Understanding the intricate elements of a vintage aquatic vehicle is essential for enthusiasts and repair professionals alike. These machines are composed of various mechanisms and accessories, each playing a crucial role in overall performance and reliability. A detailed overview of these components not only aids in maintenance but also enhances the enjoyment of the riding experience.

For aficionados, having a comprehensive reference guide to the structure and assembly of their watercraft can significantly simplify repairs and upgrades. This knowledge empowers owners to tackle challenges effectively, ensuring their vessel remains in prime condition for adventures on the water.

In this article, we delve into the assembly of a well-known model, showcasing its essential elements. We will highlight each section, offering insights that will be invaluable to anyone looking to restore or enhance their beloved machine.

Overview of 1994 Sea-Doo XP

This model represents a significant milestone in the evolution of personal watercraft. Known for its sleek design and enhanced performance capabilities, it quickly became a favorite among enthusiasts. The integration of advanced features not only improved handling but also elevated the overall riding experience, making it a sought-after choice during its time.

Key Features

Among the standout characteristics are its lightweight construction, powerful engine, and ergonomic design. These elements contribute to a responsive ride and increased maneuverability on the water. Furthermore, the craft’s unique hull shape plays a pivotal role in its stability, allowing for confident navigation even in challenging conditions.

Specifications

| Feature | Details |

|---|---|

| Engine Type | Two-stroke, water-cooled |

| Displacement | 720 cc |

| Horsepower | 85 hp |

| Length | 8.2 ft (2.5 m) |

| Width | 4.3 ft (1.3 m) |

| Weight | 375 lbs (170 kg) |

Key Features of Sea-Doo XP

The Sea-Doo XP stands out for its advanced design and innovative features that cater to enthusiasts of water sports and recreation. Crafted with precision engineering, this model integrates cutting-edge technologies to enhance performance and ensure a thrilling experience on the water.

Performance and Handling

- Dynamic hull design for improved maneuverability and stability.

- Enhanced propulsion system that boosts acceleration and speed.

- Precise steering mechanism for responsive control in varying water conditions.

Comfort and Ergonomics

- Ergonomically designed seating for maximum comfort during long rides.

- Integrated storage compartments for convenient access to essentials.

- Adjustable handlebars and controls tailored to fit different rider preferences.

These features collectively redefine the experience of riding a personal watercraft, offering both performance enthusiasts and recreational users a reliable and exhilarating aquatic adventure.

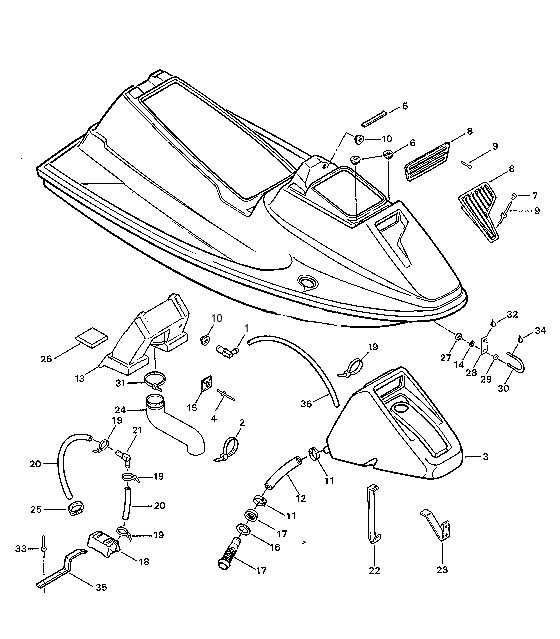

Importance of Parts Diagrams

Visual representations of component arrangements play a crucial role in understanding the assembly and functionality of machinery. These illustrations not only aid in identifying individual elements but also enhance the overall comprehension of how these elements interact within a system. Accurate depictions facilitate efficient maintenance and repairs, ensuring optimal performance and longevity.

Facilitating Maintenance

Comprehensive visuals significantly streamline the upkeep process. By providing a clear view of each component’s location and connection, users can swiftly identify issues and address them without unnecessary delays. This efficiency ultimately saves time and reduces the risk of further damage during repair procedures.

Enhancing Learning and Understanding

For individuals new to machinery, these visual guides serve as valuable educational tools. They break down complex systems into manageable parts, allowing users to gain a better grasp of how each piece functions. This understanding not only boosts confidence but also encourages proper handling and care.

| Benefits | Impact |

|---|---|

| Quick Identification | Reduces repair time and effort. |

| Improved Understanding | Enhances user confidence and competence. |

| Efficient Repairs | Minimizes risk of further damage. |

| Educational Value | Supports learning and skill development. |

Common Replacement Parts Available

Maintaining and restoring personal watercraft involves identifying essential components that may need to be replaced over time. Regular usage, exposure to water, and environmental factors can lead to wear and tear on critical elements, impacting performance and safety. Understanding which components are commonly available for replacement can help enthusiasts keep their machines in optimal condition.

Among the frequently sought-after items are the propulsion systems, including impellers and pumps, which are crucial for efficient movement across water. Additionally, electrical components such as ignition coils and starter motors often require attention, ensuring reliable starts and smooth operation. Fuel delivery parts, including carburetors and fuel filters, also play a vital role in maintaining engine performance.

Furthermore, the hull and body may need various components, such as bumpers, handles, and seat cushions, to enhance both aesthetics and functionality. Routine maintenance kits, including gaskets and seals, are readily available and are essential for preventing leaks and ensuring proper sealing. By focusing on these common components, owners can enhance their watercraft’s lifespan and enjoyment on the water.

Understanding Engine Components

The inner workings of a watercraft’s propulsion system are vital for its performance and efficiency. Each part plays a crucial role in ensuring that the engine operates smoothly and reliably. A comprehensive understanding of these elements can enhance maintenance practices and improve overall functionality.

Powerhead serves as the core of the engine, housing essential components such as the crankshaft and cylinders. It is responsible for converting fuel into mechanical energy. The cylinder block is another integral element, providing the framework for the cylinders, which contain the combustion process that powers the craft.

Pistons move within the cylinders, converting the energy produced from combustion into rotational motion. This motion is transmitted through the connecting rods to the crankshaft, which ultimately drives the craft. Proper lubrication is crucial, and the oil system ensures that all moving parts are adequately lubricated to minimize wear and enhance efficiency.

Additionally, the intake and exhaust systems regulate the flow of air and fuel into the combustion chamber and expel exhaust gases. Understanding these components can lead to better troubleshooting and performance optimization, making it essential for enthusiasts and technicians alike.

Electrical System Breakdown

The electrical system of a personal watercraft is crucial for its operation and efficiency. Understanding its components and functions is essential for effective maintenance and troubleshooting. This section delves into the various elements that make up the electrical system, ensuring optimal performance and reliability.

Key Components

- Battery: Provides the necessary power to start the engine and operate electrical accessories.

- Ignition System: Responsible for initiating the combustion process within the engine.

- Wiring Harness: A network of wires that connects various electrical components, allowing for the transfer of power and signals.

- Fuse Box: Protects the electrical system by preventing overloads and short circuits through the use of fuses.

- Regulator/Rectifier: Converts the generated AC power into DC power, ensuring a stable voltage for the system.

Maintenance Tips

- Regularly inspect and clean battery terminals to ensure a solid connection.

- Check wiring for any signs of wear, corrosion, or damage.

- Test the ignition system periodically to verify proper operation.

- Replace fuses as needed and ensure that the fuse box is securely mounted.

- Monitor voltage output from the regulator/rectifier to prevent electrical issues.

Fuel System Overview

The fuel system is a critical component of any watercraft, responsible for delivering the necessary energy to the engine for optimal performance. This system comprises various elements that work in harmony to ensure efficient fuel management, allowing the vessel to operate smoothly on the water. Understanding its functionality and components can help maintain and enhance the performance of the craft.

Key Components

At the core of the fuel system are several essential components, including the fuel tank, fuel lines, pump, and injectors. The fuel tank stores the gasoline, which is then transported through fuel lines to the pump. This pump pressurizes the fuel, delivering it to the injectors, which atomize the fuel for proper combustion within the engine. Each part plays a vital role in ensuring that the engine receives the right amount of fuel at the appropriate pressure, contributing to overall efficiency and performance.

Maintenance and Troubleshooting

Regular maintenance of the fuel system is crucial for preventing issues that can affect engine performance. This includes inspecting fuel lines for leaks, ensuring the fuel filter is clean, and monitoring the pump’s operation. Common problems may include poor fuel delivery, which can lead to sluggish performance or engine stalling. Addressing these issues promptly can help ensure that the watercraft remains reliable and enjoyable to operate.

Jet Pump and Impeller Details

The propulsion system of personal watercraft plays a crucial role in performance and efficiency. Central to this system are two key components: the jet propulsion mechanism and the rotating element that creates thrust. Understanding their design and functionality can enhance maintenance and improve overall operation.

The jet propulsion mechanism comprises various elements that work together to draw water in and expel it forcefully, generating forward motion. Key features include:

- Housing: Encloses the internal components and directs the flow of water.

- Wear Ring: A replaceable liner that minimizes clearance between the pump and impeller, ensuring optimal performance.

- Exit Nozzle: Directs the expelled water, influencing the direction and speed of the craft.

The rotating component, commonly known as the thrust generator, is vital for converting engine power into movement. Its characteristics include:

- Design: Engineered to maximize water flow while minimizing cavitation, which can reduce efficiency and cause damage.

- Material: Typically constructed from durable alloys to withstand the harsh marine environment.

- Balancing: Precision balancing is essential to reduce vibrations and enhance longevity.

Regular inspection and maintenance of these components ensure peak performance and reliability. Understanding their roles within the propulsion system empowers users to make informed decisions about upkeep and repairs.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and performance of any watercraft. Regular maintenance not only enhances functionality but also prolongs the lifespan of various components, minimizing the risk of unexpected breakdowns. Adopting a consistent care routine can help owners enjoy many trouble-free days on the water.

Routine Inspections

Conducting frequent inspections is vital for identifying potential issues before they escalate. Check for signs of wear and tear on essential parts, including the engine and electrical systems. Look for any leaks, corrosion, or unusual sounds during operation. Addressing minor concerns early can prevent costly repairs down the line.

Fluid Management

Maintaining proper fluid levels is crucial for optimal performance. Regularly check and replace oil, coolant, and fuel as needed to ensure smooth operation. Using high-quality fluids can enhance efficiency and protect critical components from damage. Additionally, always flush the cooling system after use in saltwater to prevent buildup and corrosion.

Following these guidelines can lead to a more enjoyable and hassle-free experience. Remember, a well-maintained watercraft not only performs better but also provides peace of mind for every adventure.

Finding OEM vs Aftermarket Parts

When it comes to sourcing components for your watercraft, understanding the difference between original equipment manufacturer (OEM) and aftermarket options is crucial. Both types of components serve the purpose of maintaining or enhancing performance, but they differ significantly in quality, pricing, and availability.

OEM components are produced by the manufacturer of the vehicle, ensuring a perfect fit and compatibility. These items often come with a warranty and are designed to meet the specific standards set during production. However, they may come with a higher price tag.

On the other hand, aftermarket options are created by third-party companies. These alternatives can be more affordable, but their quality can vary widely. It’s essential to research these options carefully to ensure they meet your expectations for performance and durability.

- Quality: OEM parts are typically made from higher-quality materials and designed to last, while aftermarket options may compromise quality for lower costs.

- Cost: Aftermarket alternatives can provide significant savings, but it’s vital to balance cost against potential quality issues.

- Availability: OEM components may have longer lead times, especially for older models, whereas aftermarket options are often readily available.

- Warranty: OEM parts usually come with a manufacturer’s warranty, while aftermarket items may have limited or no warranty coverage.

Ultimately, the choice between OEM and aftermarket components will depend on your individual needs, budget, and the specific requirements of your vehicle. Careful consideration of these factors will help you make an informed decision that best suits your situation.

Tools Required for Repairs

When undertaking maintenance or restoration tasks on watercraft, having the right set of tools is essential. A well-prepared toolkit not only facilitates efficient repairs but also ensures safety and precision during the process. Below is a guide to the necessary implements that can aid in various tasks.

Essential Hand Tools

- Socket Wrench Set

- Combination Wrenches

- Flat and Phillips Screwdrivers

- Needle-Nose Pliers

- Adjustable Wrench

Specialized Equipment

- Torque Wrench

- Compression Tester

- Digital Multimeter

- Oil Filter Wrench

- Propeller Puller

Using the appropriate tools can greatly improve the quality of repairs and maintenance. It is advisable to inspect and organize these tools regularly to ensure they are in good working condition, ready for any task that may arise.

Resources for Repair Manuals

Accessing the right resources for repair documentation is essential for effectively maintaining and restoring watercraft. These guides provide detailed information on various components, troubleshooting techniques, and assembly instructions. Utilizing reliable manuals can enhance your understanding of the machinery and help in performing repairs with confidence.

Where to Find Repair Guides

Several sources offer comprehensive manuals for watercraft enthusiasts. Here are some of the best options available:

| Source | Description |

|---|---|

| Manufacturer’s Website | Official websites often provide downloadable manuals for their products, ensuring accuracy and reliability. |

| Online Forums | Community-driven forums can be valuable for finding shared manuals, tips, and personal experiences from other users. |

| Retailers | Many parts retailers sell repair manuals alongside their products, offering detailed information tailored to specific models. |

| Library Resources | Local libraries may carry a collection of repair manuals, often available for borrowing or reference. |

Importance of Accurate Manuals

Using precise and well-structured repair guides is crucial for successful maintenance. Quality manuals minimize the risk of errors during repairs, ensuring that every task is performed correctly. Investing time in sourcing the right documentation pays off by prolonging the life of your equipment and enhancing overall performance.

Community Forums and Support Groups

Engaging with others who share similar interests can greatly enhance your understanding and enjoyment of recreational watercraft. Online platforms dedicated to enthusiasts provide a space for individuals to exchange knowledge, seek advice, and share experiences related to maintenance and upgrades. These communities serve as invaluable resources for both novice and seasoned users.

Active forums and support groups often feature a wealth of information, including troubleshooting tips, user reviews, and recommendations for aftermarket components. Participants can benefit from the collective wisdom of fellow members, who may have faced similar challenges or have insights into effective solutions. Additionally, these platforms foster connections among users, leading to potential meet-ups or group rides, further enriching the experience.

For those looking to dive deeper into the world of aquatic vehicles, joining a community can be a transformative experience. Engaging in discussions, asking questions, and sharing your journey not only contributes to your personal growth but also supports others in the community. The camaraderie built within these groups often extends beyond online interactions, creating friendships that last for years.