The intricate arrangement of various elements within a vehicle is essential for both functionality and maintenance. Recognizing the specific configurations of these components can significantly enhance your ability to troubleshoot issues and perform upgrades effectively. In this section, we will explore the essential features of a particular automotive model’s structural design, shedding light on its operational framework.

Knowledge of how different systems interact and where each component is situated aids in optimizing performance and ensuring longevity. By grasping the relationships among these critical elements, you can make informed decisions when addressing repairs or modifications. This understanding paves the way for a smoother and more efficient driving experience.

Additionally, familiarizing yourself with this layout can empower you to communicate more effectively with automotive professionals, facilitating better service and support. Whether you are an enthusiast or simply looking to maintain your vehicle, a solid comprehension of the component arrangement will serve as a valuable asset.

Understanding 2006 Nissan Pathfinder Components

Gaining insight into the various elements of an automotive system is essential for effective maintenance and repair. Each vehicle comprises numerous interconnected parts, each serving a specific function to ensure smooth operation. Familiarity with these components can enhance the owner’s experience and extend the lifespan of the vehicle.

Key components can be categorized into several groups:

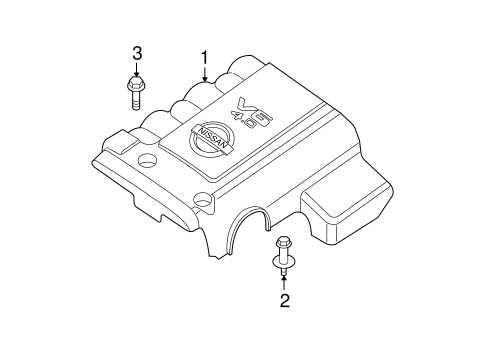

- Engine Assembly: The heart of the vehicle, responsible for generating power.

- Transmission System: This mechanism transfers power from the engine to the wheels, enabling movement.

- Electrical System: Comprising the battery, wiring, and various sensors, this system powers essential functions.

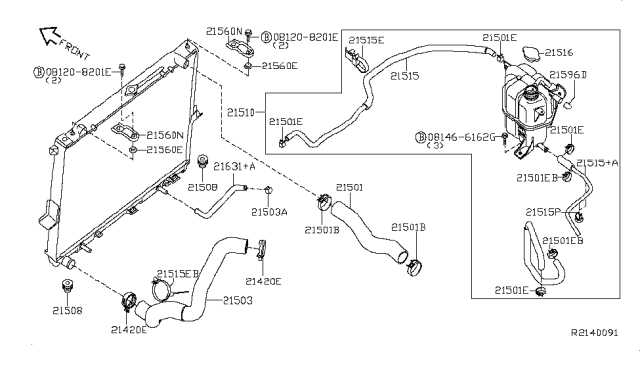

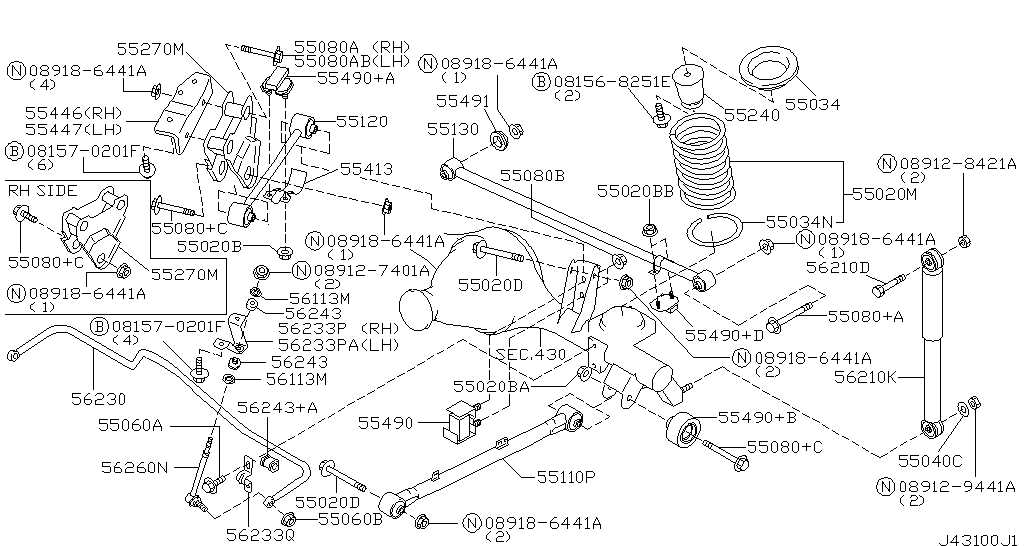

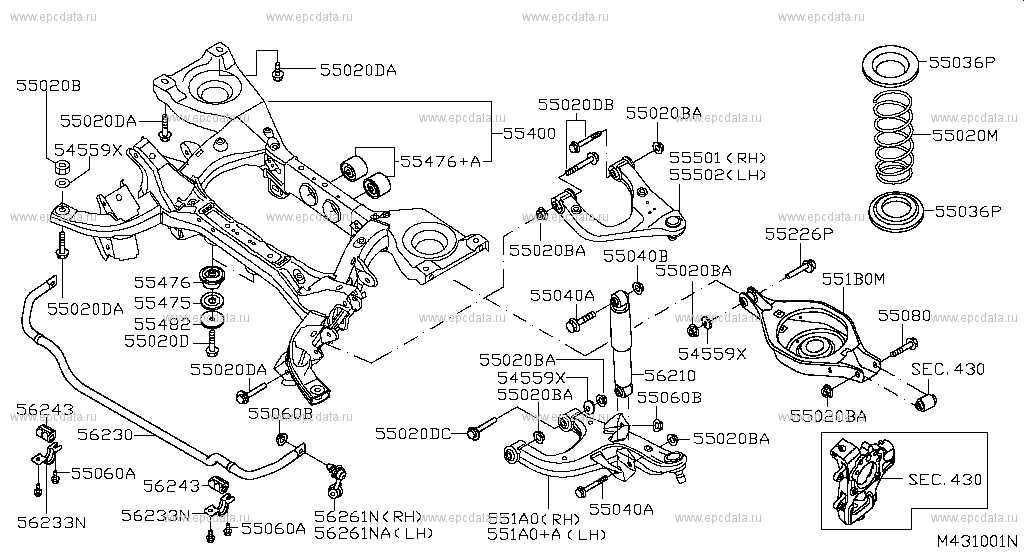

- Suspension Components: These parts support the vehicle’s weight and ensure a smooth ride over various terrains.

- Braking System: Crucial for safety, this assembly enables the vehicle to stop effectively.

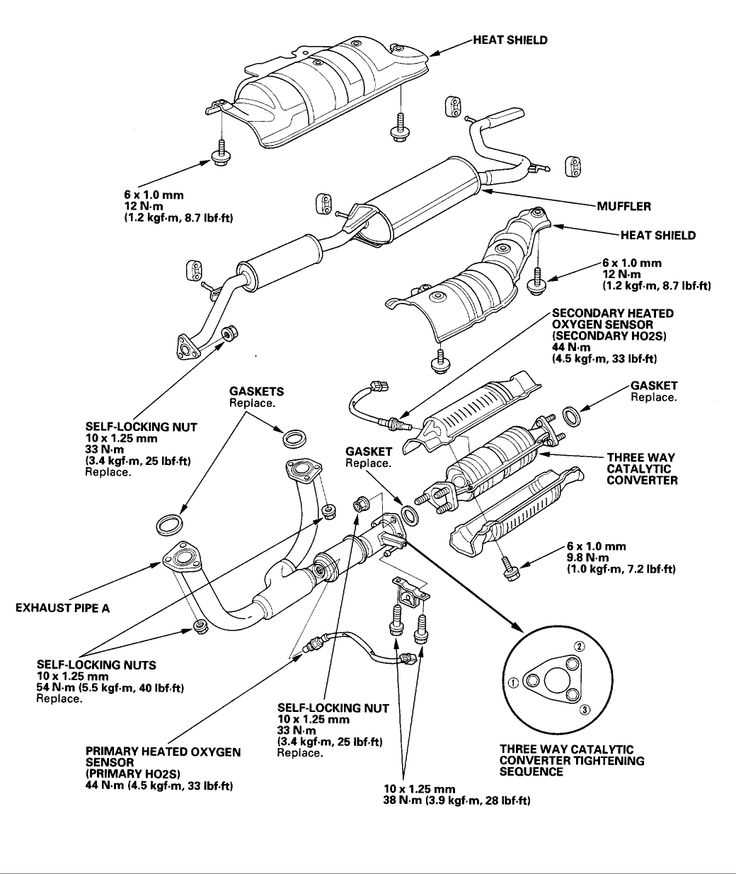

- Exhaust System: This system channels harmful gases away from the engine, promoting environmental safety.

Understanding these categories aids in diagnosing issues, performing repairs, and making informed decisions regarding upgrades or replacements. By becoming familiar with the components and their functions, vehicle owners can ensure their automobiles operate efficiently and safely.

Key Features of the Pathfinder Model

The vehicle offers a blend of versatility, performance, and comfort, making it a favored choice for families and adventure seekers alike. With a focus on robust design and innovative technology, it stands out in its class.

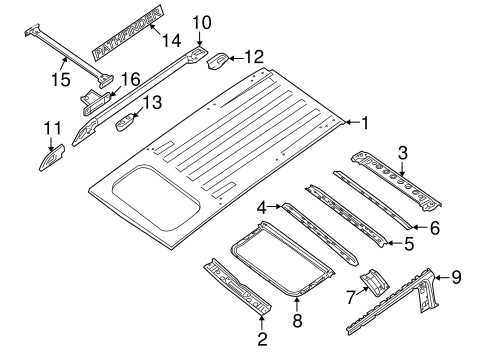

- Spacious Interior: Designed to accommodate up to seven passengers, providing ample legroom and cargo space.

- All-Terrain Capability: Equipped with advanced traction systems that enhance handling on various surfaces, ensuring confidence in different driving conditions.

- Safety Features: Incorporates a range of safety technologies such as stability control, multiple airbags, and advanced braking systems.

- Powerful Engine Options: Offers a selection of efficient and powerful engines, delivering a balanced combination of performance and fuel efficiency.

- Modern Infotainment System: Features an intuitive multimedia interface with connectivity options, providing entertainment and navigation support.

This model showcases a harmonious blend of functionality and style, appealing to those who seek both practicality and elegance in their driving experience.

Essential Replacement Parts Overview

Understanding the fundamental components necessary for vehicle maintenance is crucial for ensuring optimal performance and longevity. Recognizing which elements require regular attention can help prevent more extensive issues and enhance the driving experience.

Key Components to Consider

Among the vital elements, the engine, transmission, and braking system stand out. These components are essential for the vehicle’s functionality, safety, and efficiency. Regular inspections and timely replacements can mitigate wear and tear, maintaining peak operational standards.

Maintenance Tips

It is advisable to routinely check the condition of filters, belts, and hoses. Keeping these items in good shape contributes significantly to overall vehicle reliability. Additionally, consulting with professionals for periodic assessments can ensure that all critical elements are functioning as intended.

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your vehicle requires regular upkeep and attention to various components. Implementing a consistent maintenance routine can significantly enhance performance and reliability. This section offers valuable insights into effective practices that promote a smoother driving experience.

Regular Inspections: Conduct routine checks on critical elements such as the engine, transmission, and braking systems. Identifying wear and tear early can prevent more severe issues down the line.

Fluid Levels: Keeping an eye on fluid levels, including oil, coolant, and transmission fluid, is essential. Ensure these fluids are at optimal levels and replace them as needed to maintain proper function.

Tire Maintenance: Regularly inspect tire pressure and tread depth. Properly inflated tires not only enhance fuel efficiency but also improve handling and safety. Rotate tires periodically to promote even wear.

Air Filter Replacement: A clean air filter allows for better airflow to the engine, improving fuel efficiency and performance. Check and replace the air filter according to the manufacturer’s recommendations.

Battery Care: Inspect the battery terminals for corrosion and ensure a secure connection. A well-maintained battery is crucial for reliable starts and overall vehicle performance.

Scheduled Servicing: Follow the manufacturer’s recommended service intervals for essential maintenance tasks. Adhering to this schedule can help prevent unexpected breakdowns and maintain optimal performance.

By following these maintenance guidelines, you can help ensure that your vehicle remains in excellent condition, providing a reliable and enjoyable driving experience.

Identifying Common Issues with Parts

Understanding the frequent challenges associated with automotive components is crucial for effective maintenance and repair. Identifying these problems early can help avoid costly repairs and ensure the vehicle operates smoothly. Below are some typical issues encountered with various automotive elements.

- Wear and Tear: Many components experience natural degradation over time, leading to decreased performance.

- Leakage: Seals and gaskets may fail, causing fluids to leak, which can result in further complications.

- Corrosion: Metal parts are susceptible to rust and corrosion, especially in areas exposed to moisture.

- Electrical Failures: Wiring and connectors can become damaged or corroded, leading to electrical issues that affect performance.

- Noise: Unusual sounds may indicate misalignment or failure of certain components, requiring immediate attention.

Regular inspections and a proactive approach can help identify these common concerns before they escalate into more significant problems. Ensuring all components are functioning correctly enhances overall vehicle reliability and safety.

How to Access Vehicle Specifications

Understanding the details of a vehicle is essential for maintenance, repairs, and upgrades. Accessing specific information can enhance your experience as an owner or enthusiast. Various resources are available to help you find the necessary specifications effectively.

- Owner’s Manual: The first place to check for information about your vehicle is the owner’s manual. This document typically contains comprehensive details about the engine, transmission, dimensions, and other vital specifications.

- Online Resources: Numerous websites offer databases with vehicle specifications. Manufacturer websites often provide detailed information and downloadable manuals.

- Automotive Forums: Engaging with online communities can yield valuable insights. Enthusiasts and experts often share their knowledge and resources about different models.

- Dealerships and Repair Shops: Consulting with professionals at dealerships or repair shops can be beneficial. They have access to manufacturer databases and can provide accurate information.

- VIN Decoder Tools: Utilizing a Vehicle Identification Number (VIN) decoder can give you specific details about your vehicle, including engine type, production year, and other unique features.

By leveraging these resources, you can effectively access the specifications you need, ensuring a well-informed approach to vehicle maintenance and modifications.

OEM vs. Aftermarket Components: A Comparison

When it comes to vehicle maintenance and repairs, choosing the right components can significantly impact performance and longevity. The market offers a variety of options, including original equipment manufacturer (OEM) items and aftermarket alternatives. Each choice has its advantages and disadvantages, making it essential to understand the differences to make informed decisions for your vehicle.

Understanding OEM Components

Original equipment manufacturer items are produced by the same company that made the original components for the vehicle. These products are typically designed to meet specific standards set by the manufacturer, ensuring compatibility and reliability. Choosing OEM items can provide peace of mind, as they often come with warranties and are known for their durability.

Exploring Aftermarket Alternatives

Aftermarket components are made by third-party manufacturers and may offer a range of prices and quality levels. While some aftermarket options can provide equal or superior performance compared to OEM items, others may lack the same reliability. It’s crucial to research the reputation of the aftermarket manufacturer and consider factors such as warranty, materials used, and customer reviews.

| Criteria | OEM Components | Aftermarket Alternatives |

|---|---|---|

| Quality | Consistently high | Varies widely |

| Price | Generally higher | Often lower |

| Warranty | Typically includes warranty | Varies by manufacturer |

| Availability | Limited to specific dealerships | Widely available |

Tools Needed for DIY Repairs

When it comes to performing maintenance or fixing issues on your vehicle, having the right tools is essential for successful repairs. Whether you’re a novice or an experienced enthusiast, equipping your workspace with the necessary instruments can streamline the process and enhance efficiency. Below is a list of commonly used tools that can aid in various repair tasks.

| Tool | Description |

|---|---|

| Wrenches | Used for loosening or tightening nuts and bolts of various sizes. |

| Socket Set | Allows for easy access to fasteners in tight spaces with interchangeable heads. |

| Screwdrivers | Essential for removing and securing screws, available in various head types. |

| Pliers | Helpful for gripping, twisting, and cutting wires or small parts. |

| Jack and Stands | Critical for lifting the vehicle to access the undercarriage safely. |

| Multimeter | Used for diagnosing electrical issues by measuring voltage, current, and resistance. |

| Torque Wrench | Ensures that fasteners are tightened to the correct specifications. |

| Fluid Containers | Essential for catching and disposing of fluids safely during repairs. |

Step-by-Step Repair Process Guide

This section provides a comprehensive approach to addressing mechanical issues efficiently and effectively. By following a structured methodology, you can ensure that each phase of the repair is executed with precision, ultimately leading to optimal performance of the vehicle.

Preparation

- Gather all necessary tools and materials.

- Ensure a clean and organized workspace.

- Review the vehicle’s manual for specific details related to the repair.

Execution

- Begin by disconnecting the battery to ensure safety.

- Carefully remove any components that obstruct access to the area requiring attention.

- Inspect the parts thoroughly for wear or damage.

- Replace or repair components as necessary, following the guidelines in the manual.

- Reassemble the removed parts, ensuring that each is secured properly.

- Reconnect the battery and conduct a test to confirm the effectiveness of the repair.

By adhering to this systematic approach, you can navigate through the complexities of vehicle maintenance with confidence.

Upgrading Components for Better Efficiency

Enhancing various elements within a vehicle can lead to significant improvements in overall performance and fuel economy. By focusing on key areas, drivers can experience a smoother ride, better handling, and reduced wear on the engine. Investing in modern replacements can transform the driving experience, ensuring optimal functionality and longevity.

Assessing Current Elements

Before making any upgrades, it is crucial to evaluate the existing components for wear and efficiency. Identifying outdated or malfunctioning parts allows for targeted improvements that yield the best results. Common areas to examine include the intake system, exhaust components, and suspension elements. Upgrading these parts can significantly enhance airflow, reduce engine strain, and improve handling characteristics.

Selecting Suitable Replacements

When choosing replacements, it is essential to prioritize quality and compatibility. Opting for high-performance alternatives can lead to better fuel efficiency and improved responsiveness. Researching reputable brands and consulting with experts can provide valuable insights into the most effective options available, ensuring a successful upgrade that meets individual driving needs.

Resources for Finding Genuine Parts

Locating authentic components for your vehicle is crucial for maintaining its performance and reliability. With the right resources, you can ensure that the items you acquire meet the required standards for quality and compatibility.

Online Retailers

- Official manufacturer websites often provide access to genuine items specifically designed for your model.

- Reputable online marketplaces offer a wide selection of certified products, often including customer reviews and ratings.

- Specialized automotive parts websites can help you find specific components, along with detailed descriptions and compatibility information.

Local Dealerships

- Authorized dealerships are reliable sources for original equipment, ensuring that you receive parts that are built to the manufacturer’s specifications.

- Inquire about special orders or rare components that may not be readily available in stock.

- Some dealerships offer loyalty programs or discounts for repeat customers, making it more economical to source parts from them.

Utilizing these resources can greatly enhance your ability to find the right components for your vehicle, ensuring optimal performance and longevity.

Safety Precautions During Repairs

When undertaking maintenance on a vehicle, ensuring safety is paramount. Proper precautions can prevent accidents and injuries, making the repair process more efficient and less stressful. Familiarizing oneself with safety guidelines before starting any task is essential for a successful and secure experience.

Always wear appropriate personal protective equipment, such as gloves and safety glasses, to shield against harmful substances and debris. It’s vital to work in a well-ventilated area to avoid inhaling fumes or dust. Additionally, keeping a first aid kit nearby can be invaluable in case of minor injuries.

Before commencing any repairs, ensure the vehicle is securely parked on a level surface with the engine turned off. Utilizing wheel chocks and jack stands can prevent the vehicle from rolling or collapsing while being worked on. Furthermore, disconnecting the battery helps to mitigate electrical hazards.

Lastly, being aware of your surroundings and potential hazards in the workspace is crucial. Avoid distractions, keep tools organized, and always double-check that you are using the correct equipment for each specific task. By following these guidelines, you can help ensure a safe and productive repair session.