Understanding the configuration of critical elements in a modern toilet system is key to ensuring smooth operation and effective maintenance. Each part plays a specific role in the overall functionality, and recognizing how these elements work together is crucial for identifying potential issues and maintaining optimal performance.

In this section, we will explore the various integral pieces that contribute to the efficiency of the flushing mechanism. The detailed layout of these components will help you comprehend the internal structure, making troubleshooting and replacements easier when necessary.

By gaining insight into the arrangement and purpose of each piece, you can enhance your knowledge of how this system functions, ensuring that any repairs or adjustments can be handled with confidence and precision.

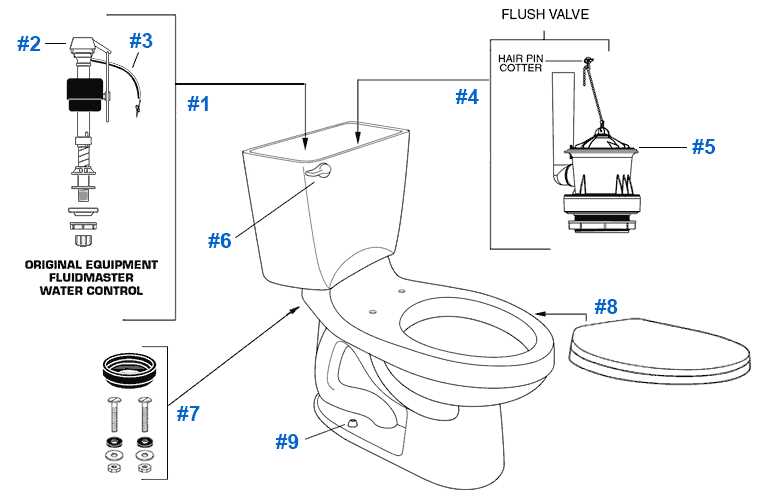

American Standard Champion 4 Parts Diagram Overview

This section provides a detailed look at the key elements that make up this highly efficient flush system. The design focuses on durability and performance, ensuring a powerful and reliable operation with every use. Below, we will explore the critical components that contribute to its efficiency.

- Flush Valve: This piece controls the release of water from the tank, offering optimal water flow for a thorough and quick cleaning of the bowl.

- Flapper:

Main Components of the Champion 4 System

The system in question is known for its highly efficient and durable design, incorporating several key elements that ensure optimal performance. These components work together to provide consistent results, making the system a reliable choice for a variety of needs.

The flush valve plays a crucial role by regulating water flow during use. Its design ensures that water is released quickly and efficiently, maximizing the system’s effectiveness.

Understanding the Internal Mechanism Layout

The internal layout of modern flush systems is designed for efficiency and reliability. This section focuses on the key components inside the unit, explaining how they work together to ensure a smooth operation. By understanding the arrangement and purpose of these essential parts, one can maintain or troubleshoot the system more effectively.

Flush Valve: This is a critical element responsible for releasing water from the tank

Exploring the Flush Valve and its Function

The flush valve plays a crucial role in the effective operation of any water-saving system, controlling the release of water into the bowl. Its design ensures a swift, powerful action to clear waste with minimal water use. Understanding how this component functions is essential for anyone looking to maintain or repair their water fixture.

How the Flush Valve Works

When the handle is pressed, the flush valve opens, allowing water from the tank to flow swiftly into the bowl. This movement creates the necessary pressure to remove waste and clean the surface. The valve then closes to prevent further water from escaping, ensuring efficiency in each cycle.

Common Flush Valve Issues

Over time, the flush valve may experience wear and tear, leading to leaks or reduced performance. Signs of malfunction include water continuously running or weak flushing. Regular inspection and timely replacement of the valve can prevent more significant issues from occurring.

The Role of the Tank in Efficient Operation

The water reservoir is a key element that directly impacts the effectiveness of a flushing system. Its size, design, and internal mechanisms are responsible for ensuring a strong and consistent flush, while also helping to conserve water. By managing water flow efficiently, the reservoir contributes to overall system performance and longevity.

Key Functions of the Tank

- Water Storage: The reservoir holds the necessary

Details on the Bowl Design and Features

The design and functionality of the toilet bowl play a crucial role in ensuring efficient performance and user satisfaction. A well-constructed bowl incorporates innovative features that enhance usability, hygiene, and overall comfort. Understanding these elements is essential for anyone looking to appreciate the intricacies of modern toilet technology.

Innovative Structure

The toilet bowl’s structure is engineered to optimize flushing efficiency while minimizing water usage. This is achieved through various design elements that facilitate effective waste removal. The shape and depth of the bowl contribute significantly to its performance, ensuring a powerful flush without excess water consumption.

Comfort and Hygiene

Comfort is a priority in the design of toilet bowls, with many models featuring ergonomic shapes that accommodate the user’s needs. Additionally, advanced materials and finishes enhance hygiene, making the surface easier to clean and resistant to staining. These features not only improve the overall experience but also promote better sanitation.

Feature Description Flushing Technology Utilizes a high-efficiency flush mechanism to reduce water usage. Ergonomic Design Designed to provide comfort during use with a contoured shape. Hygienic Surface Made from materials that resist stains and are easy to clean. Water Efficiency Engineered to perform effectively with minimal water consumption. How the Trip Lever Contributes to Performance

The trip lever is an essential component that significantly influences the overall efficiency of a toilet system. It serves as the link between the user’s actions and the internal mechanisms that control the flushing process. By effectively translating a simple motion into a series of precise operations, the trip lever ensures optimal functionality and user satisfaction.

When engaged, the trip lever initiates the flushing sequence by activating the flapper valve. This action allows water to flow from the tank into the bowl, facilitating a powerful and effective clean. The design of the trip lever can impact the speed and volume of water released, which directly affects the toilet’s performance. A well-designed lever will promote a quick response, reducing the chances of clogs and ensuring a thorough flush.

Furthermore, the trip lever’s placement and ergonomic design contribute to user convenience. A lever that is easily accessible encourages regular use, while its responsive nature enhances the overall experience. Maintenance of the trip lever is also crucial; any wear or malfunction can lead to inefficiencies, highlighting the importance of regular inspections to ensure consistent performance.

In summary, the trip lever plays a pivotal role in the effective operation of toilet systems. Its design, functionality, and maintenance are critical factors that contribute to a reliable and satisfactory flushing experience.

Installation and Positioning of Gaskets

Proper installation and correct placement of sealing elements are essential for ensuring a leak-free connection in plumbing systems. These components act as barriers that prevent fluid from escaping between joined surfaces, thereby maintaining system integrity and performance. Understanding the correct methodology for their installation can significantly enhance the longevity and efficiency of the overall assembly.

Preparation for Installation

Before proceeding with the installation, it is crucial to clean all surfaces thoroughly. Remove any debris, old sealant, or contaminants that may hinder proper adhesion. A smooth, dry surface ensures that the sealing elements fit snugly and perform effectively. Additionally, reviewing manufacturer guidelines can provide insights into specific requirements for different types of gaskets.

Positioning Techniques

When placing the gaskets, ensure they are aligned precisely with the corresponding surfaces. Avoid twisting or stretching the sealing elements, as this can lead to uneven pressure and potential failure points. It is advisable to start at one end and gradually work your way to the other, applying even pressure. Secure the assembly firmly but be cautious not to overtighten, as this can compromise the integrity of the gasket.

Water Supply Line Connections Explained

Understanding the intricacies of water supply connections is essential for ensuring optimal performance and reliability in plumbing systems. This section delves into the various aspects of these connections, highlighting their significance in maintaining efficient water flow and preventing potential issues.

Types of Water Supply Connections

Several connection types are commonly used in plumbing systems. Each type serves a specific purpose and is designed for particular scenarios:

- Rigid Connections: These are fixed and often used for permanent installations, providing a sturdy link between pipes.

- Flexible Connections: Ideal for areas that require movement or adjustments, these connections allow for easier installation and maintenance.

- Threaded Connections: Utilized in various fittings, these connections involve screwing parts together to ensure a tight seal.

- Soldered Connections: Commonly found in copper piping, this method involves melting a filler metal to join two pieces together.

Installation Considerations

When connecting water supply lines, several factors must be considered to ensure a successful installation:

- Material Compatibility: Ensure that the materials of the pipes and fittings are compatible to avoid leaks or failures.

- Pressure Ratings: Consider the pressure ratings of the components being used to ensure they can withstand the system’s demands.

- Accessibility: Install connections in accessible locations for easy maintenance and repairs.

- Local Codes: Always adhere to local plumbing codes and regulations to ensure compliance and safety.

Common Replacement Parts for Maintenance

Regular upkeep of plumbing fixtures is essential for ensuring their efficient operation and longevity. Understanding the various components that may require periodic substitution can help maintain functionality and prevent unforeseen issues. This section highlights several key items that are frequently needed during maintenance tasks.

Flush Valve is a critical element that controls the flow of water during each flush. Over time, wear and tear may lead to leaks or insufficient flushing, necessitating replacement to restore proper functionality.

Fill Valve regulates the water level in the tank. If this component malfunctions, it can result in continuous running water or inadequate filling after a flush. Replacing the fill valve can resolve these common issues.

Flapper Valve plays a crucial role in sealing the tank. A worn or damaged flapper can lead to water wastage, as it may not create a proper seal. Ensuring this component is in good condition is vital for water conservation.

Tank-to-Bowl Gasket provides a watertight seal between the tank and the bowl. If this gasket deteriorates, it can cause leaks, which may result in water damage. Regular inspection and replacement of this gasket can prevent such problems.

Trip Lever is the mechanism that initiates the flush. If it becomes stiff or unresponsive, it may need to be replaced to ensure smooth operation. This simple replacement can significantly enhance the user experience.

Identifying Key Seals and Washers

Understanding the various components that contribute to the effective functioning of plumbing fixtures is essential for maintaining optimal performance. Among these elements, seals and washers play a crucial role in ensuring leak-free operations and enhancing the longevity of the system.

These components can be categorized into several types, each serving a specific purpose. Proper identification of these seals and washers can significantly impact the repair and maintenance process.

- Rubber Seals: Commonly used in joints to prevent water leakage.

- Flat Washers: Often placed under screws and bolts to distribute pressure evenly.

- O-Rings: Circular seals that provide a tight fit in cylindrical components.

- Compression Washers: Designed to compress and create a watertight seal under pressure.

- Grommets: Used to protect wires or hoses passing through walls or panels.

Familiarity with these essential components allows for more efficient troubleshooting and repair processes, ensuring reliable performance in various applications.

Troubleshooting Issues with Diagrams

Identifying and resolving problems effectively often relies on visual representations that clarify complex systems. When encountering difficulties, having a clear outline can be invaluable for pinpointing issues and understanding the interactions within a setup. This section aims to highlight common challenges and their solutions through structured visuals.

When working with these illustrations, users may face various obstacles. The following table summarizes frequent issues encountered during analysis, alongside practical resolutions:

Issue Possible Causes Solutions Inaccurate representation Misinterpretation of symbols or scale Review key and scale references for accuracy Missing components Incomplete illustrations or updates Consult updated resources or complete sets Poor readability Low-resolution images or cluttered layouts Obtain high-quality visuals and simplify layouts Confusion over connections Ambiguous lines or unclear paths Trace paths methodically and clarify connection types By recognizing these common hurdles and implementing the suggested fixes, users can enhance their understanding and effectively navigate through the complexities of their systems.

- Water Storage: The reservoir holds the necessary