Heating systems play a crucial role in maintaining comfort within residential and commercial spaces. Understanding their individual elements can significantly enhance maintenance and troubleshooting processes. Each component contributes to the overall functionality, ensuring efficient operation and optimal performance.

By familiarizing oneself with the various elements, users can better identify potential issues and implement effective solutions. This knowledge empowers homeowners and technicians alike to navigate the complexities of these systems with confidence, leading to improved reliability and longevity.

In this section, we will explore the various elements of a heating system, detailing their functions and interconnections. By gaining insight into each component’s role, readers will be equipped to manage their heating solutions more effectively.

Key Components of Amana Models

Understanding the essential elements of heating systems can greatly enhance efficiency and reliability. Each model comprises various crucial components that work together to ensure optimal performance. Familiarity with these features helps users maintain their systems effectively and address potential issues promptly.

Main Elements

- Heat Exchanger: This part is responsible for transferring heat to the air that circulates through the space, ensuring a comfortable environment.

- Blower Motor: The motor drives the blower, which circulates air throughout the system, playing a vital role in air distribution.

- Control Board: This electronic component manages various functions and settings, facilitating communication between different parts of the system.

- Ignition System: This system initiates the combustion process, which is essential for generating heat.

Additional Components

- Thermostat: Regulates the temperature and provides user control over heating levels.

- Flue System: Safely directs exhaust gases outside, maintaining air quality indoors.

- Filters: Capture dust and debris, improving indoor air quality and system efficiency.

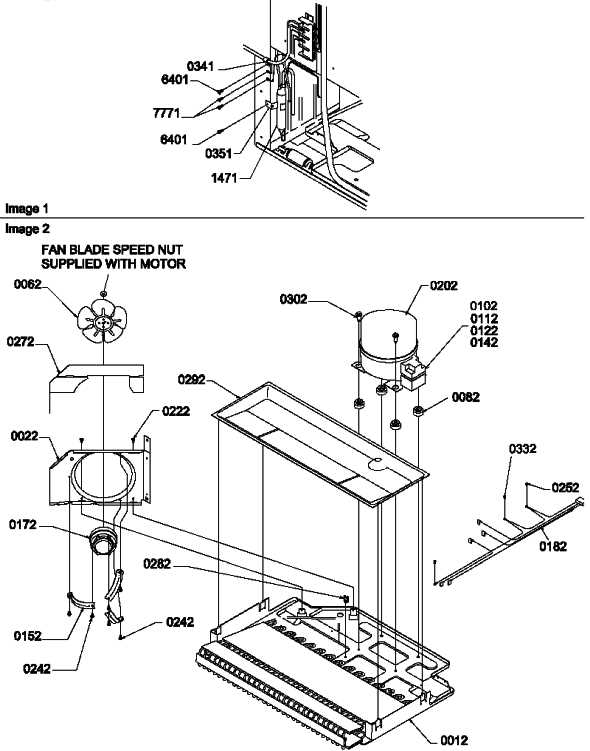

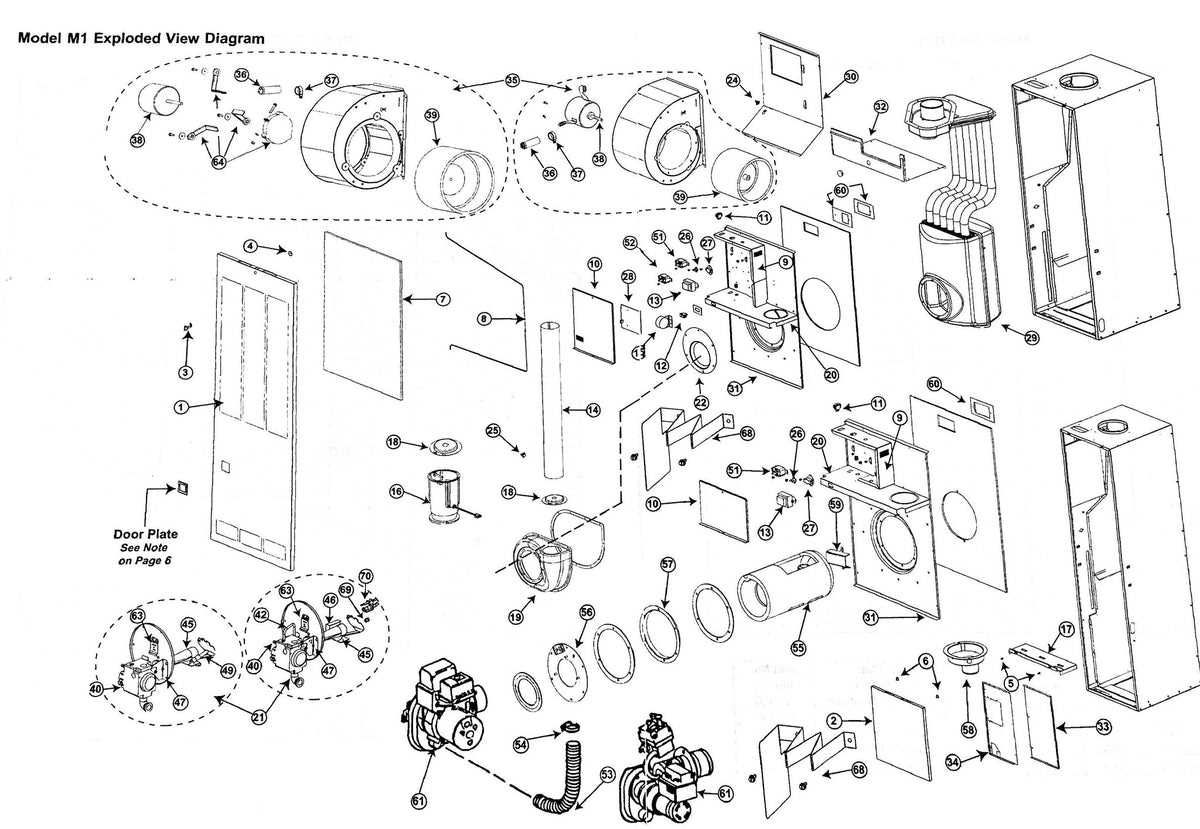

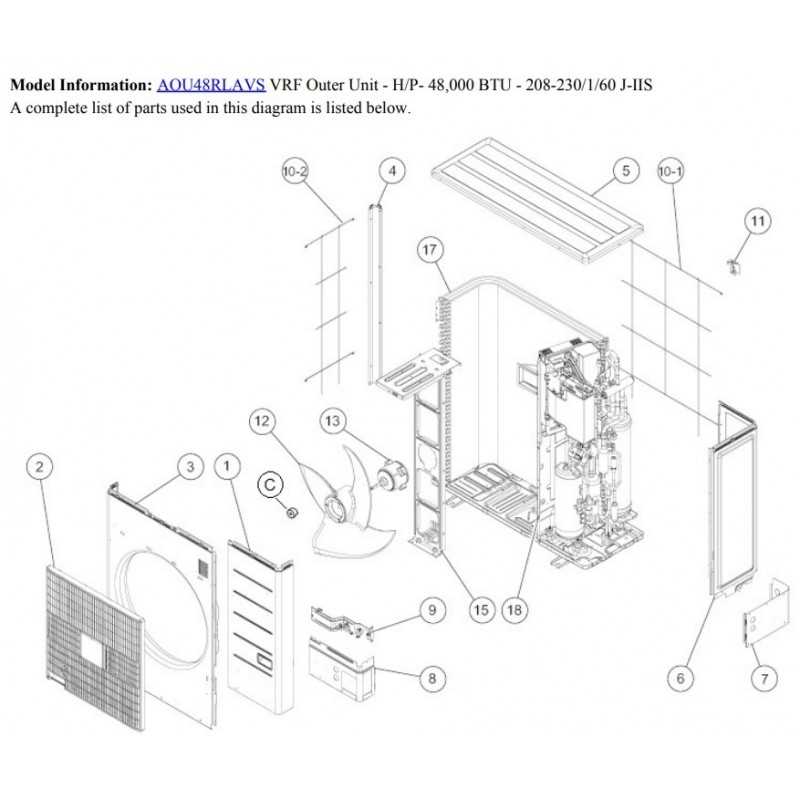

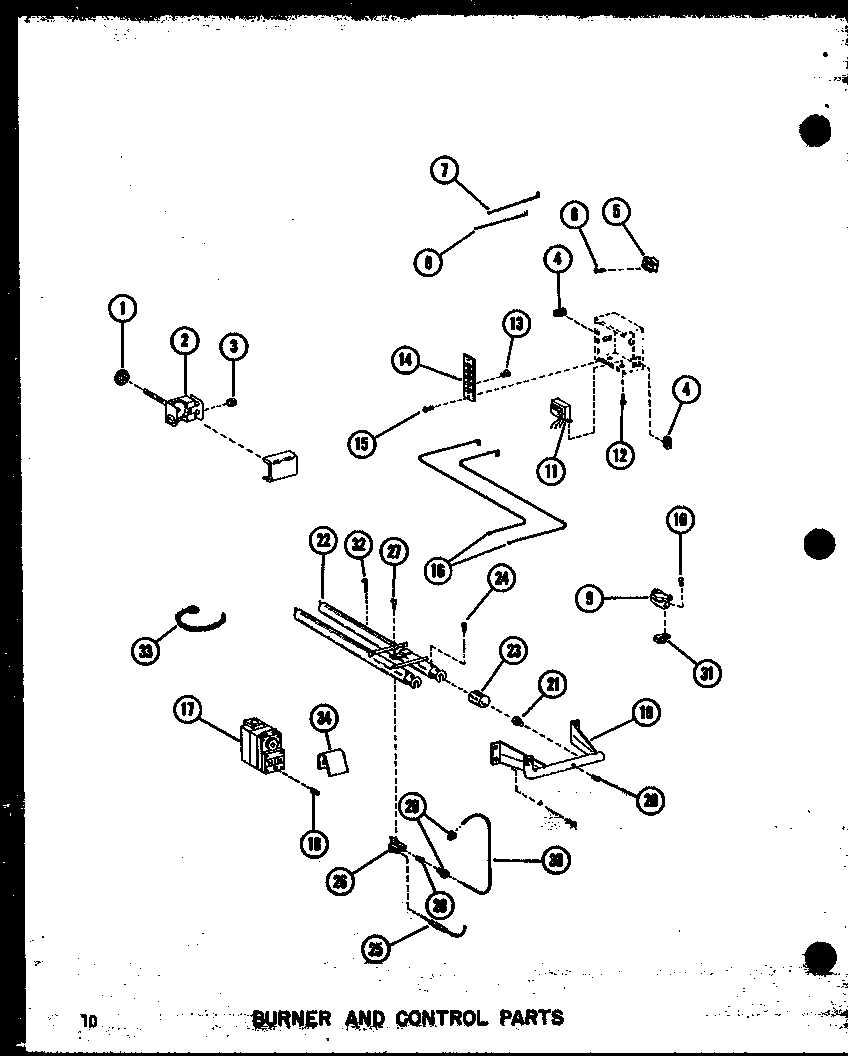

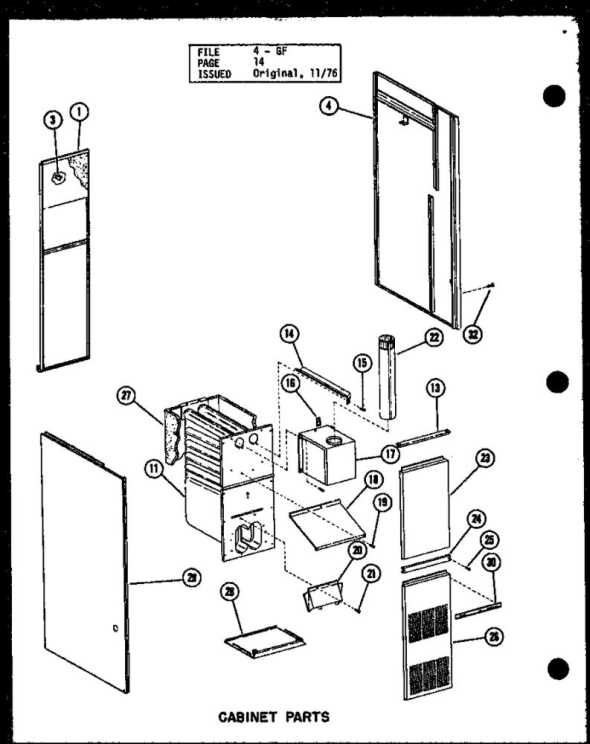

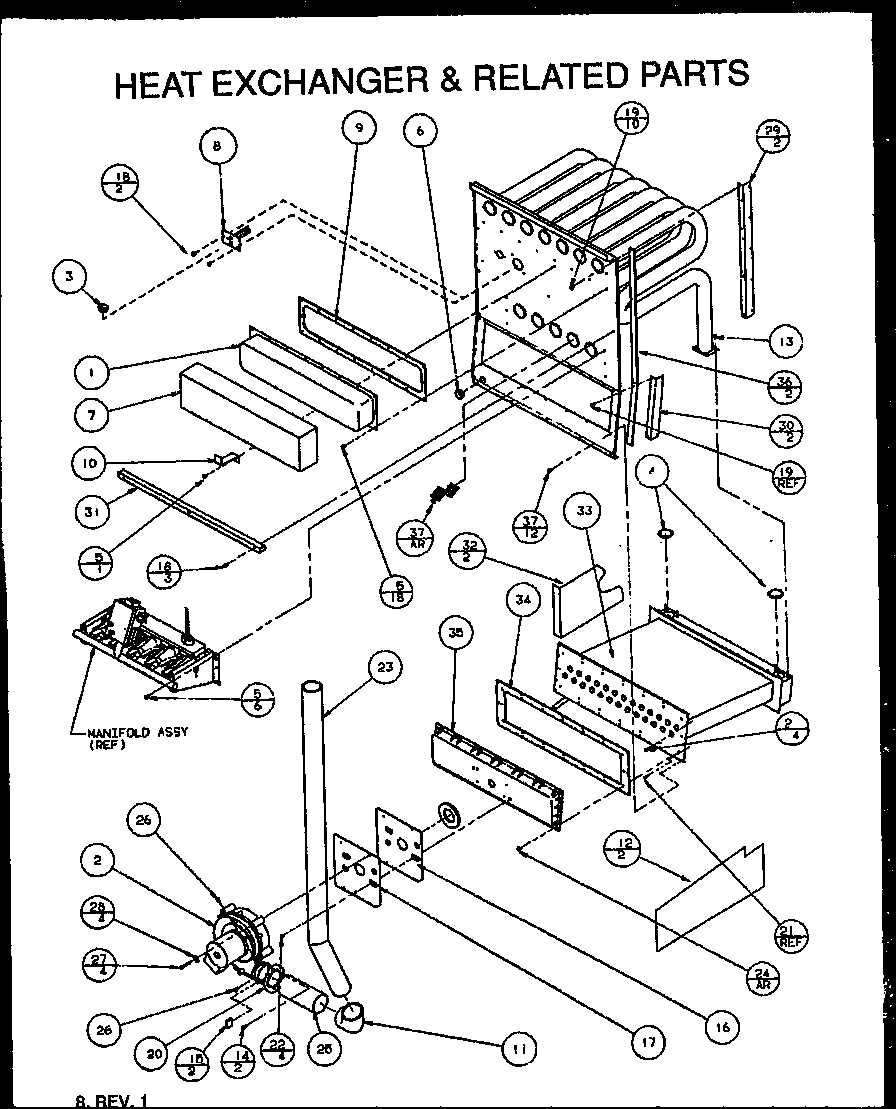

Understanding Furnace Diagrams

Grasping the layout of heating systems is essential for effective maintenance and troubleshooting. These illustrations provide a visual representation of the components involved in heating mechanisms, allowing users to identify each element’s function and interconnections. Such knowledge is crucial for anyone seeking to enhance their familiarity with their heating setup, whether for repair purposes or general understanding.

Key Components in Heating Systems

Each heating unit consists of several critical components that work together to ensure optimal performance. Familiarity with these elements can significantly improve the efficiency of system operation. Below are some common components found within these systems:

| Component | Function |

|---|---|

| Blower Motor | Circulates air throughout the living space. |

| Heat Exchanger | Transfers heat to the air, ensuring warmth in the environment. |

| Thermostat | Monitors and regulates temperature settings. |

| Ignition System | Initiates the combustion process to generate heat. |

| Flue Pipe | Exhausts harmful gases outside the building. |

Importance of Understanding Layouts

A comprehensive understanding of these layouts not only aids in identifying potential issues but also enhances the ability to conduct effective repairs and replacements. When users are aware of how various components are interconnected, they can make informed decisions regarding maintenance practices and safety measures. This foundational knowledge is instrumental in ensuring the longevity and reliability of heating systems.

Common Parts and Their Functions

This section provides an overview of essential components commonly found in heating systems and their respective roles in ensuring efficient operation. Understanding these elements is crucial for effective maintenance and troubleshooting, as each plays a significant role in the overall performance of the system.

Heating Elements

Heating elements are responsible for generating heat within the system. They convert electrical energy into thermal energy, which is then distributed throughout the space. These components can vary in design and functionality, affecting how heat is produced and circulated.

Thermostats

Thermostats regulate the temperature within the environment by monitoring and adjusting the system’s operation. They signal when to activate or deactivate the heating process based on the desired temperature settings, contributing to energy efficiency and comfort.

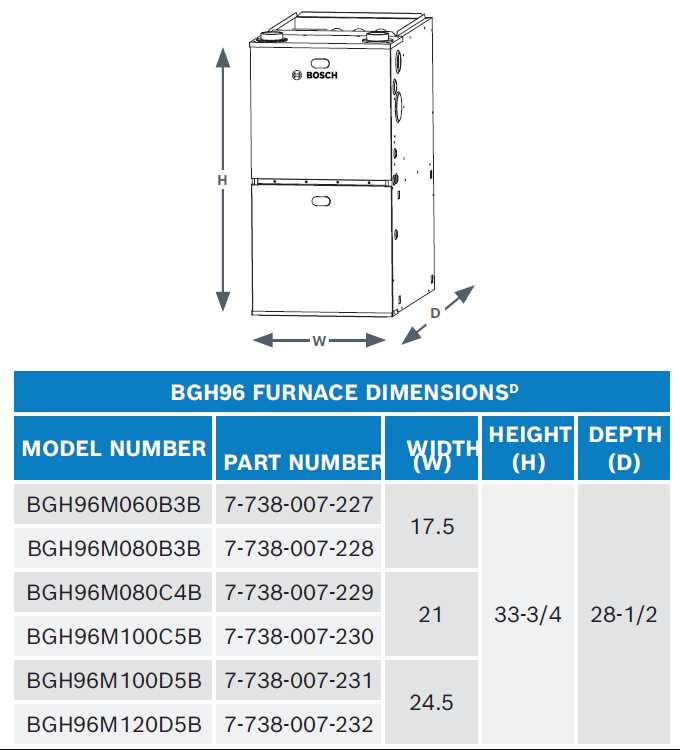

Visualizing Amana Furnace Layouts

Understanding the configuration of heating systems is essential for effective maintenance and repair. A clear representation of the components and their arrangement can aid technicians and homeowners alike in troubleshooting issues. This section focuses on visualizing the arrangement of key elements within these heating units, facilitating better comprehension and efficiency in service tasks.

Key Components and Their Functions

Every heating system consists of various components, each serving a distinct role in the overall operation. Recognizing these elements and their interactions is crucial for diagnosing problems and ensuring optimal performance. Below is a table summarizing the essential components and their respective functions:

| Component | Function |

|---|---|

| Blower Motor | Circulates air through the duct system. |

| Heat Exchanger | Transfers heat to the air while ensuring safety. |

| Thermostat | Regulates temperature by controlling the heating cycle. |

| Burner Assembly | Ignites the fuel to generate heat. |

| Flame Sensor | Detects the presence of a flame to ensure safe operation. |

Importance of Proper Layout

A well-organized arrangement of the heating system components enhances efficiency and safety. Understanding how each part fits together allows for more straightforward repairs and better maintenance practices. Familiarity with the layout can lead to quicker diagnostics and more effective solutions, ultimately resulting in improved performance and longevity of the heating unit.

Maintenance Tips for Your Furnace

Regular upkeep of your heating system is essential to ensure optimal performance and longevity. Proper maintenance can help prevent costly repairs and enhance efficiency, allowing for a comfortable environment during colder months.

Here are some helpful suggestions to keep your heating unit running smoothly:

- Check the Filters: Replace or clean filters monthly to maintain airflow and efficiency.

- Inspect the Vents: Ensure that air vents are not blocked or obstructed, allowing for even heat distribution.

- Schedule Professional Inspections: Have a qualified technician examine your system annually to identify potential issues.

- Test the Thermostat: Regularly check and calibrate your thermostat to ensure accurate temperature settings.

- Clean the Blower: Dust and debris can accumulate in the blower, reducing performance; clean it periodically.

Implementing these practices will enhance the efficiency and reliability of your heating system, providing a warm and comfortable atmosphere.

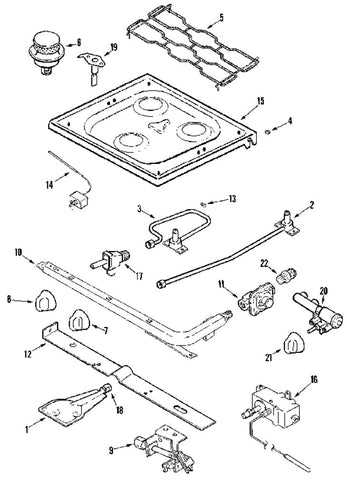

Identifying Replacement Parts Easily

Understanding the components of your heating system is essential for effective maintenance and repair. By familiarizing yourself with the key elements, you can streamline the process of locating the necessary items when repairs are needed. This knowledge empowers you to make informed decisions, ensuring that your unit operates efficiently and reliably.

Start by referencing the user manual, which often contains illustrations and descriptions of various components. In addition, online resources can provide detailed visual guides, helping you to pinpoint the exact elements you need. Take note of the part numbers and specifications, as these details will aid in purchasing replacements from suppliers or retailers.

When inspecting your unit, pay close attention to any visible wear or damage. Identifying signs of malfunction can lead you directly to the components requiring replacement. Additionally, utilizing online forums and communities can offer insights from other users who have faced similar issues, further assisting you in identifying the right items for your repair tasks.

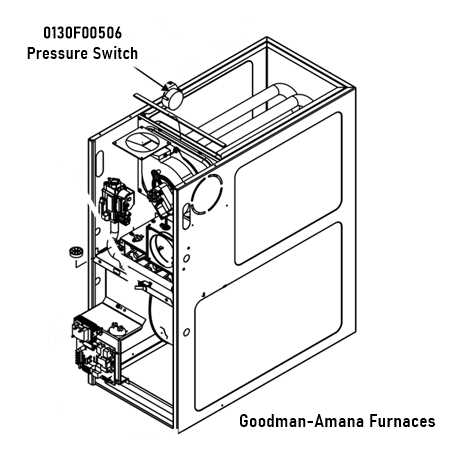

Safety Features in Amana Systems

The importance of protective mechanisms in heating appliances cannot be overstated. These systems incorporate various safety attributes designed to prevent malfunctions and ensure user security. The implementation of advanced technologies enhances operational reliability while minimizing the risks associated with heat generation.

Key safety components work together to create a secure environment. These elements are engineered to detect irregularities and take appropriate actions, ensuring that the equipment operates within safe parameters. Below is a table highlighting some of the essential safety features commonly found in these heating units:

| Feature | Description |

|---|---|

| Limit Switch | Monitors temperature levels and shuts down the system if overheating occurs. |

| Flame Sensor | Detects the presence of a flame; if it goes out, the system will automatically turn off. |

| Pressure Switch | Ensures that the airflow is adequate; if not, the system will deactivate to prevent damage. |

| Vent Safety | Prevents toxic gas buildup by ensuring proper venting of exhaust gases. |

| Gas Valve | Automatically shuts off gas supply in case of a malfunction. |

These safety features exemplify a commitment to reliability and user protection. Regular maintenance and checks are essential to ensure these mechanisms function effectively, providing peace of mind during operation.

Energy Efficiency of Amana Units

Energy efficiency is a critical aspect of modern heating systems, significantly impacting both environmental sustainability and household utility expenses. High-efficiency models are designed to optimize fuel consumption while delivering maximum warmth, making them an excellent investment for homeowners.

These advanced systems often incorporate innovative technologies that enhance performance. Features such as variable-speed blowers and modulating gas valves allow for precise temperature control and reduced energy usage. Moreover, units are rated with annual fuel utilization efficiency (AFUE) scores, which provide insight into their operational effectiveness.

By investing in high-efficiency units, users can not only lower their energy bills but also contribute to a greener planet. Understanding the benefits of energy-efficient systems empowers consumers to make informed choices that align with their comfort and environmental goals.

Common Troubleshooting Techniques

Addressing issues with heating systems often requires a systematic approach to identify and resolve malfunctions. Employing effective strategies can enhance efficiency and extend the lifespan of the unit. Below are some essential methods for diagnosing common issues.

Initial Inspection Steps

- Check the power source to ensure the system is receiving electricity.

- Inspect the thermostat settings to confirm they are correctly adjusted.

- Examine filters for dust accumulation, which can impede airflow.

Advanced Diagnostic Methods

- Listen for unusual noises that may indicate mechanical problems.

- Use a multimeter to test electrical components for continuity.

- Evaluate the venting system for blockages that could hinder performance.

By following these troubleshooting techniques, individuals can effectively address common challenges and ensure optimal operation of their heating systems.

Where to Find Replacement Diagrams

Locating accurate illustrations for system components is essential for effective maintenance and repair. Understanding how to access these resources can significantly simplify the troubleshooting process and ensure proper reassembly.

Online Resources

- Manufacturer’s Website: Visit the official site for the most reliable and up-to-date resources.

- Parts Retailers: Many online retailers offer diagrams alongside their product listings, making it easy to find compatible components.

- Technical Forums: Community-driven sites often have shared resources and advice from experienced users.

Printed Manuals and Guides

- Owner’s Manual: The original manual typically includes useful schematics.

- Service Manuals: These in-depth documents often provide comprehensive illustrations for complex systems.

- Local Libraries: Check for copies of manuals in the reference section or ask for interlibrary loans.

Professional Repair vs. DIY Options

When facing issues with heating systems, homeowners often find themselves at a crossroads: should they seek professional assistance or attempt repairs on their own? Each approach has its own set of advantages and disadvantages, making the choice dependent on various factors such as expertise, time, and budget.

Opting for professional services can offer several benefits:

- Expertise: Trained technicians have the knowledge and experience to diagnose and resolve issues effectively.

- Warranty Protection: Many service providers offer warranties on their work, ensuring peace of mind.

- Time Efficiency: Professionals can complete repairs quickly, minimizing downtime.

However, some homeowners may prefer the DIY route for the following reasons:

- Cost Savings: Handling repairs personally can reduce expenses associated with labor costs.

- Learning Opportunity: DIY repairs can be a valuable way to gain knowledge about home maintenance.

- Flexibility: Homeowners can work at their own pace and schedule repairs according to their convenience.

Ultimately, the decision between hiring a professional or taking on the task independently depends on individual capabilities and circumstances. Assessing the complexity of the problem is crucial in making an informed choice.