Understanding the internal setup of fishing equipment can significantly improve both maintenance and performance. Knowing how different elements interact ensures that anglers are better prepared to handle repairs or replacements when needed.

Each individual element serves a specific function, contributing to smooth operation and durability. By identifying these elements correctly, users can troubleshoot issues efficiently and keep their gear in optimal condition for a longer time.

This section offers a detailed breakdown of how essential components fit together, helping users navigate their way through complex assemblies with ease. Proper awareness of these connections not only extends the lifespan of the equipment but also enhances the fishing experience overall.

Alvey Reels Parts Diagram

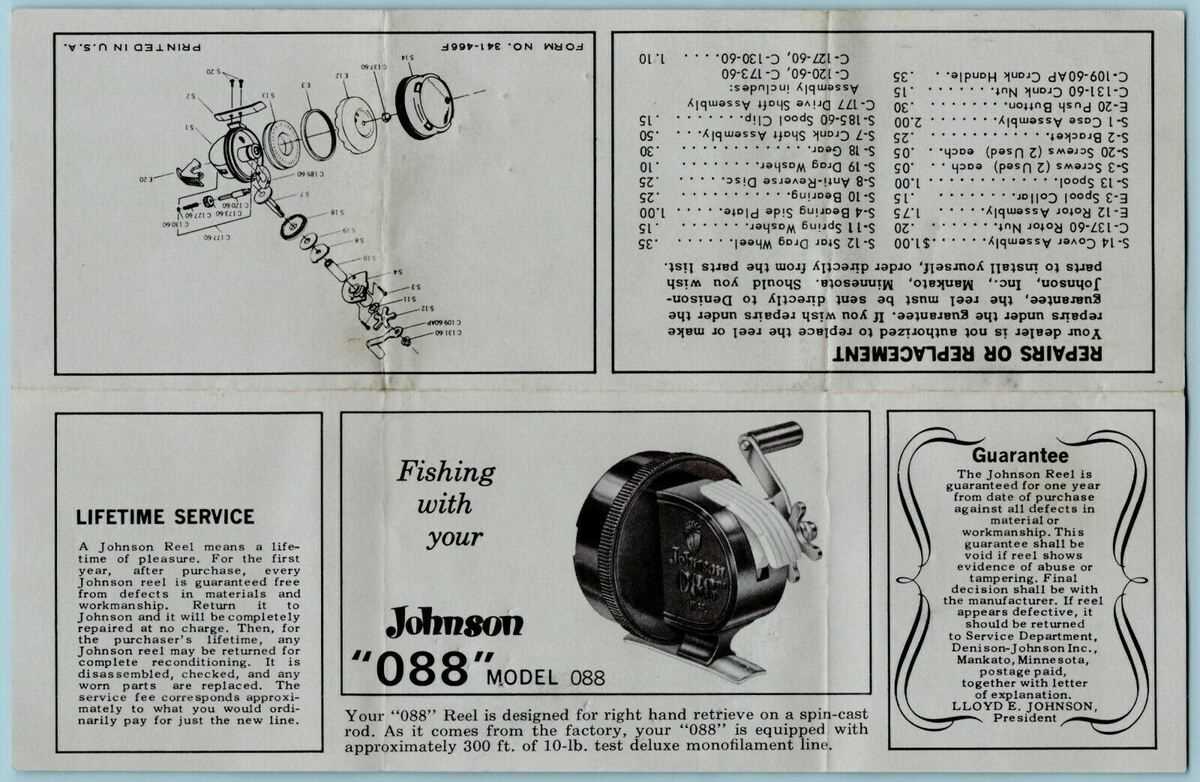

This section aims to provide a comprehensive overview of the components associated with a popular fishing device. Understanding the various elements and their functions is crucial for effective maintenance and repair. Familiarity with the internal and external mechanisms can enhance performance and longevity.

The illustration presented will help enthusiasts identify essential features and components, aiding in troubleshooting and assembly. Each element plays a vital role in the overall functionality, and recognizing them can greatly improve the user’s experience.

By studying the layout, individuals can grasp how different segments interact, enabling more informed decisions during modifications or upgrades. This knowledge not only enhances the enjoyment of fishing but also fosters a deeper appreciation for the craftsmanship behind these tools.

Understanding Key Components Overview

This section provides an essential examination of the main elements involved in the functionality and performance of fishing mechanisms. By familiarizing oneself with these crucial components, users can enhance their understanding and maintenance of these devices, ensuring optimal operation and longevity.

Core Elements

The primary constituents of these fishing devices play a vital role in their overall efficiency. Each component contributes to the smooth operation, allowing for a seamless experience during use. Recognizing the significance of each element is essential for proper handling and troubleshooting.

Maintenance and Care

Regular attention to these integral parts is necessary for preserving the functionality of fishing equipment. Users should routinely inspect and clean each section to prevent wear and prolong the lifespan of the device. Adopting a proactive approach to care ensures reliability and performance in various fishing conditions.

How to Identify Reel Parts Quickly

Recognizing components of fishing equipment can greatly enhance your efficiency and effectiveness. Familiarity with the various elements not only streamlines the setup process but also aids in maintenance and repair. Here are some key strategies to help you identify these components swiftly.

Understand Common Terminology

Familiarizing yourself with the vocabulary associated with fishing gear is essential. Knowing the correct terms will allow you to communicate effectively and access resources more efficiently.

- Frame: The main structure that holds everything together.

- Handle: The part you use to maneuver the equipment.

- Spool: The section where the line is wound.

- Drag System: Controls the resistance against the line being pulled.

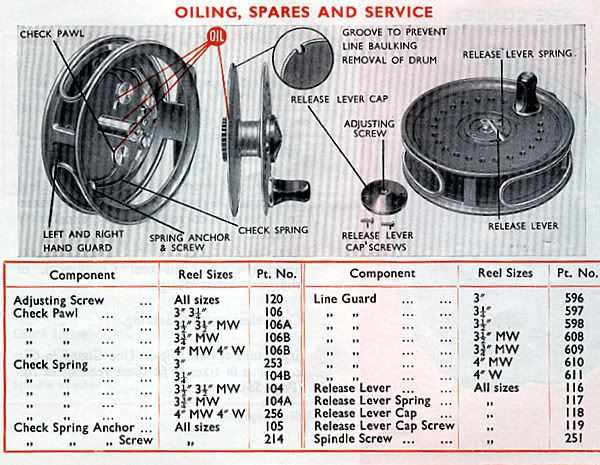

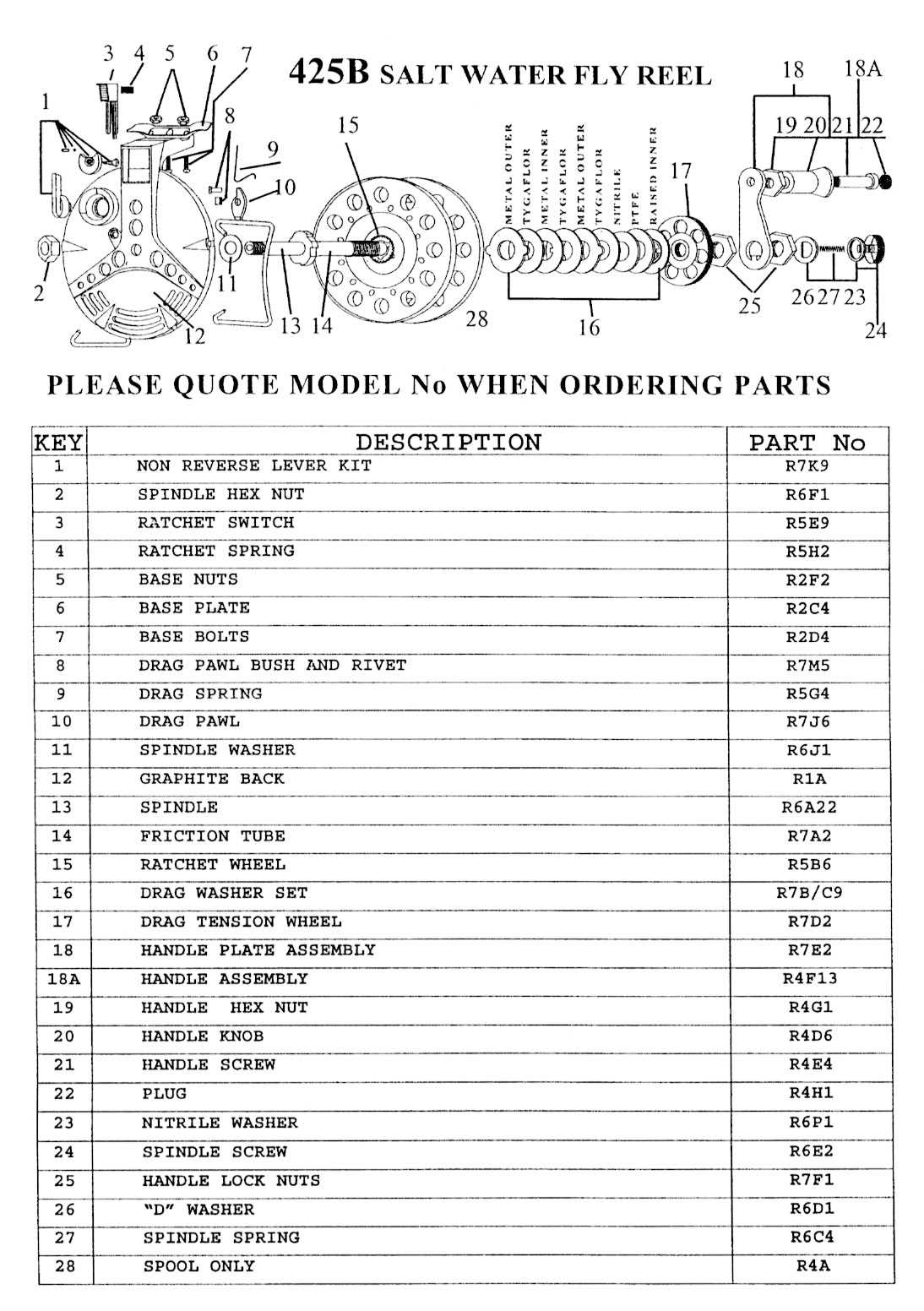

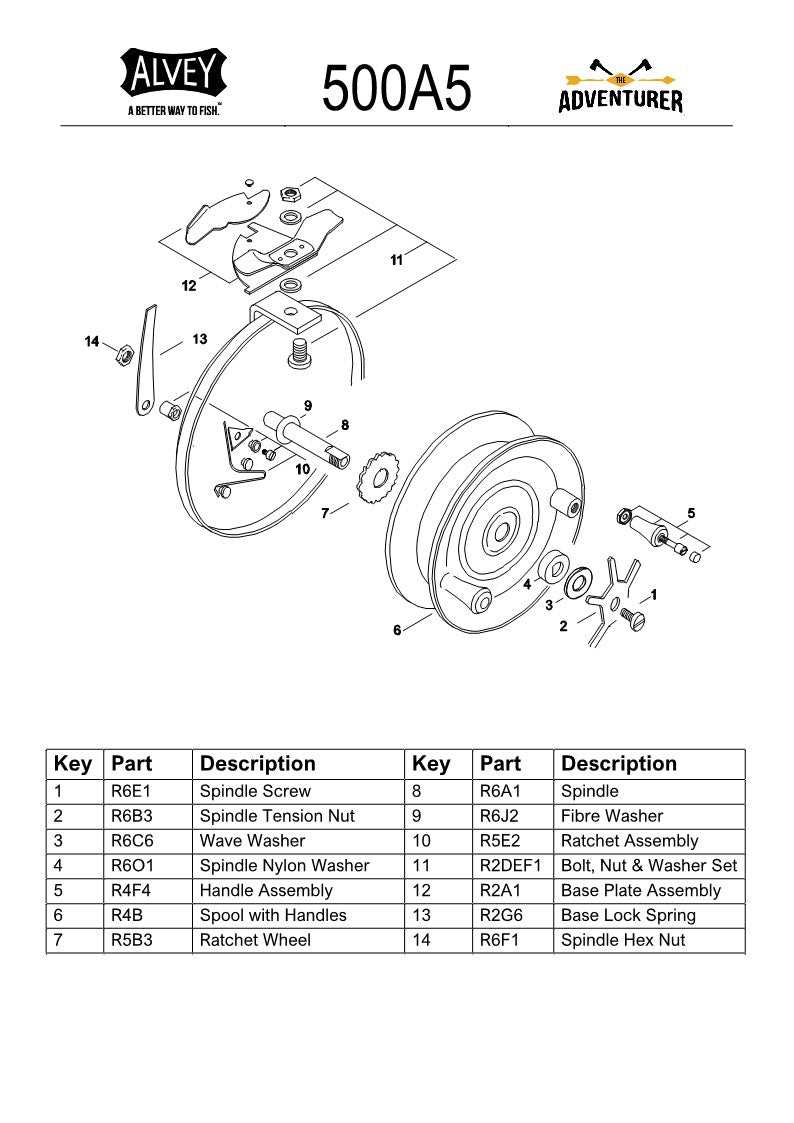

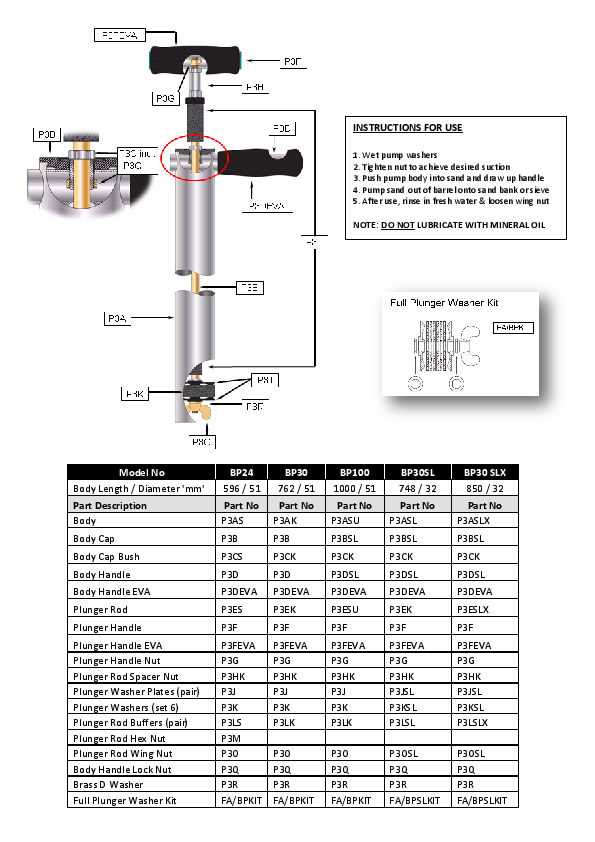

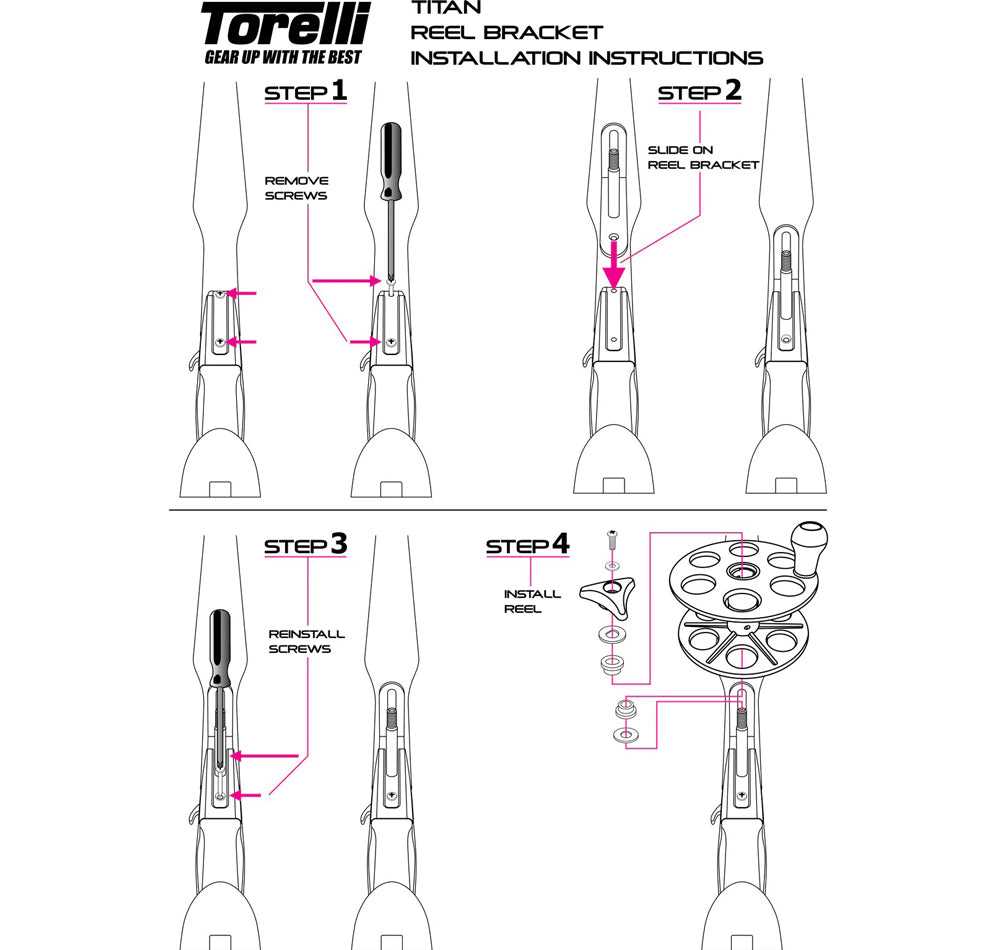

Use Visual References

Visual aids can significantly simplify the identification process. Utilizing images or charts can provide clarity on what each component looks like.

- Search for labeled illustrations online.

- Consult manuals that feature annotated diagrams.

- Visit local shops to see the equipment in person.

By combining a solid understanding of terminology with visual aids, you can quickly become proficient at recognizing the various components of fishing equipment.

Disassembly Tips for Alvey Reels

When it comes to maintaining your fishing equipment, understanding the process of taking apart your gear can be essential. Proper disassembly not only ensures effective cleaning and lubrication but also helps in identifying any wear and tear. Here are some valuable tips to guide you through the disassembly process.

Preparation Steps

- Gather necessary tools such as screwdrivers, pliers, and a clean workspace.

- Ensure you have a soft cloth or a mat to prevent damage to components during the process.

- Familiarize yourself with the assembly before disassembling to understand the placement of parts.

Disassembly Process

- Start by removing the handle or crank, typically secured with screws.

- Next, carefully detach any covers, making sure not to lose small screws or components.

- Proceed to take apart the internal mechanisms, noting the order of removal to simplify reassembly.

- Keep all parts organized to avoid confusion when putting everything back together.

Visual Guide to Internal Mechanisms

This section offers an insightful exploration of the intricate components that work harmoniously within a mechanical assembly. Understanding these elements enhances the appreciation of their functionality and provides clarity on how each contributes to the overall operation.

By examining the internal configuration, one can gain valuable insights into the design principles that govern efficiency and performance. The layout below illustrates key elements and their interrelationships, serving as a reference for enthusiasts and professionals alike.

| Component | Description | Function |

|---|---|---|

| Drive Gear | Transmits motion from the handle to the internal mechanisms. | Enables smooth operation and torque transfer. |

| Drag Washer | Provides resistance to line pull, regulating tension. | Ensures controlled line release during use. |

| Spindle | Central shaft around which components rotate. | Houses the spool and facilitates line management. |

| Bearing | Reduces friction between moving parts. | Enhances smooth operation and longevity. |

Common Issues with Reel Components

When using fishing apparatus, users often encounter a variety of challenges related to individual elements. Understanding these common problems can enhance the overall experience and performance of the device. Below are some frequent concerns that may arise during operation.

Mechanical Malfunctions

One of the most prevalent issues stems from mechanical failures, which can hinder functionality. Here are some typical mechanical problems:

- Worn bearings affecting smooth operation

- Corroded gears leading to stiffness

- Loose screws resulting in instability

- Snapped lines causing abrupt interruptions

Maintenance Challenges

Proper care is crucial for maintaining the efficiency of components. Neglecting routine maintenance can result in several issues, including:

- Accumulation of debris impacting movement

- Lack of lubrication causing friction

- Improper storage leading to environmental damage

- Overlooking minor repairs escalating into major problems

Best Practices for Part Replacement

When it comes to maintaining equipment, understanding the principles of component substitution is essential for longevity and performance. Ensuring that each element is appropriately selected and installed can significantly impact overall functionality. Adopting a systematic approach can help streamline the process and enhance the effectiveness of repairs.

Assessing Compatibility

Before proceeding with any replacement, it is vital to evaluate the compatibility of the new component with existing mechanisms. This involves checking specifications, dimensions, and functionality. A thorough assessment ensures that the new part integrates seamlessly, preventing future malfunctions.

Proper Installation Techniques

Once a suitable replacement is identified, employing proper installation techniques is crucial. Following manufacturer guidelines and utilizing the right tools will facilitate a secure fit. Careful handling during installation minimizes the risk of damage, while meticulous attention to detail enhances the durability of the overall assembly.

Maintenance Guide for Optimal Performance

To ensure the best functionality and longevity of your equipment, regular upkeep is essential. Proper maintenance not only enhances performance but also prevents potential issues that may arise from neglect. Following a systematic approach can greatly improve efficiency and reliability.

Here are key practices to maintain your device:

- Regular Cleaning: Remove dirt and debris after each use to prevent buildup that can affect operation.

- Lubrication: Apply appropriate lubricants to moving components to reduce friction and wear.

- Inspection: Periodically check all elements for signs of damage or wear. Address any issues immediately to avoid further complications.

- Storage: Store the equipment in a dry and cool environment to protect it from moisture and extreme temperatures.

- Replacement of Worn Parts: Identify and replace any components that show signs of deterioration to maintain optimal functionality.

By adhering to these guidelines, you can significantly enhance the operational lifespan of your equipment, ensuring a seamless and efficient experience.

Choosing Compatible Spare Parts

When it comes to maintaining equipment, selecting the right replacement components is crucial for optimal performance and longevity. Ensuring that the new elements fit seamlessly with the existing setup can enhance functionality and prevent potential issues down the line.

Here are some key considerations when searching for suitable replacements:

- Compatibility: Always verify that the replacement components are designed to work with your specific model. Check manufacturer specifications and guidelines to ensure a perfect match.

- Quality: Prioritize high-quality materials to guarantee durability. Choosing superior components can significantly impact the overall performance of your device.

- Availability: Opt for components that are readily accessible in the market. This will not only simplify the replacement process but also allow for easy future maintenance.

- Cost-effectiveness: While budget is important, consider the long-term benefits of investing in reliable replacements that may save you money on repairs in the future.

By focusing on these aspects, you can ensure that your equipment remains functional and efficient for years to come.

Troubleshooting Reel Mechanism Failures

When dealing with mechanical issues in fishing equipment, identifying the root cause of the malfunction is essential for effective repairs. Common symptoms may include difficulty in winding, unusual noises, or complete failure to operate. Understanding the potential problems and how to address them can enhance the longevity and performance of your gear.

Common Issues and Solutions

- Sticking Mechanism:

- Check for debris or corrosion around the moving parts.

- Apply appropriate lubricant to ensure smooth operation.

- Unusual Noises:

- Inspect for loose components that may need tightening.

- Examine gears for wear or misalignment.

- Inability to Wind:

- Assess the condition of the line and remove any tangles.

- Verify that the handle is functioning correctly and not obstructed.

Preventive Measures

- Regularly clean and lubricate the mechanism to prevent wear.

- Store equipment in a dry place to avoid corrosion.

- Conduct periodic inspections to identify potential issues before they escalate.

Proper Storage to Avoid Part Damage

Ensuring the longevity of your equipment involves careful consideration of how it is stored. The right storage techniques not only help maintain functionality but also prevent unnecessary wear and tear on various components. By following best practices for storage, you can significantly extend the life of your gear and minimize the need for replacements.

Choosing the Right Environment

It’s crucial to select an appropriate environment for storing your equipment. Ideally, the storage space should be cool, dry, and well-ventilated. Avoid places that are prone to humidity or extreme temperatures, as these conditions can lead to rust and degradation of materials. Using protective covers can also help shield your items from dust and moisture.

Organizing for Easy Access and Safety

Effective organization is key to preventing damage. Keep items neatly arranged and avoid overcrowding, which can lead to scratches or other harm. Using storage bins or designated shelves can help separate different components, making it easier to locate what you need without rummaging through a cluttered space.