In the realm of mechanical and electronic assemblies, a clear representation of individual elements is essential for efficient maintenance and assembly processes. Such representations serve as vital guides for technicians and engineers, enabling them to comprehend the relationships between various components and their functions within a larger system.

These visual aids not only enhance understanding but also facilitate troubleshooting and repairs. By providing a structured view of each element, users can quickly identify issues and make informed decisions regarding modifications or replacements. The effectiveness of these illustrations is particularly evident in complex systems where numerous parts interact closely.

Ultimately, a well-crafted layout empowers users with the knowledge they need to ensure the longevity and reliability of their equipment. Embracing such resources can lead to improved performance and a smoother operational experience for all involved.

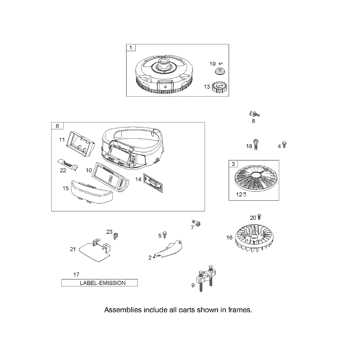

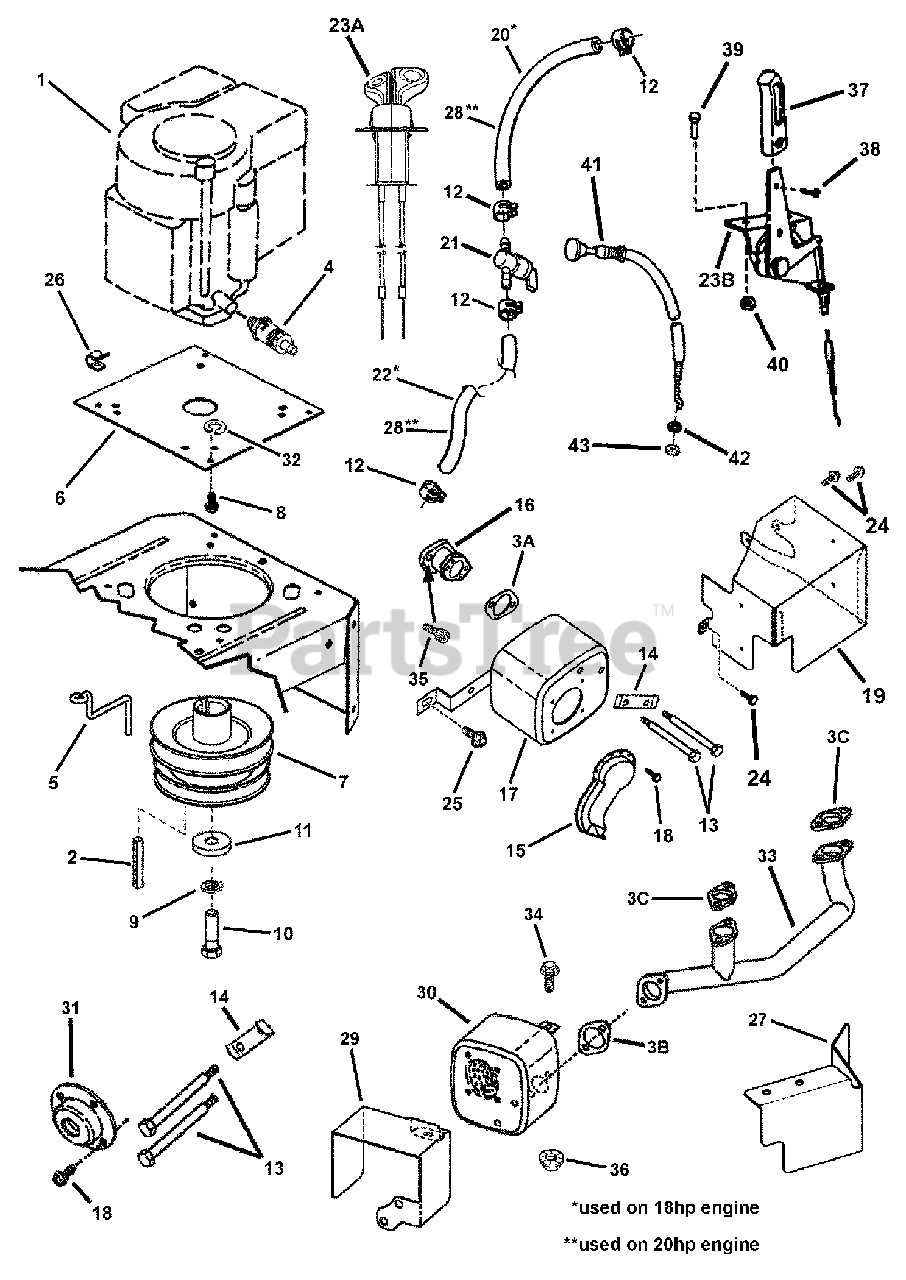

Key Features of the 31h777 Model

This section delves into the essential characteristics that define this specific model. It encompasses the notable attributes that contribute to its functionality and performance, making it a valuable addition to any compatible setup.

Design and Build Quality

- Robust construction ensures durability under various operating conditions.

- Compact design allows for easy integration into existing systems.

- High-quality materials enhance longevity and resistance to wear.

Performance and Efficiency

- Optimized for superior performance, offering reliable operation.

- Energy-efficient mechanisms reduce power consumption.

- Advanced technology provides enhanced output and productivity.

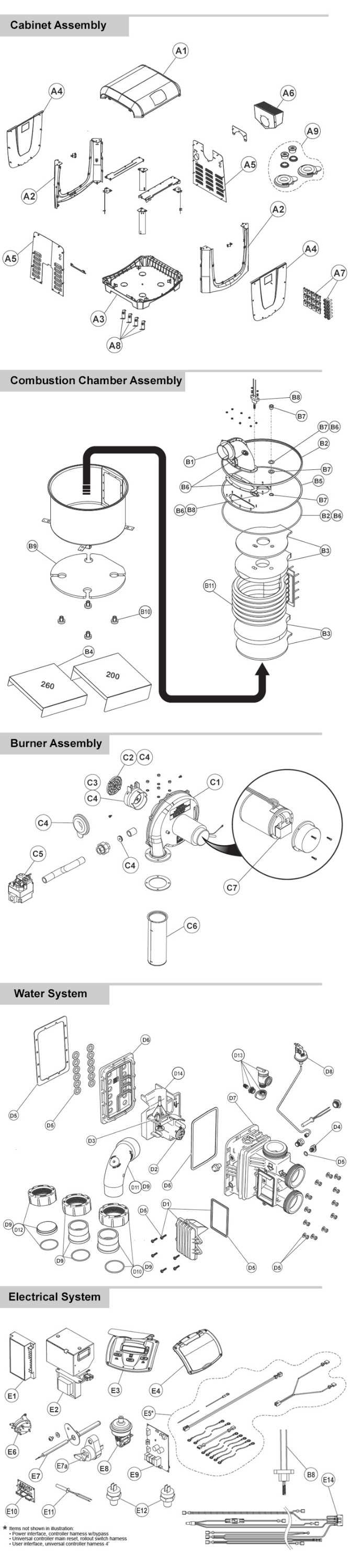

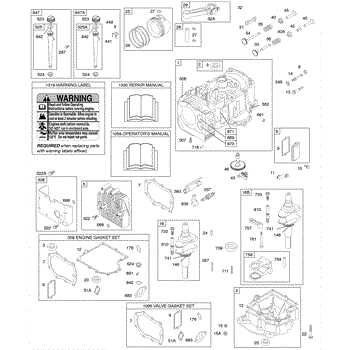

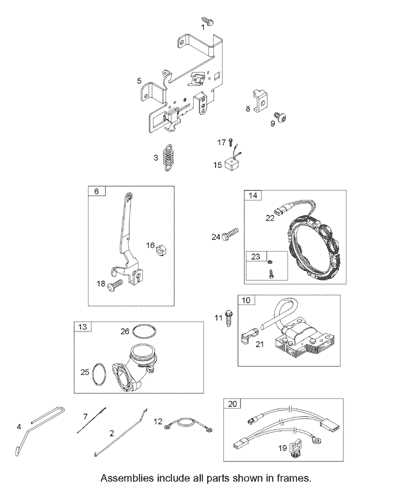

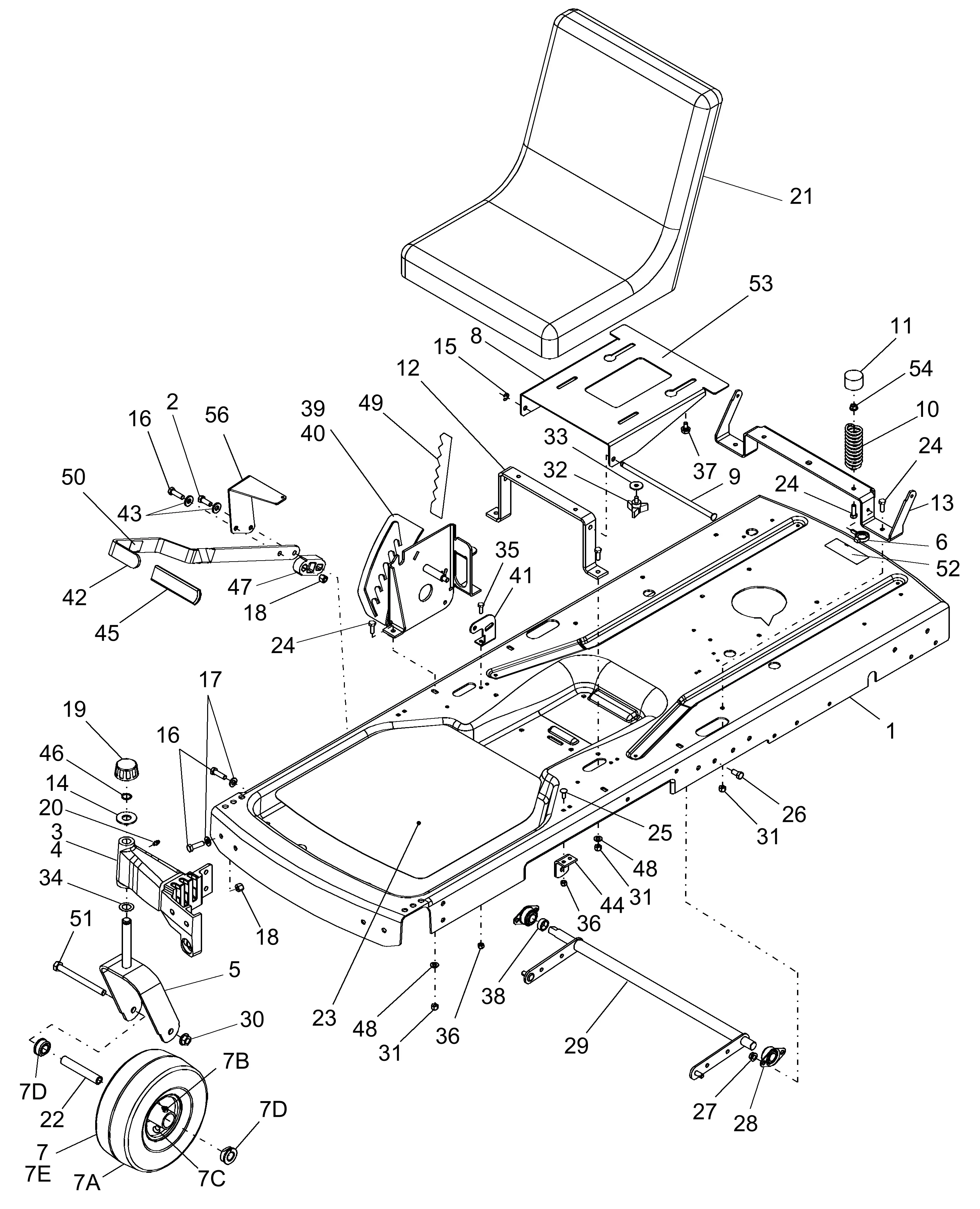

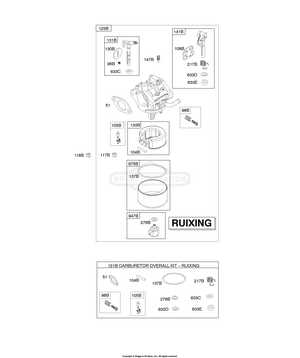

Understanding the Parts Layout

Grasping the arrangement of components within a mechanical assembly is crucial for effective analysis and maintenance. This overview aims to illuminate the spatial organization and interconnections among various elements, enabling users to navigate and comprehend the system more intuitively.

Each element plays a significant role in the overall functionality, and understanding their placements can lead to better troubleshooting and optimization. By familiarizing oneself with how these components interact, one can enhance both the performance and longevity of the device.

Furthermore, recognizing the layout assists in identifying potential issues and streamlining repair processes. It empowers individuals to approach maintenance tasks with confidence, knowing precisely where each component resides and how it contributes to the assembly’s operation.

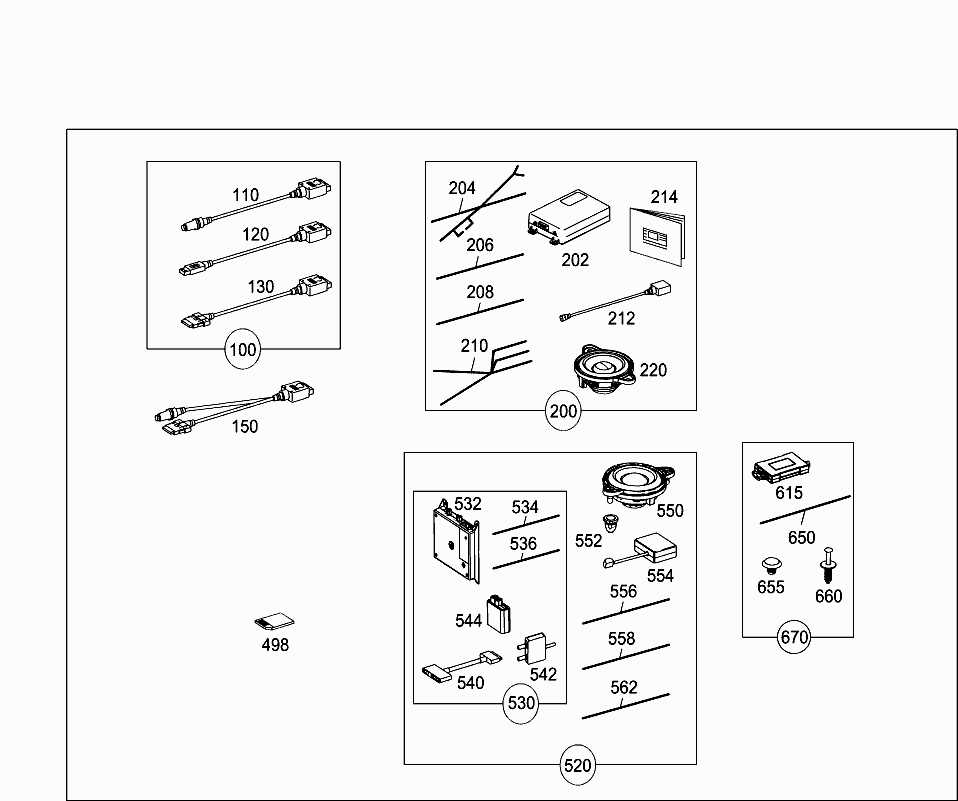

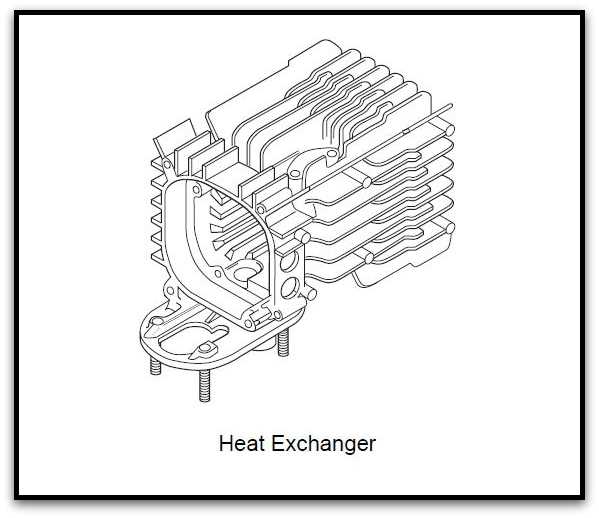

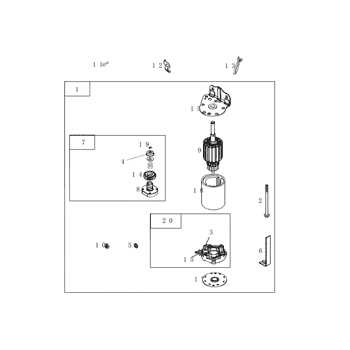

Functionality of Each Component

This section explores the role of various elements within the system, highlighting their unique contributions to overall operation. Understanding these functions is crucial for optimizing performance and ensuring seamless integration.

Power Unit: The primary source of energy, this component regulates voltage levels and ensures stability throughout the system. Its efficiency directly affects the reliability of all connected elements.

Control Module: Acting as the brain, this unit processes signals and coordinates actions among different components. Its responsiveness determines how effectively the entire assembly reacts to input.

Sensor Array: This group of detectors monitors environmental changes and transmits data to the control module. Accurate readings are vital for adjustments, enhancing functionality and safety.

Connector Interface: Facilitating communication between components, this interface ensures data flows smoothly. Proper connections are essential for maintaining operational integrity.

Output Mechanism: Responsible for executing commands, this element translates signals from the control module into physical actions. Its performance is critical for achieving desired results.

Common Issues with 31h777 Parts

When dealing with mechanical components, various complications can arise that affect functionality and performance. Understanding these challenges can help in troubleshooting and ensuring optimal operation. This section highlights frequent problems encountered with specific components used in various applications.

Frequent Challenges

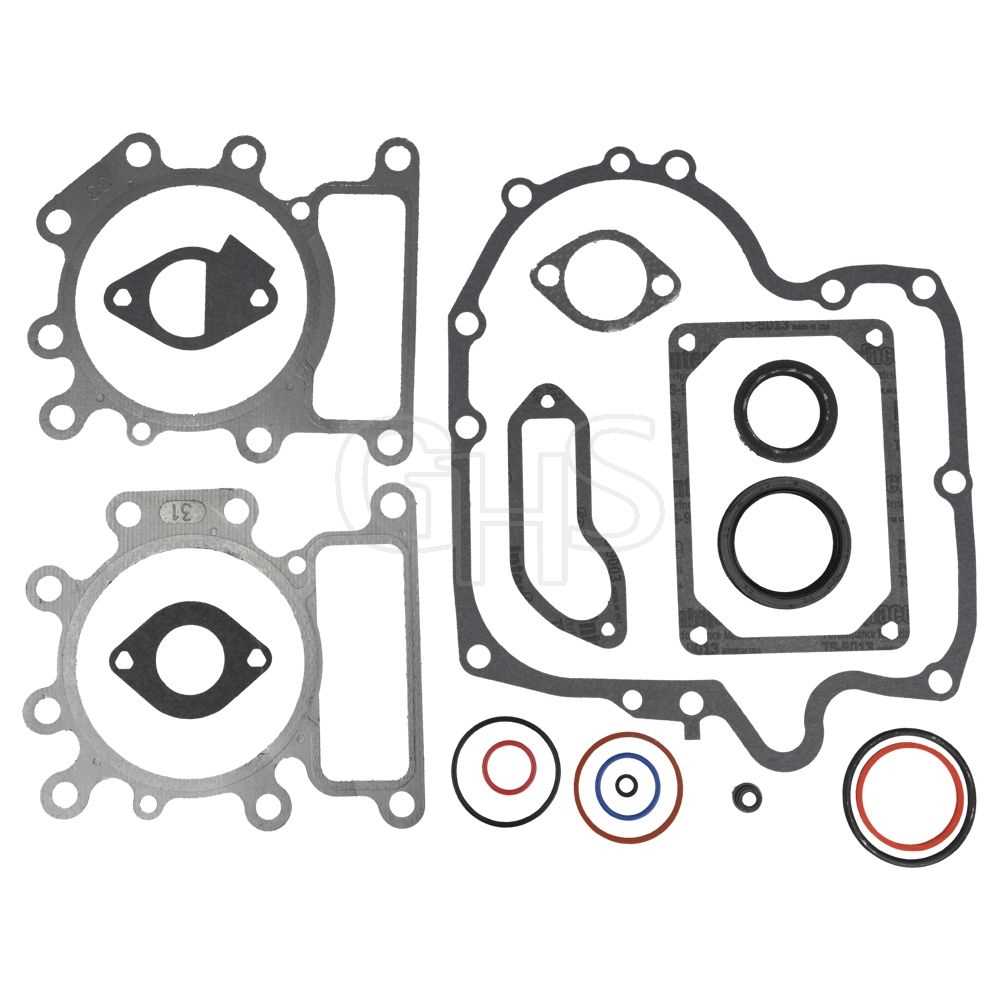

One of the main difficulties faced by users is wear and tear over time, which can lead to decreased efficiency. Components may become less responsive, resulting in performance issues that require immediate attention. Regular maintenance and timely replacement can mitigate these problems significantly.

Compatibility Concerns

Another issue that users often experience is compatibility with different systems or configurations. Components that are not ideally matched can lead to improper functioning or even damage. It is crucial to verify specifications and compatibility before installation to avoid such predicaments.

| Issue | Description | Solution |

|---|---|---|

| Wear and Tear | Gradual degradation affecting efficiency | Regular inspection and replacement |

| Compatibility | Incompatibility with systems causing malfunction | Check specifications before use |

| Installation Errors | Improper setup leading to operational issues | Follow guidelines for accurate installation |

Maintenance Tips for Longevity

Ensuring the durability and efficient operation of any machinery involves consistent care and attention. By adopting a few essential practices, users can significantly extend the lifespan of their equipment, reducing the need for frequent repairs and replacements.

Regular Inspections

Performing routine checks on your equipment helps identify potential issues before they escalate. Look for signs of wear, loose connections, or any unusual sounds during operation. Early detection allows for timely interventions, ensuring optimal performance.

Proper Lubrication

Maintaining appropriate lubrication levels is crucial for smooth functioning. Regularly apply the recommended lubricants to moving parts, as this minimizes friction and wear. Consult the manufacturer’s guidelines for specific lubrication intervals and types to use.

Replacement Parts Availability

When it comes to maintaining machinery, understanding the accessibility of components is crucial for ensuring optimal functionality. Having reliable sources for acquiring necessary items can significantly enhance the longevity and efficiency of the equipment.

There are various avenues through which one can secure these essential elements:

- Manufacturer’s Website: The primary resource for original items often provides comprehensive listings along with compatibility details.

- Authorized Dealers: Partner organizations that specialize in the distribution of official components usually offer high-quality selections.

- Online Retailers: E-commerce platforms can feature a wide variety of options, including both new and refurbished selections.

- Local Repair Shops: Community-based services may have access to spare pieces or can assist in sourcing them directly.

- Salvage Yards: For those seeking budget-friendly alternatives, these locations can provide used components that are still in good working condition.

In addition to availability, it’s advisable to verify the specifications and compatibility of each item to ensure a proper fit. By exploring multiple resources, individuals can enhance their chances of obtaining the required elements efficiently.

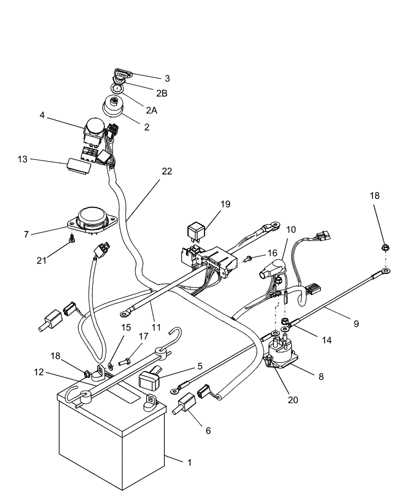

Assembly Instructions for Users

This section provides essential guidelines for users to effectively assemble the components of the device. Following these instructions carefully will ensure a successful setup, allowing for optimal performance and longevity of the unit.

Preparation Steps

Before starting the assembly process, gather all necessary tools and components. Ensure you have a clean, organized workspace to facilitate the procedure. Review the list of items required for assembly to confirm that everything is on hand.

Assembly Process

Begin by following the step-by-step instructions outlined in the table below. Each step includes a description and any tools required to complete the assembly effectively.

| Step | Description | Tools Needed |

|---|---|---|

| 1 | Attach the base to the main unit securely. | Screwdriver |

| 2 | Connect the wiring harness to the appropriate connectors. | Wire Strippers |

| 3 | Install the cover, ensuring all clips are properly engaged. | None |

| 4 | Verify all connections are tight and secure. | None |

Following these instructions will aid in achieving a successful assembly. Once completed, the device will be ready for use.

Tools Required for Repairs

To effectively carry out maintenance or restoration tasks on machinery, a well-equipped toolkit is essential. Having the right instruments not only enhances efficiency but also ensures safety during the process. Various tools serve specific functions, enabling technicians to address different issues that may arise.

Basic hand tools such as screwdrivers, wrenches, and pliers are fundamental for disassembly and reassembly tasks. A good quality socket set can be invaluable for reaching tight spaces and loosening stubborn fasteners. Additionally, cutting tools, including utility knives and wire cutters, assist in making precise adjustments and modifications.

For more intricate repairs, specialized equipment like multimeters and soldering irons may be necessary to diagnose electrical problems or make connections. Furthermore, having access to measuring devices such as calipers and tape measures ensures accuracy in all adjustments. Investing in a comprehensive selection of tools will significantly facilitate the repair process.

Safety Precautions During Work

Ensuring a secure working environment is crucial for the well-being of individuals engaged in various tasks. Adhering to specific safety measures minimizes the risk of accidents and injuries, fostering a productive atmosphere. It is essential to recognize potential hazards and take proactive steps to mitigate them, thereby promoting a culture of safety and responsibility.

General Safety Guidelines

Before commencing any task, it is important to familiarize oneself with the tools and equipment involved. Always wear appropriate personal protective gear, such as gloves, goggles, and hard hats, to safeguard against potential risks. Regularly inspect all tools for defects or damage, and ensure they are in proper working condition to prevent malfunctions during use.

Emergency Preparedness

Having an emergency plan in place is vital for addressing unexpected situations. Ensure that first aid supplies are readily available and that all team members are aware of the nearest exits and emergency contact numbers. Conduct regular drills to practice response procedures, fostering confidence in handling emergencies effectively.