In the realm of outdoor machinery, a thorough comprehension of the various components is essential for optimal performance and maintenance. Each element plays a crucial role in ensuring that your equipment functions smoothly and efficiently. Whether you are a seasoned user or a newcomer, familiarizing yourself with the intricacies of your device can lead to improved handling and longevity.

By examining the assembly of your machinery, you can identify potential areas for enhancement or repair. Recognizing each part’s function not only aids in troubleshooting issues but also empowers you to make informed decisions regarding upgrades and replacements. This knowledge can ultimately save time and resources, allowing you to focus on your tasks rather than on unexpected disruptions.

Additionally, having access to a visual representation of the assembly can simplify the understanding of complex structures. It enables users to quickly locate and reference specific components, making maintenance and assembly more straightforward. A clear overview promotes confidence in handling the equipment, fostering a proactive approach to upkeep and repair.

Identifying Key Components and Functions

Understanding the essential elements and their roles is crucial for effective operation and maintenance. Each component plays a significant part in the overall functionality, contributing to the efficiency and reliability of the equipment.

- Engine: The powerhouse responsible for generating the necessary energy to drive the machine’s performance.

- Fuel System: This system manages the delivery of fuel, ensuring optimal combustion and power output.

- Transmission: Facilitates the transfer of power from the engine to the working parts, enabling smooth operation.

- Electrical Components: These parts control various functions, including ignition, lighting, and instrumentation.

- Cooling System: Maintains the appropriate temperature of the engine, preventing overheating and ensuring longevity.

Each of these key elements interacts with others to ensure seamless performance. Recognizing their specific functions aids in troubleshooting and enhances overall understanding of the machinery.

Regular inspection and maintenance of these critical components can prevent potential issues, ensuring the equipment operates at peak efficiency.

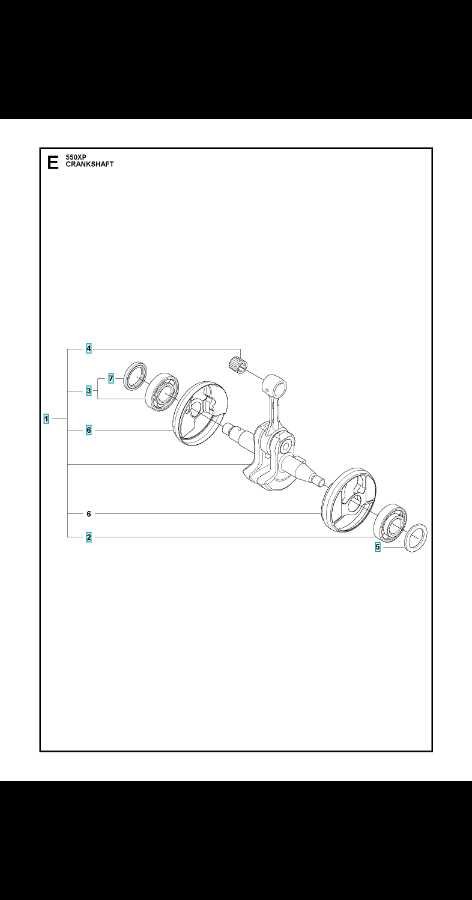

Detailed Breakdown of Engine Parts

This section provides an in-depth analysis of the various components that make up the power unit, highlighting their functions and importance in overall performance.

- Crankshaft: This crucial element converts linear motion from the pistons into rotational force, driving the machinery forward.

- Pistons: These cylindrical parts move up and down within the cylinders, creating the necessary pressure to ignite fuel and generate power.

- Cylinder Head: Located at the top of the engine, this part houses valves and spark plugs, playing a vital role in air and fuel intake as well as exhaust expulsion.

- Valves: Responsible for controlling the flow of air and fuel into the cylinders and the expulsion of exhaust gases, valves operate in a precise timing sequence.

- Camshaft: This component regulates the timing of the valve movements, ensuring they open and close at the right moments during the engine cycle.

- Connecting Rods: These rods connect the pistons to the crankshaft, transferring motion and force efficiently throughout the engine.

- Oil Pump: This pump circulates lubricating oil to reduce friction between moving parts, essential for maintaining optimal performance and longevity.

Understanding the intricate relationships and functions of these components is essential for troubleshooting and maintenance, ultimately ensuring the engine operates smoothly and efficiently.

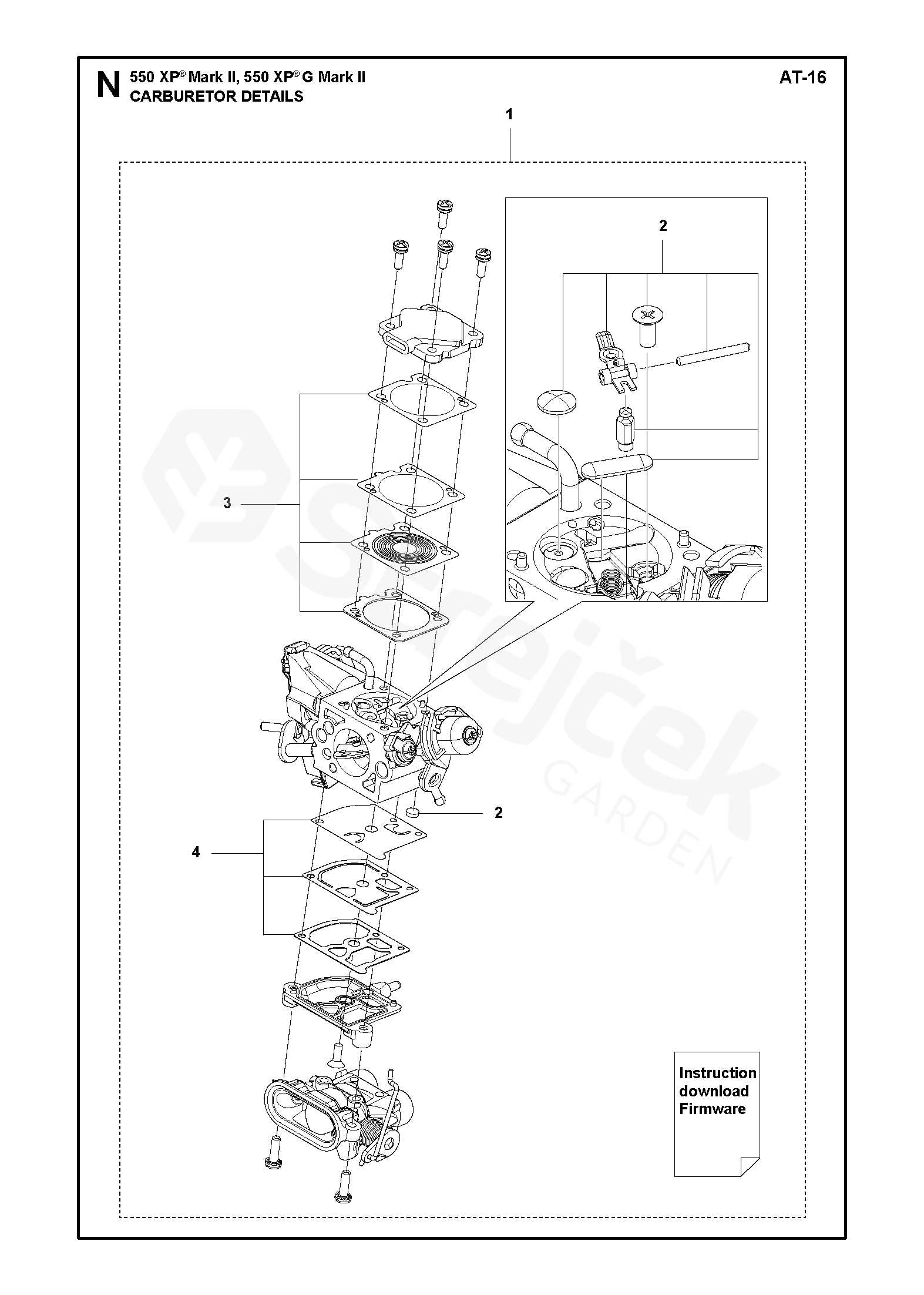

Understanding the Fuel System Layout

The fuel delivery system plays a critical role in the efficient operation of any engine, ensuring that the appropriate mixture of fuel and air reaches the combustion chamber. By comprehending its configuration, users can better maintain their equipment and troubleshoot issues that may arise. This section delves into the essential components and their interactions within this vital system.

Key Components of the Fuel Delivery System

The main elements that constitute the fuel delivery system include the fuel tank, fuel lines, fuel filter, fuel pump, and carburetor. Each component serves a distinct purpose, working in unison to facilitate the transfer of fuel from storage to combustion. Understanding how these parts connect and function together is crucial for effective maintenance and repair.

System Functionality Overview

The process begins with the fuel tank, where the fuel is stored. From there, it travels through fuel lines to the filter, which removes impurities. The fuel pump then propels the clean fuel towards the carburetor, where it is mixed with air before entering the engine. This intricate process ensures optimal performance and longevity of the equipment.

| Component | Function |

|---|---|

| Fuel Tank | Stores fuel for the engine |

| Fuel Lines | Convey fuel from tank to engine |

| Fuel Filter | Removes contaminants from fuel |

| Fuel Pump | Pumps fuel to the carburetor |

| Carburetor | Mixes fuel with air for combustion |

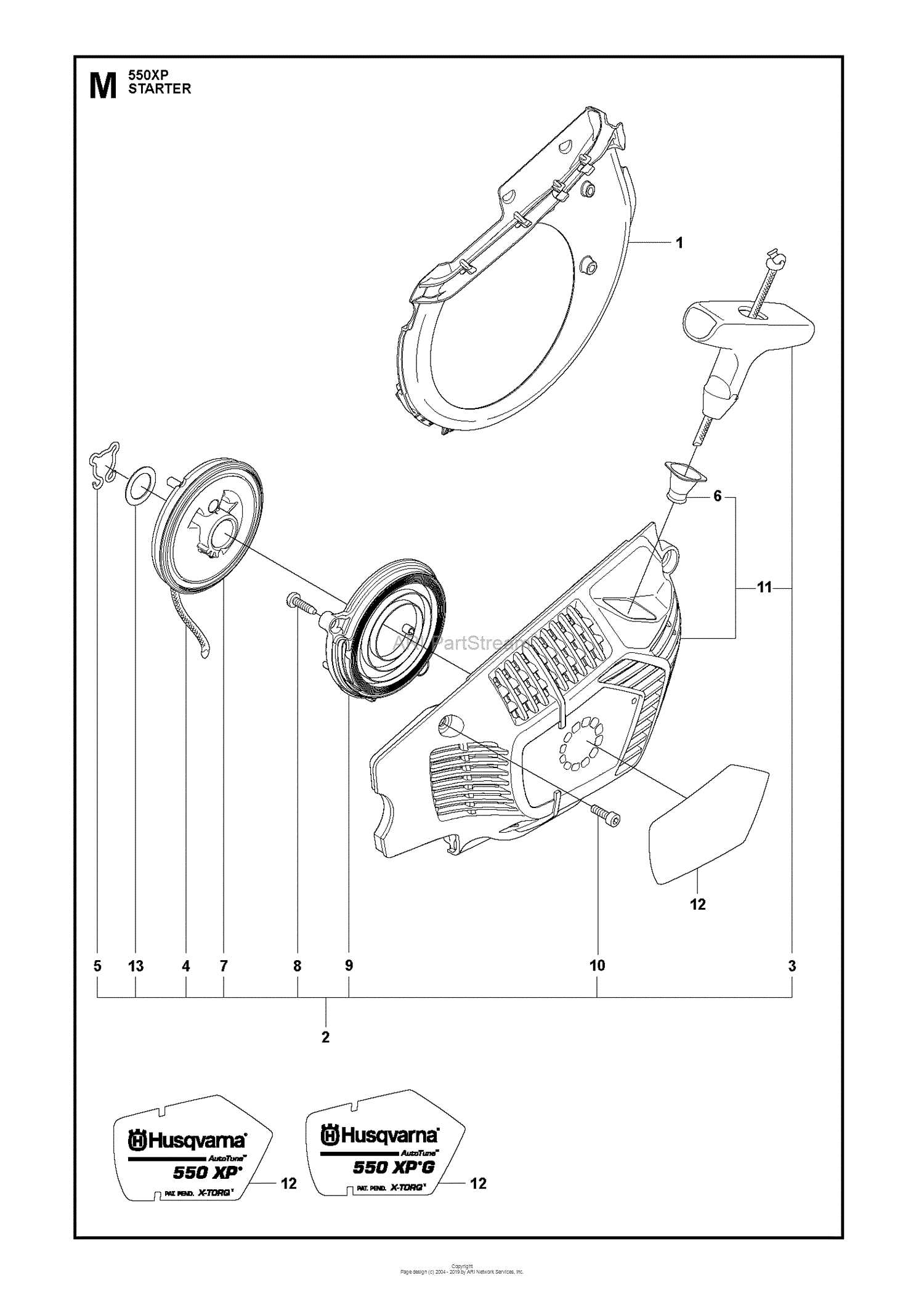

Exploring the Ignition System Design

The ignition system is a critical component in the operation of any internal combustion engine, responsible for initiating the combustion process. It plays a vital role in ensuring optimal performance, efficiency, and reliability. Understanding its design and functionality provides insights into how engines operate and the importance of each element in the system.

Key Components and Their Functions

At the core of the ignition system lies several essential elements, including the spark plug, ignition coil, and control module. The spark plug is responsible for generating the spark that ignites the fuel-air mixture in the combustion chamber. The ignition coil, on the other hand, transforms the battery’s low voltage into the high voltage necessary to create that spark. The control module manages the timing and duration of the spark, ensuring it occurs at the optimal moment for efficient combustion.

Importance of Proper Maintenance

Regular maintenance of the ignition system is crucial for ensuring longevity and performance. Worn or faulty components can lead to misfires, reduced power output, and increased emissions. Periodic inspection and timely replacement of parts can help maintain the overall health of the engine and enhance its performance.

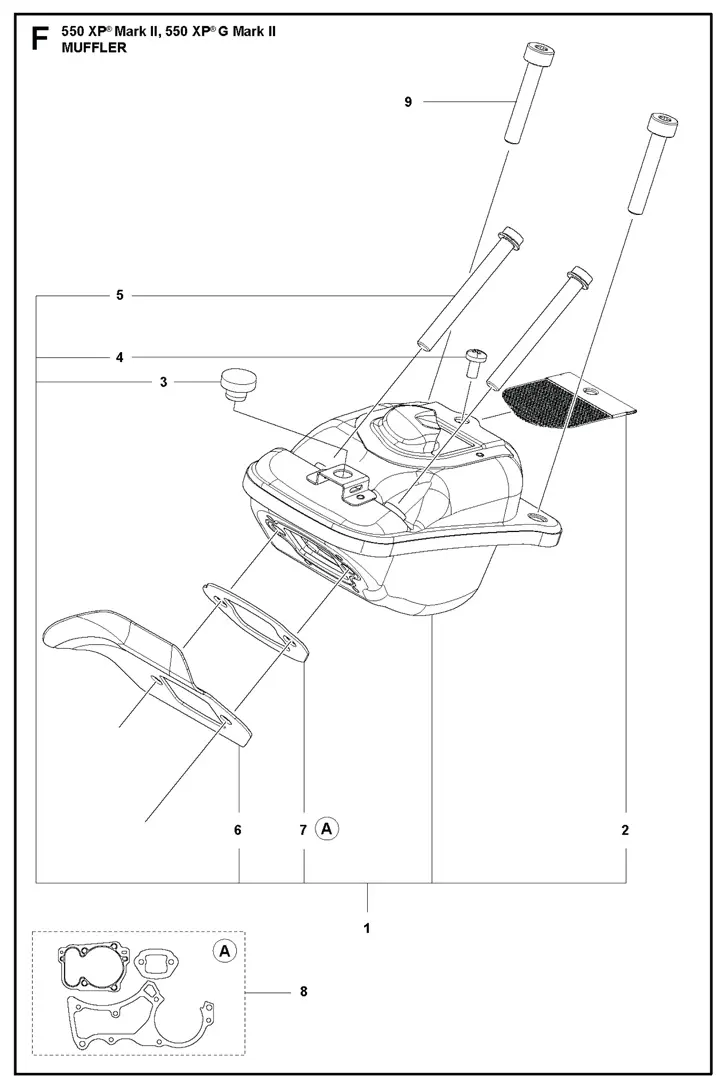

Analysis of the Exhaust Components

This section delves into the various elements associated with the exhaust system, emphasizing their crucial role in engine performance and emissions control. Understanding the structure and function of these components is essential for effective maintenance and troubleshooting.

Key Components of the Exhaust System

The exhaust system consists of several integral parts that work together to manage the gases produced during combustion. Each component contributes to the overall efficiency and effectiveness of the system.

| Component | Function |

|---|---|

| Exhaust Manifold | Collects exhaust gases from the engine cylinders and directs them to the exhaust pipe. |

| Catalytic Converter | Transforms harmful emissions into less harmful substances before they exit the vehicle. |

| Muffler | Reduces noise produced by the engine’s exhaust gases. |

| Exhaust Pipe | Channels exhaust gases from the manifold to the rear of the vehicle. |

| Oxygen Sensors | Monitor the level of oxygen in the exhaust gases to optimize fuel efficiency and reduce emissions. |

Importance of Regular Maintenance

Regular inspection and maintenance of the exhaust components are vital for ensuring optimal engine function and compliance with environmental standards. Neglecting these parts can lead to reduced performance and increased emissions.

Hydraulic System and Its Parts

The hydraulic mechanism is an essential component that utilizes fluid pressure to facilitate movement and operation within various machines. This system is designed to provide the necessary force and control for performing tasks efficiently and effectively. Understanding its components is crucial for ensuring optimal functionality and maintenance.

Key Components of the Hydraulic System

This mechanism comprises several vital elements that work in unison. Each part plays a significant role in the overall performance, contributing to the system’s ability to generate power and execute movements. The primary components include the following:

| Component | Description |

|---|---|

| Hydraulic Pump | Converts mechanical energy into hydraulic energy, generating fluid flow. |

| Actuator | Transforms hydraulic energy back into mechanical energy to perform work. |

| Hydraulic Fluid | Transmits power throughout the system, lubricating and cooling components. |

| Reservoir | Stores hydraulic fluid, ensuring a constant supply to the system. |

| Valves | Regulate fluid flow and pressure, controlling the operation of the system. |

Importance of Regular Maintenance

Maintaining the hydraulic system is crucial for ensuring its longevity and efficiency. Regular inspections and servicing can help identify potential issues before they escalate, minimizing downtime and repair costs. Proper care extends the lifespan of each component, ensuring the system operates at peak performance.

Maintenance Tips for Common Components

Proper upkeep of essential elements is crucial for ensuring optimal performance and longevity. Regular attention to these parts can prevent wear and tear, enhance functionality, and ultimately save on replacement costs. Below are some key maintenance practices to consider.

- Regular Cleaning: Dust and debris can accumulate, affecting performance. Clean surfaces using a soft brush or cloth to remove any buildup.

- Lubrication: Applying the right lubricant to moving parts helps reduce friction and wear. Ensure you use the recommended type for each component.

- Inspection: Periodically inspect components for signs of damage or excessive wear. Look for cracks, rust, or other abnormalities that may require attention.

- Tightening Fasteners: Loose bolts and screws can lead to instability. Regularly check and tighten any fasteners to maintain structural integrity.

- Replacement of Worn Parts: Identify components that show signs of fatigue and replace them promptly to avoid further damage or failure.

Implementing these maintenance strategies can significantly enhance the reliability and efficiency of the equipment, ensuring it remains in peak condition throughout its usage.

How to Order Replacement Parts

Obtaining necessary components for your equipment can enhance its performance and longevity. Knowing how to properly order these elements is essential for ensuring you receive the correct items in a timely manner. Here’s a straightforward guide to assist you in the ordering process.

Follow these steps to facilitate your order:

- Identify the Required Components:

Before placing an order, confirm the specific elements you need. Refer to your equipment’s user manual or maintenance guide for details.

- Check Compatibility:

Ensure that the components you are ordering are compatible with your equipment. Look for model numbers and specifications to avoid mismatches.

- Choose a Reliable Supplier:

Opt for reputable suppliers or manufacturers known for quality and service. Research customer reviews and ratings to guide your choice.

- Gather Necessary Information:

When ready to order, have all pertinent details on hand, including model numbers, descriptions, and quantities. This information will streamline the process.

- Place Your Order:

Visit the supplier’s website or contact them directly to place your order. Ensure to review your selections before finalizing the transaction.

- Track Your Shipment:

After placing your order, keep an eye on your shipment’s status. Most suppliers provide tracking information to monitor the delivery process.

By following these steps, you can ensure a smooth ordering experience and get your equipment back to optimal performance in no time.

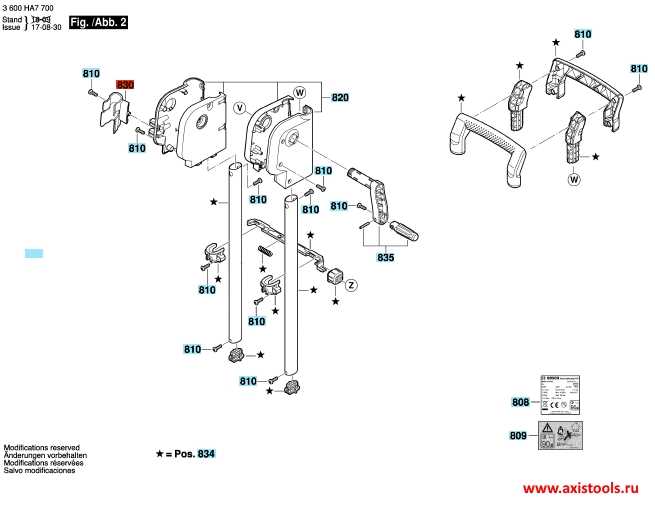

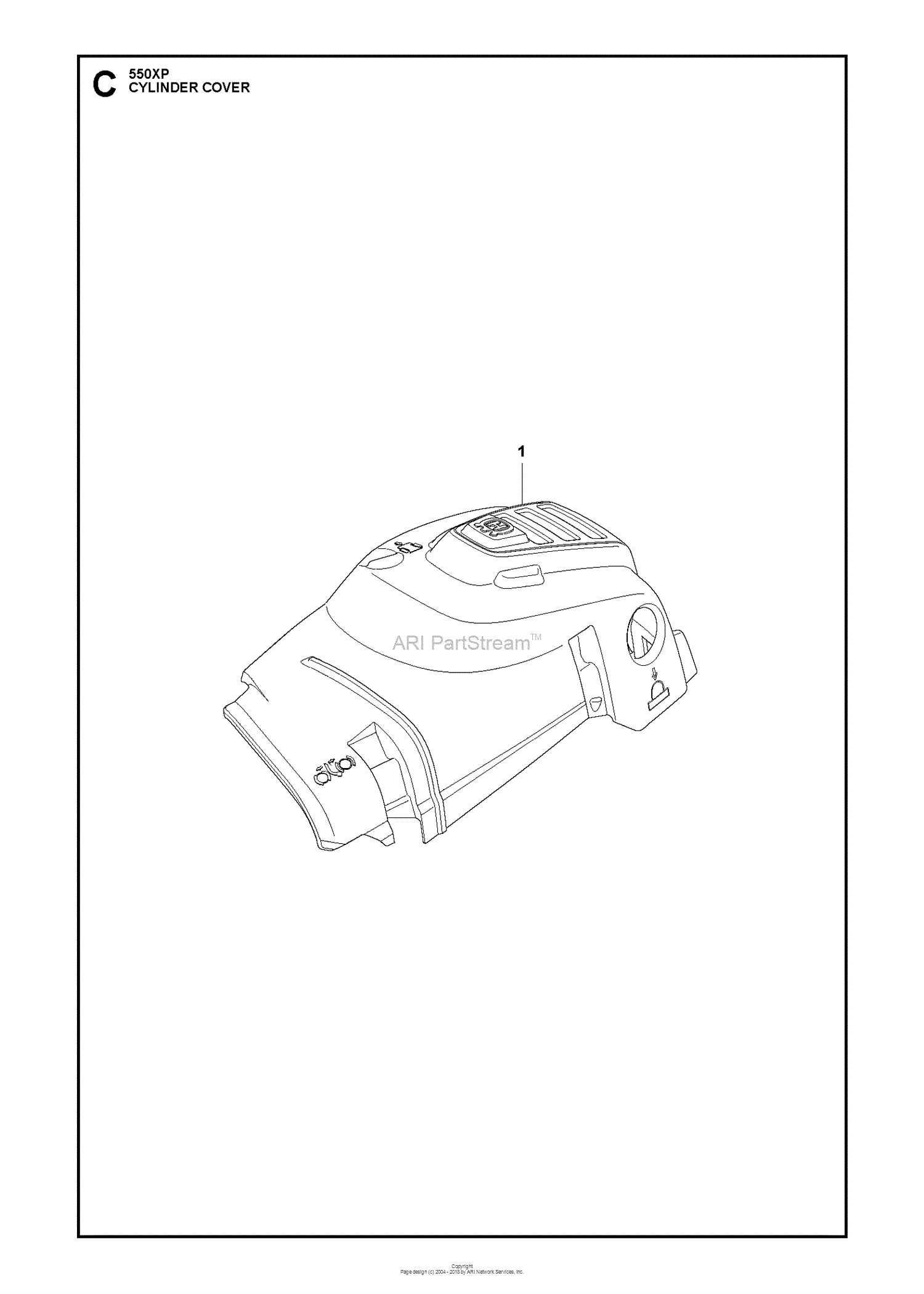

Visual References for Assembly Guide

This section provides essential visual aids to assist in the assembly process of your equipment. Clear illustrations and well-organized layouts serve as valuable resources, enhancing understanding and ensuring accurate assembly. By utilizing these visual references, users can easily navigate through the components and their respective placements.

| Component | Illustration | Description |

|---|---|---|

| Base Unit | Illustration of the base structure | The foundational part providing stability and support for the assembly. |

| Upper Housing | Illustration of the upper casing | The protective cover that houses the internal mechanisms and components. |

| Engine Assembly | Illustration of the engine setup | The crucial part responsible for power generation and performance. |

| Fuel Tank | Illustration of the fuel storage | Container for holding fuel, ensuring proper operation of the machinery. |

| Control Panel | Illustration of the control interface | The user interface for monitoring and controlling functions during operation. |

Frequently Asked Questions About 550xp

This section addresses common inquiries regarding a popular model in the world of outdoor equipment. Whether you are a seasoned user or a newcomer, these questions cover various aspects of functionality, maintenance, and performance, providing valuable insights to enhance your experience.

What should I know about maintenance?

Regular upkeep is crucial for optimal performance. Ensure that all components are inspected periodically, lubricated when necessary, and replaced if worn. Following the manufacturer’s guidelines will help maintain efficiency and extend the lifespan of your equipment.

How can I troubleshoot common issues?

If you encounter difficulties, start by checking the fuel supply and air filter, as these are common culprits. Additionally, inspect the ignition system for any signs of wear. Understanding these basics can significantly reduce downtime and improve overall functionality.