The intricate world of automotive machinery encompasses a myriad of elements that work in harmony to ensure optimal performance. Each component plays a crucial role in the overall function, making it essential for enthusiasts and mechanics alike to grasp their interactions and significance.

In this section, we will explore a specific set of mechanical parts that contribute to a particular transmission system. By examining these elements, readers will gain insight into their functionalities and the way they contribute to seamless operation.

Moreover, delving into the assembly not only aids in maintenance and repair but also enhances understanding of how to achieve the ultimate efficiency in vehicle performance. Knowledge of these mechanical intricacies can empower users to make informed decisions when it comes to servicing and upgrades.

Understanding the 62te Transmission Parts

This section aims to explore the intricate components that comprise a specific type of automatic gearbox, focusing on their roles and functionalities. A solid grasp of these elements is essential for anyone interested in automotive engineering or maintenance, as each part contributes to the overall performance and reliability of the system.

Key Components Overview

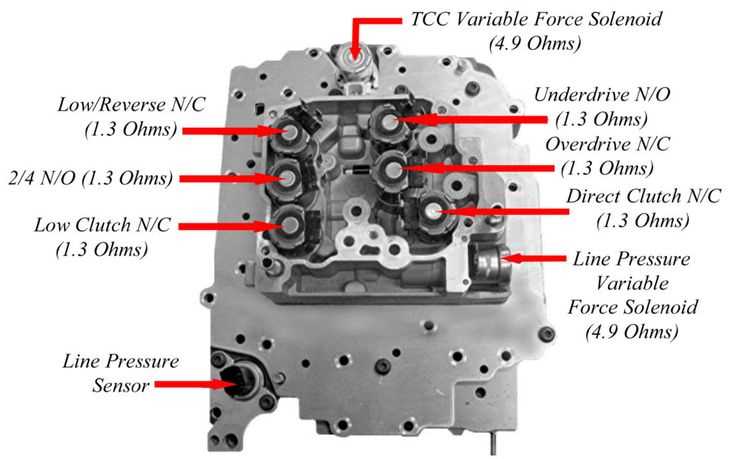

In automatic transmissions, various mechanisms work together to ensure smooth gear shifts and efficient power delivery. Familiarity with these crucial elements allows for better diagnostics and maintenance practices.

Commonly Found Elements

| Component Name | Description |

|---|---|

| Clutch Packs | Responsible for engaging and disengaging gears during operation. |

| Planetary Gear Set | Enables different gear ratios for varied driving conditions. |

| Torque Converter | Facilitates smooth acceleration by transferring power from the engine. |

| Valve Body | Controls fluid flow and directs the hydraulic pressure for shifting. |

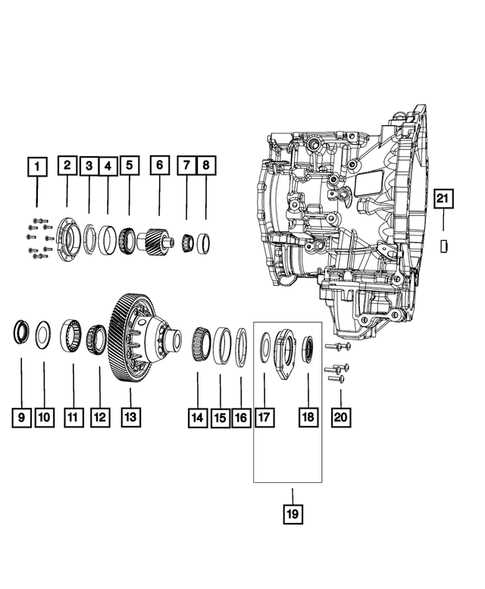

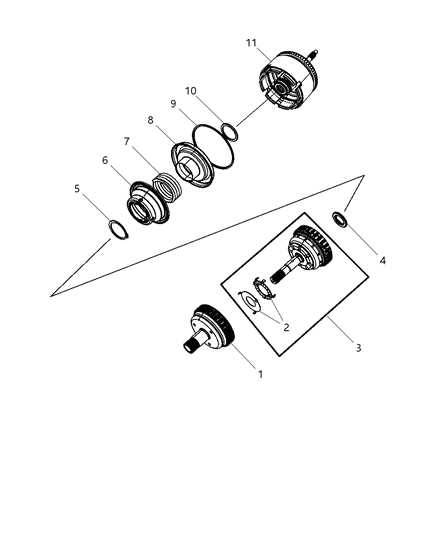

Components of the 62te System

This section explores the various elements that make up a sophisticated assembly designed for optimal functionality and efficiency. Understanding the individual components is crucial for grasping how they work together to achieve seamless operation. Each part plays a vital role, contributing to the overall performance of the system.

Key Elements

The primary constituents include mechanisms responsible for power transmission, control units that manage operations, and structural components that provide stability. These elements are engineered to interact smoothly, ensuring reliable performance under various conditions. Each component is crafted with precision to enhance durability and efficiency, forming a cohesive unit.

Functional Roles

Each constituent serves a specific purpose within the system. For instance, certain components facilitate movement, while others are tasked with monitoring and adjusting performance metrics. The interplay of these roles is essential for achieving the desired outcomes, making it imperative to maintain and understand each element’s function.

Common Issues in 62te Parts

When dealing with complex mechanical systems, various challenges can arise that affect performance and reliability. Understanding these common complications is crucial for effective maintenance and troubleshooting. Numerous factors can contribute to wear and malfunction, often stemming from design flaws, improper installation, or lack of regular upkeep.

Wear and Tear: One of the most prevalent issues is the gradual degradation of components over time. This can lead to decreased efficiency and eventual failure if not addressed promptly. Regular inspections are essential to identify early signs of damage.

Inadequate Lubrication: Insufficient lubrication can cause friction, leading to overheating and accelerated wear. It’s important to ensure that all moving parts are adequately serviced to prevent this issue from escalating.

Incorrect Installation: Installing components incorrectly can lead to misalignment and functional issues. Following precise specifications during installation is vital to ensure optimal operation and longevity.

Environmental Factors: Exposure to harsh conditions, such as extreme temperatures or contaminants, can negatively impact component performance. Protective measures should be taken to mitigate these risks and prolong the lifespan of the system.

Quality of Materials: The durability of materials used in construction can greatly influence performance. Using subpar components can lead to frequent breakdowns and increased maintenance costs. Investing in high-quality materials is a prudent strategy.

By being aware of these common challenges and implementing proactive measures, users can enhance the performance and reliability of their systems, ensuring they operate smoothly for years to come.

Importance of Proper Maintenance

Ensuring the longevity and efficiency of any machinery or equipment relies heavily on regular upkeep and attention. Proper maintenance not only enhances performance but also prevents unexpected breakdowns and costly repairs. By adopting a proactive approach, individuals can safeguard their investments and ensure optimal functioning over time.

Enhancing Performance

Regular servicing and attention to detail can significantly boost the overall efficiency of any system. Routine checks and adjustments can lead to smoother operation, reducing wear and tear on critical components. Moreover, an adequately maintained unit often operates at a higher capacity, delivering better results and increasing productivity.

Cost-Effectiveness

Investing time and resources into maintenance can yield substantial savings in the long run. Preventive care reduces the likelihood of major failures that can necessitate expensive repairs or replacements. By addressing minor issues before they escalate, individuals can enjoy uninterrupted operation and avoid the financial strain of emergency fixes.

How to Identify 62te Components

Understanding the various elements of a transmission system is crucial for effective maintenance and repair. Recognizing these components enables technicians and enthusiasts to ensure optimal performance and longevity. Below are key steps and tips for identifying these essential parts.

Visual Inspection

Start with a thorough visual examination. Look for specific characteristics that distinguish each element:

- Shape and Size: Note the dimensions and overall form; each component has unique proportions.

- Material: Identify the material composition, such as metal or plastic, which can indicate its function.

- Labels and Numbers: Check for any identifying markings, serial numbers, or part codes.

Functional Understanding

Grasping how each component operates will aid in accurate identification:

- Research: Use manuals and online resources to learn about the specific roles of each piece.

- Consult Experts: Engage with mechanics or forums specializing in transmissions for insights.

- Hands-On Experience: Practice by disassembling and reassembling units to familiarize yourself with the parts.

By combining visual inspection with functional knowledge, you can effectively identify the key elements of the system and enhance your repair skills.

Replacement Parts for the 62te

Ensuring optimal performance of your transmission system requires access to high-quality components. When it comes to maintenance or repairs, finding the right items is crucial for longevity and efficiency. This section explores the essential replacements that will keep your mechanism functioning smoothly.

First and foremost, it’s important to identify the components that are most likely to wear out over time. Seals and gaskets often need replacement due to degradation, which can lead to leaks and diminished performance. Additionally, friction elements are vital for smooth operation; replacing them at the right intervals can prevent serious damage.

Another key category involves hydraulic components. These play a significant role in fluid dynamics within the system, so ensuring their integrity is essential. If you notice any signs of malfunction, such as erratic shifting, it may be time to check these elements closely.

Lastly, don’t overlook the importance of electronic sensors and control units. These advanced features are critical for monitoring performance and ensuring precise operation. Upgrading or replacing these devices can significantly enhance the overall functionality of your system.

By prioritizing these essential components, you can maintain the reliability and efficiency of your transmission system, ultimately extending its lifespan and performance.

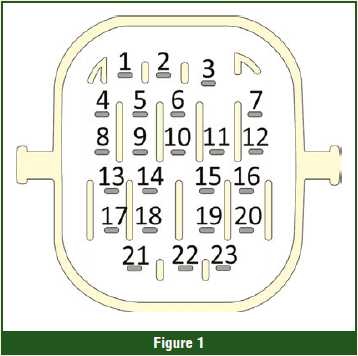

Diagnostic Tools for 62te Transmission

Effective troubleshooting and maintenance of automatic gear systems require specialized instruments that provide insights into performance and issues. These tools enable technicians to monitor operational parameters, diagnose faults, and ensure optimal functioning of the transmission unit.

Essential Diagnostic Instruments

Several key devices are integral to the diagnostic process, each serving unique purposes. They help in identifying problems that could affect the overall performance and longevity of the transmission.

| Tool Type | Description |

|---|---|

| Scan Tool | Reads and interprets error codes from the vehicle’s computer system. |

| Pressure Gauge | Measures hydraulic pressure within the transmission to ensure it meets specifications. |

| Oscilloscope | Analyzes electrical signals to diagnose issues in the transmission’s control system. |

Benefits of Utilizing Diagnostic Tools

Employing these specialized instruments allows for timely identification of potential failures, leading to improved reliability and efficiency of the system. Ultimately, this proactive approach can save time and reduce costs associated with extensive repairs.

Upgrades for Enhanced Performance

Improving the functionality and efficiency of your equipment can lead to significant gains in performance. By strategically implementing enhancements, users can experience better reliability, increased power output, and improved overall operation. This section delves into various modifications that can elevate the effectiveness of your machinery.

Types of Upgrades

- Engine Modifications

- Transmission Improvements

- Suspension Enhancements

- Electronic Tuning

Benefits of Upgrading

- Enhanced efficiency and fuel economy

- Improved handling and stability

- Increased longevity of components

- Greater adaptability to various conditions

These enhancements not only contribute to superior performance but also provide a more enjoyable experience for the user.

62te Transmission Repair Tips

When addressing issues related to automatic gear systems, understanding the common pitfalls and effective strategies can significantly enhance the repair process. This section offers essential advice to help troubleshoot and fix complications that may arise in these complex mechanisms.

| Tip | Description |

|---|---|

| Regular Maintenance | Ensure fluid levels are checked frequently and replaced as needed to prevent overheating and wear. |

| Diagnostic Tools | Utilize specialized diagnostic equipment to identify error codes and potential failures accurately. |

| Component Inspection | Conduct thorough inspections of clutches, gears, and electrical connections to identify any signs of damage. |

| Fluid Quality | Use high-quality transmission fluid that meets manufacturer specifications for optimal performance. |

| Professional Help | When in doubt, seek assistance from experienced technicians to ensure repairs are performed correctly. |

Frequently Asked Questions on 62te

This section aims to address common inquiries regarding a specific mechanical assembly, providing clarity and insight into its functionality, maintenance, and troubleshooting. Understanding these components can enhance overall performance and longevity.

What are the key components of this assembly?

The primary elements include gears, shafts, and various seals that work together to ensure smooth operation.

How often should I perform maintenance?

Regular checks should be conducted every few months, focusing on fluid levels and wear of essential parts.

What signs indicate a malfunction?

Unusual noises, leaks, or difficulty in operation can signify that attention is needed.

Can I replace components myself?

While some parts can be replaced with basic tools, it’s advisable to consult a professional for complex repairs.

Where can I find detailed information on these components?

Official manuals and manufacturer websites offer comprehensive resources to delve deeper into specifications and maintenance procedures.

Resources for 62te Owners

For enthusiasts and owners of this specific model, having access to reliable information and tools is essential for maintenance and upgrades. A variety of resources can assist in troubleshooting and enhancing performance, ensuring a rewarding ownership experience.

Essential Manuals and Guides

Detailed manuals and repair guides are crucial for understanding the nuances of your vehicle. They provide insights into maintenance procedures, troubleshooting common issues, and enhancing overall performance.

| Resource Type | Description | Link |

|---|---|---|

| Owner’s Manual | Comprehensive guide for daily operation and maintenance. | Download Here |

| Repair Manual | In-depth resource for troubleshooting and repairs. | View Online |

| Parts Catalog | Catalog of available components for replacement and upgrades. | Browse Catalog |

Online Communities and Forums

Connecting with fellow owners can provide invaluable insights and shared experiences. Online forums and social media groups are great platforms for exchanging tips, asking questions, and finding support.