| Model A | 25 HP | 60 inches | Heavy-duty frame, adjustable height |

| Model B | 30 HP | 72 inches | Turbo cooling system, quick-change blades |

| Model C | 20 HP | 54 inches | Compact design, enhanced maneuverability |

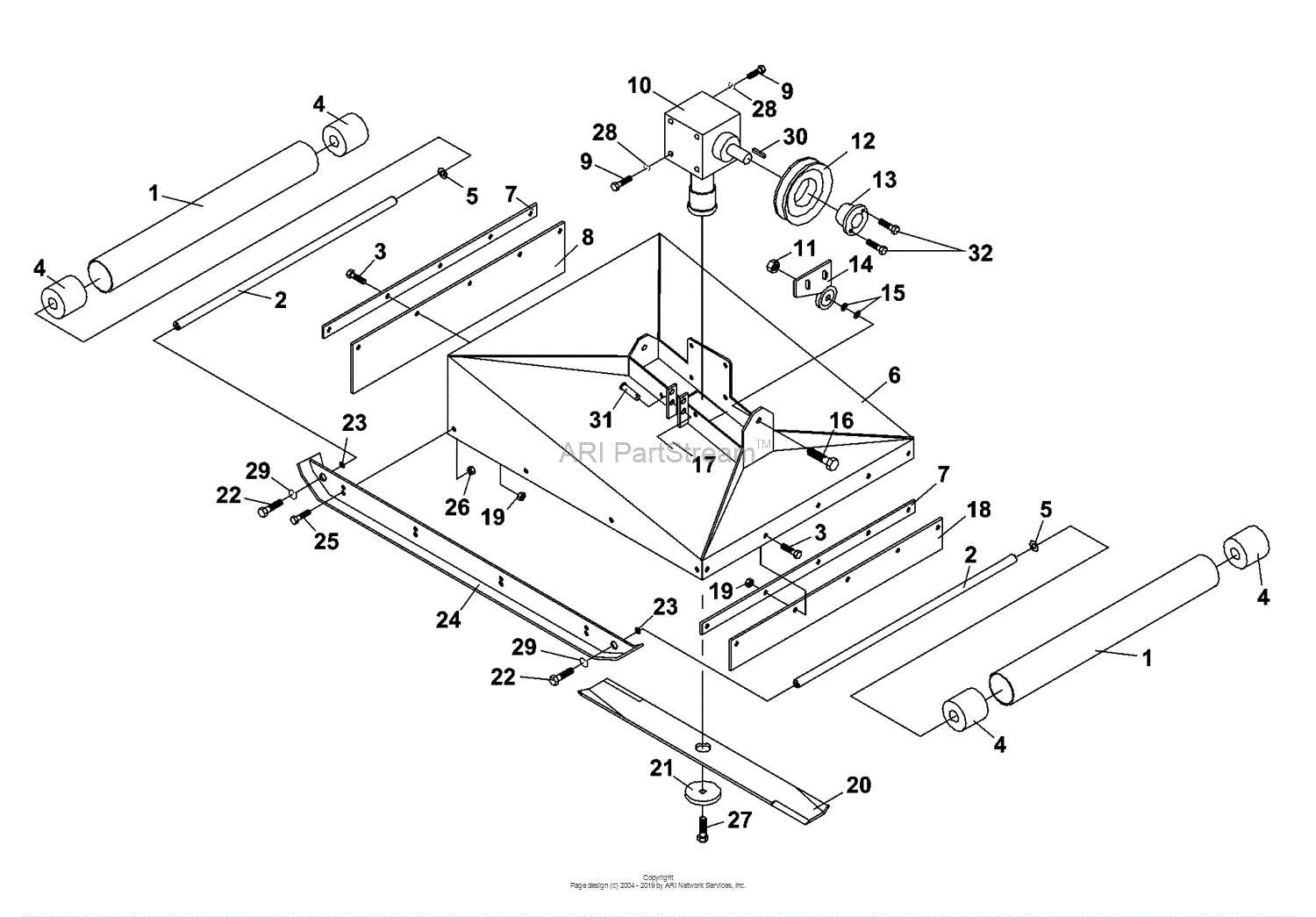

Identifying Key Components in Diagrams

Understanding the intricate elements within technical illustrations is essential for effective maintenance and repair. Recognizing these vital components enables users to diagnose issues and implement solutions efficiently. This section will delve into how to identify and interpret the essential features within these visual aids.

One of the primary aspects to focus on is the legend or key, which often provides valuable information regarding symbols and their meanings. Familiarizing yourself with these indicators can significantly enhance your comprehension of the schematic. Additionally, paying attention to the layout is crucial; components are typically arranged in a logical sequence that reflects their relationship and functionality.

Another important factor is the scale of the illustration, as it can impact your understanding of the size and positioning of each element. Be sure to compare these features with actual components to ensure accurate identification. Lastly, look for any annotations or notes that may provide context or additional details about specific parts, as they can be instrumental in guiding your analysis.

How to Read Mower Parts Diagrams

Understanding technical illustrations for machinery can significantly enhance your maintenance and repair skills. These visual guides provide crucial information about components and their arrangement, making it easier to identify issues and source replacements. By learning to interpret these graphics, you can ensure your equipment operates optimally.

First, familiarize yourself with the symbols and notations used in the illustration. Each component will typically be represented by a specific icon or label, often accompanied by numbers that correspond to a parts list.

Next, pay attention to the layout and organization of the components. The arrangement often follows the assembly order, helping you visualize how everything fits together. This is particularly useful when troubleshooting problems or reassembling after disassembly.

Lastly, use the accompanying documentation to enhance your understanding. Descriptions, specifications, and maintenance tips are usually provided alongside the visual representation, serving as a valuable resource for effective operation and care.

Where to Find Accurate Diagrams

Finding detailed and reliable illustrations is crucial when working on equipment. These visual guides help ensure proper assembly and maintenance. However, knowing where to look for precise schematics can be challenging without the right resources.

Official Sources

The most reliable place to obtain correct schematics is through official channels. Many manufacturers provide access to comprehensive visual references on their websites. These diagrams are typically updated and verified for accuracy.

Online Communities and Forums

Another excellent way to locate trustworthy diagrams is by connecting with online communities. Enthusiasts often share valuable insights and illustrations, especially for older or less common equipment. Always verify the information with official documentation to avoid errors.

Benefits of Using OEM Parts

Opting for original equipment manufacturer (OEM) components ensures a high level of compatibility and reliability. These products are specifically designed to meet the exact specifications of the machinery, providing superior performance compared to aftermarket alternatives.

Increased Durability

OEM components are crafted from high-quality materials, ensuring a longer lifespan and less frequent replacements. Their precise fit also minimizes wear and tear on related mechanisms, helping the machine operate smoothly for extended periods.

Enhanced Safety and Performance

Choosing original components enhances the safety of the equipment by reducing the likelihood of malfunctions. These parts are tested rigorously to guarantee they meet industry standards, ensuring that the machine performs at its best and poses fewer risks to users.

DIY Repairs Using Parts Diagrams

Undertaking home repairs can be significantly simplified by using visual guides that show how various components fit together. These resources offer a detailed breakdown of each element, making it easier to identify the necessary components for fixing or replacing. By studying these illustrations, even complex tasks become more manageable, allowing you to confidently address mechanical issues.

Step-by-step guidance is another major advantage of these visual references. They provide a clear sequence for assembling or disassembling equipment, which is crucial for avoiding mistakes. With a good reference, you can ensure each piece is in its proper place, enhancing both efficiency and accuracy during the repair process.

Additionally, visual references often include specific details about various tools and techniques required, helping you to prepare thoroughly before starting any repair. This preparation can sav

Common Issues with Grass Cutting Machines

Mechanical devices designed for trimming large areas of grass can face a variety of operational challenges over time. These issues are often related to normal wear and tear, improper maintenance, or external conditions such as rough terrain. Identifying these problems early can help prevent more serious malfunctions.

| Problem | Potential Cause | Solution |

|---|---|---|

| Uneven cutting | Blades may be dull or improperly aligned | Sharpen or replace blades, adjust alignment |

| Machine stalls during use | Clogged air filter

Tips for Effective Mower MaintenanceRegular care and attention can significantly extend the life of your equipment, ensuring optimal performance over time. Simple routines can prevent larger issues from developing and keep everything running smoothly. By following key maintenance practices, you can avoid unnecessary repairs and enhance the efficiency of your device. Regular CleaningCleaning your machine after each use is crucial. Grass buildup, dirt, and debris can affect its functionality, causing wear and tear faster than usual. Always clear out any clippings or blockages to maintain peak performance and longevity. Inspecting and Replacing ComponentsMake it a habit to inspect various elements frequently. Worn or damaged components can cause issues in performance. By identifying these problems early, you can replace them before they lead to more serious damage. This simple step helps ensure smooth operation and Replacing Worn Parts: A GuideOver time, machinery components can wear down, reducing the efficiency and lifespan of your equipment. Regular maintenance, including the replacement of damaged or deteriorated elements, ensures optimal performance and prevents potential breakdowns. It’s important to know when a specific element has reached the end of its usefulness and how to effectively replace it. Identifying Worn Components involves regularly inspecting key areas for signs of wear and tear, such as cracks, thinning, or other visible damage. Replacing these early can save you from costly repairs in the future and keep the equipment running smoothly. When it comes to removing and replacing elements, always consult your manual to understand the proper procedure for your specific model. Tools and techniques can vary, but Choosing the Right Parts SuppliersFinding the best sources for replacement components can be crucial for ensuring long-term performance and durability of your machinery. A reliable supplier not only provides quality items but also offers the right guidance and support throughout the purchasing process. Reputation and ReliabilityReputation plays a significant role when selecting a supplier. Look for vendors who have a proven track record of delivering high-quality components. This ensures that you’re investing in parts that meet industry standards and maintain functionality over time. Consistent and dependable service is another important factor to consider. Availability and SupportIt’s essential to choose a supplier who offers quick availability of products and provides strong customer support. Fast delivery times can minimize downtime, while responsive service teams can help address any issues or provide assistance with installation and usage. |