When it comes to household devices, knowing the inner workings and how each section connects can be incredibly useful. Whether you’re maintaining, troubleshooting, or simply getting familiar with the setup, having a clear view of how all the elements are arranged plays a crucial role. This knowledge allows you to navigate the various elements of the system more effectively, helping you ensure everything operates as it should.

Each device is designed with multiple elements that contribute to its overall functionality. From the core mechanisms that enable operation to smaller units that play supporting roles, each part has its place. Understanding how they all fit together can make a significant difference in keeping everything running smoothly and preventing unnecessary breakdowns.

Being familiar with these elements not only helps with repairs but also allows you to take preventative measures. By understanding how the various pieces are interrelated, you’ll be able to identify issues before

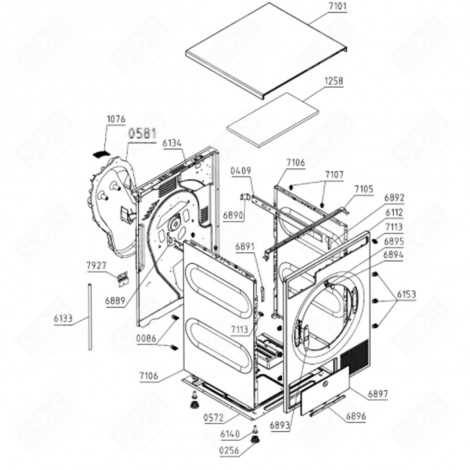

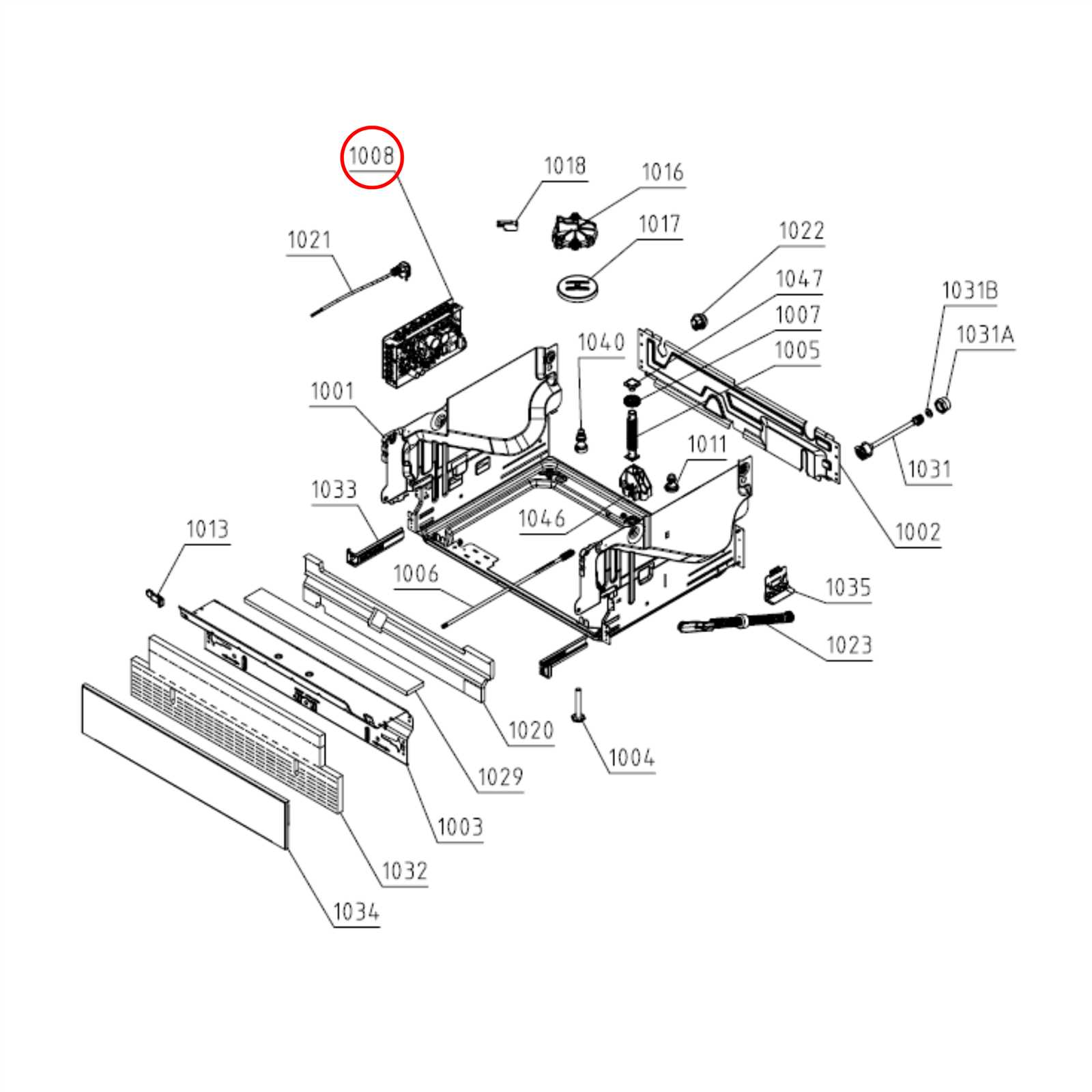

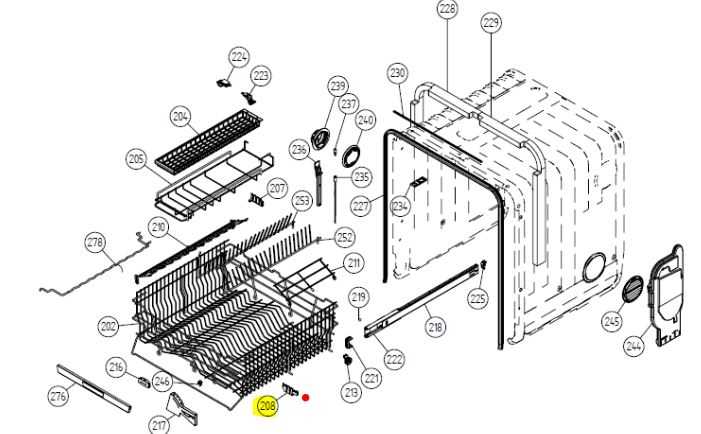

Overview of Key Components

In examining the structure of the appliance, it becomes evident that its functionality relies on several crucial elements. These essential parts work together harmoniously to ensure optimal performance and efficiency. Each component contributes uniquely to the overall operation, fulfilling specific roles in the appliance’s functionality.

Among these fundamental components are the mechanisms responsible for various operational phases, including those related to water circulation, detergent distribution, and temperature regulation. Each part is intricately designed to perform its task seamlessly, enhancing the appliance’s ability to achieve thorough cleaning results.

Moreover, the system incorporates safety features designed to protect both the appliance and its users, underscoring the importance of these components in maintaining reliable operation over time. Understanding the roles and interactions of these parts provides valuable insight into the functionality and maintenance requirements of such appliances.

Understanding the Dishwasher Structure

The layout of a dishwasher is designed to ensure efficient cleaning of kitchenware. Each component within the appliance serves a specific role in the overall operation, working together to handle the water flow, detergent dispersal, and drying process. Understanding how these elements interact is essential for grasping the inner workings of the machine.

Key Internal Components

Within the machine, a pump controls water circulation, directing it through various spray arms to reach all surfaces. Filters are also present, removing food debris to maintain optimal performance. The heating element is crucial in regulating water temperature and assisting with drying after the wash cycle is completed.

Water and Electrical System

The water system, including valves and hoses, delivers water at the required pressure to ensure thorough washing. The electrical control panel manages the entire operation, coordinating timing, water

Water Inlet and Drain System Parts

The components involved in directing water into and out of the system are essential for maintaining proper operation. These elements ensure that water is supplied efficiently and drained effectively, preventing any disruptions in functionality. Understanding the individual parts and their roles can help in identifying issues and performing necessary maintenance.

Water Inlet Mechanism

The inlet mechanism is responsible for regulating the flow of water into the machine. It includes valves and hoses designed to control the water supply, ensuring a steady flow when needed. Valves are typically controlled electronically, while hoses serve as the pathways that direct water to the appropriate areas. Regular inspection of these parts is crucial to avoid leaks or blockages.

Drainage System

The drainage system ensures that used water is effectively removed. Pumps and drain

Heating Element and Thermostat Function

The heating element and thermostat work together to regulate the temperature within a device, ensuring efficient performance. The heating element generates warmth, while the thermostat monitors and controls the temperature, ensuring it stays within a desired range. These components are essential for maintaining optimal functionality in systems that require precise heat regulation.

Heating Element transforms electrical energy into heat. It is designed to provide consistent warmth, playing a crucial role in processes that rely on controlled temperatures. The material and design of the heating element allow it to handle high levels of heat without degrading quickly, ensuring durability over time.

The thermostat acts as a controller, detecting changes in temperature and adjusting the power supplied to the heating element. By automatically turning the heating element on or off, the thermostat ensures that the temperature remains stable and safe. This balance between heat production and regulation is key to preventing overheating or energy waste.

Spray Arms and Water Circulation

One of the essential components in a cleaning device is the system that ensures efficient water distribution. This process is primarily carried out by the spray mechanisms, which are responsible for directing water to different sections. The proper flow of water is crucial for achieving thorough cleaning results and optimal functioning of the entire system.

How Spray Arms Function

The spray arms are positioned at strategic points within the appliance to distribute water evenly. They rotate as water is pumped through them, ensuring that every corner is reached. Nozzles on these arms release pressurized water, effectively removing debris and particles from surfaces.

- Upper spray arms typically target items placed on the top section.

- Lower spray arms focus on the bottom area, providing more intensive cleaning.

- Additional spray systems may be present for specialized

Control Panel and Electronic Parts

The central control system allows the user to manage various operational settings and monitor the device’s performance. This section focuses on the key components that handle communication between the user and internal systems, ensuring efficient functionality and ease of use.

Main Control Interface

The main interface is designed for easy interaction, providing buttons, dials, or touch-sensitive areas that correspond to different functions. These components work together to process input, send signals to other elements, and adjust settings based on user preferences.

- Display screen for real-time feedback

- Function keys for selecting programs

- Indicators for status notifications

Electronic Circuitry

Behind the control panel lies the electronic circuitry responsible for interpreting user commands and executing them through various mechanisms. The circuit board connects the controls to the machine’s operational systems, ensuring smooth communication between hardware components.

- Power supply unit

Door Latch and Sealing Mechanism

The mechanism responsible for securing the door plays a crucial role in maintaining the efficiency and functionality of household appliances. A well-designed latch not only ensures that the door closes tightly but also contributes to the overall energy efficiency by preventing leaks and maintaining internal temperatures.

Understanding the Functionality of the latch and sealing system is essential for proper maintenance. This assembly typically comprises various components, each working in harmony to provide a secure closure. The latch engages with the frame, ensuring that the door remains closed during operation. An effective sealing mechanism complements this by creating a barrier that minimizes air exchange, thereby enhancing performance.

Regular Inspection of these components is recommended to ensure optimal performance. Over time, wear and tear can lead to misalignment or degradation of materials, which can compromise the effectiveness of the door closure. By periodically checking and maintaining the latch and sealing elements, users can ensure the appliance operates efficiently and prolong its lifespan.

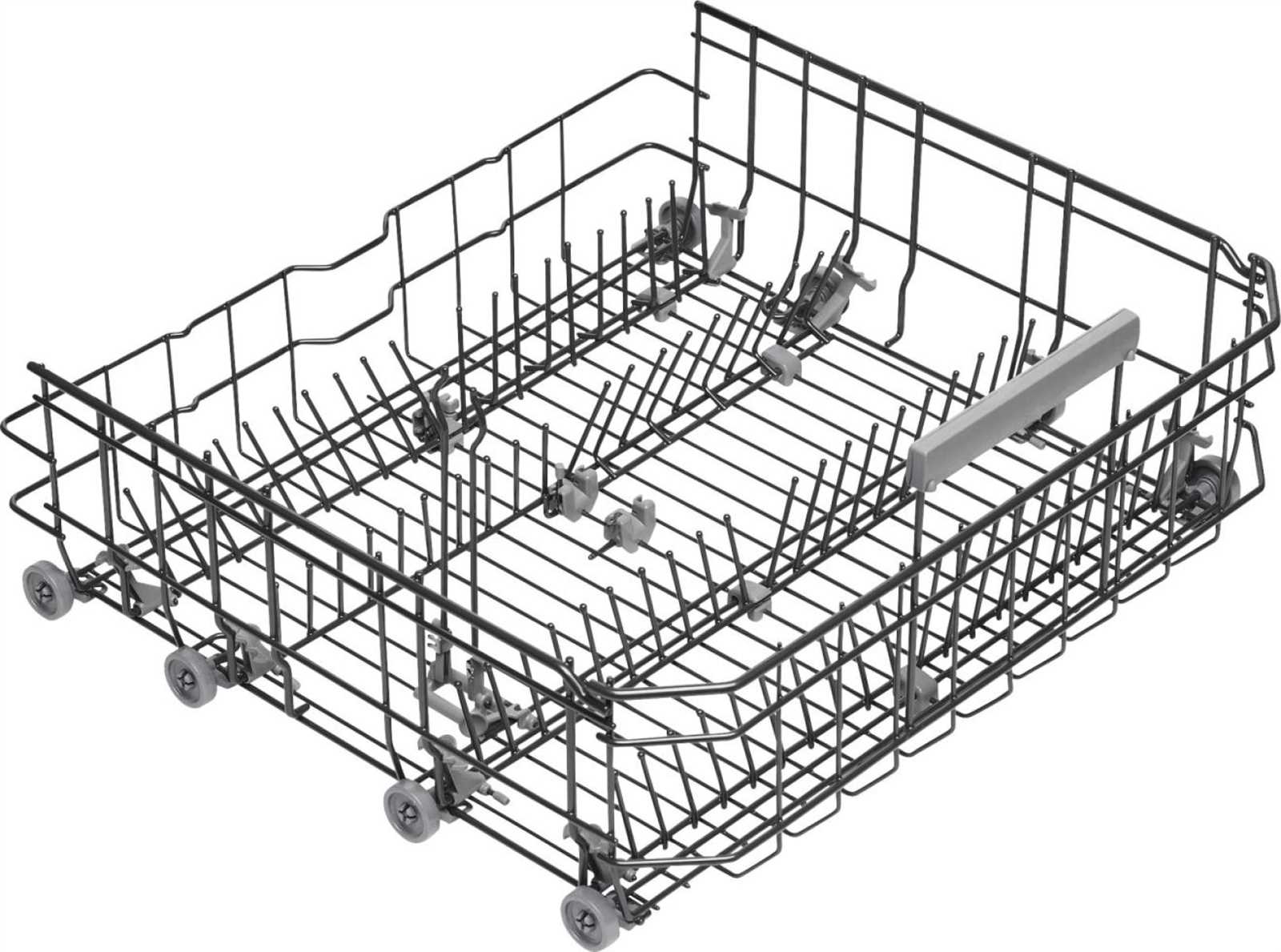

Racks and Adjustable Shelves

In modern storage solutions, racks and adjustable shelves play a crucial role in maximizing space and enhancing organization. These versatile components allow users to customize their storage setups according to their needs, making them ideal for various environments, from kitchens to workshops.

Racks are typically constructed from durable materials, providing a robust framework for holding items of varying sizes and weights. Their design often includes multiple tiers, allowing for efficient vertical storage and easy access to frequently used items. Additionally, the layout of these racks can be tailored to accommodate different types of belongings, ensuring that everything has its place.

Adjustable shelves offer even greater flexibility, as they can be repositioned to suit changing storage requirements. This adaptability is particularly beneficial in dynamic spaces where the type or volume of stored items may vary over time. By simply altering the height or spacing of the shelves, users can create a more functional and organized area, enhancing both accessibility and aesthetics.

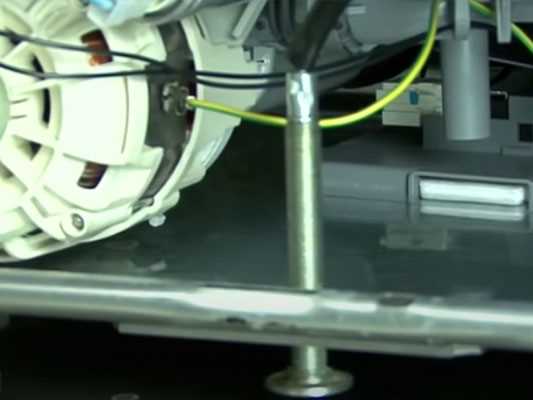

Pump and Motor Assembly Breakdown

The pump and motor assembly is a crucial component in many household and industrial appliances. Understanding the intricacies of this assembly can significantly enhance maintenance and troubleshooting efforts. This section will provide a detailed overview of the components involved, their functions, and common issues that may arise.

Key Components

This assembly typically consists of several essential elements that work together to facilitate effective operation. Each part plays a specific role in ensuring the system functions efficiently, from initiating the flow of water to maintaining optimal performance levels.

Component Description Function Pump Body The main casing housing the internal parts. Contains and directs the flow of water. Motor Electric component driving the pump. Provides the necessary force to move water. Impeller Rotating element inside the pump. Creates water flow by spinning and generating pressure. Seals Components that prevent leakage. Maintain fluid integrity within the assembly. Base Plate Foundation supporting the pump and motor. Provides stability and alignment for the assembly. Common Issues and Solutions

Understanding potential problems with the assembly can aid in effective repairs and maintenance. Typical issues include motor failure, leakage, and diminished water flow, each of which can often be resolved through straightforward troubleshooting methods.

Filters and Maintenance Parts

Regular upkeep of household appliances is essential for their optimal performance and longevity. Among the crucial components involved in this process are filtration systems and various maintenance elements. Understanding their roles can significantly enhance the efficiency of your device and prevent potential issues.

Filtration systems are designed to trap impurities, ensuring that the air or water used in the appliance remains clean. These components require periodic replacement to maintain their effectiveness. Depending on the model, filters can vary in type and function, ranging from air purifiers to water filters, each playing a vital role in the appliance’s operation.

Additionally, maintenance elements encompass a range of parts that facilitate smooth functioning. This includes seals, gaskets, and other consumables that may wear over time. Regularly checking and replacing these components can help avoid more significant breakdowns and enhance the overall efficiency of the machine.

In summary, investing time in understanding and maintaining filtration systems and other essential parts not only improves performance but also extends the lifespan of your appliance. Keeping these elements in top condition is key to ensuring reliable operation for years to come.

Replacing Commonly Worn Parts

Over time, appliances may experience wear and tear, leading to diminished performance or failure of specific components. Regular maintenance and timely replacement of these frequently used elements can ensure the longevity of your device and optimal functioning. Understanding which parts are susceptible to wear is essential for maintaining efficiency and reliability.

Identifying Worn Components

Common indicators of worn components include unusual noises, decreased efficiency, or failure to operate as expected. Observing these symptoms can help pinpoint which elements need attention. Routine inspections can also assist in early detection, allowing for proactive replacements.

Replacement Process

Once the worn components have been identified, replacing them involves a few straightforward steps. It is essential to ensure that the replacement parts are compatible and of high quality. Following a systematic approach can make the process smoother.

Component Signs of Wear Replacement Tips Seals Leaking or water damage Ensure proper fit and sealing. Filters Reduced airflow or efficiency Replace regularly as part of maintenance. Belt Squeaking sounds or slipping Check tension and alignment before replacement. Troubleshooting Common Part Issues

When dealing with appliances, it is not uncommon to encounter problems related to their components. Understanding how to identify and resolve these issues can greatly enhance the efficiency and lifespan of the device. This section aims to guide users through some of the most frequent challenges associated with various components and how to address them effectively.

Issue Possible Causes Solutions Device not starting Power supply issues, faulty switch, damaged wiring Check power outlet, inspect the switch, examine wiring connections Unusual noises during operation Loose components, worn bearings, foreign objects Tighten loose parts, replace bearings, remove any obstructions Inconsistent performance Blocked filters, malfunctioning sensors, worn parts Clean or replace filters, test sensors, replace worn components Leaks or spills Damaged seals, loose connections, cracked containers Inspect and replace seals, tighten connections, replace damaged containers