When working with complex mechanical systems, it’s essential to have a clear understanding of how each element interacts within the broader structure. This guide will help break down the arrangement and functionality of key components in an intuitive way, ensuring smoother maintenance and repairs.

Each section will cover vital mechanical elements, discussing their roles and how they connect to the overall structure. By the end, you’ll be equipped with the necessary knowledge to better navigate and work with these intricate systems, whether for routine upkeep or detailed troubleshooting.

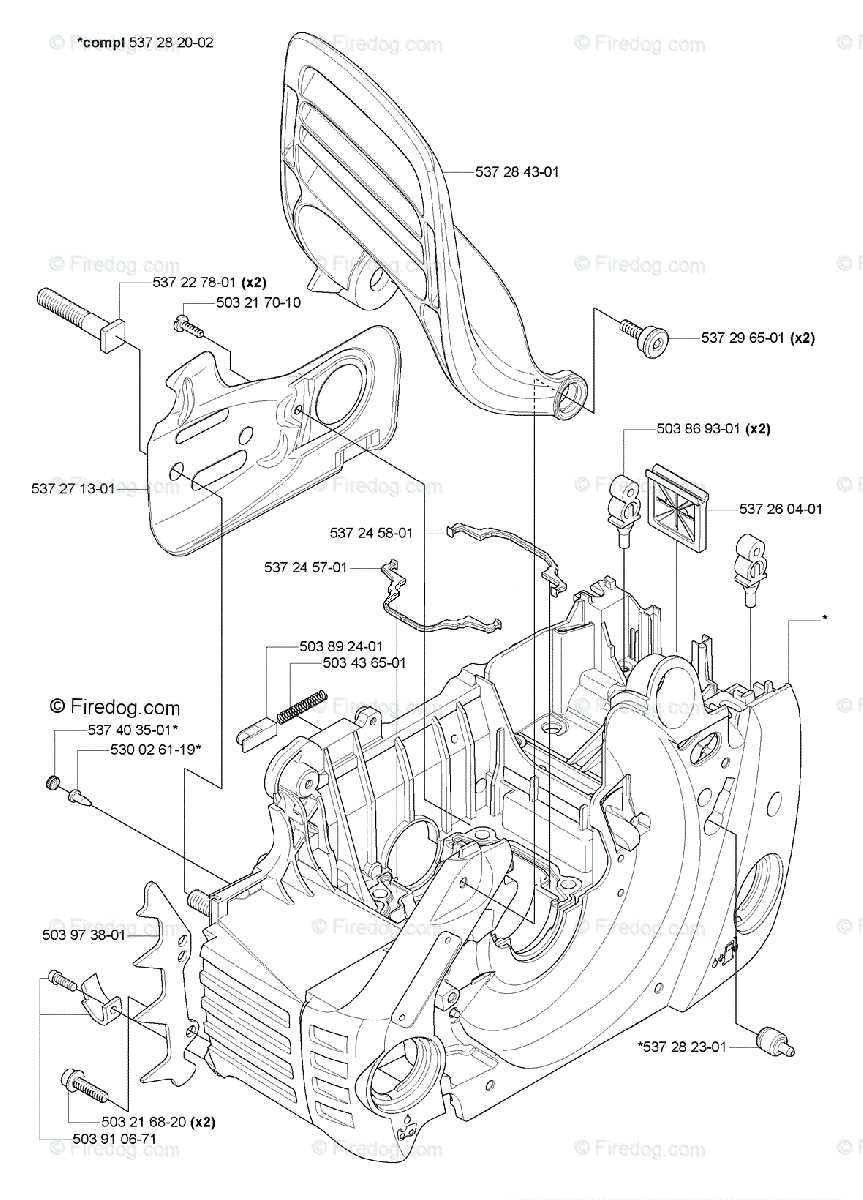

Understanding the 455 Rancher Components

When it comes to maintaining outdoor equipment, it’s crucial to understand how each element contributes to the overall functionality. A proper grasp of the essential elements helps ensure smooth operation, enhances durability, and simplifies troubleshooting when issues arise.

Key Functional Areas

Every part of the system is designed to perform a specific role. Some components manage power transfer, while others are responsible for cutting or reducing friction. Identifying these major areas and their roles allows for better performance and easier maintenance.

Maintaining Efficiency

Routine care of the different sections ensures that the system works effectively under various conditions. Periodic checks and timely replacements of crucial elements prevent unexpected breakdowns, keeping the equipment running optimally.

Key Mechanisms of the Chainsaw

Understanding the core elements that drive the efficiency and functionality of this cutting tool is crucial for both maintenance and operation. These components work together to deliver precise cutting power and durability, allowing for effective handling in various tasks.

- Engine Unit: The heart of the machine, this section generates the necessary force through combustion or electric power, delivering energy to the cutting components.

- Cutting Chain: Designed to move at high speeds, this element rotates around a guide, engaging the material with sharpened teeth to provide a clean cut.

- Guide Bar: A flat, elongated piece that directs the chain’s movement, ensuring straight and accurate cutting paths.

- Clutch System: A mechanism that helps regulate the chain’s movement, engaging or disengaging the drive to prevent unwanted operation.

- Lubrication System: Automatically applies oil to reduce friction, protecting both the chain and the guide from wear during use.

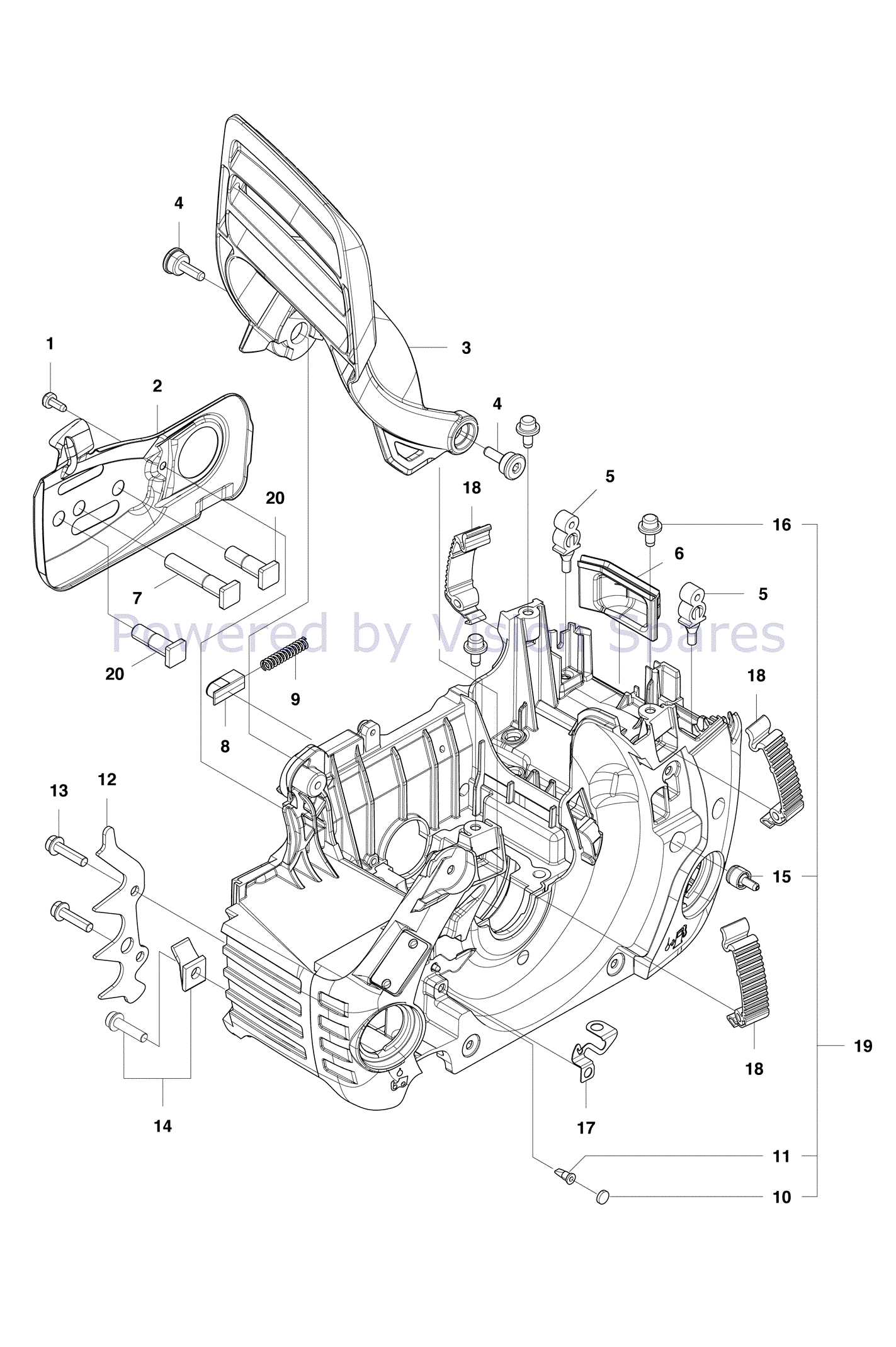

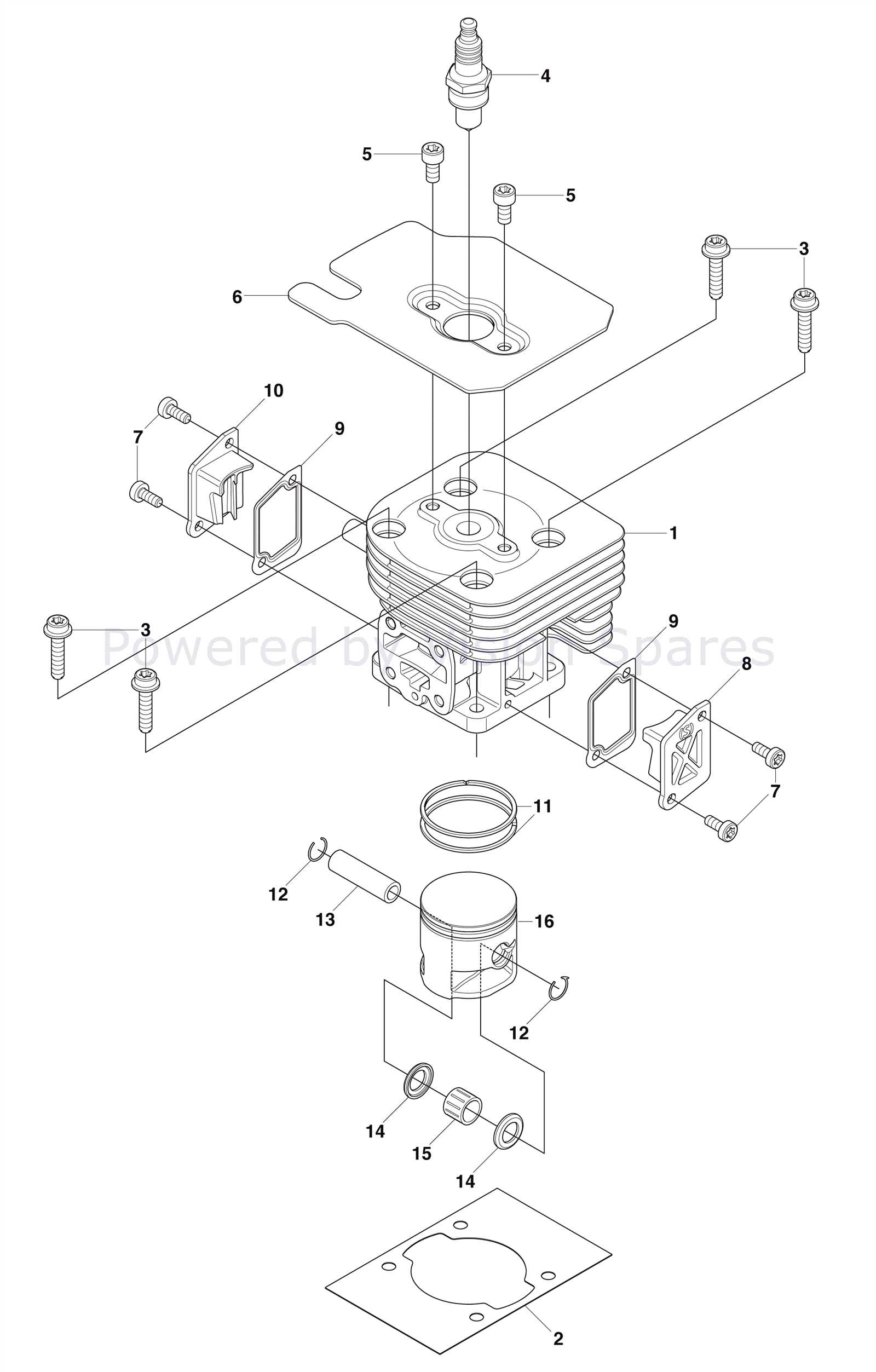

Exploring the Internal Engine Structure

Understanding the inner workings of a power unit is essential for anyone interested in performance and maintenance. This section delves into the various components that make up the engine, highlighting their functions and interconnections. Each part plays a vital role in ensuring optimal operation and efficiency, contributing to the overall effectiveness of the machine.

The engine comprises several key elements, each contributing to its functionality. The following table summarizes these components along with their respective roles:

| Component | Description |

|---|---|

| Cylinder Block | The main structure housing the cylinders and providing support for other components. |

| Pistons | Moving components within the cylinders that convert fuel combustion into mechanical energy. |

| Cylinder Head | Seals the top of the cylinder and houses valves and spark plugs, facilitating air and fuel intake. |

| Crankshaft | Transforms the up-and-down motion of the pistons into rotational motion. |

| Camshaft | Controls the opening and closing of the valves at the correct timing during the engine cycle. |

| Oil Pan | Reservoir for engine oil, ensuring lubrication for all moving parts. |

Main Engine Elements and Functions

The efficiency and reliability of a power unit are determined by its fundamental components and their roles in overall operation. Each part works synergistically to ensure optimal performance, contributing to the machine’s functionality and longevity. Understanding these elements is essential for maintenance and troubleshooting, allowing users to keep their equipment in peak condition.

Key Components

Among the critical components are the combustion chamber, which facilitates the burning of fuel, and the crankshaft, responsible for converting linear motion into rotational force. Additionally, the intake and exhaust systems play vital roles in managing airflow, ensuring that the engine breathes properly and operates efficiently.

Functional Overview

Furthermore, the ignition system initiates combustion, while the cooling mechanism maintains optimal temperatures to prevent overheating. Regular inspection of these elements helps in identifying wear and tear, ensuring that each component functions at its best. Maintaining a comprehensive understanding of these critical aspects is fundamental for anyone involved in operating or servicing the machinery.

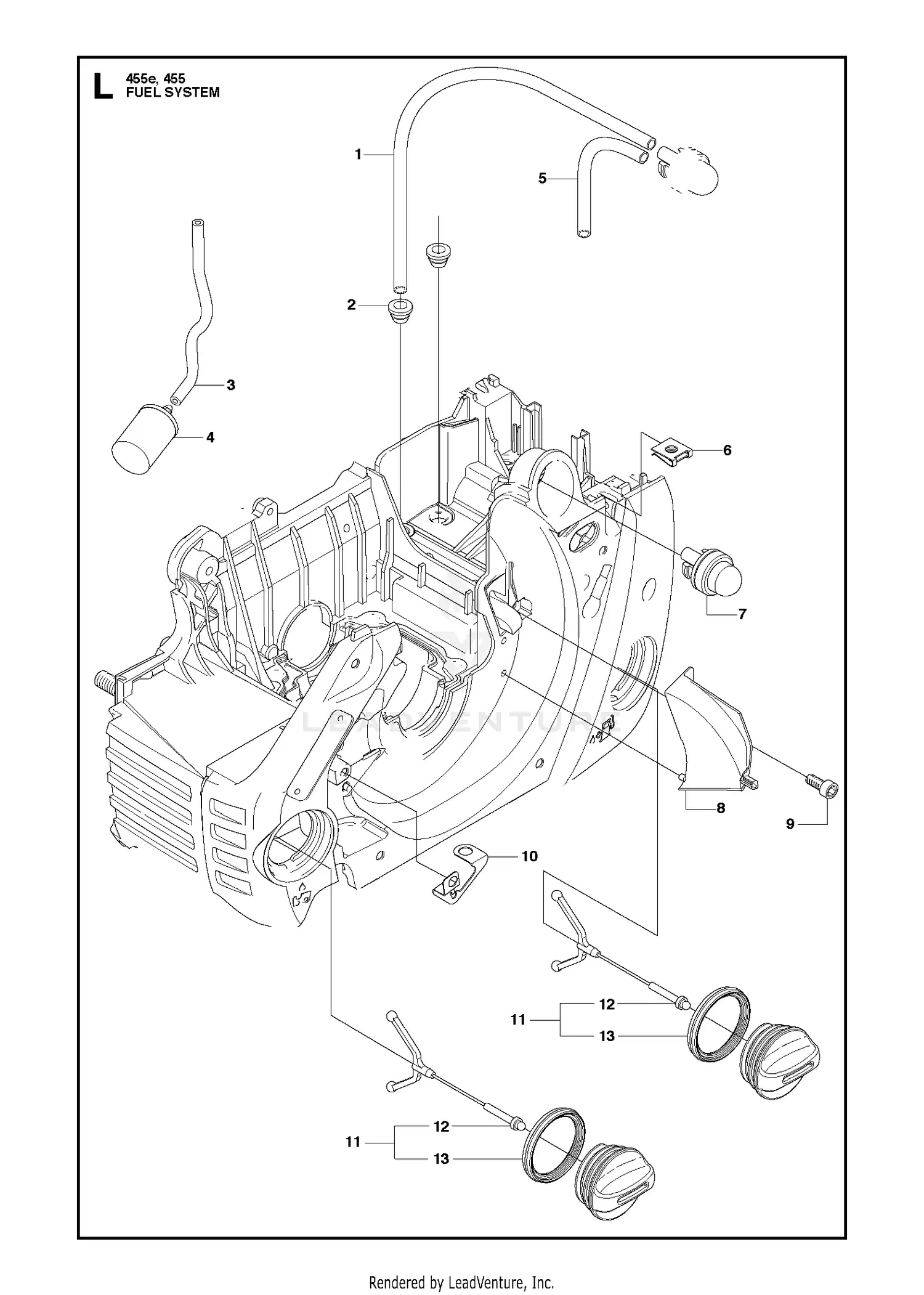

Fuel System Layout Overview

This section provides a comprehensive understanding of the arrangement and components involved in the fuel delivery mechanism of the equipment. A well-designed system is essential for optimal performance and efficiency, ensuring that the engine receives the right amount of fuel at the right time.

The configuration typically includes several key elements that work together to facilitate the smooth operation of the machinery. These components ensure that fuel is stored, filtered, and delivered to the engine as needed.

| Component | Description |

|---|---|

| Fuel Tank | Stores the fuel required for operation. |

| Fuel Pump | Moves fuel from the tank to the engine. |

| Fuel Filter | Removes impurities and contaminants from the fuel. |

| Fuel Lines | Transport fuel between various components. |

| Injectors | Spray fuel into the engine for combustion. |

Components Involved in Fuel Delivery

Effective fuel delivery is crucial for the optimal performance of internal combustion engines. This system comprises various elements that work harmoniously to ensure that fuel reaches the engine at the correct pressure and in the right quantity. Understanding the role of each component helps in diagnosing issues and performing maintenance.

| Component | Description |

|---|---|

| Fuel Tank | The reservoir where fuel is stored before being supplied to the engine. |

| Fuel Pump | A device that transports fuel from the tank to the engine, ensuring adequate pressure. |

| Fuel Filter | A filtration system that removes impurities from the fuel before it reaches the engine. |

| Fuel Lines | Pipes that convey fuel from the tank through the pump and filter to the engine. |

| Injectors | Devices that atomize the fuel, spraying it into the engine’s combustion chamber for efficient burning. |

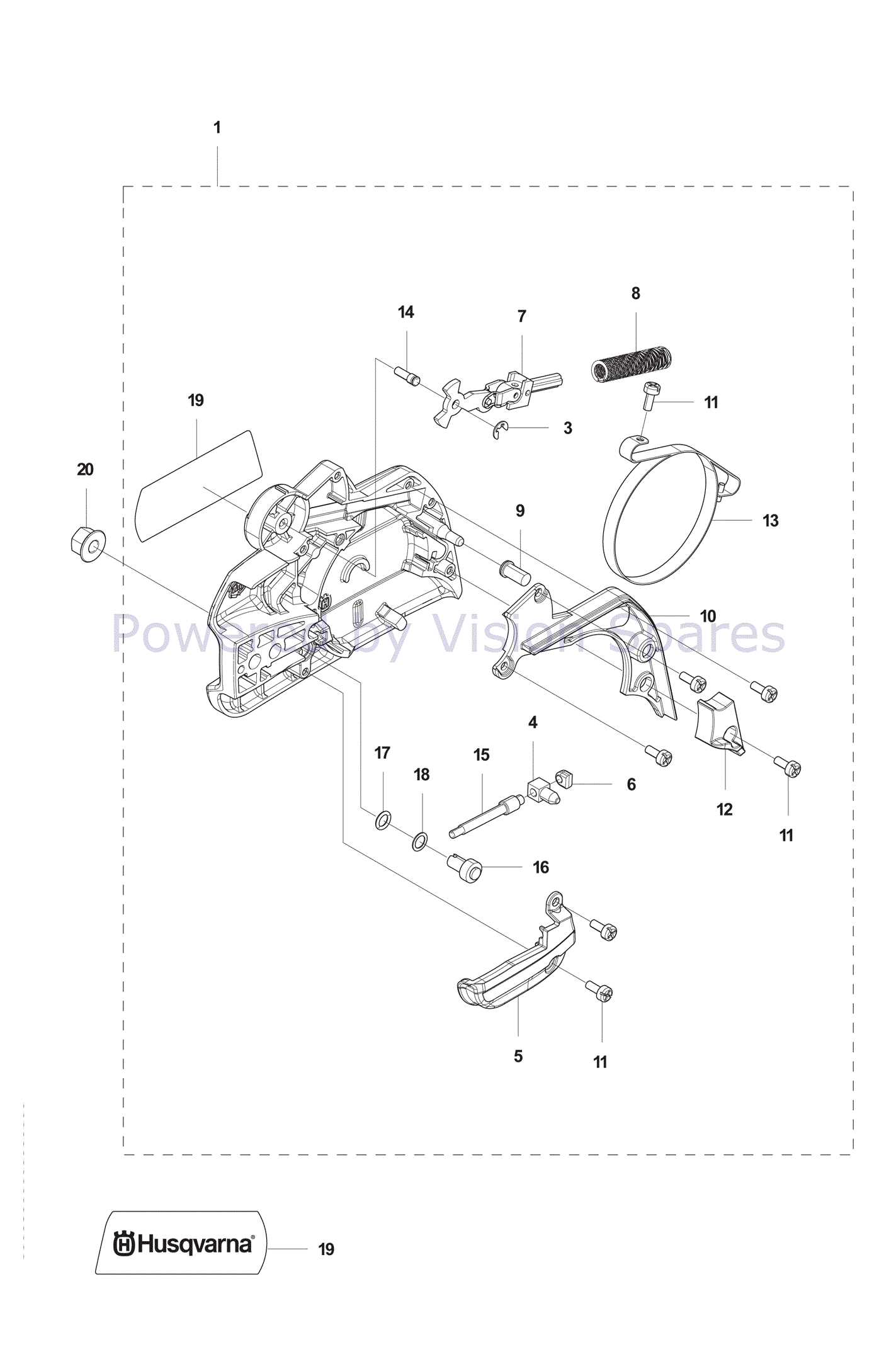

Chainsaw Chain and Guide Bar Anatomy

Understanding the components of a cutting tool is essential for optimal performance and maintenance. Two critical elements in this mechanism are the chain and the guide bar. Their design and function directly influence the efficiency and effectiveness of cutting tasks.

The chain is a continuous loop made up of interconnected links, each serving a specific role in the cutting process. It is essential to comprehend its construction to ensure proper handling and replacement when necessary. Key characteristics include:

- Drive Links: These links engage with the motor, facilitating movement around the guide bar.

- Cutting Links: Equipped with sharp teeth, they slice through materials during operation.

- Spacing Links: Positioned between cutting links, these elements maintain the chain’s structure and spacing.

The guide bar serves as a track along which the chain operates. Its length and design can vary, impacting maneuverability and the type of tasks that can be performed. Important aspects to consider include:

- Bar Length: Determines the depth of cut achievable.

- Bar Profile: Affects the chain’s performance and compatibility with different cutting scenarios.

- Mounting Slots: These openings allow the attachment of the bar to the machine securely.

Regular inspection of both components is crucial to ensure safe and effective operation. Maintaining sharp cutting edges and a well-aligned guide bar enhances the overall functionality of the tool.

Essential Parts for Smooth Operation

To ensure optimal performance of outdoor equipment, it is crucial to understand the key components that contribute to its efficiency. Each element plays a vital role in the functionality, allowing for seamless operation and longevity. This section outlines the fundamental components that every operator should be familiar with to maintain their machinery effectively.

Key Components to Consider

- Engine: The powerhouse that drives the entire system, delivering the necessary energy for operation.

- Fuel System: This includes filters and lines that facilitate the delivery of fuel to the engine, ensuring it runs smoothly.

- Ignition Assembly: Responsible for initiating the combustion process, this component is essential for starting the equipment.

- Air Filter: Vital for maintaining clean airflow into the engine, it helps prevent debris from causing damage.

- Cooling System: This includes radiators and fans that regulate temperature, preventing overheating during operation.

Maintenance and Replacement

Regular inspection and timely replacement of these elements are essential to avoid breakdowns and ensure reliable performance. Operators should create a routine maintenance schedule to check the condition of these components and address any wear and tear promptly.

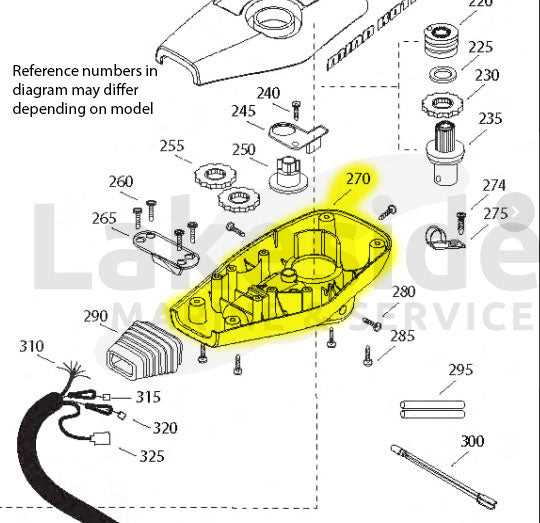

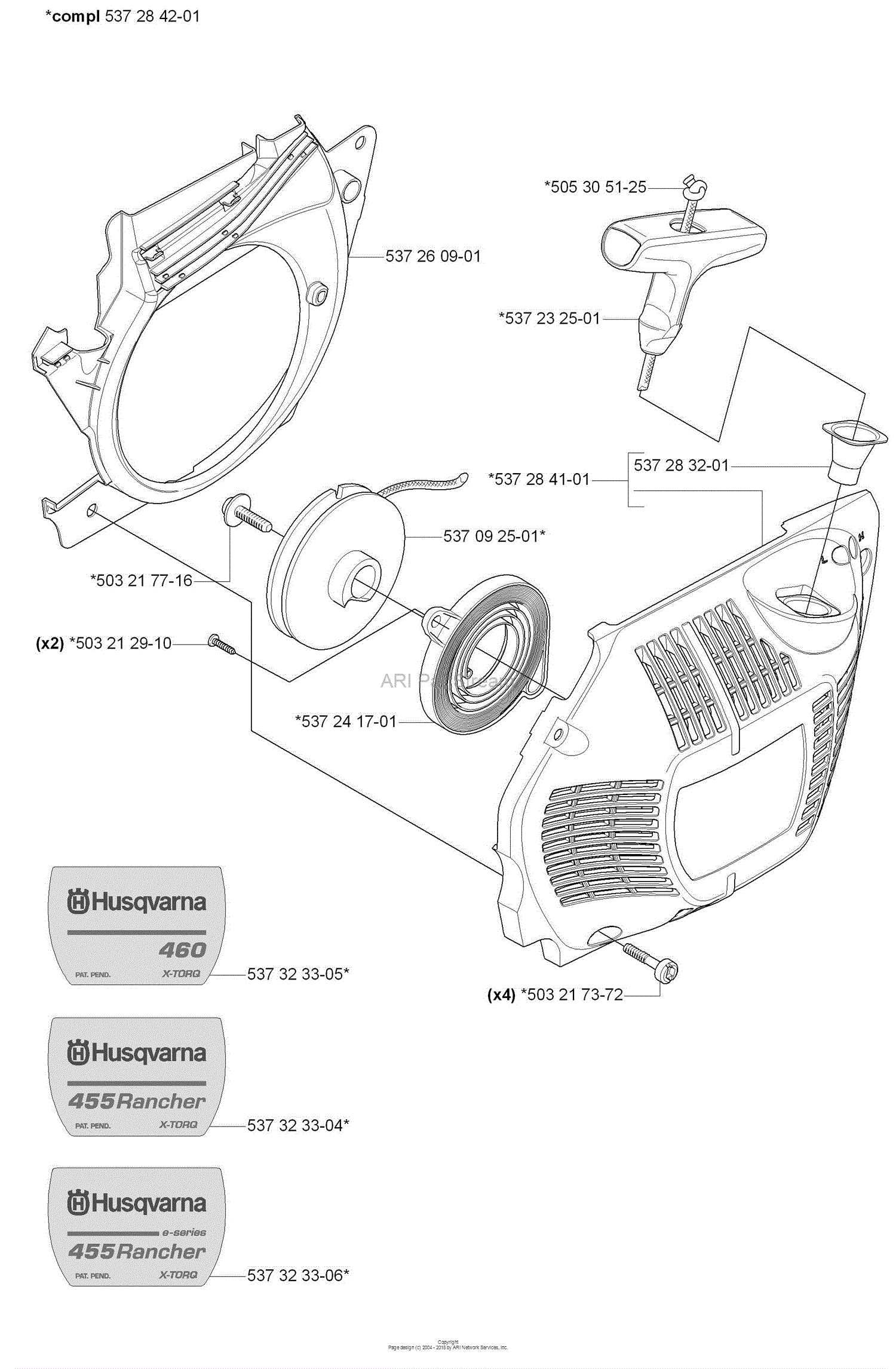

Clutch and Drive System Breakdown

The clutch and drive assembly play a crucial role in the overall functionality of motorized equipment. This mechanism is responsible for engaging and disengaging power from the engine to the drivetrain, ensuring smooth operation and efficient power transfer. Understanding the components involved in this system is essential for effective maintenance and troubleshooting.

Key Components

- Clutch Disc: This component is essential for transferring torque between the engine and the drivetrain. It engages when the clutch is activated.

- Pressure Plate: It applies pressure to the clutch disc, ensuring a secure connection when engaged.

- Flywheel: This part serves as a mounting surface for the clutch disc and assists in maintaining engine rotational speed.

- Release Bearing: This element allows for the smooth disengagement of the clutch when the pedal is pressed.

- Shift Mechanism: This assembly enables the operator to change gears smoothly, enhancing operational control.

Maintenance Tips

- Regularly inspect the clutch disc for wear and tear.

- Ensure that the pressure plate maintains proper tension.

- Check the flywheel for signs of overheating or damage.

- Lubricate the release bearing to prevent stiffness during operation.

- Examine the shift mechanism for smooth engagement and disengagement.

Proper understanding and maintenance of the clutch and drive assembly can greatly enhance the performance and longevity of the equipment, allowing for optimal operation in various conditions.

Transmission of Power from the Engine

The efficient transfer of energy from the engine to various components is crucial for optimal performance. This process involves multiple systems working in harmony to ensure that the generated force is effectively harnessed and directed where needed. Understanding the mechanics behind this transmission provides insights into the overall functionality and efficiency of the machinery.

Mechanisms of Energy Transfer

The energy produced by the engine is conveyed through a series of interconnected elements. These mechanisms include gears, belts, and hydraulic systems, each playing a significant role in converting and directing the power. The selection of these components directly influences the responsiveness and efficiency of the entire system.

Key Components in Power Transmission

Several critical elements contribute to the effective transmission of energy from the engine. Below is a table summarizing these components along with their functions:

| Component | Function |

|---|---|

| Clutch | Engages and disengages the engine from the transmission to control power flow. |

| Transmission | Adjusts the engine’s output to provide appropriate torque and speed to the wheels. |

| Drive Shaft | Transfers rotational energy from the transmission to the differential. |

| Differential | Distributes power to the wheels, allowing for differences in wheel speed during turns. |

Air Filter and Carburetor Assembly

The assembly responsible for regulating the fuel-air mixture in an engine is vital for optimal performance. This section explores the essential components involved in this system, highlighting their roles and the importance of proper maintenance.

Key components include:

- Air Filter: This component prevents debris and contaminants from entering the combustion chamber, ensuring a clean airflow.

- Carburetor: This device mixes fuel with air in the appropriate ratio for combustion, contributing significantly to engine efficiency.

Regular inspection and cleaning of these elements are crucial. Here are some recommended maintenance practices:

- Check the air filter for dirt or damage and replace it as needed.

- Inspect the carburetor for leaks or blockages and clean it periodically to prevent performance issues.

- Ensure all connections are secure to maintain the integrity of the system.

By understanding and caring for these components, users can enhance the longevity and efficiency of their equipment, ensuring reliable operation during use.

Maintaining Optimal Air and Fuel Mixture

Ensuring the correct balance between air and fuel is crucial for the efficient operation of any engine. This balance directly affects performance, fuel efficiency, and overall reliability. Proper adjustments can lead to enhanced power output and reduced emissions, which are essential for both environmental concerns and optimal functioning.

Importance of Regular Adjustments

Over time, various factors can disrupt the ideal air-fuel ratio, such as wear and tear on components, environmental changes, or the use of different fuel types. Regular assessments and adjustments are vital to maintain this balance. A well-maintained system not only enhances performance but also prolongs the life of the engine.

Signs of Imbalance

Identifying symptoms of an improper mixture is key to addressing potential issues early. Common indicators include poor acceleration, reduced fuel economy, and unusual exhaust emissions. Monitoring these signs can help in taking proactive measures to restore the optimal functioning of the engine.

Ignition System and Spark Plug Placement

The ignition mechanism plays a crucial role in ensuring optimal engine performance. It is responsible for igniting the air-fuel mixture, enabling efficient combustion. Understanding the arrangement and functionality of components in this system is essential for maintenance and troubleshooting.

Key Components of the Ignition Mechanism

- Ignition Coil: Converts low voltage from the battery into high voltage needed for spark generation.

- Distributor: Directs high-voltage electricity to the appropriate cylinder.

- Spark Plugs: Create the necessary spark to ignite the air-fuel mixture within the combustion chamber.

Spark Plug Placement and Specifications

Proper positioning of spark plugs is vital for effective engine operation. The arrangement ensures that each cylinder receives the spark at the right moment for optimal combustion. Consider the following factors:

- Gap Size: The distance between the electrodes should be adjusted according to specifications for efficient ignition.

- Torque Settings: Proper tightening of spark plugs is necessary to prevent damage and ensure effective sealing.

- Heat Range: Select plugs with the appropriate heat range to prevent fouling and ensure reliable performance.

Regular inspection and maintenance of the ignition system can significantly enhance engine longevity and efficiency.