The intricate design of a vehicle’s transmission system is crucial for its optimal performance. Various elements work in harmony to ensure smooth gear shifting and efficient power transfer from the engine to the wheels. A comprehensive overview of these components can greatly enhance one’s knowledge of automotive mechanics.

Familiarity with the layout and functionality of each component empowers enthusiasts and professionals alike to diagnose issues and perform maintenance tasks effectively. By grasping the roles of different elements within the assembly, one can appreciate the engineering that goes into crafting reliable and high-performing vehicles.

This section aims to provide valuable insights into the structure and operation of essential transmission components, highlighting their significance in the overall functionality of the automotive system. A detailed examination will help clarify how these elements contribute to the vehicle’s performance.

This section highlights the essential elements that contribute to the functionality of the automatic transmission system, which plays a vital role in vehicle performance. Understanding these components is crucial for effective maintenance and repair.

- Torque Converter: This device transmits power from the engine to the transmission, allowing for smooth acceleration.

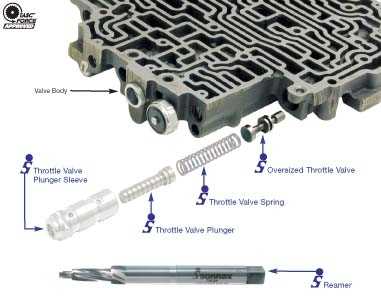

- Transmission Valve Body: Acts as the control center, directing fluid flow and ensuring proper gear shifting.

- Input Shaft: Connects the engine to the transmission, transferring rotational force.

- Output Shaft: Sends power from the transmission to the drive wheels, impacting vehicle movement.

- Clutch Packs: Engage and disengage to enable smooth gear transitions, enhancing driving comfort.

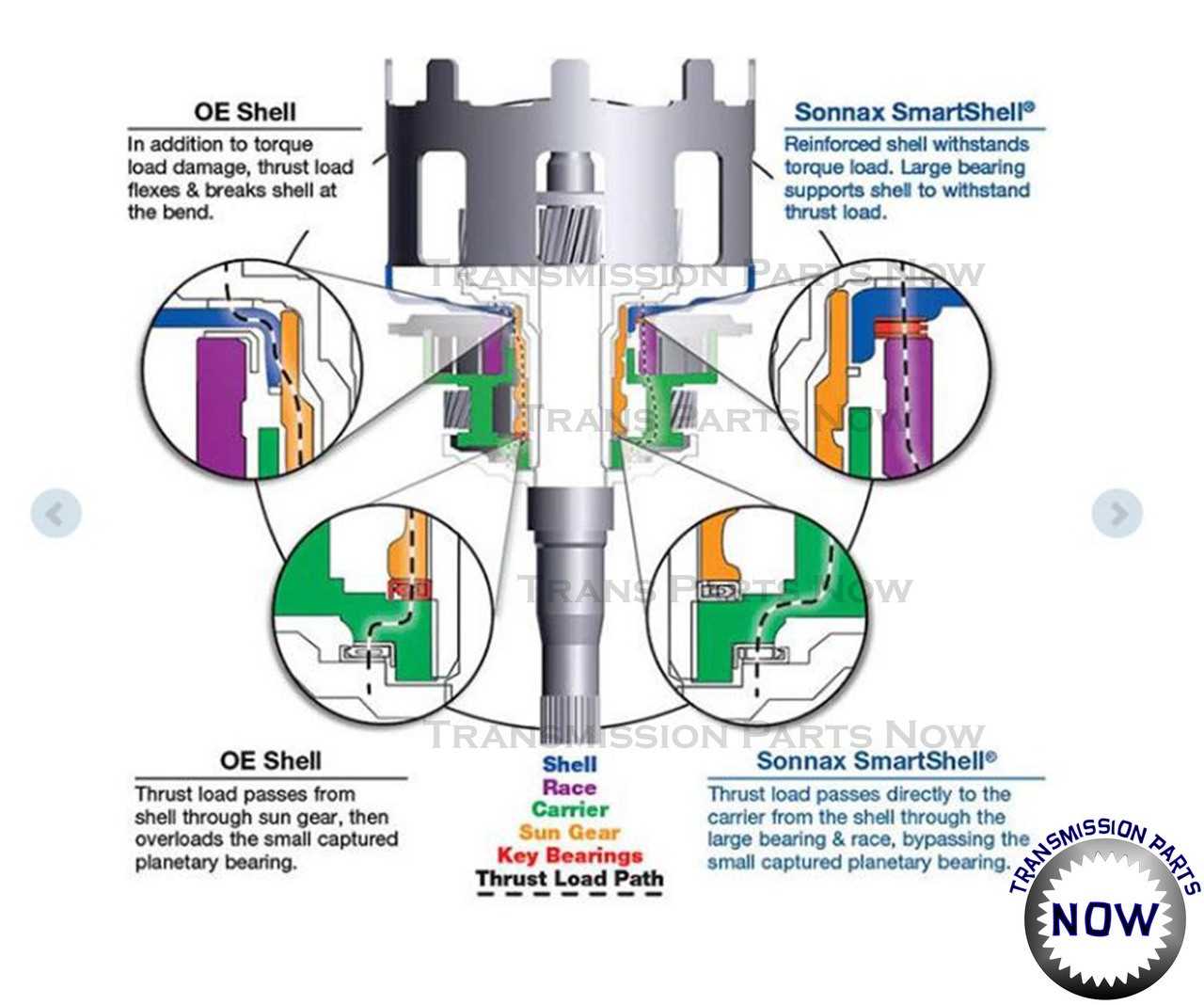

- Planetary Gear Sets: Provide various gear ratios, allowing for efficient speed and torque adjustments.

- Fluid Pump: Maintains hydraulic pressure throughout the system, essential for operational efficiency.

Each component plays a unique role in the transmission’s overall performance, contributing to the smooth operation and longevity of the vehicle.

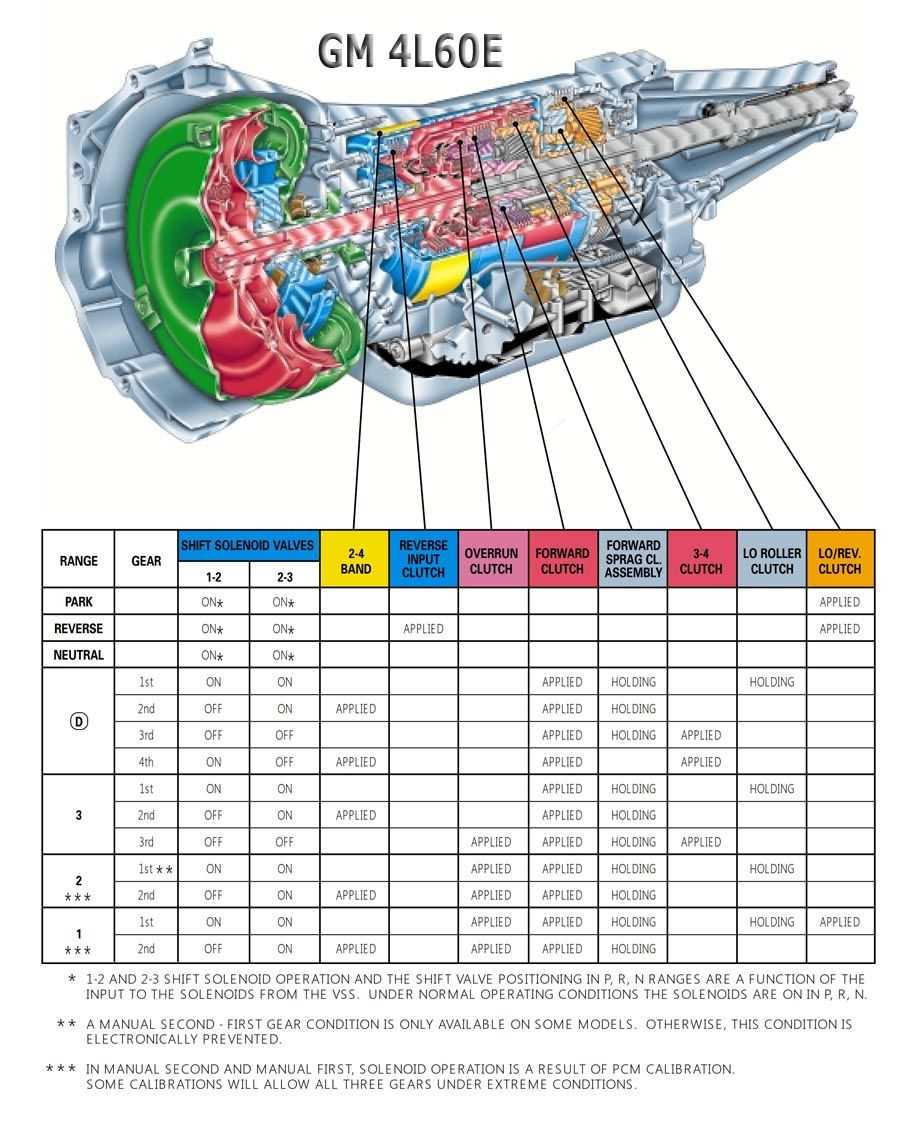

Understanding the Transmission Diagram

Grasping the layout of a vehicle’s gearbox is crucial for comprehending its functionality and maintenance. A clear representation allows enthusiasts and technicians alike to identify the various components and their interrelations, facilitating effective diagnostics and repairs. This section delves into the intricacies of such a layout, illuminating the key elements that contribute to optimal performance.

Key Components of the Gearbox

Each element within the transmission plays a significant role in the overall operation. Key components include the housing, gears, clutches, and solenoids. Understanding their positions and interactions is essential for troubleshooting issues and ensuring smooth gear shifts. By familiarizing oneself with these crucial parts, one can enhance the longevity and reliability of the system.

Common Issues and Solutions

Familiarity with the configuration can also aid in diagnosing prevalent problems. For instance, recognizing signs of wear or malfunction in specific components can prompt timely interventions, preventing further damage. A well-maintained system not only improves driving experience but also safeguards the vehicle’s performance over time.

Functionality of Major Parts

This section explores the essential components of a transmission system, highlighting their roles and interactions. Understanding the functionality of these critical elements is key to grasping how the entire mechanism operates efficiently.

The primary assembly is responsible for managing gear shifts and overall performance. It ensures that power is transferred seamlessly from the engine to the drivetrain, enabling smooth acceleration and deceleration.

Within this assembly, the hydraulic system plays a vital role, utilizing fluid pressure to activate various components. This system ensures precise engagement and disengagement of gears, allowing for optimal control and responsiveness.

The torque converter is another significant element, serving to multiply engine torque during acceleration. It provides a smooth transition between the engine and transmission, facilitating easier starts and improved efficiency.

Additionally, electronic controls contribute to the system’s functionality by monitoring performance and adjusting shift points. These controls enhance driving experience through adaptive responses to varying conditions, ensuring optimal performance across different scenarios.

Common Issues with 4L60 Parts

Understanding the common challenges associated with specific automotive components is essential for effective maintenance and repair. This section highlights prevalent problems that may arise, affecting overall performance and reliability. Recognizing these issues can assist owners in diagnosing faults early and taking appropriate action to ensure optimal functionality.

Several factors can contribute to the malfunction of these crucial elements. Below is a summary of frequent concerns observed:

| Issue | Description |

|---|---|

| Fluid Leaks | Leaks from seals and gaskets can lead to fluid loss, affecting hydraulic pressure and performance. |

| Overheating | Excessive heat can damage components and cause premature wear, often due to insufficient lubrication or coolant issues. |

| Shifting Problems | Difficulty in shifting gears can result from worn-out clutches or improper adjustments, impacting driving experience. |

| Noise | Unusual sounds during operation may indicate bearing or gear wear, requiring immediate attention to prevent further damage. |

How to Read the Diagram

Understanding a schematic representation can significantly enhance your grasp of mechanical systems. By familiarizing yourself with the various symbols and notations, you can easily interpret the intricate components and their relationships within the assembly.

Start by identifying the key symbols. Each element is typically represented by a specific icon, which conveys its function. Familiarize yourself with these symbols to quickly recognize parts and their roles.

Next, pay attention to the connections. Lines connecting symbols indicate interactions or flow between components. Understanding these connections is crucial for comprehending how the entire system operates as a unit.

Finally, refer to the accompanying legend or key if available. This section usually provides definitions and explanations for each symbol, ensuring you have all the information needed for accurate interpretation.

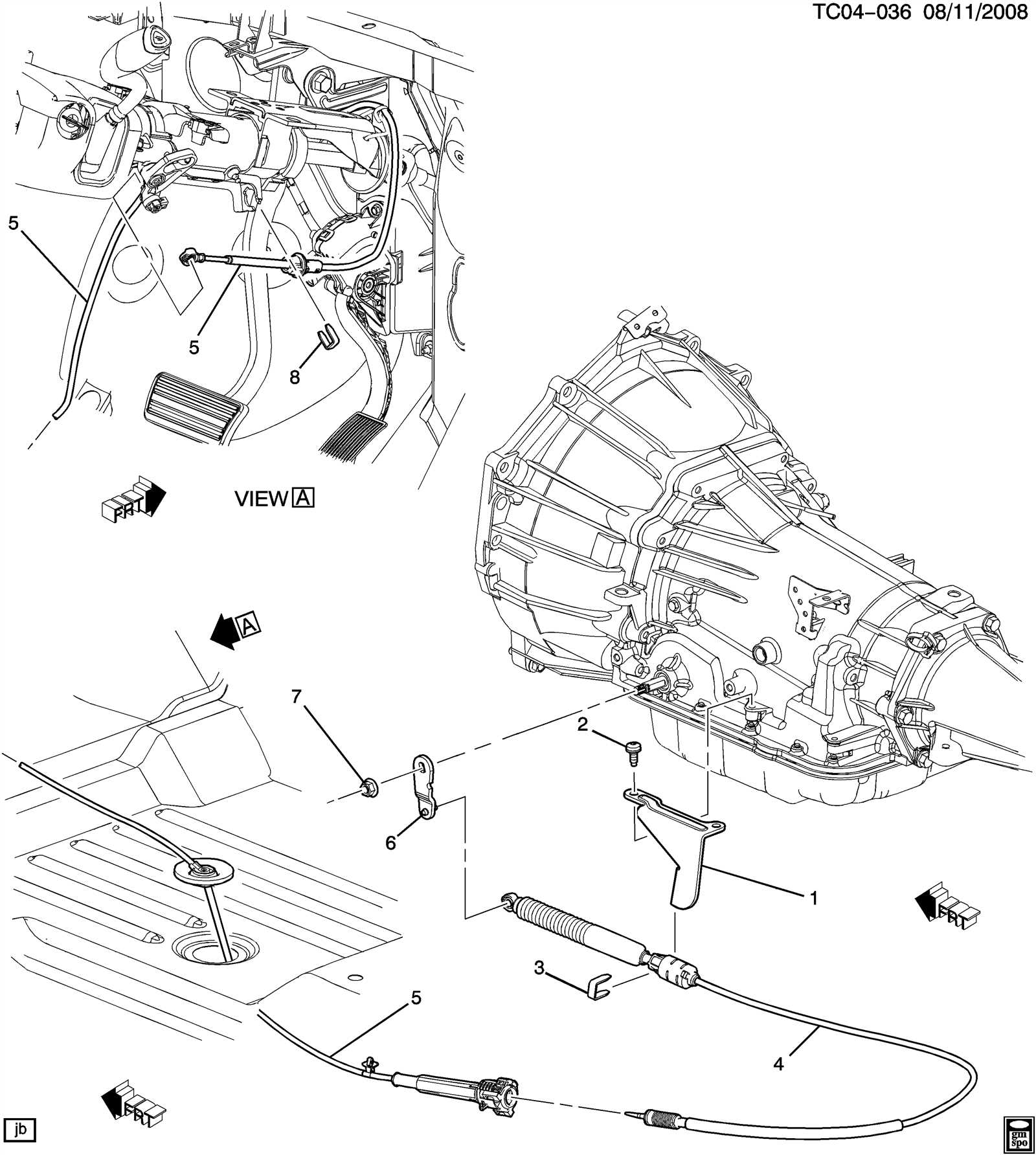

Maintenance Tips for 4L60 Transmission

Regular upkeep is crucial for ensuring optimal performance and longevity of your vehicle’s transmission system. By adhering to specific maintenance practices, you can minimize wear and tear, prevent costly repairs, and enhance the overall driving experience.

Fluid Checks and Changes

Routine inspections of the transmission fluid are essential. Ensure that the fluid is at the appropriate level and in good condition. If it appears dark or has a burnt smell, consider replacing it. Regular fluid changes can help maintain the efficiency of the system and prevent overheating.

Filter Maintenance

Replacing the filter is another critical aspect of maintenance. A clogged filter can restrict fluid flow, leading to potential damage. It is advisable to check and replace the filter periodically to ensure smooth operation and extend the lifespan of the entire assembly.

Identifying Wear and Tear

Understanding the signs of deterioration in mechanical components is crucial for maintaining optimal performance. Regular inspection can help in early detection, preventing extensive damage and costly repairs. By recognizing common indicators of wear, you can ensure the longevity of your equipment.

Common Signs of Deterioration

One of the most evident symptoms of wear is the presence of unusual noises during operation. These sounds may indicate loose or damaged elements within the assembly. Additionally, visual inspections can reveal signs such as discoloration, pitting, or uneven surfaces, all of which point to potential issues.

Importance of Regular Maintenance

Conducting routine maintenance is essential in preventing severe wear. Regularly checking lubricants, tightening loose connections, and replacing worn components can significantly extend the lifespan of your machinery. Proactive measures can save time and resources, ensuring that your equipment operates smoothly.

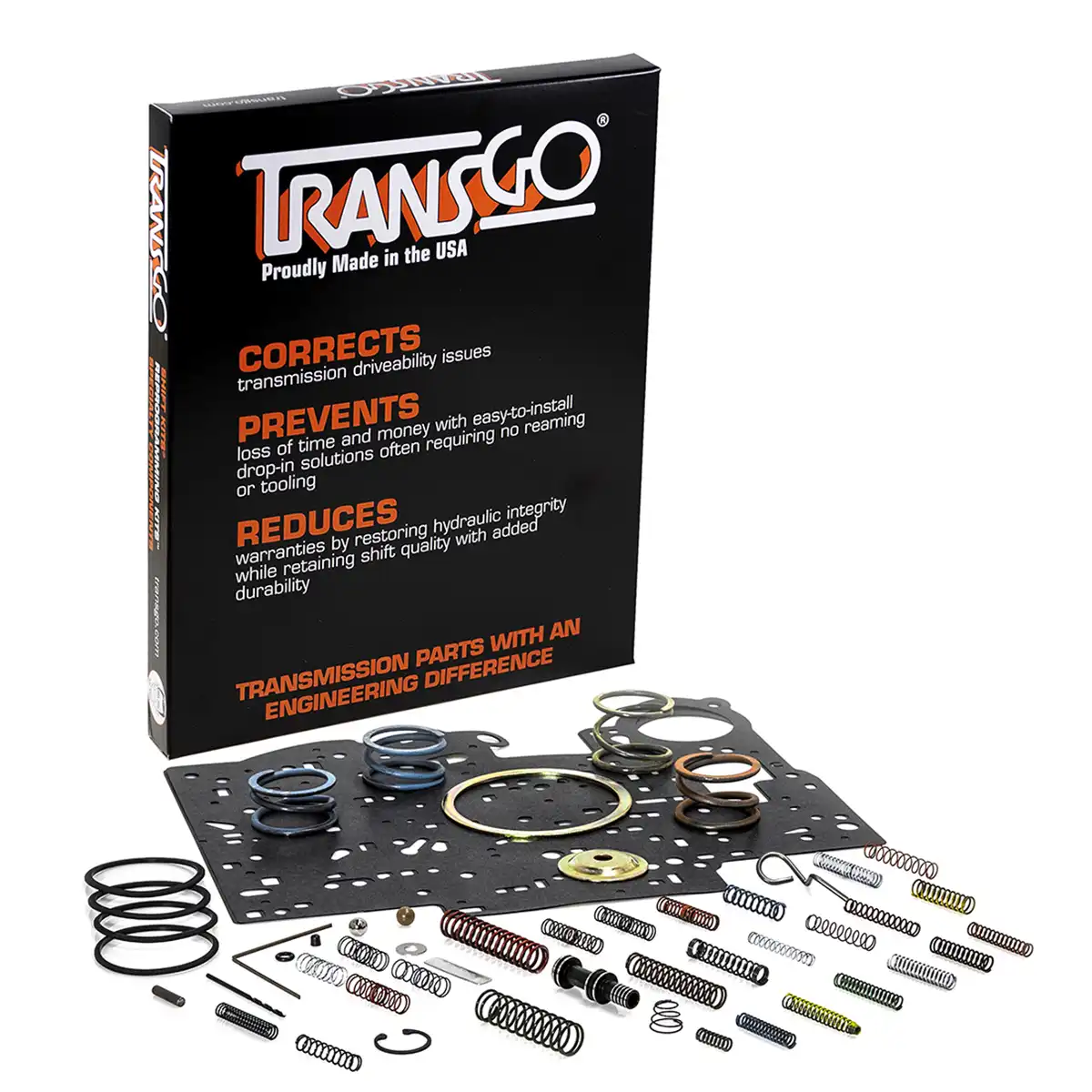

Aftermarket vs. OEM Components

The choice between aftermarket and original equipment manufacturer (OEM) components can significantly impact performance and reliability. Each option presents unique advantages and disadvantages that may influence a buyer’s decision based on their specific needs and preferences.

Aftermarket components are produced by third-party manufacturers and often provide a wider variety of choices at competitive prices. These alternatives can enhance performance, offer unique features, and may be tailored for specific applications. However, the quality and fit of these components can vary widely, making it essential to research and choose reputable brands.

On the other hand, OEM components are made by the original manufacturer and are designed to meet the exact specifications of the vehicle. This ensures compatibility and reliability, as they are tested rigorously. However, these components often come with a higher price tag and may lack the performance enhancements available from aftermarket options.

Ultimately, the decision between aftermarket and OEM components depends on factors such as budget, desired performance, and personal preferences. Evaluating these aspects will help in making an informed choice that aligns with individual requirements.

Importance of Accurate Diagrams

Precise representations play a crucial role in the understanding and assembly of complex mechanical systems. They serve as essential tools for technicians and engineers, facilitating clear communication and reducing the likelihood of errors during installation or repairs. With accurate illustrations, individuals can easily identify components, ensuring that each piece is correctly placed and functioning optimally.

Clarity in these visual aids enhances the efficiency of maintenance tasks. When every element is clearly marked and illustrated, users can quickly locate parts, which saves time and minimizes frustration. Moreover, detailed depictions can also provide insights into the operational relationships between various components, offering a comprehensive view that is often missing in written instructions alone.

Furthermore, high-quality representations foster confidence among users, empowering them to tackle intricate projects with assurance. When individuals can rely on well-crafted visual guides, they are more likely to engage in DIY repairs or upgrades, ultimately extending the lifespan and performance of their equipment.

Tools Needed for Assembly

When undertaking a complex assembly task, having the right tools is essential for achieving optimal results. Each component requires specific instruments to ensure proper installation and functionality. Below is a comprehensive list of the necessary equipment to facilitate the assembly process effectively.

Essential Tools

- Socket set

- Torque wrench

- Screwdrivers (flat and Phillips)

- Pliers

- Hammer

- Allen wrenches

Additional Equipment

- Safety goggles

- Gloves

- Work light

- Parts tray

- Cleaning supplies

Equipping yourself with these tools not only enhances efficiency but also ensures safety throughout the assembly process.

Upgrades for Enhanced Performance

Improving the efficiency and reliability of a transmission system can significantly enhance vehicle performance. Various modifications can be applied to elevate the overall functionality, ensuring smoother operation and greater power handling. This section explores several key enhancements that can lead to improved responsiveness and durability.

Common Modifications

Upgrading components within the transmission assembly can yield substantial benefits. Some popular modifications include the installation of high-performance clutches, improved valve bodies, and enhanced torque converters. These upgrades not only increase power capacity but also optimize shifting characteristics, resulting in a more engaging driving experience.

Performance Benefits

Implementing these enhancements can lead to several advantages, such as improved acceleration, reduced shift lag, and increased torque capacity. By focusing on these modifications, vehicle owners can ensure their transmission meets higher performance demands while maintaining reliability and longevity.

| Upgrade Component | Benefits |

|---|---|

| High-Performance Clutch | Increased grip and power handling |

| Improved Valve Body | Smoother shifts and better control |

| Enhanced Torque Converter | Improved torque multiplication and efficiency |